wire rope dressing pricelist

A tenacious, semi-fluid, non-melting grease designed for complete lubrication and corrosion protection on most types of wire ropes, particularly in hostile conditions.

Rocol Wire Rope Dressing is designed to penetrate to the wire rope core, protecting and lubricating inside and out to extend safe working life, reducing unplanned down time and replacement costs. Features include:-

A HISTORY OF EXCELLENCE ROCOL® has been providing engineers with high performance lubrication solutions for more than 100 years. During that time we have worked with some of the world’s leading companies in many diverse industries and applications, developing products with one common goal: to deliver optimum performance. ROCOL operates to internationally recognised standards for quality, environment and safety. ROCOL is proud of its commitment to the continual engagement and development of staff and holds Investors In People accreditation. BENEFITS OF WIRE ROPE LUBRICATION Although simple...

KEY REQUIREMENTS OF WIRE ROPE LUBRICANTS Whilst it may be clear that good lubrication is a key part of maximising rope life, delivering the correct balance of properties in a single product is a significant challenge. A good wire rope lubricant must: Be easy, pleasant and safe to apply Achieve maximum penetration to ensure lubrication and protection of the rope core Resist wash-off and ing-off Have excellent corrosion protection Reduce friction and wear Allow easy inspection of the rope ROCOL® WIRE ROPE LUBRICANTS ROCOL have manufactured wire rope lubricants for many years. This has allowed...

PSEUDOPLASTIC WIRE ROPE DRESSING One of the most difficult problems encountered in formulating wire rope lubricants is finding the optimum balance between good penetration properties and resistance to water wash-off. Good penetration is achieved by low viscosity products such as oils but these have poor resistance Good wash-off resistance is achieved by highly adhesive grease-like products but these have poor penetration properties Until now there has been a trade off between these competing requirements. However, thanks to its pseudoplastic rheology, WIRESHIELD achieves maximum penetration...

THE DIFFERENCE IS CLEAR The key safety check for wire rope users is a visual inspection of the condition of the rope. Traditional wire rope lubricants contain black solid lubricants such as graphite and molybdenum disulphide. These materials make the lubricant unpleasant to handle and impossible to see through. WIRESHIELD™ uses an advanced load carrying system based on sub-micron white solids. The result is a nished product that is both clean to handle and translucent in use - without compromising the load carrying or anti-wear properties. Below is an illustration of the translucency of the...

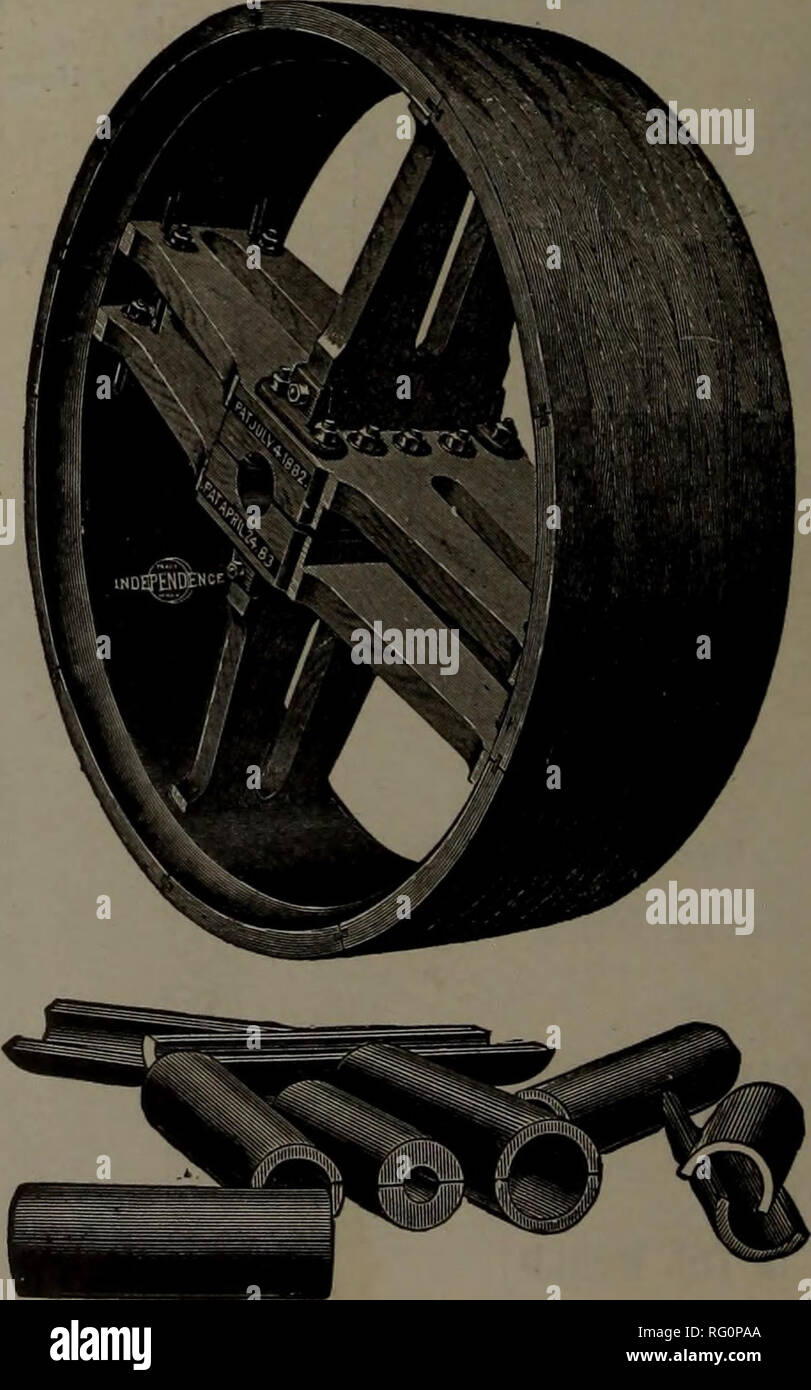

COMPREHENSIVE RANGE ROCOL manufacture a comprehensive range of wire rope lubricants. ROCOL products have been proven over many years of service to: Reduce wear on wires and strands, maximising service life Provide outstanding corrosion protection Resist water wash-off, extending re-lubrication intervals WIRE ROPE Dressing WIRE ROPE Spray Multi-purpose rope lubricant Convenient aerosol pack Semi-uid grease based on highly rened mineral oil and an organically modied clay thickener. The unique blend of lubricating solids contained in the product reduces the internal friction and wear often...

WIRE ROPE LUBRICATION Methods of rope lubrication range from traditional, unsophisticated techniques such as brushes and swabs to dedicated, high performance equipment. ROCOL wire rope lubricants are designed to be as easy to apply as possible by whichever method is most convenient. While there is no single method that is “right” and works in all situations, the modern trend is to move away from manual application, to automated systems which: Maximise efciency of lubricant delivery on to the rope Improve health and safety by reducing operator contact with the rope and lubricant To make the...

CASE HISTORIES CLIENT: P&O FERRIES Product: WIRESHIELD™ Location: Dover, UK Application Details: The Pride of Kent crosses the channel to Calais up to 10 times a day. The vessel is moored using steel wire ropes which can be immersed in sea water up to 20 times a day and are exposed to extreme coastal weather conditions. In order to lubricate the wire ropes, sh oil was applied to them on a regular basis. Although easy to apply and offering reasonable penetration to the rope core the sh oil produced unsatisfactory results, including poor wash-off resistance, leading to increased lubrication...

CLIENT: MARMAGOA PORT TRUST CLIENT: BAE SYSTEMS – SHIPLIFT ROPES Product: WIRE ROPE Dressing Product: WIRE ROPE Dressing Application Details: The wire ropes on the bulk iron ore unloaders suffered from a high degree of wear due to a combination of the large amount of abrasive iron ore dust in the atmosphere and the heavy duty nature of the unloading operation. As a result the ropes were replaced every three to four weeks costing both time and money. Required Specication: Good penetration properties to ensure that the rope core received effective lubrication Increase the operational life of...

PRODUCT NAME CORROSION PROTECTION FEATURES & BENEFITS Waxy lm for long term outdoor corrosion protection. Ideal for long term protection of machinery, elevators, forklift trucks, underground installations and offshore platforms. Temperature range -20°C to +110°C Heavy duty, waxy lm for long term corrosion protection Excellent corrosion protection outdoors for up to 2 years Good de-watering properties Good penetration Can provide a light lubricating lm in some applications Ideal for outdoor corrosion protection of exposed metal parts Does not contain silicones or chlorinated solvents...

The 6x26 grease-coated wire rope offers a high level of resistance to abrasion, and features a compact construction with solid support for the wires—which also provides a high resistance to crushing and makes the 6x26 a popular wire rope for a wide range of applications.

Its number and relative size of the inner wires adds to both the stability of the strand and the resulting fatigue resistance. This rope’s core is its own wire rope construction—known as IWRC (Independent Wire Rope Core)—meaning it moves independent to the outer strands.

There are two types of wire rope lubricants: penetrating and coating. Coating lubricants (which include greases) penetrate slightly, sealing the outside of the cable from moisture and reducing wear and fretting corrosion from contact with external bodies.

The 6x26 wire rope class is made up of six strands of 26 wires per strand for additional wire rope strength and durability. The 6x26 features IPS (Improved Plowed Steel), EIPS (Extra Improved Plowed Steel), or EEIPS (Extra Extra Improved Plowed Steel) grade wire rope. Also available in USA-made.

GZ Industrial Supplies is a distributor of JET-LUBE brand products in Nigeria, Our Jet-Lube Wire Rope Dressing Cable Grease is highly tenacious, adhesive lubricant containing both molybdenum disulfide (MoS2 ) and graphite, and is specially formulated for use on wire lines, cable and open roller chains.This Wire Rope dressing Cable grease penetrates the outer strands of wire rope and cable, displacing moisture, and permeating to the core of the rope or cable, lubricating and protecting each strand.

As the low vapor pressure carrier solvent of Wire rope dressing Cable grease evaporates, a thin, flexible film of lubricant is formed. This barrier film prevents

The barrier film of Wire lube dressing Cable grease protects against the formation of rust and prevents “rust binding”, which reduces cable flexibility and life; increasing friction and wear.

Wire Rope Dressing Cable Grease may be used on crane and drag line hoist, elevator hoist lines, sprayed directly on sheaves, or winding drum faces, oilfield wire lines, offshore rig anchor cables, chain vises, corrosion barrier for iron surfaces, drilling lines, mast hoisting cables or any wire rope cable that operates at the extremes of operating speeds and loads in harsh environments.

Wire Rope Dressing Cable Grease may also be used on open roller drive chains in both oilfield and industrial applications; on motorcycle or snowmobile drive chains; conveyor drive chains or any open roller chain.

LUBEGARD Wire Rope Lubricant is patented, aquatically non-toxic & biodegradable. It contains a unique blend of corrosion inhibitors, thickeners and wear reducers. Ideal for all types of wire ropes and chains in a variety of services and environments. Wire Rope Lubricant is biodegradable, non-toxic, and leave no oil slick! Biodegradable (EPA Shake Flask Test, EPA 560/6-82-003 with unacclimated inoculum) / Aquatically non-toxic (EPA 600/4-90-027, Rainbow trout test). Forms liquid protective layer, does not foul automatic applicators, Excellent for manual application, Water and salt water resistant. Can be applied in many ways; spray, wipe, dip or brush it on. It can also be applied with various low viscosity core lubricators. Apply as necessary for lubrication and corrosion protection.

Earthwise EAL Wire Rope Grease (3353) is a certified Environmentally Acceptable Lubricant (EAL), recommended for use in applications on or near waterways. It meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms.

It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation. Its robust additive package, including LE’s proprietary Almasol® and Quinplex® additives, further helps it protect against wear, corrosion, impact, rust and oxidation.

Cheap PriceList for Concrete Wire Saw - High-Quality Granite Diamond Wire Saw Rope With Competitive Price – Sunny Superhard Tools Detail:

Diamond wire saw – other names are diamond wire saw rope and wire saw rope. It is widely used in construction and stone field, for cutting different materials like concrete, reinforced concrete, granite, sandstone, marble, and other stones. Diamond wire saw rope comes in diamond wire saw beads and steel wire. The wire saw beads can be fixed by plastic, rubber, and spring. The condition of manufacturing diamond wire saw rope is very strict. The factors like the temperature, the air humidity, etc. will also influence the quality of diamond wire saw.

The granite diamond wire saw in this page is designed for granite block dressing. The diamond wire saw beads are fixed by high-quality plastic, under proper temperature and pressure. The great formula of wire beads makes it easy for cutting granite block. The main features are:

Sunny Superhard Tools has developed different excellent diamond beads formulas for different materials. All the steel wire of our diamond wire saw ropes is imported and with premium quality. For plastic diamond wire saw rope, we used “DIEPA” brand from Germany. For rubber type, we used “Bekaert” brand from Italy factory. Other raw materials like rubber, plastic, and spring are also with high quality. We insist on offering you the premium diamond wire saw rope with competitive price.

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Cheap PriceList for Concrete Wire Saw - High-Quality Granite Diamond Wire Saw Rope With Competitive Price – Sunny Superhard Tools , The product will supply to all over the world, such as: UK, France, Orlando, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

8613371530291

8613371530291