wire rope drawing quotation

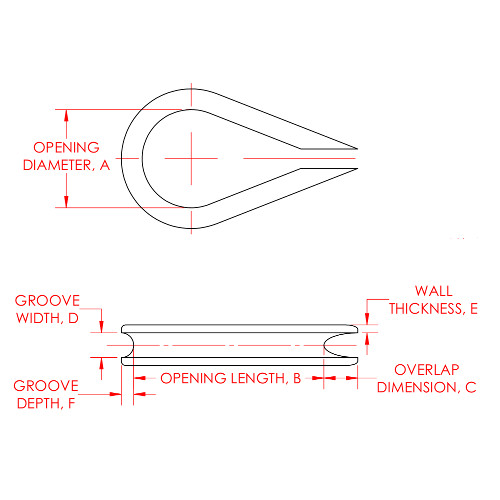

Marine Eye Fitting Size Select Marine Eye Fittings IDTMI# 360-003 wire with diameters .190, .218, .093, 1.572wire with diameters .190, .254, .108, 1.945TMI# 360-003.2 wire with diameters .190, .383.195, 2.352wire with diameters .250, .406, .202, 2.655wire with diameters .313, .543, .260, 3.071TMI# 360-003 wire with diameters .190, .218, .093, 1.572wire with diameters .190, .254, .108, 1.945TMI# 360-003.2 wire with diameters .190, .383.195, 2.352wire with diameters .250, .406, .202, 2.655wire with diameters .313, .543, .260, 3.071

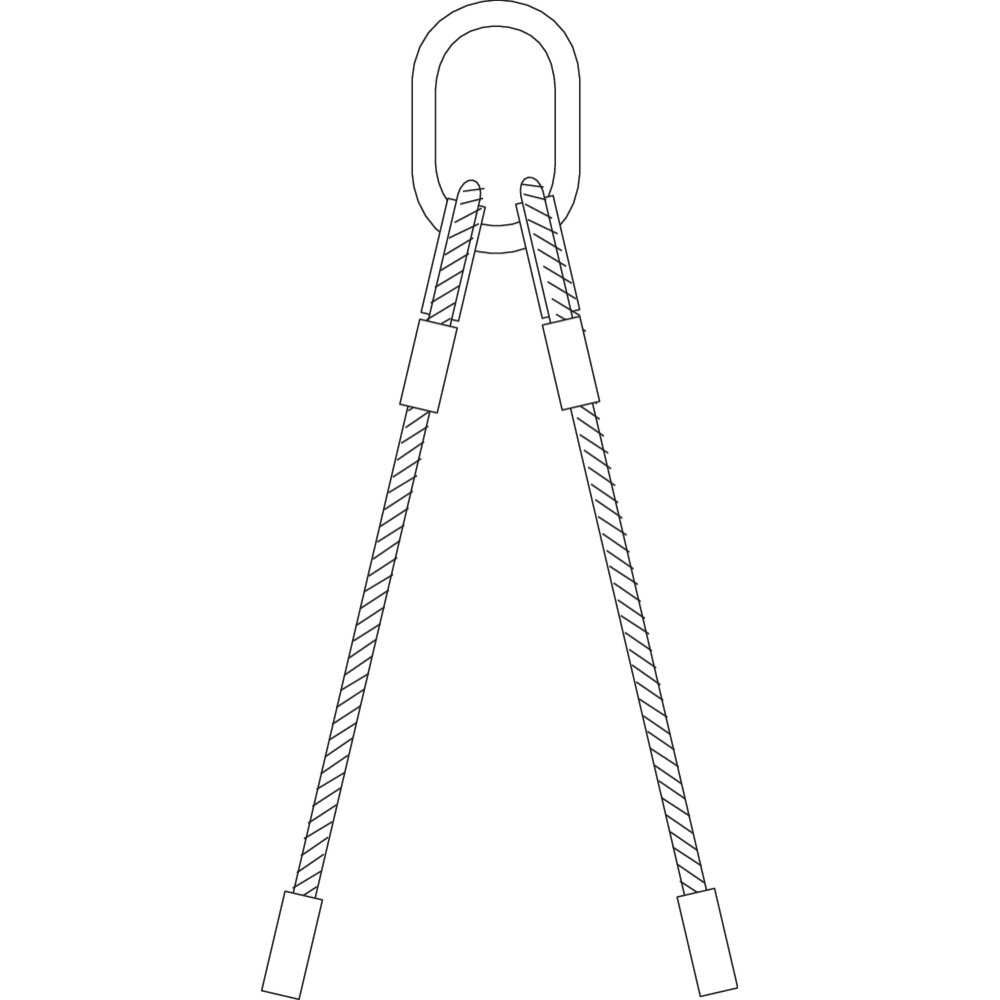

Producer Price Index by Industry: Steel Wire Drawing: Noninsulated Ferrous Wire Rope, Cable, and Fabricated Wire Rope Assemblies (Including Lifting Slings) [PCU3312223312221],

Select an AlloyInconel– Inconel® X750– Inconel® 718– Inconel® 686– Inconel® 625– Inconel® 617– Inconel® 601– Inconel® 600Nimonic– Nimonic® C-263– Nimonic® 90– Nimonic® 80A– Nimonic® 75Incoloy– Incoloy® A286– Incoloy® 825– Incoloy® 800HT– Incoloy® 800Hastelloy– Hastelloy˘ X– Hastelloy˘ C-2000– Hastelloy˘ C-276– Hastelloy˘ C-22– Hastelloy˘ C-4– Hastelloy˘ B-3Haynes– Haynes˘ 282– Haynes˘ 214– Haynes˘ 25 / L605Phynox– Phynox†MP35N– MP35NRene– Rene 41Waspaloy– WaspaloyNi-Span-C Alloy– Ni-Span-C Alloy 902®Beryllium Copper– Beryllium Copper CB 101TitaniumMonel– Monel® K-500– Monel® 400Nilo– Nilo® K– Nilo® 52– Nilo® 48– Nilo® 42– Nilo® 36Nickel– Nickel® 270– Nickel® 212– Nickel® 205– Nickel® 201– Nickel® 200Duplex– Super Duplex– DuplexNitronic– Nitronic** 60– Nitronic** 50Alloy 20– Alloy 20 CB 3Stainless Steel– Stainless Steel 321– Stainless Steel DTD 189A– Stainless Steel 316Ti– Stainless Steel 316LVM– Stainless Steel 316– Stainless Steel 304– Stainless Steel 302– Stainless Steel 1.4310Resistance Wire– 45/55 Ni Cu Resistance Wire– 80/20 Ni Cr Resistance WireHot Cutting– Heatseal 29RW– RW 70– RW 122– RW 118– RW 41

We operate from two state-of-the-art factories which, with continual investment in the latest technology and machinery, produce precision wire sizes from .001″ (0.025mm) to .827″ (21mm) in small batches and medium volumes.

We manufacture the wire you require in the quantity you require it. Our world class manufacturing performance gives you a flexible order quantity ranging from 3 meters to 3 tonnes, meaning you only pay for what you need.

Our lead times are short because we stock in excess of 200 tonnes of more than 60 ‘High Performance’ alloys and, if your finished wire is not available from stock, we can manufacture within 2 weeks to your exact specification.

We are the world leading manufacturer of precision drawn round wire, flat wire, profile wire, bars and wire rope in more than 60 different ‘High Performance’ nickel alloys, also known as ‘Exotic’ alloys.

We produce round wire, flat wire, shaped wire and wire rope to your exact specification and in exactly the quantity you are looking for. With a range of 60 Exotic Alloys available, we can provide the ideal alloy wire with specialist properties best suited to your chosen application.

Our usual delivery times are 2 weeks, however if an urgent order is required, our Emergency Manufacturing Service ensures your wire is manufactured within days and shipped to your door via the fastest route possible.

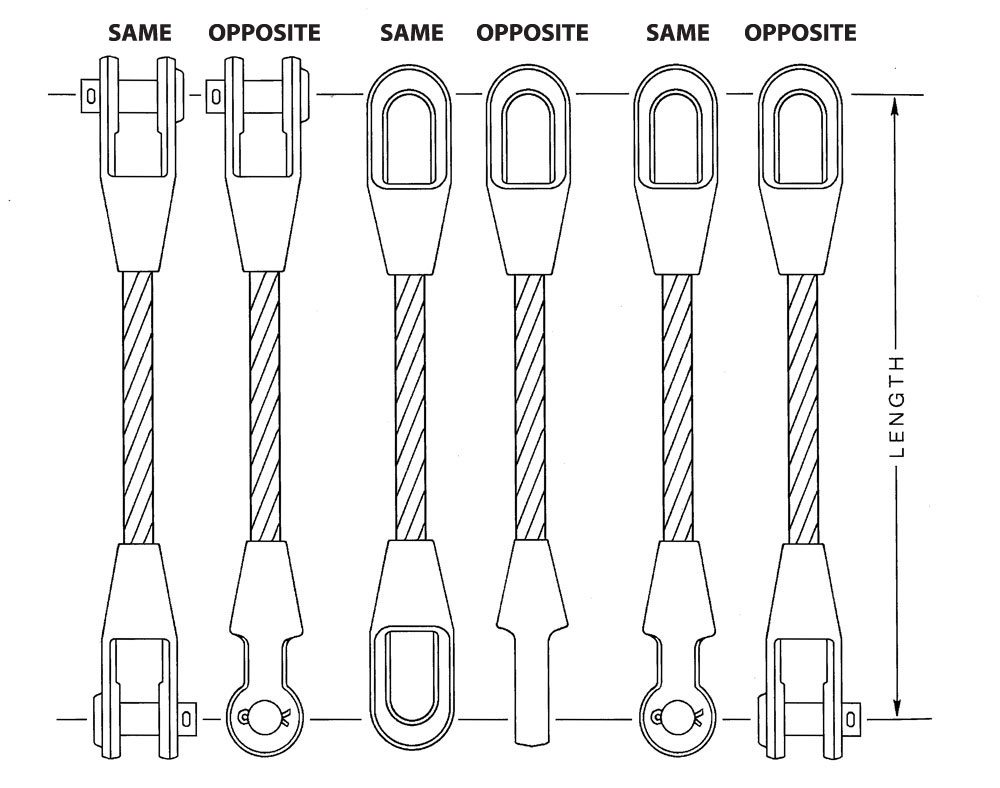

For over 60 years, Loos & Co., Inc. has pioneered and thrived in the highly critical profession of wire, wire rope, and hardware manufacturing for use in applications critical outcomes are directly at stake. This valuable experience has taught us “the ropes” about what a difference quality and performance make in your applications. Now, we can help make the difference for you with your pulley and sheave applications, too.

We’re proud to offer a wide variety of military specification and commercial wire rope, aircraft cable, and fittings to compliment your complete sheaves or pulley system. These products are the perfect compliment to the high performance products offered by esheaves.com. Pairing Loos & Co., Inc. tools, hardware, and accessories with the highest quality pulleys and sheaves will repay you with the performance you have come to expect from our products.

For over 60 years, Loos & Co., Inc. has pioneered and thrived in the highly critical profession of wire, wire rope, and hardware manufacturing for use in applications where critical outcomes are directly at stake. This valuable experience has taught us “the ropes” about what a difference quality and performance make in your applications. Now, we can help make the difference for you with your pulley and sheave applications, too.

We’re proud to offer a wide variety of military specification and commercial wire rope, aircraft cable, and fittings to compliment your complete sheaves or pulley system. These products are the perfect compliment to the high performance products offered by esheaves.com. Pairing Loos & Co., Inc. tools, hardware, and accessories with the highest quality pulleys and sheaves will repay you with the performance you have come to expect from our products.

Stainless steel wire ropes and wire rope nets such as Webnet by Jakob Rope Systems are inspiring materials for breath-taking art installations. Walkable nets, minimal and elegant supporting structures made of steel ropes or complex rope statics for tensegrity and membranes: the impressive technical possibilities of stainless steel ropes offer manifold unexplored ways of expression.

*Size14,16,18,20 are on back order. *For different sizes, length, and prices, please ask us. *In practical use, please use wire ropes within safety tolerances, taking into consideration breakage load limits.

If the force F is applied to the pin at other than the specified direction, the theoretical bridge output will be due tithe component of the force along the sensitive direction, i.e. F cos X (please see More Images Box - "Force F Direction"). Therefore, typical pins incorporate an anti-rotation device for proper alignment . (see Clevis Pin Installation Download)

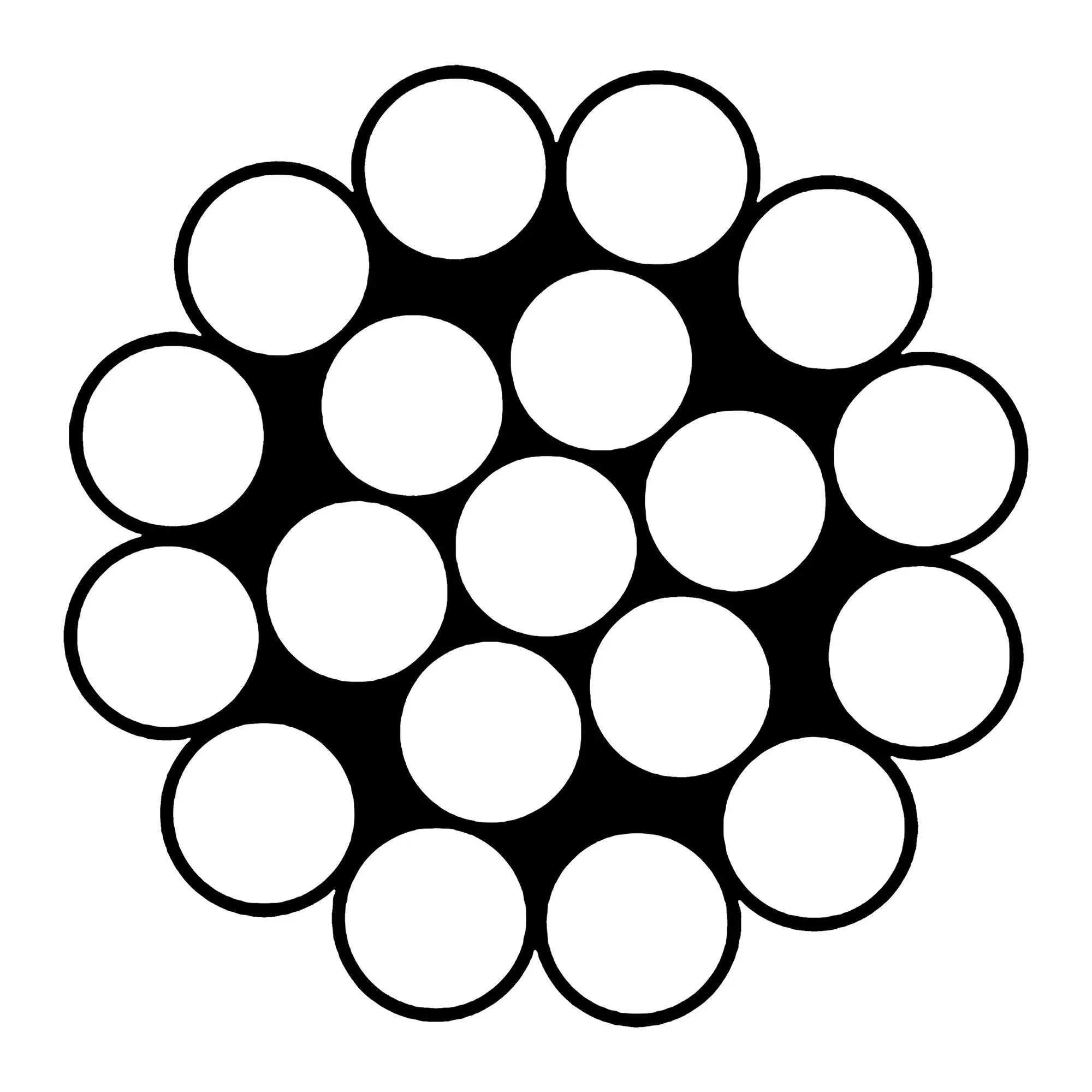

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s). There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments. Although similar in process, drawing is different from extrusion, because in drawing the wire is pulled, rather than pushed, through the die. Drawing is usually performed at room temperature, thus classified as a cold working process, but it may be performed at elevated temperatures for large wires to reduce forces.

The wire drawing process is quite simple in concept. The wire is prepared by shrinking the beginning of it, by hammering, filing, rolling or swaging, so that it will fit through the die; the wire is then pulled through the die. As the wire is pulled through the die, its volume remains the same, so as the diameter decreases, the length increases. Usually the wire will require more than one draw, through successively smaller dies, to reach the desired size. The American wire gauge scale is based on this. This can be done on a small scale with a draw plate, or on a large commercial scale using automated machinery.

Very fine wires are usually drawn in bundles. In a bundle, the wires are separated by a metal with similar properties, but with lower chemical resistance so that it can be removed after drawing.annealing before it can be redrawn.

Commercial wire drawing usually starts with a coil of hot rolled 9 mm (0.35 in) diameter wire. The surface is first treated to remove scales. It is then fed into a wire drawing machine which may have one or more blocks in series.

Single block wire drawing machines include means for holding the dies accurately in position and for drawing the wire steadily through the holes. The usual design consists of a cast-iron bench or table having a bracket standing up to hold the die, and a vertical drum which rotates and by coiling the wire around its surface pulls it through the die, the coil of wire being stored upon another drum or "swift" which lies behind the die and reels off the wire as fast as required. The wire drum or "block" is provided with means for rapidly coupling or uncoupling it to its vertical shaft, so that the motion of the wire may be stopped or started instantly. The block is also tapered, so that the coil of wire may be easily slipped off upwards when finished. Before the wire can be attached to the block, a sufficient length of it must be pulled through the die; this is effected by a pair of gripping pincers on the end of a chain which is wound around a revolving drum, so drawing the wire until enough can be coiled two or three times on the block, where the end is secured by a small screw clamp or vice. When the wire is on the block, it is set in motion and the wire is drawn steadily through the die; it is very important that the block rotates evenly and that it runs true and pulls the wire at a constant velocity, otherwise "snatching" occurs which will weaken or even break the wire. The speeds at which wire is drawn vary greatly, according to the material and the amount of reduction.

Machines with continuous blocks differ from single block machines by having a series of dies through which the wire is drawn in a continuous fashion. Due to the elongation and slips, the speed of the wire changes after each successive redraw. This increased speed is accommodated by having a different rotation speed for each block. One of these machines may contain 3 to 12 dies.

Often intermediate anneals are required to counter the effects of cold working, and to allow further drawing. A final anneal may also be used on the finished product to maximize ductility and electrical conductivity.

While round cross-sections dominate most drawing processes, non-circular cross-sections are drawn. They are usually drawn when the cross-section is small and quantities are too low to justify rolling. In these processes, a block or Turk"s-head machine are used.

Lubrication in the drawing process is essential for maintaining good surface finish and long die life. The following are different methods of lubrication:

Roller die Drawing (also referred as Roll drawing): roller dies are used instead of fixed dies to convert shear friction to rolling friction with dramatic reduction in the drawing forces as reported by Lambiase.

Various lubricants, such as oil, are employed. Another lubrication method is to immerse the wire in a copper(II) sulfate solution, such that a film of copper is deposited which forms a kind of lubricant. In some classes of wire the copper is left after the final drawing to serve as a preventive of rust or to allow easy soldering.

The strength-enhancing effect of wire drawing can be substantial. The highest strengths available on any steel have been recorded on small-diameter cold-drawn austenitic stainless wire.

Lambiase, F.; Di Ilio, A. (2011). "A parametric study on residual stresses and loads in drawing process with idle rolls". Materials & Design. 32 (10): 4832–4838. doi:10.1016/j.matdes.2011.06.019.

Lambiase, F.; Di Ilio, A. (2012). "Experimental and Finite Element Investigation of Roll Drawing Process". Journal of Materials Engineering and Performance. 21 (2): 161–166. doi:10.1007/s11665-011-9932-1.

Lambiase, F.; Di Ilio, A. (2012). "Deformation inhomogeneity in roll drawing process". Journal of Manufacturing Processes. 14 (3): 208–215. doi:10.1016/j.jmapro.2011.12.005.

Budinski, Kenneth G. (1996). Engineering Materials: Properties and Selection (5th ed.). Upper Saddle River, NJ: Prentice-Hall, Inc. ISBN 978-0-13-367715-7.

Kalpakjian, Serope; Schmid, Steven R. (2006). Manufacturing Engineering and Technology (5th ed.). Upper Saddle River, NJ: Pearson Prentice Hall. p. 429. ISBN 978-0-13-148965-3.

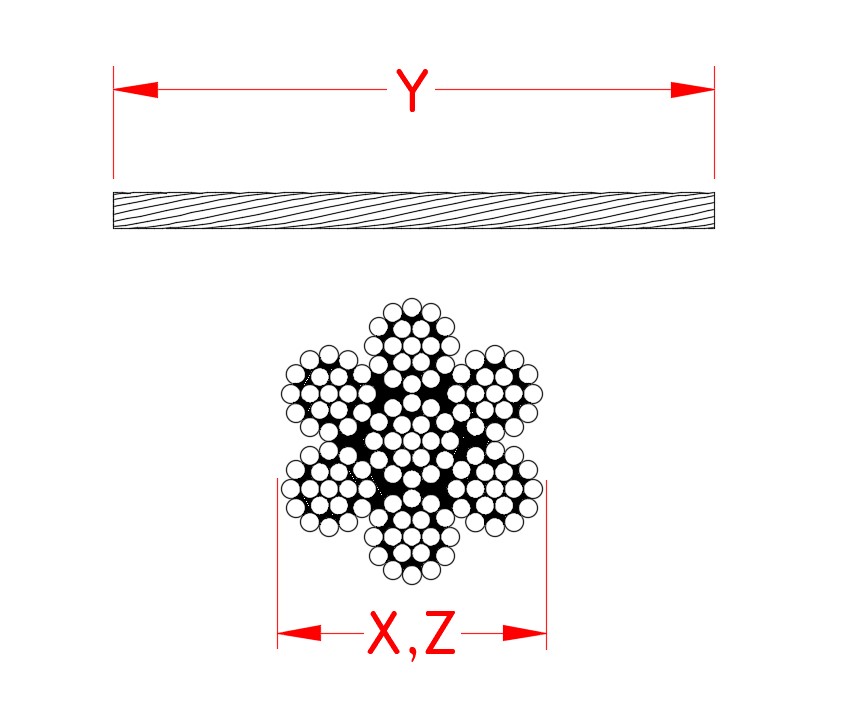

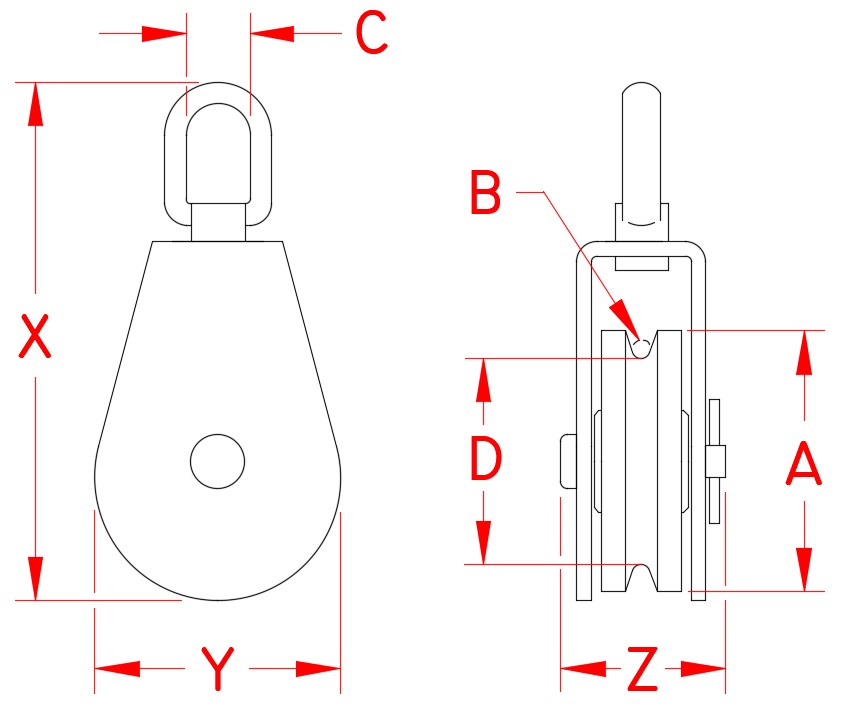

Drawings are appreciated although not required when you order sheaves, whether custom or stock. Please provide as many measurements as you can using our quote/order form as a guide. We will contact you to be clear on your needs before preparing our quote. For a copy of our latest catalog, please fill out our contact form and we"ll send one along. You can also send us any questions or comments through the same contact form. Thanks for your interest in our products. We look forward to serving you.

Did you know there are 9 different dimensions that factor into the specifications for a sheave? The central portion contains 3 important measurements: the shaft, the bore and the hub diameter. Then there"s the groove, pitch and outside diameters as well as the groove depth. Measuring along another axis we need to determine the correct rim and hub widths. And finally, the size of the wire rope is important to consider. Once you have all these measurements at hand, we can determine if a standard size will fit your needs. Or you can just give us a call and we"ll help you out! If the sheaves we carry in our regular stock are not the right size for your purposes, please contact us for pricing on custom work. Or, you may fill out an order form with your specs and we"ll gladly put together a quote for you.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Bear Equipment originally specialized in excavator and undercarriage crane parts. As our customers" demands for the supply of replacement wire rope pulley parts grew, we began specializing in sheaves. Today, wire rope sheaves is our primary business. For a manufacturer of wire rope and cable sheaves and pulleys, speak with the manufacturing experts at Bear Equipment today!

This specification covers wire ropes and wire seizing strands. This specification does not include all types, classes, constructions, and sizes of wire rope and strand that are commercially available, but it is intended to cover the more common types, classes, constructions, and sizes that are suitable for federal government use.

This specification covers the requirements for nonrotating, preformed stainless steel wire rope for aircraft rescue hoist and cargo handling winching applications. The word “cable” is used interchangeably with “wire rope” throughout this specification.

This specification covers the requirements for nonmagnetic, corrosion- resistant steel wire rope used in aircraft flight controls. The wire rope will be capable of operation within a -65 °F to +250 °F (-54 °C to +121 °C) temperature range in wind, dust, fuel and oil spills, in aircraft wash-down and other environmental stresses and aircraft experiences.

This specification covers the requirements for carbon steel and corrosion resistant steel aircraft control flexible wire rope. Type I wire rope will be capable of operation within a -65 °F to +250 °F (-54 °C to +121 °C) temperature range in wind, dust, fuel, and oil spills, in wash-down and other environmental stresses and aircraft experiences. Type II wire rope will be capable of operation within a -65 °F to +200 °F (-54 °C to +94 °C) temperature range in wind, dust, fuel, and oil spills, in wash-down and other environmental stresses and aircraft experiences.

This specification covers the requirements for carbon steel and corrosion resistant steel wire strand used in aircraft application other than over sheaves.

DescriptionJoint ball for later insertion in wire end ring with 20 mm diameter. The use of this joint ball enables movement in multiple levels of freedom.

Cancellations/Returns/ Refunds: Are not allowed unless Tandemloc fails to meet the above shipping schedule obligation or the item is not manufactured in accordance with the sales drawing provided to the customer with the order acknowledgement.

8613371530291

8613371530291