wire rope dressing price

![]()

A tenacious, semi-fluid, non-melting grease designed for complete lubrication and corrosion protection on most types of wire ropes, particularly in hostile conditions.

High performance semi-fluid wire rope dressing grease providing excellent corrosion protection in multiple environments including saltwater and under water.

Lubricating, penetrating and protective wire rope lubricant A tenacious, semi-fluid non-melting grease designed for complete lubrication and corrosion protection of most types of wire ropes, particularly in hostile conditions.

ROCOL Wire Rope Dressing is sufficiently fluid enough to penetrate through the strands to the core of the rope whilst being sufficiently greasy to resist fling off.

ROCOL Wire Rope Dressing exhibits excellent lubrication properties which reduces wear on the wires and strands thereby maximising the service life of the rope.

Made to withstand corrosions at the highest levels, it’s water-resistant properties speak for itself because it can even be applied to your gears while submerged in seawater. The Rocol Biogen Tuflube has longlasting adhesion and metal protection for your slow-moving heavy machinery.

It’s a tough grease to beat. With self-healing properties, it’s stubborn against wash-off from seawater while providing your equipment with the smooth lubrication it needs from long days of operation.

Rocol Wire Rope Dressing is designed to penetrate to the wire rope core, protecting and lubricating inside and out to extend safe working life, reducing unplanned down time and replacement costs. Features include:-

Compatible with inner wire rope core, fibre rope core, all metals & alloys, plastic, nylon, rubber, painted surfaces, electrical connections, carbon surfaces

Premium quality wire rope dressing containing specific anti-fretting and corrosion additives. Tacky semi-synthetic lubricant specially developed for wire ropes in mining, marine, earth moving & industrial equipment.

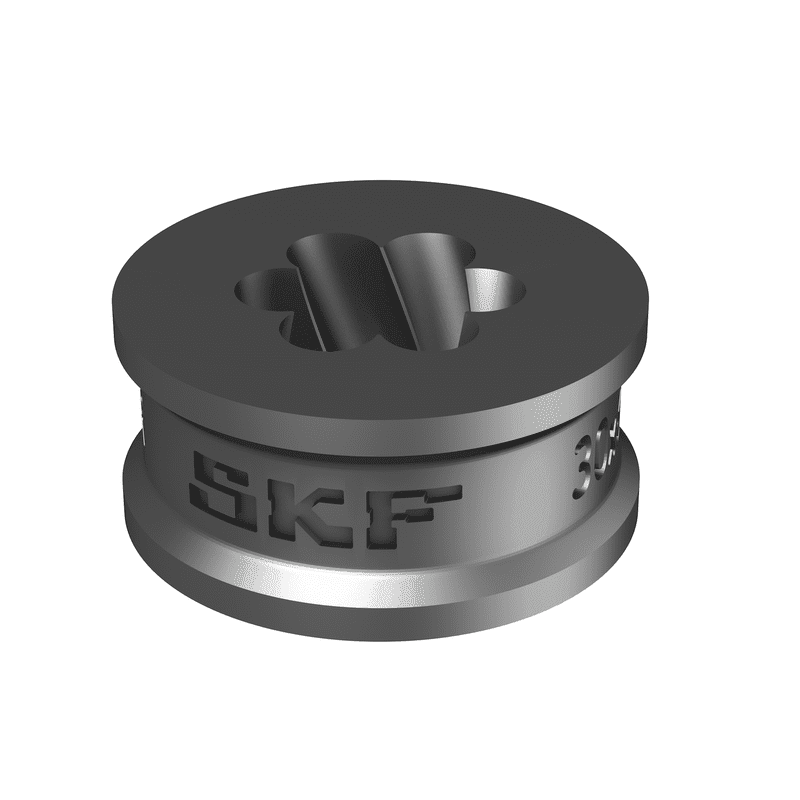

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

8613371530291

8613371530291