wire rope drum groove design free sample

Multi-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next.

Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Python Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten rather quickly.

This invention relates to drums and sheaves used to support wire rope in wire rope systems for lifting heavy loads, such as used in electric mining shovels and walking draglines.

It is important that wire rope be properly supported when it is wound up on a drum if it is not properly supported the wire rope will become mashed. This will result in the breaking of the wires in the central area of the wire rope. Breaking of the wires in the central area of the wire rope can lead to premature failure of the rope because it is not possible to visually inspect rope internal damage. This is an especially dangerous form of wire rope failure. When the wire rope is supported on a drum a spiral groove is placed in the outside periphery of the drum. In the prior art, the shape of the groove was in the form of a half radius of a circle. It was important for the height of the side of the groove to be sufficiently great in order to properly support the wire rope.

This invention provides a device adapted to support a wire rope of known nominal diameter in a system where the fleet angle of rope departure from the device is other than perpendicular to the device, the device comprising a cylindrical body, and a groove around the cylindrical body, the groove having a contour adapted to support the wire rope, the groove contour being such that the wire rope is adapted to be supported through a rope support angle somewhere between 100 degrees and 160 degrees, the rope support angle being the included angle from the nominal rope"s center to each end of the supporting groove contour on each side of the groove, the improvement comprising the groove contour being parabolic in shape over at least about the upper half of the groove contour.

This invention also provides such a device such that the improvement comprises the groove contour having a radial length from the nominal rope center to the contour greater than at the bottom of the groove over at least about the upper half of the groove contour.

This invention also provides a method of making such a device, the method comprising designing the groove contour such that as the wire rope leaves the groove there is a single line of contact between the rope and the respective side of the groove.

Figure 10 is a graphical view of the rope in the "YZ" plane Figure 11 is a plot of the solution to equation 3.30 Figure 12 is a plot of the solution to equation 3.31.

The surface mining industry utilizes large equipment to extract the Earth"s many raw materials: e.g. gold, copper, coal and phosphate. Electric mining shovels and walking draglines are the two main types of machines that are used to move or uncover these raw materials. Both of these types of excavating equipment utilize large quantities of large diameter wire rope.

The most common means of driving a rope to do work is through the use of a drum. One end of the wire rope is attached to the drum and then the drum is rotated which allows the rope to wind onto it. Drums on walking draglines are cylindrical in shape, have flanges on both ends and have a series of grooves for the rope to wind onto.

The grooves provide an excellent rope support which reduces the radial pressure and helps resist crushing, which improves rope life, when compared to an ungrooved wire rope drum. The grooves also provide a path for the rope to follow as it winds onto the drum. This keeps adjacent wraps on the drum from touching one another. The flanges on grooved drums are to provide structural support and may be used to attach the dead end of the wire rope or a bull gear which would provide the torque needed to rotate the drum.

The nomenclature of a generic drum assembly is shown in Figure 1. This illustration greatly exaggerates the rope pitch diameter, drum tread diameter and the rope diameter to better illustrate the groove angle and the rope pitch.

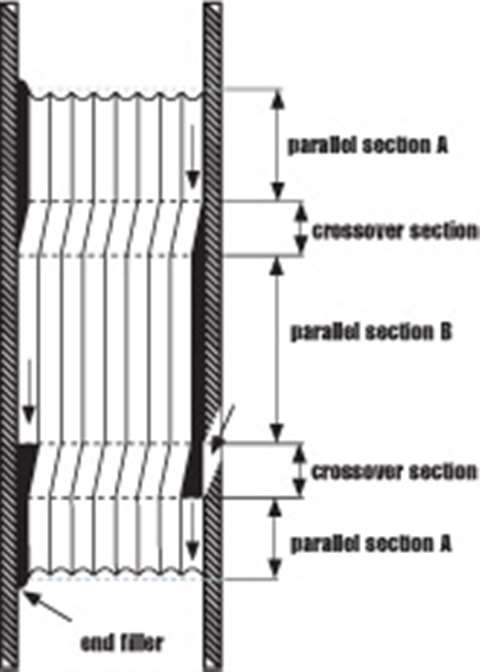

The hoisting drums on walking draglines are grooved and have only a single layer of rope wound onto it. Most of the drums have two ropes which are attached at the drum"s center. Each rope would then wind towards the flanges of the drum.

Drums on walking draglines are typically designed to the minimum recommended tread diameter to minimize the manufacturing and operating costs. Due to the enormous lengths of wire rope required to operate a Walking Dragline the length of the drum (i.e.

T"he sheaves on a Walking Dragline are very similar to a drum. They both have a rope that rides on them and have a groove contour to support the rope. The only real difference is that the sheave has no groove pitch. Figure 2 shows the nomenclature for a generic sheave. This nomenclature will be used throughout this thesis.

Wire rope is one of the most uniform and reliable mechanical products ever invented. If a wire rope is properly used and maintained it can provide an excellent service life. But, if a wire rope were to be abused in shipping, installation or during operation the service life of the rope can and probably will be much less than satisfactory.

Drum diameters are generally referenced as a ratio of the diameter of the sheave or drum (D) with respect to the diameter of the rope (d). This is the D/d ratio. Due to the limited deck space and the cost of manufacturing and operating a large drum on walking draglines and Electric mining shovels the drum D/d ratios are nearly always made to the recommended minimum value of 24.

When drums and sheaves are used in a system, the sheave diameters should be generally larger in diameter than the drum. This is due to the rope only being bent once at the drum and twice at the sheave for each direction of travel. When the rope travels over each sheave the rope will be bent to conform the radius of the sheave as it enters and then bent straight again as it exits the sheave. This is very important on walking draglines since the portion of wire rope operating at the drum may never operate at the boom point sheaves. If the fatigue accumulation is twice as great at the boom point as at the drum, the rope will fail prematurely at the boom point. This phenomenon is simply based on the design.

A fleet angle is the angle between the rope, as it leaves the drum and enters the head sheave, and the plane perpendicular to the axis of the drum. If the angle becomes too great the rope will touch "scrub" onto the groove of the drum or the adjacent wrap on the drum, or both. If a rope is scrubbing, there will be a visible thin band of worn material parallel to the axis of the rope and stretching a long distance along the rope.

This wear is often subject to high pressure, heat and abrasion. If the heat generated by scrubbing raises the local temperature beyond the steels critical temperature, martensite will form on the wires. Martensite is very brittle phase of steel. This will form surface cracks in the wires when the rope is bent around sheaves and drums. Eventually these cracks will propagate through the wire. If no heat is generated the outer wires will simply wear very thin and break.

Scrubbing is a purely geometrical concept. It is the wiping action of the rope onto another rope or the groove contour of the drum. Scrubbing is mainly caused by operating at too high of a fleet angle. Although, scrubbing is also dependent upon the system parameters such as groove contour, rope pitch, drum and rope diameters. When a drum is designed, manufactured and put into service, all of these parameters become fixed. The only geometric parameter that changes is the fleet angle. For every position on a drum there exists a unique fleet angle value.

Every rope which is wound onto a drum is subject to a fleet angle and a groove angle. The fleet angle is the angle the rope needs to follow in order to reach the head sheave as it is wound off a drum. The fleet angle changes for every position along the drum which is defined as the angle between the rope, as it leaves the drum and enters the head sheave, and the plane perpendicular to the axis of the drum. In the prior art, the groove angle, on the other hand, always remains the same for any position on the drum.

The groove angle, sometimes referred to as lead angle, equals the arc-tangent of the drums groove pitch divided by the circumference at the groove tread diameter.

Groove Angle = arcta~ Gr°°ve Pitch ~ Drum Tread Diameter 7z ( 1.1 ) The fleet angle plus the groove angle is called the total fleet angle. Figure shows a schematic of a sheave and drum system. The drum shown has a right hand lead and a left hand lead grooving with the typical 2 to 2.5 dead wraps (for normal safe operation) and the rest of the grooves are termed active grooves. As shown in Figure 5, the helix angle will either add to or subtract from the groove angle to form the total fleet angle. This is dependent on the direction of grooving. When the fleet angle is large and the drum groove pitch is large the head sheave may need to be shifted to either the right or the left in order to equalize the total fleet angle seen by the drum. If the fleet angles are large, the pitch of the grooves can be increased to eliminate "Rope to Rope"

Scrubbing can be a very serious and costly mode of rope failure. When a rope system experiences severe scrubbing, rope life on that machine will be a fraction of what is expected and the cost of altering the machine while its in operation can cost literally cost millions of dollars.

The "Roebling Wire Rope Handbook" derives a set of close form equations needed to predict the fleet angle at which rope scrubbing will occur based on known values: drum diameter, pitch of grooving and the diameter of wire rope. The following equation defines the total fleet angle that will just cause contact with the preceding wrap on the drum.

Y:= ~d2 - (X- h)2~~5 (1.3) X= h-2 2 Ch2 + 8 d2l (1.4) Where "h" equals the pitch of the grooving , "D" equals the tread diameter of the drum and "d" equals the diameter of the rope.

Using equation 1.2 we can easily find out what angle will cause scrubbing for any given position on the drum. What if we wanted to know what pitch diameter will cause scrubbing based on a known maximum fleet angle; such as 2.000°? With the use of a computer and some iterative math software a program can iterate through these equations and find the exact pitch required. To select a proper rope pitch, the program is used to find the pitch that will just induce scrubbing based on a certain fleet angle, drum and rope diameter. Then, when the rope is at its maximum material condition a small percentage of the ropes diameter is added to the pitch and a gap is defined.

Drum groove scrubbing is when the fleet angle of the rope leaving the drum would be great enough to cause interference between the actual drum profile and the rope; See Figure 3. When scrubbing occurs the outer strands are abrasively worn away in a thin band on only one side of the rope. Groove and rope scrubbing will appear to be the same on the damaged rope, but are caused by two completely different modes of generation.

Drum groove design has been virtually unchanged for many years. The drum groove contour has a specifically defined radius for each given rope diameter which is stated in "Wire Rope Handbook". The maximum allowable fleet angle of the rope is also said to be no greater than 1.50° for smooth drums and 2.00° for grooved drums. The Handbook does state however, that "Fleet angles larger than these suggested limits can cause such problems as ....... the rope rubbing against the flanges of the sheave grooves."

to No reference has been found which gives any indication as to what values design parameters like drum diameter, rope diameter, fleet angle, groove lead and groove radius should have to reduce or eliminate drum groove scrubbing. Now that CNC

machining and computer technologies has evolved so rapidly, the possibility of optimizing the groove contour and pitch to eliminate both "Rope to Rope" and "Rope to Drum"

The initial concept for formulating the governing equations was that, if the rope were to touch the groove, in three dimensional space, then a common point, or set of points, will exist between the rope and the groove. If there are many points, chances are they will form one or more three dimensional continuos curves. When the rope and the groove touch at one point it will be defined as having the coordinates <"Xend","Yend","Zend">.

The next step is to define the equation of the helical rope groove contour as a function of its governing variables in each of the three Cartesian coordinate directions.

Then the equations in the "X", "Y", "Z" directions are defined as being equal to "Xend", "Yend", "Zend" respectively. This equation definition can also be done for the ropes surface. If a point on the rope is to be common to a point on the groove, in order for scrubbing to occur, then the "Xenc~" of the rope is equal to the "Xend" of the groove. This coordinate equalization will be the basis for formulating all the governing relationships.

A single point on the groove contour is then geometrically described. This point is then swept out in the form of a helix in order to simulate the drum groove pitch. This will then define the helix in the "X", "Y" and "Z" directions. Three Cartesian equations a for the rope surface will then be defined. Extensive variable substitution and elimination then yields one equation in two unknowns. Lastly, the final equation is optimized in order to find the absolute minimum value for the drum radius, "Helix Z", that will cause "Rope to Drum" scrubbing to occur.

Once the solution for one single point was found and verified, then a computer program was written to solve for the ideal groove height for many values along the axis of the drum. This multitude of points will generate a curve which represents the complete "Ideal Groove Contour". A solution using the computer program then prints and plots the data that will create the full groove contour.

The governing equation derivation was broken into two main parts. The first part was to symbolically define the groove profile on the drum and the second part was to symbolically define the surface of rope as it leaves the drum. Both of these parts were defined in three dimensional space using the Cartesian coordinate system as a set of closed form equations.

Figure 6 illustrates a helix wound onto a drum, which will take the form of a groove. From this picture, the relationship between the drum axis, global axis and groove contour can easily be seen. Equations defining the position along the helical spiral of the drum were defined in the "X" and "Z" directions. One random point on the contour was picked to start the helix and the helix was swept out through 360° in a left handed positive direction.

1 6 Pitch - h,~ j=x X = Xend (3.1) The distance "Xend" propagates along the drum axis and is directly proportional to the "helix angle". "Xend" is defined as the final solution point in the "X" direction.

The final solution will be where the rope and the groove will just start to intersect. This is where scrubbing will just start to occur. In 360° of rotation, the distance traveled along the drum axis is equal to the pitch of the groove. The "Helix X" term is an arbitrary axial offset in the negative "X" direction. Later on this value will be a predetermined incremental step which will be used to generate the "Ideal Groove Contour".

directions will be required. The loss of one degree of freedom will be compensated for by introducing the general equation of an ellipse. When defining the equations for the rope, an ellipse is created when the cylindrical wire rope is cut with a plane at the fleet angle.

Helix Z cos(8) = Zend (3.2) The same point used in equation 3.1 was also used as the starting point on the groove profile for equation 3.2. The height of "Helix Z" is directly proportional to the cosine of the helix angle ("8"). The "Zend" term will be defined as the final solution in the "Z" direction. Figure 7 shows how "Helix X" relates to "Helix Z". For any value of "Helix X" there exists a "Helix Z" value, such that scrubbing on the drum will initially start. Our goal will be to derive an equation that equates the radial height, "Helix Z", directly to all known quantities.

First, assume that the rope fleets off of the drum in a straight line, it is centered within the drum"s radius and that the rope returns to a cylindrical shape very shortly after leaving the drums surface. The global coordinate axis will be centered on the axis of the drum with the centerline of the rope passing through the "Z" axis and the axis of the rope running directly down the "Y" axis while at a zero degree fleet angle. This is the same global position as stated above.

The fleet angle is the angle at which the rope leaves the drum. This fleet angle is zero only at when the rope leaves the drum exactly perpendicular to the "X Z"

plane. As the rope winds onto the drum the fleet angle will either increase of decrease depending on the position of the head sheave. For a single layer hoisting drum, the maximum fleet angle usually occurs when the drum is completely full. This is when the rope has wound onto the last and final wrap available on the drum. For our analysis, a random position on the drum was chosen to be the global axis system. The "~" axis of this system passes through the center of the groove and the rope. The fleet angle will be positive when the rope rotates about the positive "Z" axis. Figure 8 shows the basic geometry of a rope as it leaves the drum when subjected to a fleet angle.

Figure 9 shows how the cutting plane creates an ellipse as it intersects the rope at a fleet angle. Remember, the axis of the rope only rotates about the "Z" axis and remains in a plane parallel to the "X Y" plane. Figure 10 shows a view looking in the "YZ" plane which shows the relationship of the helical roll angle, "Yend", and the solution point "P"

direction is the distance to the center of the ellipse minus the distance back to the contour of the ellipse at the solution point "P". This is simply one half the drum rope pitch diameter "DRPD" minus the "Y Ellipse". This is shown below as equation 3.8.

.5 1 DRPD - 1 - x rl 2 - Zend 2 r2 2 (3.13) Equations 3.9, 3.11 and 3.13 are the three final equations which define the final solution on the surface of the rope. The next step is to define the values for "rl" and "r2". The quantity "rl" is the minor axis of the ellipse, which is defined as the drum rope radius "DRR" since the axis of the rope is parallel to the "X Y" plane.

rl = DRR (3.14) The quantity "r2" is the major axis of the ellipse which is defined as the drum rope radius divided by the Cosine of the fleet angle "a". The "intersecting plane" cuts the cylindrical rope at precisely that angle.

(3.17) is z22+x2cos(2)2=1 DRR DRR (3.18) Equations 3.1 and 3.2 above are restated here for the definition of the groove helix geometry so that the final five equations are all on one page.

+ ~.25 82 Fitch2 - 8 Filch Helix h"II+Helix X2 II2~ cos(ec)2 + ~ -DRR2 + . 25 DRPD2~ II2 (3.25) When the value of this equation is equal to or less than zero scrubbing is taking place. Our intent will be evaluate where this equation equals zero. This is where the groove contour and the rope contour will be touching.

as II2- cos(o~)2IZ2+cos(6)2 cos(c~c) II2 (3.27) bh ~ -2 Helix X II2 + 8 Pitch IZ~ cos( cx) sin( 8) sin( c~c) - DRPD cos( 8) II2 (3.28) cc = ~.25 62 Pyitch2 - APitch Helix XII+Helix X2 II2~ cos(a)2 + { -DRR2 + .25 DRPD2~ II2 (3.29) If we substitute "aa", "bb" and "cc" into equation 3.26 we will get one equation in one unknown "8". There are two roots, the negative root represents the intersection at the bottom of the rope and the positive root represents the intersection at the top of the rope. Due to geometry, only the negative solution is of interest to us.

In looking at Figure 11 we can see the vertical axis is "Helix Z" which is the drum radius. Therefore by inspection, the lower curves represents the underside of the rope, which is where scrubbing is likely to occur. The upper curve represents the top side of the rope, which is meaningless for groove scrubbing.

(3.31) Where "Pitch" = Pitch of the drum, "DRR" = Drum rope radius, "DRPD" = Drum rope pitch diameter, "a" = Fleet angle and "8" = Roll angle of the helix.

In many ways drums and sheaves are the same. They both have fleet angles, groove radii and D/d diameter ratios. The only big difference is that a sheave has only one straight groove and therefore has no "Pitch". When the "Pitch" in equations 3.25 and 3.31 is set equal to zero they become simplified to equations 3.32 and 3.33 respectively.

The solution for the ideal drum groove contour was presented above and it turns out that final solution, equation 3.25 and equation 3.31, is extremely nonlinear in "8".

Drum groove scrubbing will be evaluated at every value of "Helix X" along the axis of the drum up to one half of the rope pitch. Beyond that point, the solution would be meaningless; the start of the neighboring groove will obviously lie beyond that point.

The value of "Helix X" can be placed into a list and be incremented by very small amounts up to a value of half the rope pitch. Then the value of "Helix Z" can be solved for each and every value of "Helix X" by utilizing equations 3.25 and 3.31.

Since the only unknown variable in equation 3.31 is "A", TkSolver can then iterate until a solution is found. TkSolver will then utilize that value of "0" in equation 3.25 and solve for "Helix Z". The drum radii that will just allow scrubbing to occur is the value "Helix Z".

Tk-Solver provides the solution that at exactly 2.500" along the axis of the drum, for these system constants, the roll angle of the helix is "0" = 2.972°

and the ideal drum The rope support angle is defined as the angle the rope is supported within the drums groove if the rope were under high tension. The rope will flatten (elliptical) into the groove contour. If a line from the end of support is drawn through the theoretical center of the rope and a line is drawn from the other end of support through the theoretical center of the rope, then the angle included between these two lines is defined as the rope support angle. Figure 1 illustrates exactly how to measure the rope support angle.

If the rope support angle is too small then the rope will be lacking support and will then be flattened and elliptical shaped. This will cause the rope to fail by interstitial strand penning and nicking which will eventually cause the internal wires fail prematurely. This is one of the most dangerous forms of wire failure; since it cannot be found by a simple visual inspection. The internal broken wires are only noticed after they have worked their way to the outside of the rope.

If the rope support angle is too great, then the rope will scrub against the groove and cause "Rope to Drum " scrubbing. The rope will actually scrub against the groove contour, even when the fleet angle may be very low. A wire rope has an increased risk of "Drum to Groove" scrubbing when the drum diameter, pitch or the fleet angle are too large. Figure 3 shows "Rope to Drum" and "Rope to Rope" scrubbing. The question to ask is; What groove contour will provide adequate rope support and at the same time prevent or minimize groove scrubbing?

There are three specific parameters required to design a new groove. They are groove pitch, groove radius and rope support angle. There are several parameters that are set by the surrounding envirorunent and machinery. These parameters are usually defined early in the design process which usually occur long before a designer actually designs the drum groove contour. Some of these parameters are rope diameter, drum capacity (which affects the drum tread diameter and drum length) and the sheave and drum placement (which affects the maximum operating fleet angle). When these parameters are being designed, the designer needs to foresee the possible future consequences of fixing their values.

The first to be defined is the nominal rope diameter. The rope diameter is usually chosen very early in the design. It is based on the rated suspended load the Walking Dragline is expected to hoist or drag. The rope diameter typically ranges from 2.00" to 6.00" in diameter. The ropes are manufactured to a tolerance to +0% to +$% of nominal rope diameter. For this example, a nominal rope diameter of 4.00" will be used.

The second issue is drum capacity and D/d Ratio. Drum capacity is a function of the number of wraps wrapped on the drum and the drums tread diameter. The drum diameter is usually set to the minimum recommended diameter for the wire rope being used. The drum ratio typically used is a D/d equal to 24.

The maximum operating fleet angle is the last of the three predefined variables the designer needs to contend with. The maximum fleet angle is directly affected by where the sheaves and the drum are placed on a machine. The maximum operating fleet angle for a grooved drum is typically 2.00°. The designer needs to consider the placement of the drum and sheaves such that the fleet angle will never exceed this value.

For this example, the rope diameter will be 4.00", the drum tread diameter will be 24*4.00" _ 96.00" and the maximum allowable fleet angle will be set at 2.00°.

As stated above, there are three specific parameters a designer has control over when designing a new groove contour. They are groove pitch, groove radius and rope support angle. The groove pitch or lead of the rope is chosen in order to prevent rope to rope scrubbing, as described earlier. The equations initially stated above predict the exact total fleet angle at which "Rope to Rope" scrubbing will occur. Using this relationship, the equations 1.2, 1.3 and 1.4 are programmed into Tk-Solver and its iterative equation solver is used to find the value of any one variable in terms of all the others. More specifically, Tk-Solver is used to find the groove ip"tch required in order to just cause "Rope to Rope" scrubbing based on a known drum tread diameter, true rope diameter and a maximum fleet angle.

Tk-Solver will iterate through these equations by simply giving an initial guess for the rope pitch. This example has a maximum fleet angle of 2.000°, a drum diameter of 96.000" and a nominal rope diameter of 4.000" which may be manufactured at +S%

larger than standard, LE. 4.200". Tk-Solver iterates through the set of equations until a convergence is found. The ideal groove pitch is 4.5838". This is based on a rope that is manufactured at a S% oversize condition. If the designer wanted added security that scrubbing will not occur, they can simply add a small amount to the pitch. In this example, the groove pitch may be rounded up to 4.600". This will leave a small gap of .0162" even when the largest possible rope size is placed on the grooves and the rope is operating at the maximum fleet angle. In this particular example, the 4.600"

and 10% larger than the nominal rope diameter. For this example, 2.139" is used as the groove radius. This value corresponds to 6.5% larger than nominal rope diameter.

When the wire rope deforms into the groove radius, it will flatten and become oval shaped. Because of this, the rope needs to be supported on its circumference by some specified angle. Many sources specify a rope support angle which can vary from 120° to 1 SO°. Most sources recommend 135° for adequate rope support. For this particular example, a rope support angle of 135° will be used.

The last and final step is to define the drum groove depth. The depth of the groove is the distance from the bottom of the groove (D/2) to the outside diameter of the drum. At this point the designer has already defined the pitch, groove radius and the rope support angle. This is all that is required in order to define the groove depth is to create the circle that is tangent to both of the groove radii and the two 135°

This will define the "Cap" radius between two adjacent grooves. In Figure 13 there is a layout of the standard drum groove and the cap radius we have just defined.

In conclusion, the standard drum groove design procedure for a 4.000" nominal rope diameter with a maximum operating fleet angle of 2.000° and a tread diameter of 96.000", will have a groove radius of 2.139", cap radius of .351", drum outside diameter of 99.074" and a rope support angle of 135°.

The sheave design example is very similar to the drum. The only difference is that groove has no pitch and the depth of the groove is increased significantly in order to prevent the rope from bouncing out of the sheave. The only additional parameter is the "Throat Angle"; see Figure 2. The throat angle is nothing more than 180° minus the rope support angle. For our 4.000" nominal rope diameter example, the throat angle will be 45°. The groove radius and the tread diameter will remain the same, 96.000" and 2.139" respectively.

Depending on the application, the groove depth should be 1.5 to 2.5 rope diameters. Past experience of specific applications will be the best judge. If the wire rope experiences sudden changes in tension, shock load, it may jump out of a sheave.

Some applications will never experience shock loading and therefore have a groove depth as small as a standard drum. Figure 14, illustrates the standard sheave groove design with a groove depth of 1.50 times the nominal rope diameter.

The fleet angle for a sheave, just like a drum, should not exceed 2.000°. Since there is no pitch, there is no need to consider anything else. For a sheave with a nominal 4.000" rope diameter and a fleet angle of 2.000° and a tread diameter of 96.000", the sheaves groove radius will be 2.139", throat angle will be 45°, groove depth will be 6.000", rope support angle will be 135° and the outside diameter will be 108.000".

The existing groove design procedure has several similarities to the newly proposed groove design procedure. Both of these procedures have the same parameters which are defined by the surrounding environment and machinery; such as a maximum operating fleet angle, minimum drum tread diameter and nominal rope diameter.

The pitch design procedure explained above will be exactly the same in the ideal contour design procedure. The only radical alteration to the existing design procedure will be to redefine the groove radius.

When the rope groove radius is in the form of a true radius, it does not take into account the effects of "Rope to Drum" scrubbing. The equations derived above define the "Ideal Groove Contour" that will just eliminate scrubbing for any drum or sheave.

The ideal drum groove design example will incorporate many similar parameters that were previously defined above. Here, the drum tread diameter was 96.000", maximum fleet angle was 2.000° and the nominal rope diameter was 4.000". The ideal pitch that will eliminate "Rope to Rope" scrubbing was defined as 4.600". For consistence, the 135° rope support angle will also be kept the same.

The only change will be in the way the rope"s supporting radius is defined. The rope groove radius is defined as a parabolic shape ( Equation 3.25 and Equation 3.31 ). By altering the shape of the groove and keeping all of the other parameters the same, the "Cap" radius and Drum outside diameter will both be forced to change.

In order to solve for the ideal groove contour, only four parameters are required, drum tread diameter, actual rope diameter, maximum operating fleet angle and rope groove pitch. All of these parameters are defined in the existing groove design procedure stated above. A TkSolver program was written to solve for the ideal drum radius required to eliminate "Rope to Drum" groove scrubbing. The program will utilize "Newton"s Method" for finding roots and solve for "A" and "Helix Z" by starting with only an initial guess. The program is set up to solve for one single solution.

This solution will be located along the drum axis at a "Helix X" value of 1.000". The solution converges to a final value of "Helix 2" equal to 48.249" and a helix roll angle "0"of 1.518°.

This TkSolver program can solve for an ideal contour at any point along the drums axis (.01, .02, .03... 2.01, 2.02......) up to half of the groove pitch.

i , y so ve or a the positions specified. 1 0.000 48.000 2 0.100 48.002 This data was then drawn in CATIA along 3 0.200 48.009 with 4 0.300 48.021 all of the other pertinent groove and 5 0.400 48.038 drum parameters.

11 1.000 48.249 function within CATIA. The resulting 12 1.100 48.305 spline represents 13 1.200 48.369 is a parabola that defines the "Ideal 14 1.300 48.440 Drum Groove 15 1.400 48.521 Contour". 16 1.500 48.611 17 1.600 48.712 Once the contour has been created, then 1 g 1.700 48.827 the entire la 19 1.800 48.958 out of the drum rofile can be com leted y 20 1.900 49.109 p p .

Figure 15 is the final drum design using21 2.000 49.284 the newly 22 2.100 49.489 proposed design methods. Due to the new 23 2.200 49.733 groove ( 24 ~ 2.300 50.024 contour, a new "Cap" radius and new drum outside Ideal Drum Groove Contour Data diameter have been defined. The 135° rope support angle, 4.600" pitch and the 96.000"

The ideal sheave contour will have exactly the same characteristics as the standard sheave groove contour. The tread diameter, outside diameter and throat angle will all remain the same. The groove support radius will be similar to the ideal contour defined above. The main difference is that a sheave has no pitch and therefore has less of a possibility of having "Groove Scrubbing".

The output of the ideal groove contour program is then computed for when the ip tch is set equal to zero. This particular solution was located along the drum axis at a "Helix X" value of 1.000". The radial height "Helix Z" that is associated with that value is 48.258". Again, Tk-Solver will solve for all of the required points and CATIA was used to connect and analyze the data.

Figure 17 illustrates the ideal contour superimposed onto the standard groove contour. Note that the ideal contour never penetrates the standard contour.

Lines are then created which are parallel to the 45° throat angle and are tangent to the "Ideal Groove Contour". This tangency condition occurs at 140.7°, which is slightly above the standard 135°. This illustrates that there will be an .018" gap between the ideal and standard groove contours. This means that scrubbing will not be a problem for this particular design. In this example, we would typically adopt all of the "Standard Design"

This sheave will have a nominal rope diameter of 4.00", maximum operating fleet angle of 2.000° and a tread diameter of 96.000". The sheaves groove radius will be 2.139", throat angle will be 45°, groove depth will be 6.000", rope support angle will be 135° and the outside diameter will be 108.000".

The standard and ideal groove contours are very similar in shape. The standard groove has a true radius supporting the rope and the ideal contour has a parabola supporting the rope. The difference between these two geometric shapes is closely examined below. All of the other groove geometry (rope support angle, groove pitch, tread diameter) remains the same.

In order to compare the drum groove geometry, we need to define a common reference point for all of the groove shapes. The common datum is located at the center of the rope when the rope is manufactured at it"s nominal diameter. The groove contour comparison will be based on the distance from the center of this rope to all of the proposed contours.

over nominal rope diameter curves represent the recommended maximum and minimum values for the groove radius which is stated in the Wire Rope Users Manual 3rd Edition.

The rope support angle is plotted on the abscissa axis from the centerline of the rope and towards the right. This is the positive "Helix X" direction which was defined above.

The total rope support angle is twice that stated in figure 18. The two vertical reference lines define the minimum and maximum rope support angles recommended by several sources.

The radius of the rope does not change as the rope support angle increases. The distance from the center of the nominal rope diameter to the 6% and 10% are parabolic in nature. This is because the circles are not concentric. All of the circles are tangent to the tread diameter and therefore the centerlines are all shifted vertically by the change in rope radius.

If the groove radius was to be manufactured at 10% over the nominal rope diameter the "Drum Groove" scrubbing will only occur at a rope support angle of about 140° and greater, see Figure 18. If the groove support angle was to be only 135° then the rope will not scrub at all. At first, this may appear satisfactory, but when the rope is allowed too much freedom to deform to the shape of the groove, then the internal fatigue damage will greatly reduce the life of the wire rope.

If the groove was to be manufactured to 6% over the nominal rope diameter, then scrubbing will exist for nearly all rope support angles. At this small 6%

groove radius, the amount of deflection due to scrubbing interference will have a dramatic affect on the life of the rope. The rope will not only scrub severely, it may also not allow enough room for the individual wires to shift positions as the rope is wound onto the drum. This will pinch the rope and will cause accelerated cyclic fatigue.

The goal is to allow minimum movement of the rope which will still allow the individual wires to relocate as the rope is bent around a drum and to prevent "Rope to Drum" drum groove scrubbing.

In Figure 18 the "Ideal Groove Contour" is also plotted. This groove contour is slightly greater than the 6% curve up to about 40°. After that point, the amount of scrubbing increases greatly. If the groove was manufactured at this ideal contoured shape, the rope will not scrub on the drum, at all.

Above, the groove radius was chosen to be 2.139". This is the recommended radius stated in the Wire rope Handbook 2nd Edition. If this curve was plotted on the same graph, the relative distance between it and the ideal contour could then be measured. These measurements are shown in the table below. Notice that the 2.139"

Beyond that value, the deviation increases exponentially. If the rope support angle was to be only 135° we will need to modify the recommended radius by .028". If we wanted a GrooveHalf StandardTrue Deviation SupportSupportDesign Ideal From Angle Angle ProcedureContourStandard [degrees][degrees](inches][inches][inches]

When the rope is being wound onto a drum and if the drum has a 135° of rope support angle, then the rope will need to be deflected by .028" in order for the rope to pass.

When the rope is under a high tension, the actual pressure on the individual wires can become extreme. This will cause severe abrasive wear and burning of the rope, which may cause the formation martensite on the surface of the wires, which will also greatly accelerate the cyclic fatigue and initiate crack propagation.

In various embodiments of the invention, the groove contour may vary from side to side as the fleet angle changes from one side of the groove to the other, or from groove to groove. In most embodiments however, a single groove contour will be used over the entire drum.

On receipt the product should be inspected to confirm that it corresponds to the one ordered. If the steel wire rope is not to be used immediately, it must be stored in a dry place. If it is to be stored for a longer period, it must be checked regularly to determine whether it requires lubrication (see also “Maintenance of Steel Wire Rope”, page 8-26).

It is important that the steel wire rope’s dimension is checked before installation, and that it is checked that the dimension matches the equipment with which the steel wire rope is to be used (see also “Dimension Tolerances and Ovalness”, page 8-18).

The measurement is undertaken at two places at least one metre apart on a straight section without any load. At each place two measurements are made at 90° angles. The average of these four measurements defines the diameter of the steel wire rope. The degree of ovalness in the steel wire rope is the greatest difference between the four measurements, expressed as a percentage of the nominal diameter of the steel wire rope.

Before the steel wire rope is fitted, it is important to ensure that all parts that will come into contact with the steel wire rope are in good condition and match the steel wire rope, e.g.:

If the equipment is not suitable, there is a significant risk that the steel wire rope will suffer unusually great wear and tear and will thus have a shorter life expectancy.

If the rope grooves do not match the steel wire rope, the rope will suffer unusually high wear and tear, stresses will be introduced and the grooves will have to be repaired.

The steel wire rope’s life expectancy depends to a great extent on the drum’s dimensions, among other things. The larger the drum, the longer the life expectancy (see also “Sheaves/Blocks”, page 8-21).

If the distance does not match these figures, the steel wire rope will be subject to unusually significant wear and tear; the distance should therefore be changed.

Check whether the guide rolls, e.g. those on the winch, are worn. If they are, the steel wire rope will be subject to unusually significant wear and tear; the guide rolls should therefore be replaced or repaired.

If the guide roll is repaired by welding, care should be taken to ensure that the hardness of the welding material is approx. 300 Brinel, and that it is the guide roll that is worn, and not the steel wire rope.

When a steel wire rope is fed over e.g. a sheaf and bends, certain complex tensions (a combination of bending, tensile and compression stress) are generated in the wires. The greatest tensions occur in the wires furthest away from the steel wire rope’s bending centre. After repeated bends, stress failure will occur in these wires.

The steel wire rope construction and the size of the sheaves are decisive in determining when wire fracture occurs. The curve below (fig. 34) shows the influence of the D/d ratio (sheaf diameter/nominal steel wire rope diameter) on the life expectancy of steel wire rope of different types.

Please note that norms and standards often impose special requirements in respect of sheaf/drum diameters. If this is not the case, a minimum D/d = 25 is recommended for 6x7 steel wire ropes, minimum D/d = 20 for 6x19 and 6x36 and a minimum D/d = 10 for combination ropes.

If at all possible, S-bends (where the steel wire rope runs from the lower side of one sheaf to the upper side of the next) should be avoided. Such bends result in premature damage. The sheaf ratio (see below) should thus be increased by at least 25% in relation to the same change of direction. The problem is particularly great when the sheaves are placed close to each other.

The groove in the sheaf also has a significant influence on the steel wire rope’s life expectancy. The groove must be neither too large nor too small - the groove must match the steel wire rope’s dimensions (fig. 35).

Randers Reb recommends that a correct sheaf groove should support approx. 1/3 of the circumference of the steel wire rope (~120°C) and have a groove diameter of Dsp = 1.06 x the steel wire rope’s nominal diameter (see fig. 36). The groove diameter may under no circumstances be less than the relevant steel wire rope’s diameter.

The curve in the diagram below (fig. 37) indicates the effect of the D/d ratio (sheaf diameter/steel wire rope diameter) on the steel wire rope’s life expectancy.

Always check whether the sheaf groove is worn at the base and along the edges. If it is not, the steel wire rope will be subject to unusually significant wear and tear and stresses will be introduced into the rope. Defect sheaves/blocks should therefore be replaced or repaired immediately.

If the groove is repaired by welding, Randers Reb recommends that the hardness of the welding material is approx. 300 Brinel, so that it is the sheaf that is worn, and not the steel wire rope. The size of the steel wire rope’s contact angle (angle change) on the sheaf also has an effect on the steel wire rope’s life expectancy (see fig. 38).

Steel wire rope from Randers Reb is produced in such a way that in an unloaded state it is tension-free. The steel wire rope is supplied either on reels or in coils. To avoid creating tension or kinks in the steel wire rope during installation, it is necessary to place the coil/reel on a revolving platform, or as shown in fig. 39. If this is not possible, the steel wire rope can be rolled out on the ground while the end of the rope is held in place.

Remember to secure the end of the steel wire rope against opening, regardless of whether or not it is pre-formed. This can be done by such means as tapered and welded ends, beckets, or seizing with soft or annealed wire or strand (see also “Cutting and Seizing of Steel Wire Ropes”, page 8-24).

Winding from Reel to DrumDuring installation, when the steel wire rope is running directly from the reel to the drum, care must be taken to ensure that the reel is running in the same direction as the drum (fig. 41).

In order to achieve problem-free winding in multi-layer winding, it is extremely important that that the steel wire rope is under tension when applied to the drum. If the layers are too loose, the upper layers can damage or cut into the layers below when tension is applied, resulting in damage to the steel wire rope. The rope must be wound onto the drum at a tension corresponding to at least 2% of the tensile strength of the rope.

Braking of the drum can be done in several ways (see fig. 42). Please note: Steel wire rope should never be pressed between two wooden plates, as this will result in permanent damage to the rope.

Randers Reb recommends that, as long as the steel wire rope does not have welded ends, it has to be seized before being cut. The following seizing method must be used (See Fig. 44):

After the steel wire rope has been installed, Randers Reb recommends that it is run through the system several times at low speed and moderate loading (e.g. 5% of tensile strength). In this way the steel wire rope will gradually become accustomed to the new conditions. The strands will settle, the steel wire rope will lengthen and the diameter will decrease a little due to the fact that the strands and the core are compressed. The steel wire rope will thus be less susceptible to damage when maximum load is applied. The time spent “running-in” the steel wire rope will be earned many time over, as the steel wire rope will thus have a longer life expectancy.

Thorough maintenance of the equipment that the steel wire rope will come into contact with is of great significance for the steel wire rope’s life expectancy. Worn sheaf grooves, guide rolls, etc., crooked sheaves and jammed bearings all result in such effects as shock load and vibrations in the steel wire rope, which have a destructive effect on the steel wire rope, resulting in exaggerated wear and tear and fatigue.

Equipment that the steel wire rope comes into contact with must be inspected regularly. If there is a problem with the equipment, it must be replaced or repaired immediately. If the guidance equipment is repaired by welding, care should be taken to ensure that hardness of the welding material is approx. 300 Brinel, so that it is the sheaf that is worn, and not the steel wire rope (see also “Inspection of Guidance Equipment”, page 8-19).

A distinction is made between the nominal rope diameter and the effective rope diameter. The nominal wire rope diameter is an agreed theoretical value for the diameter of the smallest circle circumscribing the outer strands.

The effective rope diameter, also called actual rope diameter, is the diameter of the smallest circle enclosing all outer strands, as measured on the rope itself. The tolerance range for the effective rope diameter is specified in related national and international standards. According to EN 12385-4 it is between -0{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} and +5{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} (for nominal rope diameters ≥ 8mm)

This means that the effective rope diameter upon delivery must neither be smaller nor bigger than 5{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} than the nominal rope diameter. The tolerance range is often higher for smaller ropes like 3mm to 7mm nominal diameter. In the Oil and Gas industry, which is firmly based on US regulations, a tolerance range from -1{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} to 4{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} is applied. The effective rope diameter changes depending on the load applied. Therefore the effective rope diameter should in critical cases be measured on a rope that is loaded with 5{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} of the calculated breaking strength. verope® produces standard tolerances of +2{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} to +4{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} and special tolerances upon request.

By the design of a wire rope, one understands the formation principle according to which the elements of the wire rope (the wires and the strands) are arranged relative to each other. The designation of a fiber core is FC, for an independent steel wire rope core it is IWRC. As an example all round strand ropes of the 6×19 Warrington design with a fiber core have the construction 6 x [1-6-(6-6)] – FC.

The fill factor of a rope is defined as the ratio of the metallic cross section of the rope (or a simplified calculation of the sum of the single wire cross sections) related to the nominal rope diameter. The fill factor specifies which amount of space the wires and strands take in the rope (figure 16).

The fill factors of the most common ropes are between 0,46 and 0,75. This means, that the amount of steel in the rope volume is about 46{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} to 75{a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02}. Wire ropes with a wire rope core have higher fill factors than ropes with a fiber core.

Usually fill factors of wire ropes with a fibre core (FC) decrease with an increasing number of outer strands. A rope of the design 6×25 Filler-FC has a fill factor of 0,50, a rope of the design 8×25 Filler-FC has only a fill factor of 0,445.

Usually fill factors of wire ropes with a wire rope core increase with an increasing number of outer strands. A rope of the design 6×25 Filler-IWRC has a fill factor of 0,58 and a rope of the design 8×25 Filler-IWRC has a fill factor of 0,587.

Two lay types are to be considered: Regular or ordinary lay and lang’s lay. In regular lay ropes, the lay direction of the wires in the strands is opposite to the lay direction of the strands in the rope. We distinguish between right hand ordinary lay RHOL (right hand strand, left hand rope, zS) (figure 17) and left hand ordinary lay LHOL (left hand strand, right hand rope, sZ) (figure 18). In lang’s lay ropes, the lay direction of the wires in the strands is equal to the strands in the rope. We distinguish between left hand lang’s lay LHLL (left hand strand, left hand rope, sS) (figure 19) and right hand lang’s lay RHLL (right hand strand, right hand rope, zZ) (figure 20).

In the stranding process the initially straight wires are forced into a helical or double-helical form. Therefore, the wires in a rope are always under tension, even in an unloaded rope. Such a rope must be sealed very tightly left and right of the joint before cutting the rope because otherwise the free ends of the wires will spring open. By using a “preforming tool”, the wires and strands can be heavily plastically deformed during the stranding, so are laying nearly without tension in the rope, the rope now is preformed. The ropemakers consider such ropes to be “dead”. Preformed ropes can be cut much easier, also secured by seizings of course, than nonpreformed ropes.

Usually wire ropes have either a fiber core (FC) or a steel/wire core. The steel/wire core can be a strand (WC) or a small rope, named as independent wire rope core (IWRC). The IWRC can be made in a separate operation or during the closing operation of the wire rope (PWRC). The wire core can also have a plastic coating (EPIWRC). Cores made of compacted strands have the additional designation (K). An independent wire core made of compacted strands is therefore called IWRC (K). A rope closed in a single operation and made out of compacted strands both in the core and the outer strands is called PWRC (K).

wire ropes and their free rope end rotate to a greater or lesser extent around its longitudinal axis under the influence of tension. Wire ropes having a core lay direction opposite to the lay direction of the outer strands and 3- or 4-strand regular lay wire ropes rotate considerably less than wire ropes with the same lay direction of the wire core and the outer strands and wire ropes with fiber cores. According to VDI 2358, a wire rope is semi rotation-resistant when: “the wire rope which turns around its longitudinal axis when subjected to unguided load and/or hardly transmits a torque to the attachment at the end in the event of guided rope ends.”

According to ISO 21669 and DIN EN 12385-3: “a rope is considered to be semi rotation resistant if it rotates at least once and at most four times around its axis at a length of 1000 x d under a load of 20 {a889db705b9dbdba2a8d0dbcfc2b631547dc85af52ef75a70f044d2486ae0f02} of the minimum breaking force. In terms of rotation angle, the defined limits are between 360° and 1440°.”

According to the regulation of VDI 2358, a wire rope is rotation-resistant, when: “the wire rope, which hardly turns around its longitudinal axis when subjected to unguided load and/or hardly transmits a torque to the attachment at the end in the event of guided rope ends.”

The wire rope lubricant has two major tasks: it should protect the rope from corrosion and minimize the friction between the rope elements themselves and between the rope and the sheave or the drum. A reduction of the friction reduces the actuating power and minimizes the wear of the rope, the sheaves and the drums. We differentiate between wax-based lubricants and oil-based lubricants. While wax-based lubricants offer a better handling of the ropes, the oil-based lubricants advantage is a better closing of the lubrication film due to the gravitational force of the oil. The quality of the wire rope lubricant has a great impact on the fatigue resistance of a wire rope (figure 22).

8613371530291

8613371530291