wire rope drum capacity calculator in stock

A handy tool for finding a cable drum that suits your needs - just enter your cable diameter and required length and it will return a list of matching cable drums.

All figures given are based upon a theoretical ‘tight pack’. It is recommended that an allowance of up to 30% be made to accommodate loose winding. A lower percentage could be used if the crew are known to always wind the drums neatly!

The combined weight of cable and drum is highlighted in orange when the weight exceeds 16kg. At this weight a user may need to make a risk assessment with respect to moving and/or carrying such without assistance.

† Drums with CTS suffix have an open hub "Cable Tail Support" on their flange. This would accommodate a further couple of metre"s of cable to allow the

‡Drums with CTF suffix have cable tail supports plus an additional flange, forming an 80mm wide extra section on the side of the drum to protect the tail. Calculated capacities are shown including and excluding the extra section.

Write down the length of the wire; measure the length of wire in feet, but make the remainder of measurements in inches. Measure the width of the reel and make note of it on a piece of paper. Do this for all measurements. Make note of the measurements, marking specifically what each measurement is for.

Measure the diameter of the core. Measure the diameter of the full reel. Measure the diameter of the wire. Add the diameter of the wire to the diameter of the drum. Multiply this figure by the diameter of the wire. Multiply this figure by the width of the drum.

Multiply the current figure by the diameter of the wire; for example, if the diameter of the wire is 1.5 inches, this figure would be multiplied by 1.5. The final figure should give the length of the wire.

First, a winch works harder the more wraps there are one the drum. This means that when your winch line is mostly spooled up it"s less powerful than when most of the line is played most of the way out. This is because of the increase in distance from the drum to the outer layer of the rope. Lay your arm on a table with 5 lbs in your hand and lift your hand while keeping your elbow on the table. Now tape the 5 lbs to a broomstick and tape the broomstick to your arm. It"ll be much harder with the object of movement much further away. Winch line length is a compromise between ability to reach anchors and power.

Second, more winch cable means that you can jam up your winch more easily. For example, if you do an extreme side pull for an extended period you"ll end up with a pile of cable on the side of the drum. This can damage your cable and damage your winch if you continue to reel in while your cable or rope is jammed.

If you really need more cable length you have three options:Get one of the high-strength, small-diameter winch lines. They are more expensive than regular synthetic but you get more line on the drum in a smaller diameter.

When cross winding, start with two layers of a level wound rope using the appropriate back tension. At the end of the second layer, pull the rope quickly across the drum, allow it to wind one full turn at the side of the drum, then quickly pull it back

to the opposite side of the drum. This will force the rope to cross in the middle and form a barrier that will prevent the rope from diving into the lower layers of the drum when placed under load. Follow the cross wound layer with two layers of level

Cable drums come in many different sizes and weights depending somewhat on the materials they are made of. Usually materials include plywood, timber, plastic or metal, depending on the weight and type of cable they are expected to support and whether they are designed to be reusable and/or returnable. Additionally, the choice of material for the drums may depend on whether the drums and cables are being stored indoors or outdoors.

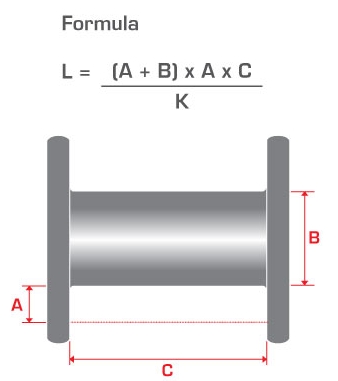

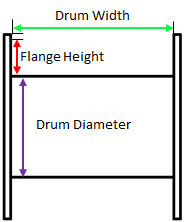

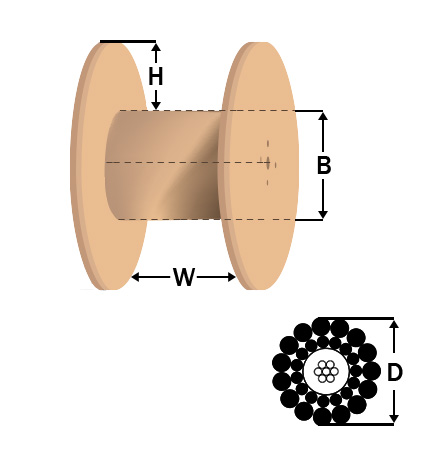

Drum sizes are typically determined by the flange height or drum diameter (D), the drum barrel or drum core (d), the width of the drum (B), and the inside width (b). See the diagram below for typical timber drums used by Eland Cables.

Crane systems can be quite complicated, and every part is crucial to the efficiency of the system as a whole. One of the most important parts of a crane is the reeving system, which affects elements like lifting capacity, overhead space, lift speed, and lateral movement. So, what is crane reeving?

Crane reeving is the configuration of the wire rope that lifts the hoist, including the drum, blocks, and pulleys. The type of reeving system will impact aspects like lift speed, headroom, and capacity of the crane. It also determines whether the crane system has any lateral movement or if it has true vertical lift.

For example, a crane system with one wire rope coming off the drum, going through a pulley at the hook, and going into an anchor point is considered a two-part single reeving system (2PS). It has one wire rope coming off the drum (single) that’s distributed over two lines (parts).

Another aspect to consider is lateral movement. When a crane system is lifting or lowering a load, the wire rope is either spooled or released, adding or removing coils on the drum. As coils are added or released, it moves the hook or load block back and forth on the drum. This is lateral movement.

Some crane applications require precision lifting with no lateral movement. In these cases, a double-reeved system is best. Because the wire rope is lowered from two points that meet in the center, the load will never have lateral movement.

Each part adds to the mechanical advantage of the crane system, allowing it to better distribute the weight. For example, a two-part crane reeving system will have twice the mechanical advantage and capacity of a single reeving system—as long as all other aspects remain the same.

While adding more parts to a crane system will increase capacity, it’ll also decrease lift speeds, since there are more lines working at once. A two-part system will have twice the capacity of a one-part system, but the lift or lowering speed will be reduced by half.

Of course, it’s impossible to determine a crane’s lifting capacity based on the reeving system alone. There are many factors that impact lifting ability:

Understanding how a crane’s reeving system works is essential to maintaining a safe and efficient work environment. The wire rope reeving system impacts everything from lift capacity and speed to lateral movement and weight distribution. It’s one of the most essential parts of any crane system.

8613371530291

8613371530291