wire rope coupler factory

We offer a full line of wire rope and aircraft cable end fittings designed for installation by crimping, clamping, speltering, swageless connectors, or our specialty — machine swaging. Most fitting types are available in a variety of sizes and materials to meet the needs of nearly any application. To complete your assembly, you may also be interested in our wire rope hardware.

In addition to the standard range, SWR supply high quality wire rope fittings for various uses including architectural, marine, yacht rigging and structural applications. SWR"s fittings are sourced from approved factories worldwide and fully supported by test certificates where applicable.

Manufacturer of standard and custom wire rope fittings. Types include clevis, eye end, oval eye, drum socket, coupling, stud and antenna fittings. Products available include open body forged clevis/socket, open body double socket forged, closed body machined clevis/socket and closed body machined double socket/clevis turnbuckles, hooks and eye swivels, insulators and replacement sleeves. Capabilities include turning, milling, drilling, tapping, metal fabrication, welding and assembly. Serves the maritime, airport, amusement park, sports stadium, construction, architectural, utility, rigging, military and other industries. Made in the USA.

Nicopress is a leading worldwide designer, manufacturer, and marketer of mechanical and electro-mechanical connectivity applications. Recognized for superior technology, innovative engineering, and dependable service, we design and manufacture a range of swaging tools, as well as connection and terminating solutions for applications in electrical cable, wire rope, and fiber rope. Nicopress compression products service global customers in industries that require safety and quality provided by our continuous innovation: aerospace, military and defense, utilities (infrastructure), industrial, rail signal and catenary, and entertainment.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

At U.S. Rigging, we offer a wide selection of wire rope and wire rope fittings. Whether you"re in need of hand swagers, wire rope cutters, or wire rope and custom cable assemblies, we offer the best rigging hardware in our DuraBrite™ brand.

Wire rope swage sleeves and fittings are used to terminate the ends of wire ropes to prevent fraying, and to securely form lifting eyes in wire ropes. Cable swage sleeves and wire rope end fittings are very versatile and are an essential part of many wire rope rigging applications.

Here at Tri-State Rigging Equipment we pride ourselves on providing only the highest quality swage sleeves and wire rope end fittings to our customers, from only the most reputable manufacturers. We can provide you with any rigging equipment on the market, so if you cannot find what you are looking for or don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

Wire rope swage sleeves, sometimes referred to as cable ferrules or duplex / crimp sleeves, are used to form eyes on the end of wire ropes. Wire rope swage sleeves are a more secure and more permanent alternative to wire rope clips. Cable swage fittings and sleeves are available in a variety of materials to fit any wire rope rigging application:

To properly fit and secure a cable swage sleeve, most use a hydraulic swaging press, while others can be hand crimped using a special hand swage crimping tool. Cable swage sleeves are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

These wire rope end fittings are used to allow wire rope to be used in a large variety of rigging applications. Wire rope end fittings are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

Tri-State Rigging Equipment is a service provider and distributor for all wire rope cable swage sleeves and wire rope end fittings for rigging and lifting serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping, and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively, the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is comprised of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper, and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion, and environmental conditions as well as the intended use for the sling.

1, We need your site ’ s floor plan size and other information to assess the best way of designing a ropes course to meet your specific requirements. 3,You can find regular and experienced steel installation team for i nstallation according to our construction drawing, video or manuals. 4, With installation completed, the final step is training your staff via our training video or manuals.

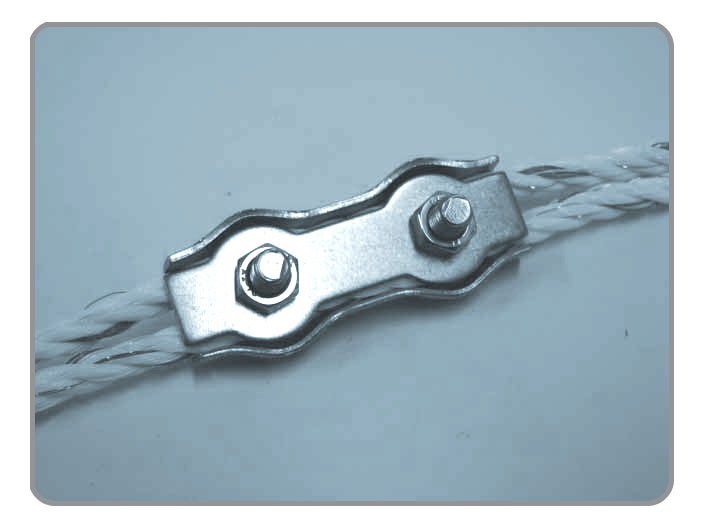

Simplex wire rope clip is one type of frequently used wire rope clamp. This wire rope clip has a simple design, but with strong and high corrosion resistance. It can be perfect for making eye-loop connections or complete loops in wire rope clip cable, we also have duplex wire rope clip for your option.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

8613371530291

8613371530291