wire rope construction types pricelist

Maple Leaf Ropes has multiple warehouse locations throughout North America and can provide you with the product you need wherever you need it, give us a call!

Source the best-quality construction rope prices on Alibaba.com for an increased catch, whether for fun or commercial use. The specially-built tools are durable, with the longevity of these construction rope prices owed to the maximum power material used in their making. These strong materials are great for use in wet and dry conditions without any damage on the ropes that are also UV-light proof to minimize their corrosion.

These classy construction rope prices provide the best precision for increased catch ratio with their special solid designs. This innovative technique makes users have more control of the rope enabling for even the slightest detection to never allow a catch to slip-away. This level of accuracy, further, enhances the zero stretch property of the rope that minimizes entanglement. With zero entanglements, the user’s cast is further to guarantee more catch without worrying about wind knots.

construction rope prices from Alibaba.com are versatile for use in different environments, the ropes are usable in salty and fresh water without affecting their performance. These ropes don’t require any maintenance, and they have high-break strength to accommodate the weight of all catches. These equipment are resistant to abrasion and hence maintain their pristine appearance and performance; these lines are also braided making them ultra-light when fishing.

Get the best quality and affordable construction rope prices options available at Alibaba.com and enjoy the experience. The pool of selection on offer ensures everybody has unlimited access to the products. Manufacturers have the opportunity to take advantage of these alluring prices on offer.

We Pearl Overseas Have Stainless Steel Wire Rope In Ready Stock, We are specialist in Stainless Steel Wire Rope, Stainless Steel Wire Rope available in 304, 304l,read more...

By following the ongoing market developments and trends, we have come up with finest quality Steel Rope Wire to our valued customers. These products are developed and designed byread more... Brochure

Symbolic to all the success that we have acquired in the market, remains our status as a prominent manufacturer, exporter and supplier of an excellent variety of Wire Rope. In order to agreement fault free production, these ropes are checked by our qualified professionals against a range of parameters. For their eminentread more...

Owing to the knowledge of this domain, we are offering to our patrons a broad spectrum of Galvanized Wire Rope. These ropes can operate in demanding conditions and must resist crushing, bending fatigue and abrasion. Apart from this, these ropes are available in different sizes and thickness.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

All Departments1x19 Stainless Steel Strand1x7 Guy Strand6x26 Wire RopesApparelBlocks and PulleysCable RailingClearanceCordageDecalsFall ProtectionGrade 70 Transport ChainHard Hat StickersHeadwearLIFTGEAR MerchRotation Resistant Wire RopesSafety MerchSynthetic Tycan® ChainSynthetic Tycan® Chain SlingsWashington Wire RopeIMPORT- WRCManual Chain HoistsGrade 70 Binder Chains7x19 Aircraft CableWire Rope SlingsLever Chain HoistsBeam ClampsG100 Chain SlingsGrade 100 ChainPlate Clamps6x36 Wire RopesDSS - DOUBLE SWIVEL SHACKLESEB - SWIVEL EYE BOLTWeb SlingsBest SellersOffroad RecoveryOffroad Recovery RopesTowing SuppliesLoad and TransportWire RopeChain and AccessoriesClampsDSR - DOUBLE SWIVEL HOIST RINGSRound SlingsAMHHoists and ClampsWire Rope ClipsSynthetic SlingsCODIPROLifting SlingsMade in USASafety ShacklesSUPER STRONG ShacklesShacklesRigging Hardware

Marine & Industrial offers a wide selection of wire rope products to meet your rigging and lifting needs. We provide a variety of types of wire rope including domestic, import, high performance, galvanized and stainless steel. We are an official distributor of Bethlehem Wire Rope and also distribute Premier Wire Rope, Kiswire, WireCo. Wire rope, Hankuk Steel Wire and DSR Corp. products as well. We can work with you to custom fabricate wire rope products and slingsfor your project needs.

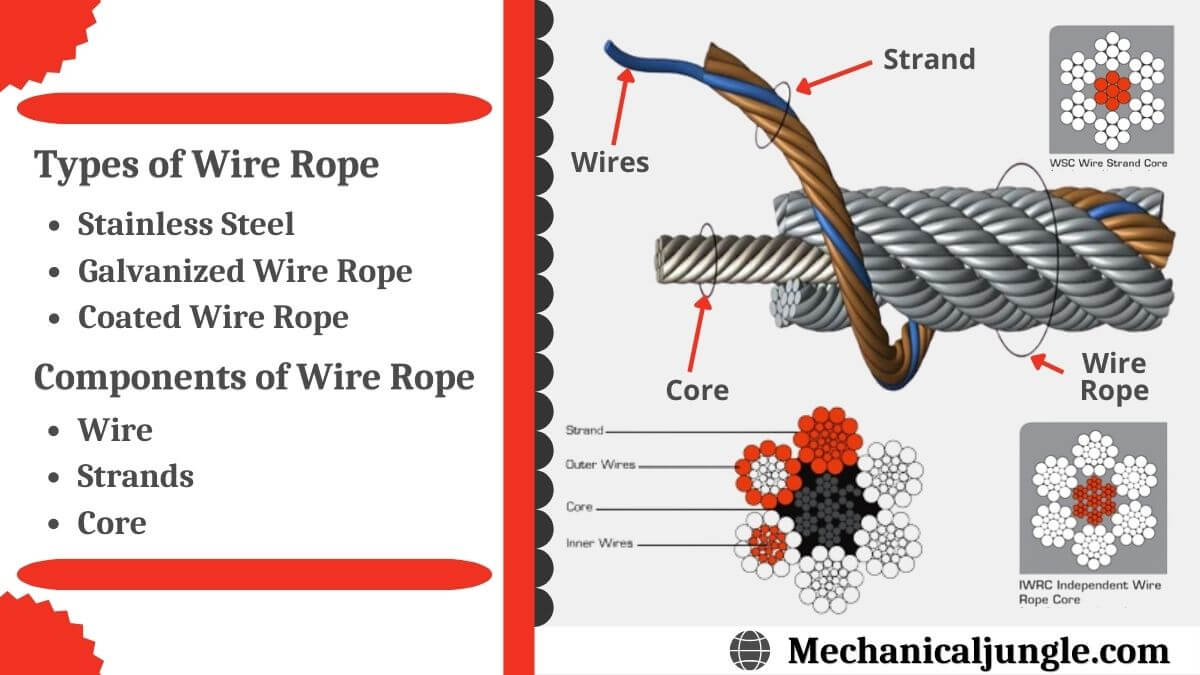

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. Wire rope comes in a variety of strand patterns including single layer, filler wire, seale, warrington, and combination. Wire rope strands can be laid around the core in different configurations including regular lay wire rope, lang lay wire rope, and alternate lay wire rope. There also many types of grades of wire rope, including: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). Some types of wire rope is preferred over others due to the unique properties, including: rotation resistant wire rope, compacted strand wire rope, swaged wire rope, plastic coated wire rope, plastic impregnated (PI) wire rope.

How much does a wire rope sling cost? How much does a shackle or a web sling cost? These are legitimate questions that we hear every day from prospective customers looking to purchase rigging products for their next lifting project.

Like most products and services, rigging gear can be purchased from a traditional brick and mortar location, or can be purchased online through a specialty supplier or catalog and supply house with an e-commerce site. If you’ve done some research and looked at different online suppliers, you’ll notice that there can be a huge disparity in pricing between the same types of rigging products for sale online and in a physical rigging shop.

Rigging shops have long been the stalwarts of the lifting and rigging industries. Rigging shops typically have a showroom or storefront with a wide selection of sling hooks, shackles, chain, synthetic slings and wire rope. They also traditionally buy the raw materials for wire rope, webbing, steel and chain and have a shop where they can make the lifting and rigging products themselves.

If you’re looking for the added benefit and expertise of speaking with a knowledgeable salesperson, want to browse an extensive inventory, and may have an immediate need for a piece of rigging hardware, chain sling, roundsling, or wire rope, then a rigging shop might be your best bet.

A common 1/2” X 10’, 6 X 25 Wire Center, Wire Rope Sling comes in at $29.00, $43.00, and $67.00 from three different online retailers. So, why is there such a wide pricing range for what appears to be the same product?

Online suppliers with the more expensive wire rope and web slings tend to be larger catalog and supply houses that offer an impressive array of all types of industrial products, including rigging gear. They also offer the convenience of selling items like gloves, eye protection, spray paint, etc.—an added convenience factor that allows you to buy everything that you need from one source.

This is also true for lengths of wire rope and chain. Larger diameter wire rope, and larger and longer lengths of chain and wire rope, often fall out of the “standard” product range of suppliers other than rigging shops. If a shop has to special order a piece due to a non-standard size or length, that extra time and effort to acquire the piece will get passed on to the customers as a price markup.

High-performance and specialty items also cost more. For instance, 3/4″ 6 X 37 with wire center rope would cost around $2.50 per foot. A high-performance cable like a 3/4” Dyform 18 would cost about $4.50 per foot. But in the right application, the Dyform 18 will last much longer to justify the higher initial cost, and may also save labor costs because the customer won’t have to perform cable changes as frequently.

However, highly-trained lifting specialists are compensated for their time and knowledge applied to a lifting project and therefore will increase the cost of your rigging solution. Unfortunately, you’re not going to solve your problem by e-mailing a catalog house or e-commerce rigging website’s customer service team. Their businesses are built to move rigging hardware, wire rope slings, chain slings, and synthetic slings out the door in a quick and efficient manner.

Generally, imported products are cheaper in price, and in many cases, the quality is comparable to products made domestically. For instance, an imported 1/2” x 10’ 6 X 25 swaged wire rope sling would cost about $20.00—the same sling made by a company who manufactures their rigging gear in the United States would charge around $30.00.

E-commerce sites that offer deals like free shipping on lifting or rigging equipment seem to target the smaller end user—mostly contractors or small construction companies that make up a large portion of the rigging buyer’s market.

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We also have locations all across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

FassadenGrün is a commercial provider of wire rope systems made of high-grade stainless steel in Germany, Europa and overseas. Information about: Which plants are suitable, are climbing/growing aids necessary, should they be made of wood or metal? Here you will find all the information needed from one provider.

Type 304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized wire rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine and salt water.

316 grade stainless steel is the standard high-corrosion-resistant steel for wire rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing, and textile industries. Type 316 stainless steel wire rope has the best pitting resistance in marine and salt water, and can be used in temperatures up to 900 degrees Fahrenheit.

The vast majority of wire rope specifications are designated with 316 or 304 (and sometimes 302 grade). The basic difference is in the elements that comprise the alloy itself—and 316 stainless wire rope is known to be more corrosion-resistant than 304.

Commonly used in aircraft controls, sailboat rigging, winches, and garage doors, a 7x19 stainless steel wire rope is made up of seven strands with 19 wires in each strand—approximately twice as flexible as a 7x7 construction. Also available in USA-made.

Arctic Wire Rope and Supply is Alaska"s longest established and largest manufacturer of slings, chokers and bridles made of wire rope, cable, nylon web, polyester round and grade 10 chain. We do it all right here in Anchorage and were awarded the Alaskan Manufacturer of the Year in 2006.

Wire rope is a complex mechanical device that has many moving parts, all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

A wire rope is a machine with many moving parts. It has a unique design consisting of steel wires that form individual strands laid in a helical pattern around a center core.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A finished wire rope is comprised of individual wires, which make up individual strands, which are then laid in a helical pattern around a synthetic or steel core.

A wire rope is a machine with many moving parts. From childhood, many of us have been conditioned to think of a machine as some device with gears, shafts, belts, cams and assorted whirring parts. Yet, by the rules of physics, an ordinary pry bar is a simple machine, even though it has only one part.

A wire rope is, in reality, a very complicated machine. A typical 6 by 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Wire rope is a complex piece of mechanical machinery with a number of different specifications and properties that can affect its performance and service life.

A finished wire rope is comprised of individual wires, which make up individual strands, which are then laid in a helical pattern around a synthetic or steel core. There are four basic components that make up the design of a finished wire rope:

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

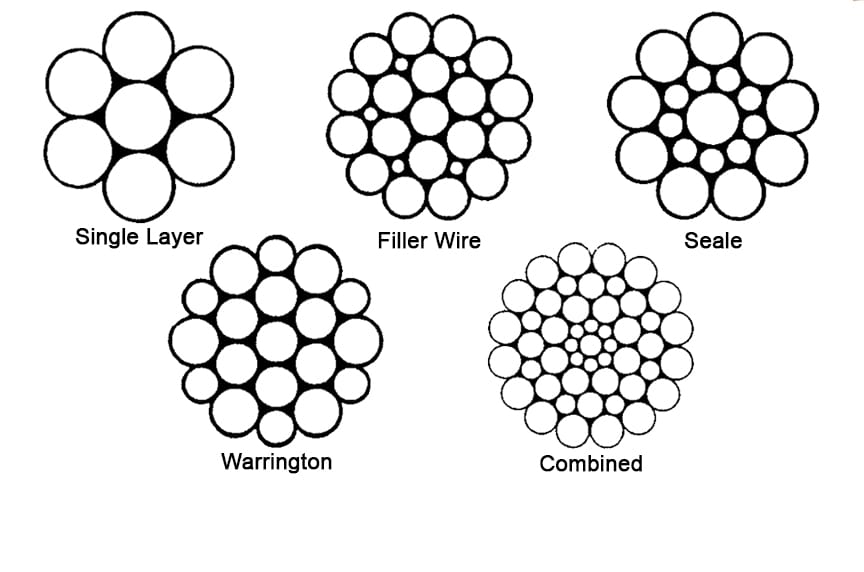

The construction of wire rope falls into one of these strand pattern classifications. The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys,and the smaller ones on the crowns of the inner layer.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

A rope with larger diameter wires will be more crush resistant and abrasion resistant, while a rope with smaller diameter wires will be more bendable and fatigue resistant.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope. Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).

Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay – The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the same strength and weight ratings and usually the same pricing.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system. Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Choosing the right wire rope for a job will be based on many factors: application, required strength, and environment, to name a few. Understanding the basic terminology and the abbreviations associated with wire rope can help you decide which will work best for you.Size

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available.

The numbers used in describing wire rope indicate its construction. For example: a 6 x 19 construction wire rope, the first number is the number of strands (6); the second number is how many wires make up one strand (19).

Regular lay:Also known as a right lay or ordinary lay, this indicates that the strands pass from left to right across the rope and the wires in the rope are laid in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

Lang lay:This indicates that the wires are twisted in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Fiber cores are made of vegetable (sisal, etc.) or synthetic (polypropylene, etc.) fiber and offer more elasticity. Independent wire rope cores offer more support to the outer strands, and has a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

8613371530291

8613371530291