wire rope diameter and capacity quotation

We don"t collect information from our users. Only emails and answers are saved in our archive. Cookies are only used in the browser to improve user experience.

Some of our calculators and applications let you save application data to your local computer. These applications will - due to browser restrictions - send data between your browser and our server. We don"t save this data.

Google use cookies for serving our ads and handling visitor statistics. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected.

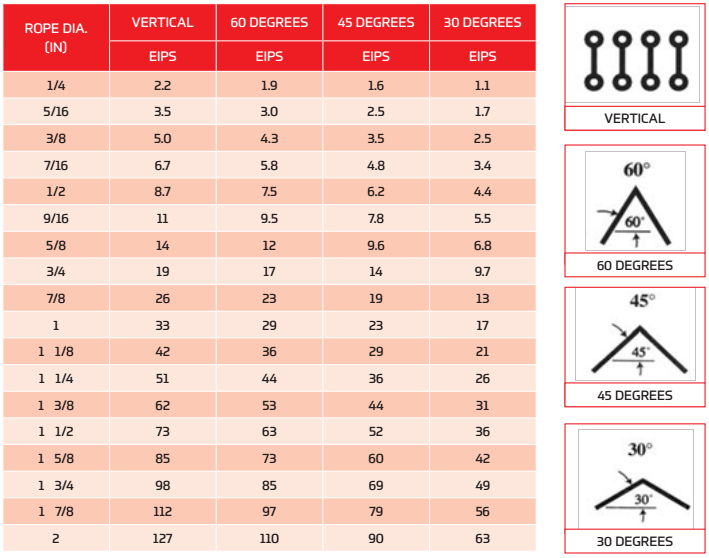

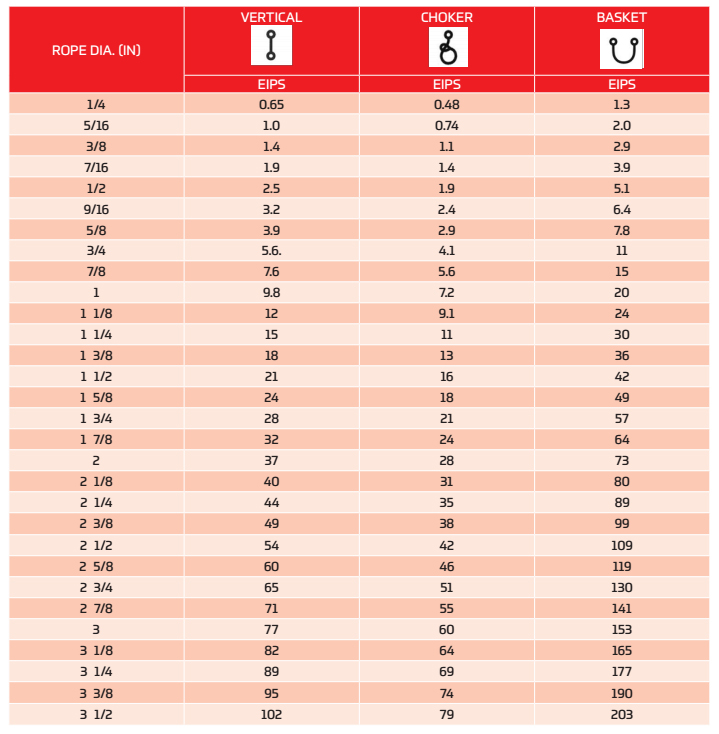

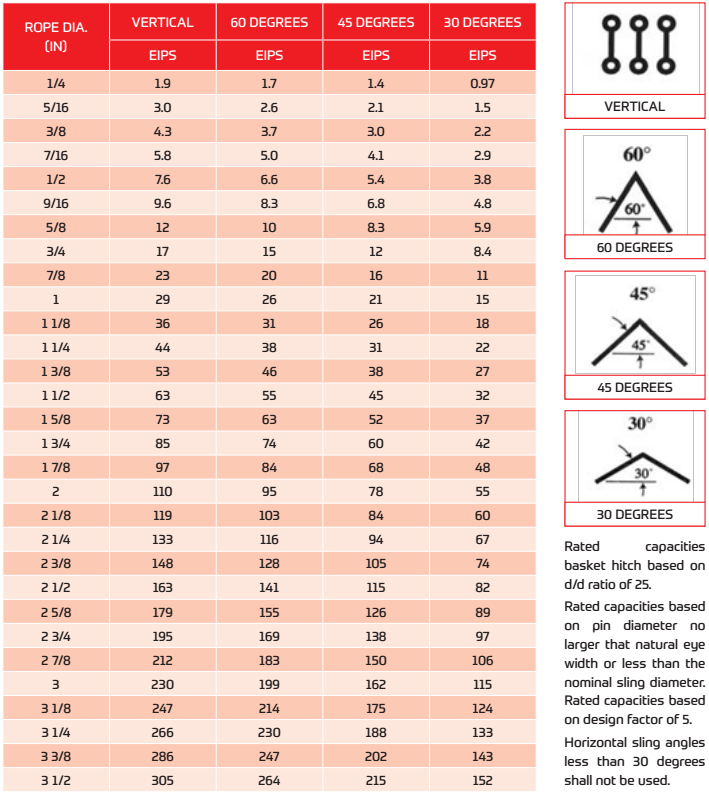

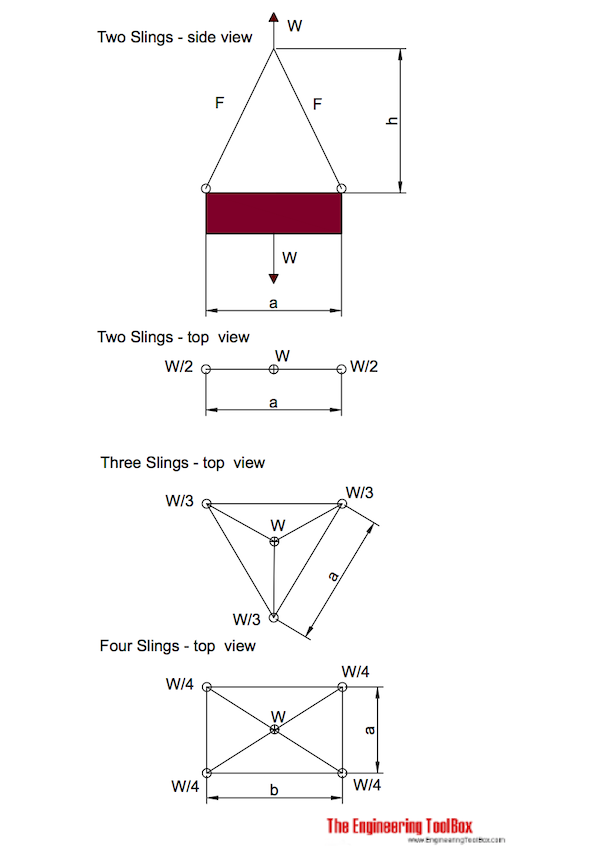

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

While it is virtually impossible to calculate the precise length of wire rope that can be spooled on a reel or drum, the following provides a sufficiently close approximation.

* This formula is based on uniform rope winding on the reel. It will not give correct results if the winding is non-uniform. The formula also assumes that there will be the same number of wraps in each layer. While this is not strictly correct, there is no appreciable error in the result unless the traverse of the reel is quite small relative to the flange diameter (“H”).

** The values given for “K” factors take normal rope oversize into account. Clearance (“x”) should be about 2 inches unless rope-end fittings require more.

Understand that most of the people out from the industry always face the problem of having no idea with the terms of wire rope when receiving quotation. In this update, we will explain in the most simple way and hopefully it is applicable to anyone.

6X36 = Construction of wire rope (There are quite a lot different constructions available for different application for example like, 6X25, 6X29, 6X31, 4X39, 19X7, 8X26 etc.)

RHOL = Right hand ordinary lay, it is the wire lay direction and very important to select the right direction of wire when dealing with multi-reeving, crane and hoist application.

EIPS (1960) = Extra improved plow steel and 1960 stands for the tensile strength 1960N/mm2. The figure is telling you the grade of wire rope, lower or higher tensile strength will result in different breaking strength.

UNGALVD = Ungalvanized, the surface finishing of wire rope. Galvanized and Ungalvanized are the basic surface finishing selection with different grade of lubrication.

G411 THIMBLE EYE = Thimble eye model. Soft eye will be stated with the effective working length and the size of soft eye is based on nominal diameter x 15times according to EN131411 standard.

MECH SPLICED = Mechanical splicing is the process of using hydraulic pressure to press the aluminum sleeve or metal sleeve and a loop is formed. This phrase is always telling you the terminal of both end wire rope. It can be plain, socketed, fuse tapered or eye formed.

Wire rope could have a lot of variation upon the application which I will cover in the next update. The essay above is good enough to tell the basic and hope it helps for procurement department while dealing with steel wire rope. Last but not least, selecting the right wire rope is crucial to your company"s long term expenditure and safety purposes. Do not take the risk because of cheap.

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Flexibility and handling ease for rigging large lifts are the main benefits of the 9-PART Slings. The 9-Part sling is made by laying wire rope continuously through both eyes and the sling body. This results in a body formed with nine parts.

The improved efficiency of the 9-Part Super-Flex slings is backed with a proven design that provides internal adjustment to distribute the load among all nine parts of the sling body. The 9-Part sling is made by laying wire rope components continuously through both eyes and the sling body. This results in a body with improved flexibility and handling ease for rigging large lifts. Only two splices occur in the entire sling-where the component rope ends are spliced at the eyes. The sling construction makes it possible to easily inspect all parts of the sling before and after each lift, which is important to remember if the sling is to be used many times.

When a sling body must conform to a tight choke hitch or must bend in a tight radius, such as around a pin or post, a 9-Part construction may be the most suitable since it can develop greater lifting capacity from a smaller component rope.

WHEN USING IN BASKET OR CHOKER CONFIGURATION, TAKE LIFTING ANGLES INTO CONSIDERATION. TO OBTAIN FULL RATED CAPACITY, THE PIN THAT THE EYE OF THE SLING PASSES OVER MUST BE A MINIMUM OF 4 TIMES THE DIAMETER OF THE COMPONENT WIRE ROPE.

Rated capacities of basket hitches are based on 40 times wire rope diameter (1/4″ through 1″ diameter slings) and 25 times wire rope diameter (1-1/8″ and larger diameter slings). Basket ratings are calculated for vertical lifting.

There are many different sizes, configurations, and materials that form wire rope, and these are different types including stainless steel wire rope, galvanized wire rope, and bright wire rope.

Looking for accessories to use with wire ropes? Our rigging supplies include hardware and accessories for use with cranes, hoists & winches, and oilfield applications.

Diameter:To properly measure the diameter of steel wire ropes, measure the rope at its widest point. This is an industry standard with wire cable manufacturers and steel cable suppliers.

Grade of Steel – EIPS, EEIPS: EIPS is Extra Improved Plowed Steel and has roughly 10% more strength than IPS. EEIPS is Extra Extra Improved Plowed Steel and is approximately 10% stronger than the EIPS. We offer every variety of EIPS Wire Rope and have a one day lead time on any EEIPS ropes.

Direction of Lay: Right hand and left hand designates which way the strands wrap around the core of the steel rope. Regular lay and Lang lay specify which way the wires are formed in the helix pattern. Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands are wrapped around the wire rope core.

Finish – Bright Wire, Galvanized Wire, and Stainless Steel: Most wire ropes have a bright, self-colored finish hence the name. Wire ropes generally have a coating of lubricant to reduce friction and protect from corrosion. However, there are wire ropes that are galvanized, stainless steel, or coated in vinyl and other plastics.

Material of the Core: Fiber Core (FC) or Independent Wire Rope Core (IWRC) – Fiber cores are made of natural (sisal, etc.) or synthetic (polypropylene, etc.) fibers and allow for increased flexibility. IWRC offers more support to the outer strands, and have a higher resistance to crushing. IWRC also offers more resistance to heat, reduces the amount of stretch, and increases the strength of the rope.

Strands: Another variable in wire rope is how many strands make up the rope and how many wires make up one strand. For instance, a 6×26 wire rope has 6 strands around a core with 26 wires making up each strand. The 6×19 class is the most common and offers higher resistance to abrasion whereas the 6×37 class offers higher flexibility.

Although there are exceptions for special applications, the constructions in 6×36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

The 6×19 classification of wire ropes includes standard 6 strand, round strand ropes with 16 through 26 wires per strand. This is a good rope to withstand abrasion or crushing on the drum. Ropes with independent wire rope strands and a core (IWRC) in general, are more crush resistant than fiber core ropes.

When you purchase our 6×19 Class of wire ropes, you get more than just another rope. Manufactured in an ISO 9001 certified factory and backed by the industry’s largest staff of professional engineers, we do more than meet published specifications.

The 6×26 WS has better resistance to abrasion than a 6x25FW. It features a compact construction with solid support for the wires; therefore it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue resistance comparable to a 6×25 FW. A standard 6×26 WS construction provides the best rope for a wide range of applications. In general, we recommend the use of the 6x26WS in any application where a 6x25FW is used.

Mast Raising Lines, also called Bull Lines or Bridle Lines, are usually two pieces: each having sockets on both ends. These lines can be fabricated from either right regular lay rope or right lang lay rope. They must be fabricated from IWRC ropes.

Premium ropes may be used for specific applications. PFV cushions the strands, distributes internal stresses, keeps in wire rope lubricant and keeps out dirt and debris, extending the service life.

Flex-X® 9 features compacted strands and swaging for extra drum crushing resistance and increased stability. Its high-density strands deliver extra strength and resistance to abrasion. Flex-X® 9 is manufactured with a dual compaction process to produce a compact cross-section with minimum voids and greater surface area on outer wires that contact drums, sheaves and the rope, itself during operation. The high-density compacted strands minimize nicking at strand-to-strand contact points. Flex-X® 9 was specifically designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

Flex-X® 6 users receive superior performance and increased service life in many applications compared to the ropes they had previously employed. When compared to conventional six-strand ropes, Flex-X® 6 ropes provide greater surface area and more steel per given diameter. This increases rope stability and strength. This results in a longer service life and less sheave and drum wear.

Flex-X® 19, a Category 2 rotation resistant rope, is made from 19 strands. Six strands are laid around a core strand in one direction, and then 12 strands are laid around this first operation in the opposite direction. Because of its tightly compacted smooth design, Flex-X® 19 offers more crushing resistance than standard 19×7 rope, higher strength-to-diameter, resistance to bending fatigue, exceptional stability, reduced wear to sheaves and drums, and improved handling, operating and spooling characteristics.

Eyes are formed using the flemish eye splice. End are secured by pressing a metal sleeve, either steel or aluminum, over the ends of the strands of the splice. Pull is directly along the centerline of rope and eye. Gives most efficient use of rope capacity, is economical.

Flemish eye splice – In the standard flemish eye mechanical splice, rope is separated into two parts – 3 adjacent strands, and 3 adjacent stands and the core. These two parts are then re-laid back in opposite directions to form an eye, and ends are secured with a pressed metal sleeve.

*Rated Capacities basket hitch based on D/d Ration of 25 * Rated capacities based on pin diameter no larger than natural eye width or less than the nominal sling diameter * Rated capacities based on design factor of 5 * Horizontal sling angles less than 30 degrees shall not be used * Rated capacities show apply only to 6 X 19 and 6 X 37 classification wire rope ** When angle of choke is less than 135°, capacity is reduced.

Bengaluru Shop 06, Ground Floor and First Floor, Channakeshava Farm House Indiranagar, Gangondanahalli Main Road Doddabidarakallu, Nagasandra, Bengaluru - 560073, Dist. Bengaluru, Karnataka

Bengaluru No. 127/4,Heelalige Road,H.K.Chandra Shekara Reddy Building,Chandapur, Anekal Taluk, Bangalore,,Ben Bengaluru (Bangalore) Urban,Karnataka, Bengaluru - 560099, Dist. Bengaluru, Karnataka

Galvanized Wire ropes available in all sizes from 1.8mm upto 72mm , constructions available are 1x7 , 7x7 , 6x19 , 6x36 , 6x31 , 6x41 , 35x7 . Please contact us forread more...

With rich industrial experts, we are most appreciated name in the market by offering best collection of Wire Rope Sling that is used in the rigging industry.read more...

8613371530291

8613371530291