wire rope diameter and capacity pricelist

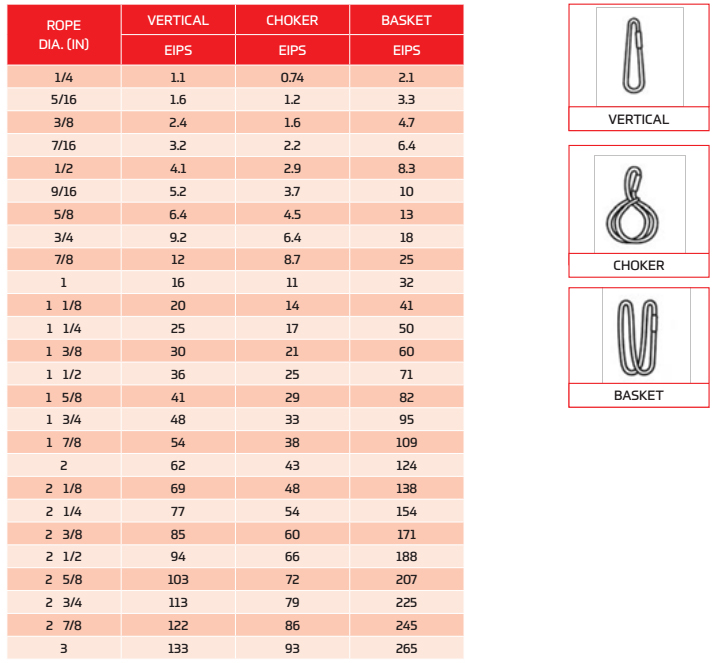

Wire Rope Material: The lifting slings are made from independent wire rope core (IWRC) offering less stretch and resistance to crushing while maintaining sling flexibility. Wire rope slings are fabricated from extra improved plow steel (EIPS).

A low quality wire rope sling can cause injury and damage. A look-alike wire rope sling often found at lower prices is also often advertised to conform to the same safety standards (if at all). Be aware that it may refer to safety ratings in effect decades ago. So for example under the same safety standard a decade ago, a wire rope sling may be rated to 100% without proof load testing while today it may be 300% with proof load testing. Be assured that we only sell the highest quality wire rope slings and our advertised safety standards conform to the current ASME standards.

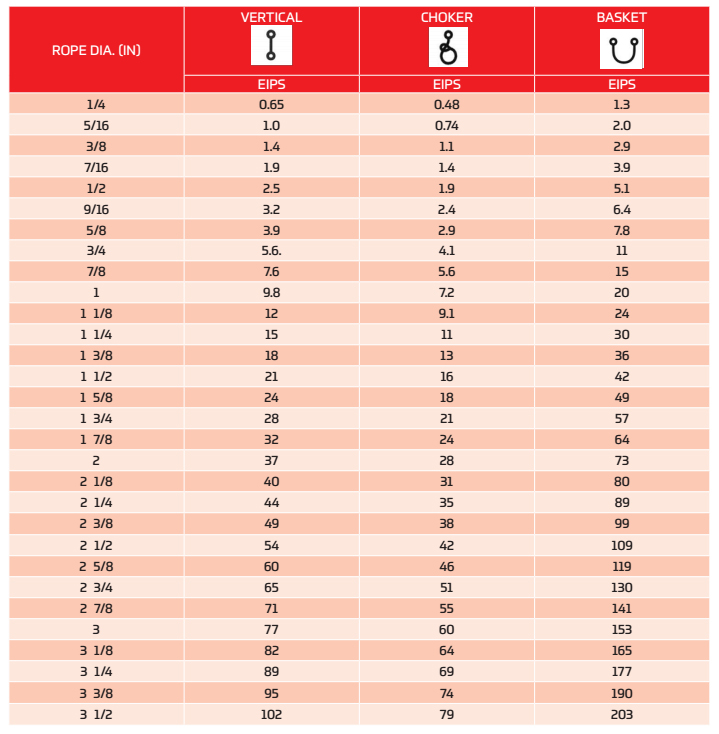

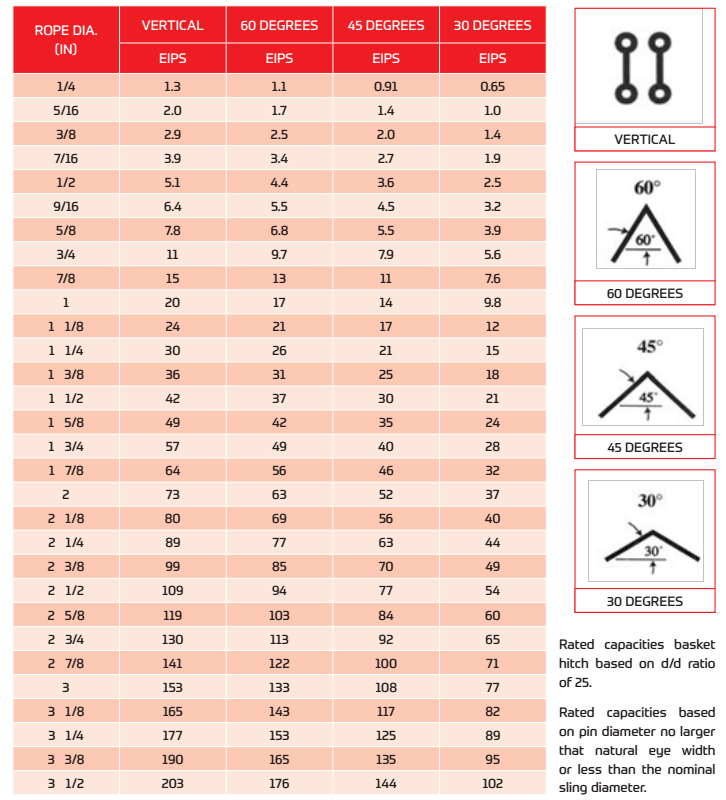

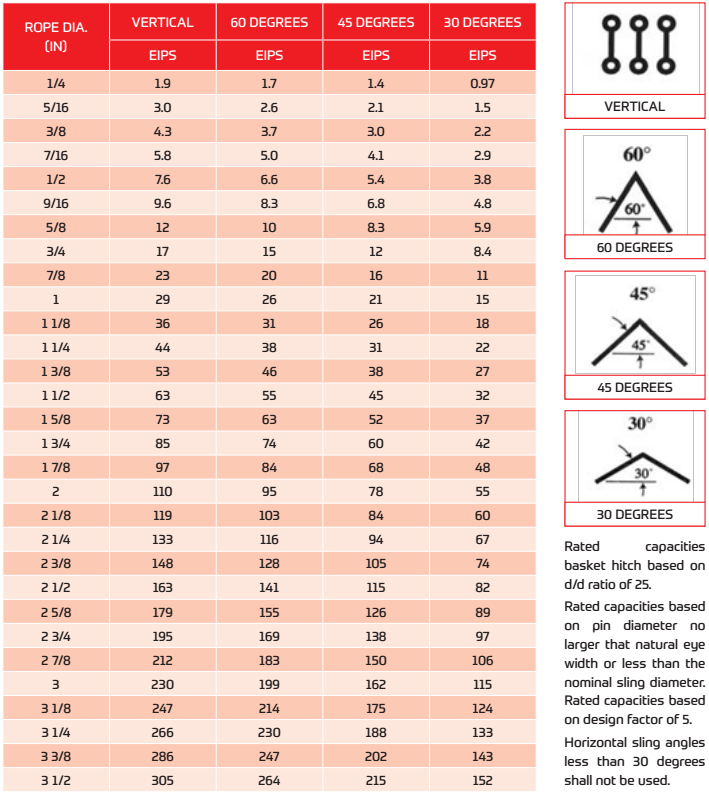

Working load limits (capacity) of the wire rope lifting slings vary depending on the angle of use. The capacity is reduced as the angle of use declines. See drawing below how a 1,000 lbs sling capacity is reduced as the angle of use declines. The capacity of the sling is always highest at a 90 degree angle of use and smallest at an angle of 30 degrees (or less).

The chain sling has the advantage of being durable, very flexible and its length can be made adjustable. It will tolerate a wide range of temperatures; however, compared to other types, it is relatively expensive and, depending upon the grade of chain used, relatively heavy.

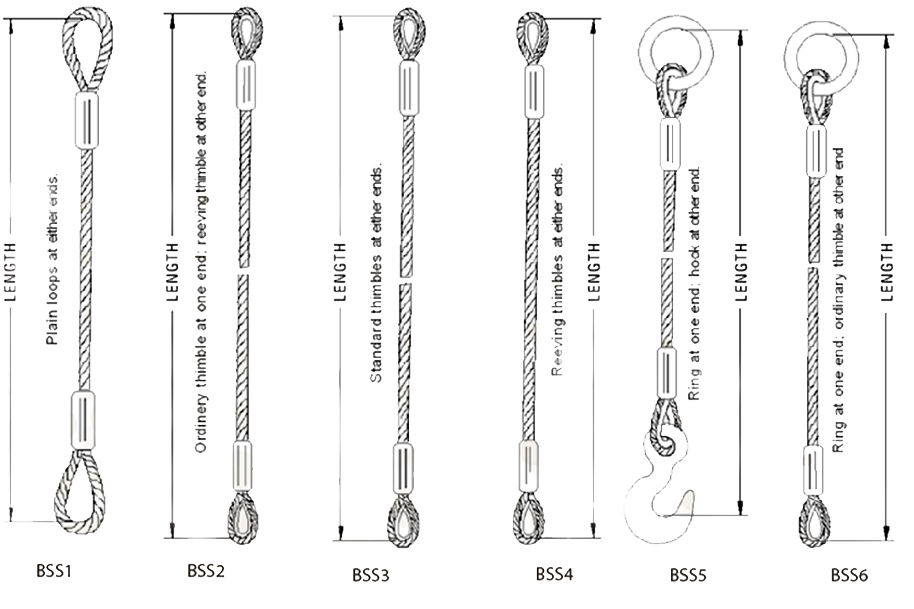

The wire rope sling is not quite as durable. The wire rope sling is not as flexible as chain but its greater stiffness can be an advantage if it has to be inserted through a small opening or beneath a load. However, when wrapped around a load, the wire rope sling often tends to deform permanently to the shape of the load. Wire rope suitable for slings comes in a variety of grades and constructions. In most cases looping back and securing the loop with a metal sleeve terminates the rope. This forms a loop or soft eye, the simplest form of sling end. Thimbles are used to support and protect the eye from abrasion. Wire rope is generally cheaper and lighter than chain which can be a plus, particularly for applications that require long sling lengths.

The nylon and polyester slings have the advantage of being lightweight in comparison to chain and wire rope slings. They are very flexible and relatively soft; therefore, they are suitable in applications were minimal damage to the load"s surface finish is important. The rope is made endless or terminated with an eye by means of a handmade splice. Similar to a wire rope sling, various terminal fittings are available. Without adequate protection, nylon and poly slings are susceptible to being severed when impinging on even a relatively moderate sharp edge.

Wire rope is often commonly referred to as cable; they are one in the same. Wire rope is composed of wires, strands, and a core. The basic unit is the wire, which is formed into strands. The strands are wound around the core. Various types of wire rope exist to meet a range of uses and operating conditions. These types are designated by the number of strands; the number, sizes and arrangement of the wires in each strand; and the way in which the wires and strands are wound, or laid, about each other.

Important characteristics of wire rope relate to the number and size of the outer wires. A small number of large outer wires result in better resistance to wear and corrosion. A large number of small wires result in better flexibility and resistance to fatigue.

The core acts as the axial member about which the strands are laid. Wire rope cores are made in two different forms. The one used most extensively is a wire rope of suitable size to serve as a core. It is called as independent wire rope core (IWRC). IWRC has increased tensile strength, offers less stretch, and is resistant to crushing; however, is less flexible. The other type is a wire strand core (WSC). This consists of a multiple-wire strand, and may be the same construction as the main rope strands.

Two grades of carbon steel wire are offered. The bulk of commercial wire rope lifting sling is made from improved plow steel (IPS) or extra improved plow steel (EIPS) which has a higher tensile strength.

Hand Splicing:Because no metal sleeve is required to secure the eye in the hand spliced sling, it exhibits more flexibility than mechanically splice slings of equal diameter. They have a more narrow profile and therefore can fit through tight spaces. Without benefit of a metal sleeve, lifts must be limited to applications where the wire rope sling is restrained from rotation and possible unlaying of the sling body.

Mechanical Splicing:Mechanically spliced eyes do not suffer the limitations of hand splicing, are economical, and offer the highest rated capacity of any spliced wire rope sling. This wire rope sling is fabricated by unlaying the rope body into two parts, one containing half the number of strands, the other having the remaining strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together. The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the body of the wire rope sling.

Silvassa, Dist. Dadra and Nagar Haveli and Daman and Diu Survey No.269, Village Sayli, Silvassa - 396230, Dist. Dadra and Nagar Haveli and Daman and Diu, Dadra and Nagar Haveli and Daman and Diu

We Pearl Overseas Have Stainless Steel Wire Rope In Ready Stock, We are specialist in Stainless Steel Wire Rope, Stainless Steel Wire Rope available in 304, 304l,read more...

JALALPURA, Nagpur Shri Gokulesh Bhavan, Near Rapid Transport Co., Behind Prateesh Sales Near Madhur Courier, Opposite Shankar Mandir, Gandhi Bagh,, JALALPURA, Nagpur - 440002, Dist. Nagpur, Maharashtra

Dombivli East, Dombivli, Dist. Thane Block No. 10, Sudame Apartments, Vidya Mandir Road, Tuljai CHS Tilak Nagar, Dombivali East, Dombivli East, Dombivli - 421201, Dist. Thane, Maharashtra

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We don"t collect information from our users. Only emails and answers are saved in our archive. Cookies are only used in the browser to improve user experience.

Some of our calculators and applications let you save application data to your local computer. These applications will - due to browser restrictions - send data between your browser and our server. We don"t save this data.

Google use cookies for serving our ads and handling visitor statistics. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

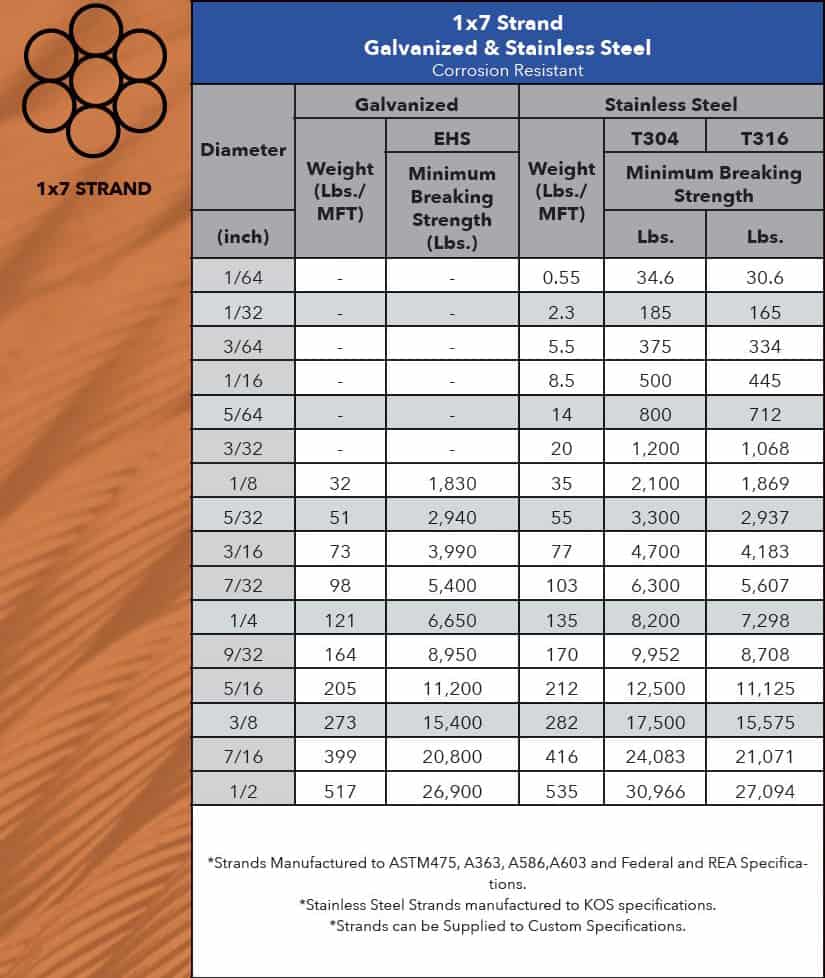

1X7 strand wire rope consists of one (straight) center core wire, and six wires helically stranded around the core, with diameters ranging from 1/8" – 5/8". The construction of 1x7 strand yields minimal stretch, and this basic strand is used to make 3X7 and 7X7, and 7X19 cable.

Galvanized wire rope is dipped in molten zinc to form a thick layer of zinc coating before the wire is drawn through dies—to reduce diameter and increase tensile strength. At the same time, the zinc coating bonds to the steel wires and compresses to form a more durable layer to protect the steel from corroding, thus maintaining more wire rope strength and wire rope load capacity over longer durations.

Common applications include fencing applications, guying applications, bracing & tensioning, and use in the metal building industry. Also available in USA-made.

These Terms and Special Conditions (if any) shall apply to all Contracts for the sale of Goods by Tractel and shall prevail over any inconsistent terms or

quotation shall constitute an offer made to Tractel in accordance with these Terms and shall only be binding on Tractel if it is accepted by Tractel in

illustrations contained in Tractel"s catalogue, price list or publicity material are intended only to present a general idea of their subject matter and

causes; accident, breakdown of plant or machinery, war, riots, civil commotion, strikes, lockouts, fire, explosions, requisitions, and Acts of God. Tractel

The Contract shall in all respects be subject to and constructed in accordance with English Law and the English Courts shall have exclusive jurisdiction

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the wire rope sling price you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal wire rope sling price for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, wire rope sling price will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The prices of raw materials and finished products in the manufacturing industry increased dramatically throughout 2021, and we know you’ve been feeling the effects. Unfortunately, we expect the current inflationary market conditions to continue into 2022.

Mazzella has been in the lifting and rigging business for nearly 70 years, and we’re going to provide some answers to why the price and availability of wire rope, slings, rigging hardware, and other lifting gear has been so abnormal, and what the outlook is for the immediate future.

In this article, you’ll learn the answers to the following questions:What factors are affecting the price and availability of wire rope, slings, and rigging products?

Are you finding that once-readily available materials are now becoming increasingly more difficult to purchase? If you are able to find those materials, is it taking far longer and costing much more than it used to?

Supply chain issues are going to continue into at least the second quarter of 2022, and numerous leading supply chain experts are concerned the current challenges could extend into 2023. The question is when will the market begin to stabilize? While that question proves difficult to answer accurately, there are factors causing dynamic issues within the supply chain.

When the COVID-19 pandemic began, every industrial company, even retailers, cut back inventory to align with market demand, as well as protect their businesses. Specific to the steel industry, which has far-reaching impact because many lifting and rigging products are made of steel, all the material suppliers struggled to gain access to the same supply. This happened because some steel mills were shuttered and numerous people were laid off.

Before the latest surge in COVID-19 cases, companies began reopening and producers needed more raw materials to make more products. Increased demand in the market far exceeded available inventory.

The supply of the material, be it steel or non-steel, remains very tight due to low inventory levels. That applies to the raw material with the actual producers, as well as the people who distribute products. Producers are scrambling to take care of increased demand in 2021.

Large and inconsistent increases in lead time do not allow companies to have an on-time delivery schedule for their materials and products. They don’t have as much inventory to pull products off the shelf and send out to their customers / distributors.

Even in the most credible and productive supply chain of any industry, car manufacturers are struggling to produce vehicles because of chip shortages, as well as inconsistent delivery of steel and resins. Dealerships across the country are struggling with car lots that are half-empty or worse.

All industries, including ours, have struggled to hire employees because of government program extensions, ongoing COVID-19 concerns, and childcare needs.

We’re seeing these issues creating a chain-reaction effect going all the way to the companies that mine the actual elements used in the manufacturing of lifting and rigging products. Raw material production has been difficult because of increased demand for employees, which creates further market instability.

If you’re the raw material manufacturer of a product, i.e. a steel mill, chemical, or resin producer, you’re seeing an exponential increase in demand right now. Steel mills want to get tonnage out and have been able to raise market costing as demand continues to clearly exceed production capabilities.

To ensure continuous supply, our material costs have increased, and unfortunately, we must pass on incurred supplier costs to our customer base. Because of our company size, and the volume of which we buy, we have been able to negotiate cost and delivery more aggressively than others in the market.

Companies have idle machines because they don’t have the people to run the equipment. With the government extending benefits programs due to the pandemic and working to pass sweeping infrastructure bills, we expect that labor costs are going to continue rising.

Delays at any point in the supply chain, particularly at the beginning with production, have a ripple effect down the line for manufacturers, distributors, and customers.

The time to buy was yesterday, but there is still an opportunity for you to get ahead of the curve and plan accordingly to keep your business running, as close to normal, with the current market restraints.

At some point, prices are going to stabilize and not fluctuate as drastically. However, we expect that there’s going to be a “new normal” in terms of prices remaining higher than pre-pandemic levels for the foreseeable future.

While “experts” are predicting different market reactions, history proves that most things are cyclical. However, in the short term, labor costs are continuing to increase. Manufacturers and customers in all industrial markets are experiencing price levels higher than what products used to cost.

Mazzella is doing everything in our power to keep inventory levels as high as possible for wire rope, slings, and rigging hardware. Fortunately, Mazzella has stayed ahead of the demand increase and supply shortage by procuring product early and often throughout 2021.

Mazzella made a multi-million-dollar investment in our inventory before market issues took hold, which helped our supply chain by providing our suppliers extra lead time to produce and maintain their production schedules.

By making an investment in wire rope, slings, and rigging hardware, Mazzella has attempted to position ourselves to minimize any supply chain disruption for our customers.

While many competitors rely on one supplier for certain products, our footprint and volume has allowed us to maintain relationships with four domestic wire rope suppliers and eight domestic hardware vendors.

If rigging shops have relied on one supplier and didn’t plan and buy ahead, their distribution certainly has been disrupted. However, Mazzella can offer a range of product options to our customer base.

Mazzella is in constant communication with suppliers and will continue to monitor market trends and costs. We’re committed to working with you as the market changes.

Also, we’ll educate and communicate what we know to you, the customer, as things change. We want you to understand the current market conditions, and how you and your business can thrive during these challenging times.

Mazzella sources and procures steel, and other key commodities, on a global basis. We’re making every effort to work closely with our vendor base to drive down the impact of these unprecedented market conditions and offer you competitive pricing. Also, we’ve been as proactive as possible in securing needed inventory to meet our customer product requirements.

Fortunately, as Mazzella anticipated the shortage, we placed large stock of raw and finished material in early 2021 and filled all of our locations across the country. with most common items. Even with the current market volatility, we are working closely with our customers to anticipate their needs in order to minimize any interruption of the supply chain.

With our national footprint and diverse product offerings, which include, but are not limited to lifting and rigging supplies to crane ropes, general-purpose wire rope, warehouse solutions, and fall protection, Mazzella can be a one-stop shop for service and products to meet your needs.

An ISO 9001:2015 and BIS/ISI certified MAHADEV INDUSTRIES is one of the leading manufacturer of various types of tested Steel Wire Ropes, Strands and Wire Rope Slings in India.

We are MSME / SSI Unit. We have state of art machineries and fully equipped testing labs for continuous process for testing of raw material, chemical analysis and mechanical testing of wire, wire ropes and other allied articles/accessories to finished goods according to National and International Standards and for this we can say rather we are having breaking load capacity of 300 M.T. with crimping machine (for slings) up to 2000 M.T. We can proudly say that the company is regularly supplying its material to various Government, Semi-Government departments and several industries.

We are manufacturing all types of steel wire ropes for General Engineering purpose, Oil Well and Oil wells drilling, Shipping, Suspension Bridges, Cranes, Elevators, Automobiles, Winches, Mining, Man riding and Haulage purpose, high quality PVC coated wire ropes, Stainless Steel wire ropes / strands,higher abrasion resistance with higher breaking strength COMPACTED wire ropes for piling, Cradle ropes

As far as quality concern, we are very much confident about our product quality. We are putting a identical strip inside the rope of our brand name "MAHADEV" for the identification of our genuine product and the convenience of our valuable old and new customers.

8613371530291

8613371530291