wire rope drive mechanism made in china

The utility model discloses a drive mechanism for a wire rope reel and a cable reel and belongs to the technical field of rubbish carrying grab bucket bridge type cranes. The cable reel is connected with the wire rope through the drive mechanism; the drive mechanism comprises a driving gear, a driven gear, a first gear shaft, a second gear shaft, a first bearing seat, a second bearing seat and a bolt, wherein the first gear shaft is installed on the first bearing seat and connected with an end plate of the wire rope reel through keys; the second gear shaft is installed on the second bearing seat and connected with an end plate of the cable reel through the bolt; the driving gear is installed on the first gear shaft, and the driven gear is installed on the second gear shaft; the driving gear is meshed with the driven gear. According to the drive mechanism for the wire rope reel and the cable reel, by means of a drive manner of meshing a pair of exposed gears, the wire rope reel and the cable reel can keep synchronized operation, and drive accuracy and stability between the wire rope reel and the cable reel are improved.

Waste handling bridge grabbing crane (hereinafter to be referred as hoisting crane) is the nucleus equipment of garbage incinerating power plant, major part comprises crane span structure, dolly, traveling mechanism of the larger traveller and garbage grab bucket, and wherein garbage grab bucket is a part and the load-engaging device of crane hoisting mechanism.Crane operation work manipulating crane complete rubbish carrying, stir, feed intake, the task such as collapse of setting and weighing.

The dolly of traditional Waste handling crane adopts two reductors of a direct motor drive and two cable drums, and cable drum is connected with grab bucket by steel rope.The power supply of grab bucket motor realizes by the cable being wrapped on cable drum.Cable drum is for drum cable, should ensure simultaneously by under grab bucket cable and steel rope Synchronous Radio with pack up.The lasting rotating of lifting motor can realize hoisting of grab bucket and decline.The chain gearing of one end of a cable drum installation is therein connected with cable drum, to provide power to cable drum.

Traditional chain drive structure form is simple, install easily manufactured, but after the wear of hinge of chain, envoy causes greatly disconnection apart from becoming, and is not easy to ensure that cable drum synchronizes with cable drum, even if install tightening device additional, effect also cannot reach expection, is difficult to meet client"s requirement.

The transmission device for cable drum and cable drum that the utility model provides, by the intermeshing type of drive of a pair of exposed gear (driving gear and ring gear), make cable drum and cable drum can keep synchronized operation, improved transmission accuracy and stability between cable drum and cable drum.

The transmission device for cable drum and cable drum that the utility model embodiment provides, by adopting the intermeshing type of drive of a pair of exposed gear (driving gear and ring gear), the cable drum and the cable drum that have solved existing chain driving are difficult for synchronous problem, ensure the synchronized operation of cable drum and cable drum, improved transmission accuracy and stability between cable drum and cable drum.

Wire rope is a key bearing component of hoisting, lifting, high altitude cableway and other driving force transmission and material transportation systems [1,2,3,4]. Its service status directly determines the safe and reliable operation of the equipment system and is closely related to the safety of the operator [5]. However, in practical engineering applications, there are friction and wear problems caused by different contact features of the wire rope, which greatly threatens the service safety and reliability of wire ropes [6,7]. In order to achieve long-distance and large-load material transmission, wire rope, in most cases, is used with different types of sheaves, as shown in Figure 1. The wire rope bends over the sheaves at different speeds and loads during the operation of transmission systems [8,9]. Thus, there is extrusion contact and relative sliding between the wire rope and the sheave groove, which causes surface wear of the wire rope and affects the stability of the system. Additionally, wire rope has a certain elasticity, which causes system vibration in the service process [10]. The sliding contact and surface wear of the wire rope is complex. Furthermore, wear degrades the performance of wire rope and accelerates its failure [11]. Therefore, it is necessary to study the sliding friction and wear behavior between the wire rope and the sheave, which is of great significance for the safe use of wire rope and prolongation of its service life.

In recent years, scholars have carried out a lot of research on damage and safe service of wire rope under actual working conditions. Wear is one of the main reasons of wire rope failure, and includes fretting wear between steel wires and surface wear of wire ropes [12,13]. Fretting wear behavior is mainly determined by different stress states and the service environment of the wire rope. Zhang et al. [14] studied the influence of different cross contact angles on fretting wear and fatigue damage of rope wires. The friction and wear coefficient decrease when the contact angle is small. Wang et al. [15,16] analyzed the fatigue damage and crack propagation characteristics of steel wires under different sliding parameters. Zhang et al. [17] investigated the effect of bending and dynamic tension on fretting fatigue behavior of rope wires. They found that the wear depth of steel wire decreases with the increase of sheave diameter. Additionally, the multi-wire spiral structure of wire rope leads to many different contact forms between its internal wires [18]. Based on Hertz contact theory and a semi-analytical method, Chen et al. [19,20] revealed the contact characteristics between the internal steel wires of wire rope under different loads. To explore the contact characteristics between the wire rope and the pulley, Hakala et al. [21] established a finite element model of contact between paste lubricated steel wire and cast iron. Furthermore, the service environment of the wire rope is very harsh [22]. The main wear mechanisms under different corrosive environmental media includes abrasive wear, adhesive wear, corrosion wear and fatigue wear [23,24]. Moreover, lubrication is an important way to protect the wire rope, and different lubrication states have great influence on friction and wear characteristics of wire ropes [25]. By adjusting the concentration of graphene and multilayer graphite additives, modified grease can improve the fretting wear behavior between steel wires and prolong the service life of the wire rope [26].

The surface wear of the wire rope is mainly caused by the contact collision between the wire rope and the extrusion contact between the wire rope and rope groove (drum and sheave) [27,28,29]. To study the friction and wear behavior between different wire ropes on the drum, Chang et al. [30] studied the tribological behavior of wire rope under different crossing angles and directions. The results show that cross direction had an obvious effect on the distribution of wear scar and wear morphology of wire rope. Oksanen et al. [31] investigated the wear mechanism of relative sliding between roller and wire rope under different contact conditions, and found spalling is the main mechanism of material removal on the wear surface. Considering the influence of hoisting system vibration, Zhang et al. [32] carried out friction and wear tests between wire ropes under different longitudinal vibration amplitudes and frequencies. Additionally, different working conditions affect the wear evolution characteristics of wire rope, especially corrosive solutions, which are most harmful to the friction and wear of wire rope [33]. Furthermore, surface lubrication can effectively reduce the infringement of a corrosive environment on the wire rope [34,35]. However, the open-air service conditions of wire ropes can easily lead to performance degradation and failure of lubricating oil. Therefore, the wear problem of wire rope is inevitable. A comprehensive understanding of the tribological properties of the wire rope is an important prerequisite to ensure its safe and reliable service.

There has been much previous research on the friction and wear of wire ropes, but these studies mainly focused on fretting wear between internal rope wires. The surface wear characteristics of wire rope is closely related to different contact forms. Existing research focuses on sliding friction and wear behavior between two wire ropes, which is different from the actual working conditions, while research on surface wear of wire rope caused by the contact between the wire rope and the sheave has rarely been carried out. Although rolling contact is the main contact form between the wire rope and the sheave during the operation of a transmission system, friction and wear caused by the sliding contact is a more serious problem. Moreover, when the frequency of use of the wire rope is high, wear and deterioration are a continuous processes during long-term service. Therefore, it is of great engineering significance to study the sliding friction characteristics between the wire rope and the sheave to ensure the safe service of wire ropes and reduce damage.

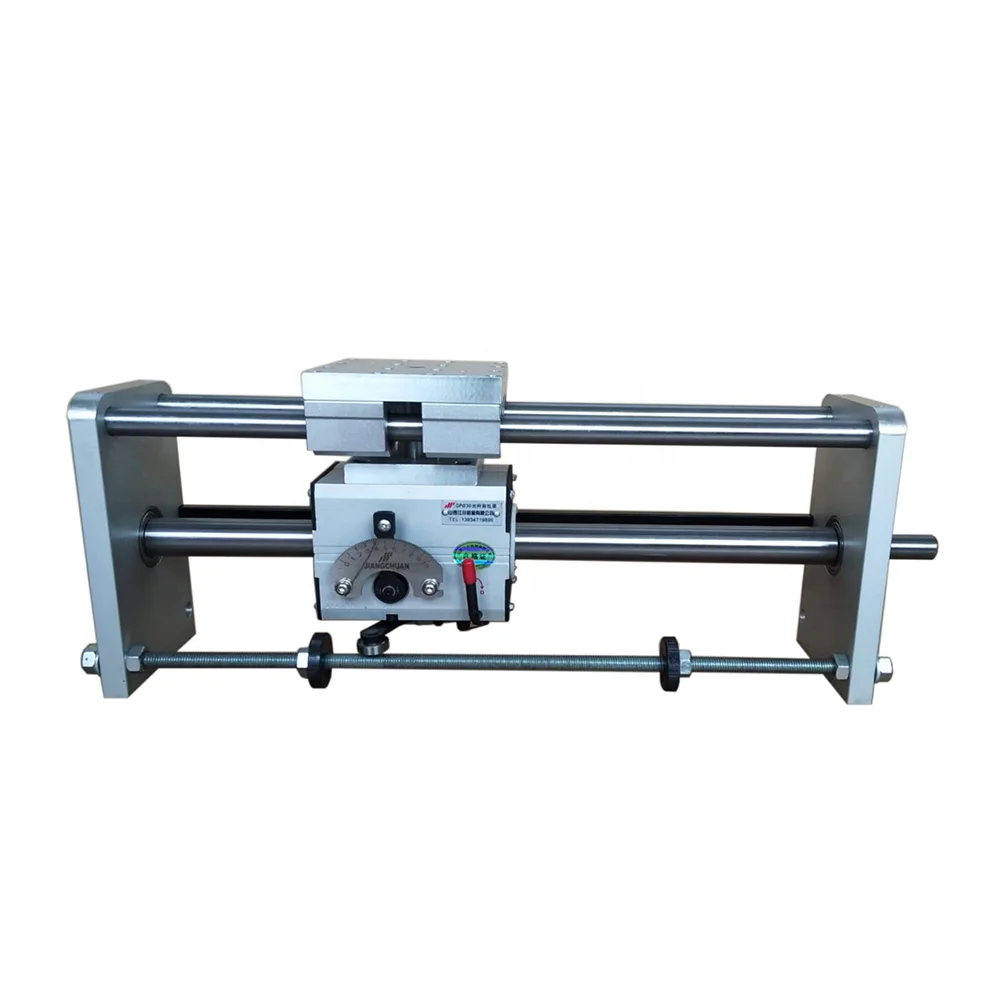

The aim of this paper was to reveal the friction characteristics and wear mechanisms of wire rope in sliding contact with the sheave. A rope-sheave friction testing machine was developed and sliding friction tests at different sliding velocities were carried out using a homemade test rig. Using the data acquisition system of the test rig and an infrared thermal imager, variations of the COF and friction temperature rise of the wire rope under different sliding conditions were revealed. Additionally, distribution of wear scar on the rope strand was analyzed. The wear width and wear amount of rope samples under different test conditions were measured and analyzed. Furthermore, the wear debris characteristics, wear morphology and wear mechanism of wire rope were analyzed by an optical microscope and SEM (scanning electron microscope) (Mocai Materials Science and Technology Co., Let., Shanghai, China). Finally, the influence of surface wear caused by rope-sheave contact on the fracture characteristics of rope wires was analyzed using a breaking tensile test.

Rope Drive - You find here 7 suppliers from Germany and ✓ China. Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companies.

Are you looking for Rope Drive. IndustryStock"s product and service search engine will not only help you find relevant results for Rope Drive but also related products and services. All contact information of listed Rope Drive manufacturers, traders, suppliers and dealers are freely available to all users.

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

This responds to your June 1, 1999, letter to the Occupational Safety and Health Administration (OSHA), requesting information on wire rope and Crosby clips used around the perimeter of buildings as a guardrail. You also requested clarification on when employees must tie-off when a guardrail system is removed to facilitate hoisting operations. We apologize for the long delay in providing this response.

Question 1: How many Crosby clips are required to be used when setting up a wire rope guardrail? Is it permissible to splice two wire ropes by overlapping or must the connections be turned back into eyelets and properly secured?

Answer: For construction work covered by 29 CFR 1926 Subpart M, §1926.502(b) sets forth the criteria that must be met when using wire rope as a guardrail. The standard requires guardrails to meet several specific criteria. For example, 1926.502(b)(3) states that the guardrail shall be capable of withstanding, without failure, a force of at least 200 pounds applied within 2 inches of the top edge, in any outward or downward direction, at any point along the top edge. Section 1926.502(b)(4) states that when the 200 pound test load noted in §1926.502(b)(3) is applied in a downward direction, the top edge of the guardrail shall not deflect to a height less than 39 inches above the walking/working level. Section 1926.502(b)(9) states that the top rail and mid-rails shall be at least ¼-inch nominal diameter or thickness to prevent cuts and lacerations. These and other criteria must be met when using wire rope as a guardrail around the perimeter of a building.

The OSHA standard does not specify a minimum number of clips when using wire rope as a guardrail. However, as a practical matter, it is unlikely you could meet the specific requirements under §1926.502(b) unless you follow the manufacturer"s recommendations for the number of clips to be used on wire ropes of different diameters (for example, the Crosby Group Inc. general catalog, 2000 edition has tables showing their recommendations for their clips). Also, note that OSHA"s standard for rigging equipment used for material handling, 29 CFR §1926.251, has a table for the number of clips required for wire rope ½-inch and greater. Although that standard does not apply to wire rope used for guardrails, when you design a rope system to meet the §1926.502 requirements, following those tables will normally ensure that you have enough clips.

Made of multiple strands wound together, the steel Wire Rope is one of the most crucial components in a Crane. Each strand has a tensile strength ranging between 1470 N/mm2 and 2160N/mm2.As the load carrying rope used in the Hoisting Mechanism, it can be sent through different surface treatment to suit specific environmental condition.

Designed for higher breaking strength and better strength to weight ratio, our Crane Wire Rope is made of high-toughness steel wires that have been stretched to their tolerance limit prior to being stranded together to form a rope with optimum spacing between each strand.

Even if wire strands are tightly twisted, there still be spaces in places where the strand touches with each other. To improve the fill factor of the wire rope, we have added irregularly-shaped wire strand to the rope and sent it through rotary swaging process. Steel wires that are laid in a parallel pattern increase the cross section of the rope.

Special-purpose steel rope is commonly seen in various engineering projects. Via precision design and rigorous test, the rope usually can meet very high safety standards.

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands— that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.

The right way to unreel.To unreel wire rope from a heavy reel, place a shaft through the center and jack up the reel far enough to clear the floor and revolve easily. One person holds the end of the rope and walks a straight line away from the reel, taking the wire rope off the top of the reel. A second person regulates the speed of the turning reel by holding a wood block against the flange as a brake, taking care to keep slack from developing on the reel, as this can easily cause a kink in the rope. Lightweight reels can be properly unreeled using a vertical shaft; the same care should be taken to keep the rope taut.

The wrong way to unreel.If a reel of wire rope is laid on its flange with its axis vertical to the floor and the rope unreeled by throwing off the turns, spirals will occur and kinks are likely to form in the rope. Wire rope always should be handled in a way that neither twists nor unlays it. If handled in a careless manner, reverse bends and kinks can easily occur.

The right way to uncoil.There is only one correct way to uncoil wire rope. One person must hold the end of the rope while a second person rolls the coil along the floor, backing away. The rope is allowed to uncoil naturally with the lay, without spiraling or twisting. Always uncoil wire rope as shown.

The wrong way to uncoil.If a coil of wire rope is laid flat on the floor and uncoiled by pulling it straight off, spirals will occur and kinking is likely. Torsions are put into the rope by every loop that is pulled off, and the rope becomes twisted and unmanageable. Also, wire rope cannot be uncoiled like hemp rope. Pulling one end through the middle of the coil will only result in kinking.

Great stress has been placed on the care that should be taken to avoid kinks in wire rope. Kinks are places where the rope has been unintentionally bent to a permanent set. This happens where loops are pulled through by tension on the rope until the diameter of the loop is only a few inches. They also are caused by bending a rope around a sheave having too severe a radius. Wires in the strands at the kink are permanently damagedand will not give normal service, even after apparent “re-straightening.”

When wire rope is wound onto a sheave or drum, it should bend in the manner in which it was originally wound. This will avoid causing a reverse bend in the rope. Always wind wire rope from the top of the one reel onto the top of the other.Also acceptable, but less so, is re-reeling from the bottom of one reel to the bottom of another. Re-reeling also may be done with reels having their shafts vertical, but extreme care must be taken to ensure that the rope always remains taut. It should never be allowed to drop below the lower flange of the reel. A reel resting on the floor with its axis horizontal may also be rolled along the floor to unreel the rope.

Wire rope should be attached at the correct location on a flat or smooth-faced drum, so that the rope will spool evenly, with the turns lying snugly against each other in even layers. If wire rope is wound on a smooth-face drum in the wrong direction, the turns in the first layer of rope will tend to spread apart on the drum. This results in the second layer of rope wedging between the open coils, crushing and flattening the rope as successive layers are spooled.

A simple method of determining how a wire rope should be started on a drum. The observer stands behind the drum, with the rope coming towards him. Using the right hand for right-lay wire rope, and the left hand for left lay wire rope, the clenched fist denotes the drum, the extended index finger the oncoming rope.

Clips are usually spaced about six wire rope diameters apart to give adequate holding power. They should be tightened before the rope is placed under tension. After the load is placed on the rope, tighten the clips again to take care of any lessening in rope diameter caused by tension of the load. A wire rope thimble should be used in the eye of the loop to prevent kinking.

U-bolt Clips.There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in TheRightWayimage below. The base of the clip bears on the live end of the rope; the “U” of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached—only the center clip in the top view is correct. When the “U” of the clip bears on the live end of the rope, there is a possibility of the rope being cut or kinked, with subsequent failure.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

The majority of wire rope problems occurring during operation actually begin during installation, when the rope is at its greatest risk of being damaged. Proper installation procedures are vital in the protection and performance of wire rope products.

Until the rope is installed it should be stored on a rack, pallet or reel stand in a dry, well-ventilated storage shed or building. Tightly sealed and unheated structures should be avoided as condensation between rope strands may occur and cause corrosion problems. If site conditions demand outside storage, cover the rope with waterproof material and place the reel or coil on a support platform to keep it from coming directly in contact with the ground.

While lubrication is applied during the manufacturing process, the wire rope must still be protected by additional lubrication once it is installed. Lubricants will dry out over a period of time and corrosion from the elements will occur unless measures are taken to prevent this from happening. When the machine becomes idle for a period of time, apply a protective coating of lubricant to the wire rope. Moisture (dew, rain, and snow) trapped between strands and wires will create corrosion if the rope is unprotected. Also apply lubricant to each layer of wire rope on a drum because moisture trapped between layers will increase the likelihood of corrosion.

Always use the nominal diameter as specified by the equipment manufacturer. Using a smaller diameter rope will cause increased stresses on the rope and the probability of a critical failure is increased if the rated breaking strength does not match that of the specified diameter. Using a larger diameter rope leads to shorter service life as the rope is pinched in the sheave and drum grooves which were originally designed for a smaller diameter rope. Just as using a different diameter rope can create performance problems, so can the use of an excessively undersized or oversized rope.

Measure the wire rope using a parallel-jawed caliper as discussed in Measuring Rope Diameter at the top of this page. If the rope is the wrong size or outside the recommended tolerance, return the rope to the wire rope supplier. It is never recommended nor permitted by federal standards to operate cranes with the incorrect rope diameter. Doing so will affect the safety factor or reduce service life and damage the sheaves and drum. Note that in a grooved drum application, the pitch of the groove may be designed for the rope’s nominal diameter and not the actual diameter as permitted by federal standards.

Wire rope can be permanently damaged by improper unreeling or uncoiling practices. The majority of wire rope performance problems start here.Improper unreeling practices lead to premature rope replacement, hoisting problems and rope failure.

Place the payout reel as far away from the boom tip as is practical, moving away from the crane chassis. Never place the payout reel closer to the crane chassis than the boom point sheave. Doing so may introduce a reverse bend into the rope and cause spooling problems. Follow the guidelines highlighted under Unreeling and Uncoiling and Drum Winding. Take care to determine whether the wire rope will wind over or under the drum before proceeding. If the wire rope supplier secured the end of the rope to the reel by driving a nail through the strands, ask that in the future a U-bolt or other nondestructive tie-down method be used; nails used in this manner damage the rope.

Take extra precaution when installing lang lay, rotation-resistant, flattened strand or compacted ropes. Loss of twist must be avoided to prevent the strands from becoming loosened, causing looped wire problems.

The end of the rope must be securely and evenly attached to the drum anchorage point by the method recommended by the equipment manufacturer. Depending on the crane’s regulatory requirements, at least two to three wraps must remain on the drum as dead wraps when the rope is unwound during normal operations. Locate the dead end rope anchorage point on the drum in relation to the direction of the lay of the rope. Do not use an anchorage point that does not correspond with the rope lay. Mismatching rope lay and anchorage point will cause the wraps to spread apart from each other and allow the rope to cross over on the drum. Very gappy winding will occur resulting in crushing damage in multilayer applications.

Back tension must be continually applied to the payout reel and the crewman installing the rope must proceed at a slow and steady pace whether the drum is smooth or grooved.Regardless of the benefits of a grooved drum, tension must be applied to ensure proper spooling. An improperly installed rope on a grooved drum will wear just as quickly as an improperly installed rope on a smooth drum. If a wire rope is poorly wound and as a result jumps the grooves, it will be crushed and cut under operating load conditions where it crosses the grooves.

Every wrap on the first or foundation layer must be installed very tightly and be without gaps. Careless winding results in poor spooling and will eventually lead to short service life. The following layers of rope must lay in the grooves formed between adjacent turns of the preceding layer of rope. If any type of overwind or cross-winding occurs at this stage of installation and is not corrected immediately, poor spooling and crushing damage will occur.

On a multilayer spooling drum be sure that the last layer remains at least two rope diameters below the drum flange top. Do not use a longer length than is required because the excess wire rope will cause unnecessary crushing and may jump the flange. Loose wraps that occur at any time must be corrected immediately to prevent catastrophic rope failure.

The use of a mallet is acceptable to ensure tight wraps, however a steel-faced mallet should be covered with plastic or rubber to prevent damage to the rope wires and strands.

Rotation-resistant ropes of all constructions require extra care in handling to prevent rope damage during installation. The lay length of a rotation-resistant rope must not be disturbed during the various stages of installation. By introducing twist or torque into the rope, core slippage may occur—the outer strands become shorter in length, the core slips and protrudes from the rope. In this condition the outer strands become over- loaded because the core is no longer taking its designed share of the load. Conversely, when torque is removed from a rotation-resistant rope core slippage can also occur. The outer strands become longer and the inner layers or core become overloaded, reducing service life and causing rope failure.

The plain end of a wire rope must be properly secured. If the entire cross section of the rope is not firmly secured, core slippage may occur, causing the core to pull inside the rope’s end and allowing it to protrude elsewhere, either through the outer strands (popped core) or out the other end of the line. The outer layer of the outside strands may also become overloaded as there is no complete core-to-strand support.

Secure the ends of the rope with either seizing or welding methods as recommended under Seizing Wire Rope. It is imperative that the ends be held together tightly and uniformly throughout the entire installation procedure, including attaching the end through the wedge socket and the drum dead end wedge

When installing a new line, connect the old line to the new line by using a swivel-equipped cable snake or Chinese finger securely attached to the rope ends. The connection between the ropes during change-out must be very strong and prevent torque from the old rope being transferred into the new rope.Welding ropes together or using a cable snake without the benefit of a swivel increases the likelihood of introducing torque into the new rope. A swivel-equipped cable snake is not as easy as welding the ropes, but this procedure can be mastered with a little patience and practice.

As the most widely used lifting device, wire rope electric hoist has always been the first choice for light and small lifting as the most commonly used equipment, then a suitable for various working conditions and environments, to meet the needs of various countries and regions of electric hoist, has become inevitable, as this, Tavol Brand European Design wire rope hoist was born, Heritage FEM. European standard design concept, do our best to create higher value for customers, truly save more raw materials for customers, reduce more maintenance costs, TAVOL services to promote industrial development.

Whether you"re looking for a wire rope hoist with state-of-the-art or standard functionality, we offer wide solutions to meet our customers" needs. Our Demag wire rope hoists include excellent safety features, high handling rates, and cost-effective operation up to 100 tonnes.

As basic hoist units for integration into plant and machinery, or as lifting solutions with electronic controls that are optimized forcrane applications, with our wide range of wire rope hoists we offer the optimum solution to meet our customers’ specific requirements for efficiently lifting loads weighing up to 100 tonnes.

Our DMR modular wire rope hoists offer groundbreaking flexibility for diverse applications. With our DMR wire rope hoists, we can produce either a C-design or co-axial design. Some of the features include:

8613371530291

8613371530291