wire rope failure causes in stock

Safety should be the top concern of anyone employed in rigging. When working a job where so many lives could be cut short due to carelessness, there is no excuse for laziness or distraction. Rigs should be inspected thoroughly for any potential areas of breakage. It is important for employees to gain a fluency in the causes of wire rope damage and failures so they can spot areas of weakness and fix them before they grow into a dangerous problem.

Corrosion issues in wire ropes are one of the most difficult causes of wire rope damage and failures to identify, which is why it is one of the most dangerous. Wire rope failures due to corrosion are typically the result of poor lubrication. You can measure some amount of the lubrication by looking at the pitted surface of every individual rope, but this tells us little of the damage done to the core. Since it is difficult to identify the full spectrum of corrosion, this break stands apart as mysterious and deadly.

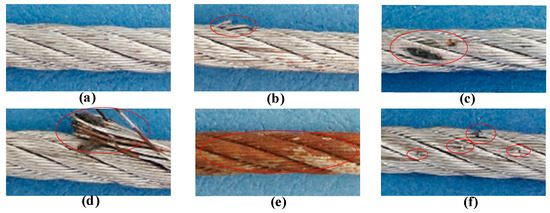

Abrasion-caused failure occurs when the wire rope has been damaged by irregular contact with hoist sheaves and drums or when it awkwardly rubs against an object such as shelving or a crane girder. It is also often caused by poorly grooved drums and sheaves. You know the wire ropes have experienced abrasions when the wire ends are worn thin.

When hoist ropes go through repetitive bending over sheaves, cracks will eventually develop in the individual wires. Sections of the wire that move over the sheaves develop the worst fatigue. The damage can often be seen by the naked eye. Whenever one broken wire appears due to fatigue, more will follow. Since these issues are essentially the result of wear and tear on the rope wire, they are considered a normal part of operating a crane.

Being fluent in safety measures is just as valuable to an employer as competency with cable rigging hardware. People who know how to spot areas for potential failures can keep themselves and their coworkers secure, which saves time, money, and even lives.

Hoisting loads with a wire rope is a simple operation. Hook it up; lift it. Turns out, it’s more complicated than it appears. The details of setting up, inspecting, and maintaining lifts with wire ropes are not complicated, but are critical. A lift that goes awry is dangerous. A bad lift puts workers at risk. In this article, we discuss the causes of wire rope failure and how to avoid them.

Abrasion breaks are caused by external factors such as coming into contact with improperly grooved sheaves and drums. Or just hitting against some object during operation. Worn, broken wire ends is the result of an abrasion break. Common causes of abrasion breaks include:

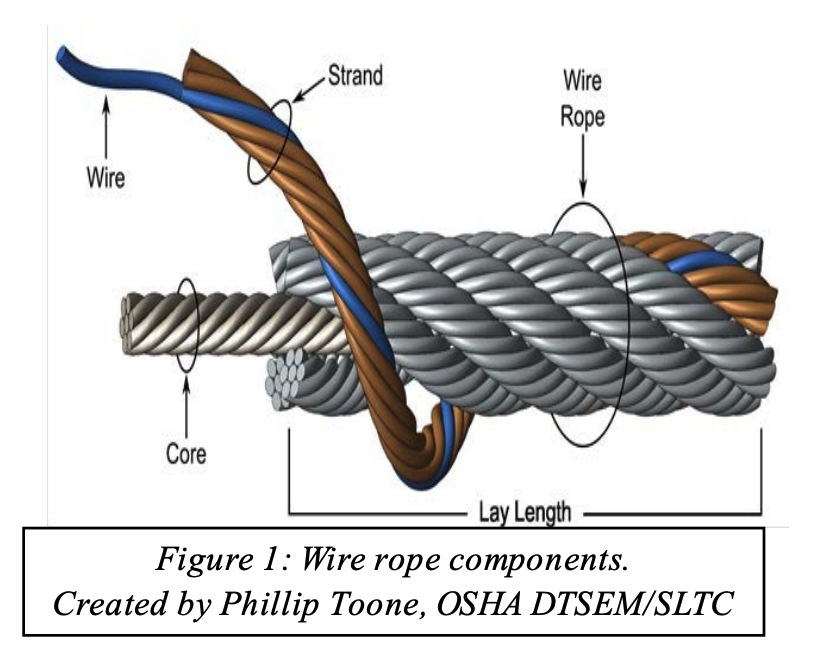

Core slippage or protrusion is caused by shock load or improper installation of the wire rope. Excessive torque can cause core slippage that forces the outer strands to shorten. The core will then protrude from the rope. Wire ropes designed to be rotation-resistant should be handled carefully so as not to disturb its lay length.

Corrosion breaks cause pitting on the individual wires that comprise the rope. This type of damage is caused by poor lubrication. However, corrosion breaks are also caused by the wire rope coming into contact with corrosive chemicals, such as acid.

There are many ways the strands of a rope can be crushed or flattened. Improper installation is a common cause. To avoid crushing, you’ll want the first layer of the wire rope to be very tight. You’ll also need to properly break-in a new wire rope. Other causes of crushing include cross winding, using a rope of the wrong diameter, or one that it too long.

Cracks to individual wires are caused by fatigue breaks. Fatigue breaks happen because the wire rope is being bent over the sheave over and over again. In time, the constant rubbing of the wire rope against the sheave or drum causes these breaks. Sheaves that are too small will accelerate fatigue breaks because they require more bending. Worn bearings and misaligned sheaves can also cause fatigue. A certain number of broken wires is acceptable. The worker responsible for equipment inspection prior to use should know the American Society of Mechanical Engineers (ASME) standard for wire ropes. The ASME standard determines whether the wire rope must be replaced. (https://www.asme.org/)

Selecting the right wire rope for the job is critical. There is never a perfect rope. For example, you will need to make a tradeoff between fatigue resistance and abrasion resistance. There are several aspects to wire rope design to consider, including:

In general, the proper wire rope will have a strength rating high enough to handle the load. (Strength is rated in tons.) It can handle the stress of repeated bending as it passes over sheaves or around drums. How you attach the rope in preparation for the lift matters and should only be handled by properly trained workers.

The wire rope (and all the equipment involved in a lift) should be fully inspected prior to the lift. The worker performing the inspection should be well-versed in the types of damage that can cause a wire rope to fail. Using a checklist is highly recommended. This will ensure that the inspection is complete. Worker and supervisor signoff will increase accountability. Of course, the wire rope must be maintained according to the manufacturer’s instructions.

How a wire rope is stored, the weather conditions in which it is used, and how they are cleaned all affect its useful life. The Occupational Safety and Health Administration (OSHA) provides these recommendations: (Source: https://www.osha.gov/dsg/guidance/slings/wire.html)

Preventing wire rope failures starts with selecting the right one for the job. When in doubt, talk with your local equipment dealer. Be prepared to discuss your specific job requirements. A thorough inspection of the wire rope prior to using it is critical. Finally, properly store your wire rope. The selection, inspection, and care of wire rope is key to job safety.

In 1998, a crane load line broke while lifting the south topside module of the Petronius platform, dropping the module into the Gulf of Mexico. The cost was estimated to be around 116 million US dollars. Since 1999 more than 60 people have been killed as a result of wire ropes breaking and more than 65 associated injuries.

Not many people appreciate that there are literally thousands of wire rope designs, most of which can be put into a specific category. According to BS ISO 4309 2010 there are currently more than 25 categories of crane wire rope, each with differing characteristics and also different discard criteria. Deterioration can be measured, counted or calculated and the wire rope eventually taken out of service based on sophisticated discard criteria published in chosen standards, codes of practice or users handbooks.

Unfortunately there is no simple answer to either of these questions. All wire ropes will eventually break due to corrosion, wear or fatigue even if they are maintained and used properly. Unpredictable wire rope failures will inevitably occur, quite often when you least expect it if the discard criteria is ignored, or those using the equipment are ignorant of it.

James Dawes of Topeka, Illinois, was killed in 2008 after being struck by the boom of a Link-Belt crane; the accident was caused by the boom hoist wire rope breaking. The crane rope had been inspected, but a report said that the inspector failed to reject the rope showing a high number of visible wire breaks. Premature or unexpected wire rope failures can also be attributed to poor manufacture, incorrect handling and storage, poor installation technique, poor selection or fitting of its termination, infrequent or inadequate inspection and poor maintenance. Of course there is always the possibility that mechanical damage can occur and this is usually attributed to human error.

It is necessary, particularly during offshore operations that frequent inspections are carried out over the whole length of the working part of all steel wire ropes. The frequency of inspections should be based on the severity of use and risk assessment and particular attention should be paid to the critical areas of the wire rope; areas that are frequently running over sheaves, compensating sheaves and the rope termination to name a few.

If a wire rope has not been subjected to an abnormal environmental condition such as excessive heat, chemical attack or any corrosive solution and it has not been the victim of any form of mechanical damage, then trained operatives and inspectors can reasonably predict the length of time the steel wire rope is likely to last. That prediction, of course, will be dependent on the knowledge and experience of those making it coupled with known facts about the rope, its current condition and the application it is running on. The Inspector should be aware of the previous rope’s history, capacities of loads and the reeving systems employed together with the frequency of use etc.

Various standards and codes of practice have been written by recognized bodies and institutes based on the experience of experts or representatives of corporate organizations who have a vested interest. These standards do offer guidance on when a wire rope should be removed from service based on wear, abrasion and fatigue amongst others things, but none of these standards have any legal status except when they are called up by contract. Indeed they can all be supported or overturned in a court of law by an expert.

The users handbook, or more importantly the safe use instructions do have legal status. In many parts of the world these days, suppliers of cranes or any machinery for that matter, issue safe use instructions with new equipment. Modern applications employ modern wire rope and, in some cases, sheaves and pulleys that are made with materials other than steel. Original equipment manufacturers of such applications may impose discard criteria for the wire rope that is stricter than those in chosen standards. By law the user must follow manufacturers’ instructions.

Wire ropes will deteriorate much more quickly if they go dry and are allowed to remain in that condition. Tests have proven that a dry rope will lose up to 60 % of its expected life if it is not re-lubricated. There are differing schools of thought as to how wire rope should be lubricated. Some believe that a thin lubricant should be applied using a paintbrush. It is thought that this method allows the lubricant to penetrate. Experience has proven however, that thin penetrative lubricants will easily drain away or fly off in hot climates.

Another school of thought, and the one I stand on, is that grease should be pressure lubricated into the rope. This method, if applied properly, will ensure that the grease penetrates the rope pushing out the old lubricant with it and any possible corrosive agents such as salt water and sand. Any lubricant that is used must be compatible with the type that was applied previously and it is a good idea to consider the environment as well.

In any event, wire ropes usually announce that they are about to break. A series of individual wire breaks can be heard. These are likely to go on over several seconds and continuing for up to ten minutes before ultimate failure. Therefore, if operatives understand the warning signals, expensive incidents could be avoided.

Figure 2 shows two pieces of the same rope, the bottom portion quite clearly shows a progression of wire breaks. The operator was able to put the load down before disaster struck. The root cause of this fault was core deterioration brought about by internal corrosion.

To answer the other question on accountability, the list is extensive. Usually the first suspect is the wire rope manufacturer and that may be where the problem lies, but very often that is not the case. What if you were supplied the wrong rope for the application? Maybe you ordered the wrong rope or your buyer bought it from a cheap unapproved manufacturing source.

Perhaps your supplier is responsible, maybe he provided you with a rope that was produced to the wrong specifications. Would you know the difference? Perhaps you were sold a rope that had been stored in the suppliers or manufactures stock for a number of years and, whilst it was there, it hadn’t been properly maintained. Maybe the rope had been badly handled or installed incorrectly. The list of possibilities is endless.

In 1999 a ropeway in the French Alps snapped causing 21 deaths. In 2003, a ropeway wire rope snapped and 7 people died and a further 42 were injured. In 2007 a crane wire rope snapped at New Delhi’s metro, the entire structure tumbled down crushing workers underneath, six people were killed and 13 more were injured. In 2009 26 people were killed and 5 people were injured when a rope failed in a mine and a further 6 people were injured when a lift rope broke inside London’s Tower Bridge.

If you find yourself in the unfortunate situation after the unthinkable premature failure of a wire rope, then you might like to know that there are independent analytical services capable of determining probable cause. One of these is Doncaster Analytical Services Ltd (DAS), they have an independent metallurgical laboratory providing factual analysis and testing of wire rope for any reason (contact Mr Shui Lee, Technical Director, Tel +44(0)1302 556063, email: shui.lee@doncasteranalyticalservices. com).

You do not need a wire rope to fail in order to learn. Careful analysis of discarded ropes can also give you valuable information about your application, the way it operates, and the rope you have been using.

Based on this information, a trained, skilled and experienced inspector will be able to advise on a better crane or wire rope design, or to an improvement in maintenance procedures and safety.

A failure analysis of a broken multi strand 71mm steel wire rope used in the main towing winch was carried out. The wire rope was failed during a bollard pull test. The wire rope was a new one and had failed during the first use. The wire rope was in IWRC/ RHO 6X41 constructions. Fig.1 shows the typical cross section of the wire rope. The failure investigation is performed by chemical and metallurgical examinations.

(ii) the uniformity and cleanliness of the microstructure of the rope steel and the effect of microstructure on crack initiation and propagation, and

1) Chemical analysis of steel wire rope is presented in Table 1. The analysis showed that it is made of high carbon steel corresponding to AISI 1074 grade, and galvanized with zinc to resist corrosion.

2) The microstructure observed under optical microscope and is shown in Figs. 2. It was typical of a drawn ferrite–pearlitic steel wire with heavily cold worked micro structure. Further examination of microstructure of the failed wires did not indicate any sign of metallurgical problems such as de- carburized layer, nonmetallic inclusions, or martensite formation. In addition, the wires were free from any sort of corrosion and pitting. Therefore, corrosion had no role in the failure of wires.

4) Table 3 represents the tensile values of the wire. The result indicates relatively less value comparing the metallographic results and the mill test certificate supplied by the Client. Figs. 3 showing Stress- Strain during tensile testing of the wire

The high hardness values, chemical composition, and the pearlitic structure of wires indicating that this is a type of extra extra improved plow steel (EEIPS) grade wire ropes. These types of wires have typically higher load-bearing capacity as compared with other grades. They are considered as heavy-duty wire ropes. The minimum tensile strength of EEIPS is 2160 N/mm2. (Ref. API Spec 9A)

5) The fractured ends of group of wires were visually inspected. Majority of wires failed in shear, and the remaining had cup-and-cone fracture, some of which are shown in Fig. 4.

Fractographs of broken wires in the form of cup and cone and shear are shown in Fig. 5 and Fig.6. Tensile overload fracture occurs when the axial load exceeds the breaking strength of the wires. This type of fracture usually appears in ductile manner, either in the form of cup and cone or in shear mode. In the former case, there is a reduction at the fracture which is called necking, whereas in the case of the latter, fracture surface is inclined at 45degree to the wire axis. In both cases, ductile dimple formations are clearly observed and confirm the tensile overloading of wires.

Every wire rope failure will be accompanied by a certain number of tensile over load breaks. The fact that tensile overload wire breaks can be found therefore necessarily mean that the rope failed because of an overload. The rope might have been weakened by fatigue breaks. The remaining wires were then no longer able to support the load, leading to tensile overload failures of these remaining wires.

Only if the metallic area of the tensile overload breaks and shear breaks combined is much higher than 50% of the wire rope’s metallic cross section is it likely that the rope failed because of an overload.

Shear breaks are caused by axial loads combined with perpendicular compression of the wire. Their break surface is inclined at about 45degree to the wire axis. The wire will fail in shear at a lower axial load than the pure tensile over load.

If a steel wire rope breaks as a consequence of jumping a layer or being wedged in, a majority of wires will exhibit the typical 45degree break surface.

In the instant case the wire rope was failed at 100 Ton or even less. As the breaking load of the wire rope is 353 Tons, there is no reason for a tensile over load breaks in an axial direction and that too considering the fact that the wire rope was failed during a bollard pull test. Fig. 7 shows the maximum stress generations in the wire rope at 100 Ton under normal bollard pull test. More over the metallurgical investigation is also not suggesting for any factors that fostering an axial overload failure.

The failure of the wire rope was studied in detail. In order to investigate the problem metallurgical and mechanical post failure analyses were performed. The wire rope was made of AISI 1074 grade steel, and it was a type of EEIPS. The microstructure was composed of severely deformed and elongated ferrite–pearlite, and no other phase formation or nonmetallic inclusions could be detected. The morphologies of fractured surfaces indicated that the wires were mainly failed in shear mode and few in tensile mode. Owing to galvanized coating, the wires were free from corrosion.

The tensile strength of the wire material is less than the required value. The required tensile strength of EEIPS is 2160 N/mm2 and the obtained value is 2059 N/mm2. But this factor is not a reason for the current failure of the wire rope. The said point is substantiated by the following:

It is concluded that the wire rope was failed due to shear breaks. Shear breaks were caused by high axial loads combined with perpendicular compression of the wire. It is worthwhile to note that the rope was failed in its first usage. The shear break is linked to the lapses during the installation/ spooling of the wire rope.

b) Lack of pretension of lower rope layers during spooling. In the absence of proper pretension the upper layers might be pulled in between the lower layers during loading.

c) Under high tension, the rope tends to be as round as possible. With no load, a rope can be deformed and flattened much easily. Highly tensioned upper layers will therefore severely damage loose (and therefore vulnerable) lower layers.

A customer recently contacted us to reorder the wire rope component of their Electrolifttwin hook monorail hoist. While the hoist was only a year old, they had replaced the wire rope twice within six months. They sent a picture of the damaged rope and asked for reasons why the wire rope was failing.What’s killing my wire rope?

It’s important to note that the wire rope used for hoists and overhead cranes is specially made of extra flexible Improved Plow Steel (IPS). It’s considered superior in durability and tensile strength (bending) to standard, everyday wire rope.

When properly sized and lubricated, a wire rope should last for years, even with frequent use. Wire rope hoists are recommended for heavy duty applications, high frequency usage and where long lifts are needed.

The Answer:Most likely, there’s a problem with how the hoist is operated. Wire rope failure is almost always due to operator error. By design, hoist hook blocks must be raised and lowered straight up and straight down, and the wire rope cable wraps around the drum, within the grooving, in one layer. In the course of picking up a load, if the operator side pulls the rope by more than about three degrees from vertical, the wire rope will jump the drum’s grooves.

Once the grooves are jumped, the operator must realize the error and stop using the hoist immediately. To correct the issue, the load must be lowered and the wire rope must be allowed to return it to the correct drum grooves. If the operator continues to use the hoist with the wire rope piled up at one end of the drum, the rope gets pinched and the cable can become damaged. Also in the course of usage, if the cable goes slack and the wire rope jumps over the drum guard, it could get caught between the drum and the shaft, and the wire rope could fail.

To prevent this problem, we recommend operator training classesand regular inspection of the unit. Every shift should start with an examination of the rope by lowering the hook all the way down. If the rope is damaged, including even one strand broken, stop the process and get the rope replaced. We recommend keeping spare ropes in stock to avoid downtime and

Mechanical damage caused by the rope contacting the structure of the crane on which it is operating or an external structure—usually of a localized nature.Generally results from operational conditions.

Note—Rotation Resistant ropes are designed with a specific strand gap which may be apparent on delivery in an off tension condition. These gaps will close under load and will have no effect on the operational performance of the rope.Check sheave and drum groove radii using sheave gauge to ensure that they are no smaller than nominal rope radius +2.5%—Bridon recommends that the sheave and drum groove radii are checked prior to any rope installation.

Check if the rope has been cut “on site “ prior to installation or cut to remove a damaged portion from the end of the rope. If so, was the correct cutting procedure used? Incorrect cutting of Rotation Resistant, low rotation and parallel closed ropes can cause distortion in operation.

Wire breaks usually resulting from crushing or abrasion.Check tension on underlying layers. Bridon recommends an installation tension of between 2% and 10% of the minimum breaking force of the wire rope. Care should be taken to ensure that tension is retained in service. Insufficient tension will result in these lower layers being more prone to crushing damage.

“Pigtail” or severe spiralling in rope.Check that the sheave and drum diameter is large enough— Bridon recommends a minimum ratio of the drum / sheave to nominal rope diameter of 18:1.

Two single axial lines of broken wires running along the length of the rope approximately 120 degrees apart indicating that the rope is being “nipped” in a tight sheave.Check sheave and drum groove radii using sheave gauge to ensure that they are no smaller than nominal rope radius + 2.5%—Bridon would recommend that the sheave / drum groove radii are checked prior to any rope installation.

One line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving.Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter.

Fatigue induced wire breaks are characterized ends by flat on the broken wires.Bending fatigue is accelerated as the load increases and as the bending radius decreases. Consider whether either factor can be improved.

Fatigue induced wire breaks are characterized ends by flat on the broken wires.Bending fatigue is accelerated as the load increases and as the bending radius decreases. Consider whether either factor can be improved.

Localized fatigue breaks indicate continuous repetitive bends over a short length. Consider whether it is economic to periodically shorten the rope in order to move the rope through the system and progressively expose fresh rope to the severe bending zone. In order to facilitate this procedure it may be necessary to begin operating with a slightly longer length of rope.

Broken rope—ropes are likely to break when subjected to substantial overload or misuse particularly when a rope has already been subjected to mechanical damage.

Corrosion of the rope both internally and/or externally can also result in a significant loss in metallic area. The rope strength is reduced to a level where it is unable to sustain the normal working load.Review operating conditions.

Wave or corkscrew deformations normally associated with multi-strand ropes.Check sheave and drum groove radii using sheave gauge to ensure that they are no smaller than nominal rope radius +2.5%—Bridon recommends that the sheave / drum groove radii are checked prior to any rope installation.

Rope accumulating or “stacking” at drum flange— due to insufficient fleet angle.Review drum design with original equipment manufacturer—consider adding rope kicker, fleeting sheave, etc.

Check tension on underlying layers—Bridon recommends an installation tension of between 2% and 10% of the minimum breaking force of the wire rope—Care should be taken to ensure that tension is retained in service. Insufficient tension will result in these lower layers being more prone to crushing damage.

Review rope selection. The smooth surface of Dyform wire ropes gives better contact with drum and sheaves and offers improved resistance to “interference” between adjacent laps of rope.

Rigging machines like cranes use various components to operate, including a wire rope. Proper choice, installation, use, and maintenance are essential to keep the rope in top condition for a longer time. However, even with appropriate care, it will eventually reach its end of life, as it’s still an object prone to natural wear and tear.

There are various causes of wire rope damage, and you must be familiar with them as a crane owner. It helps determine an issue on the first sign and act on it immediately before it leads to failure. Neglecting it may cause injuries, property damage, and delay in the business operation. Check out some of the common causes of wire rope problems below.

Improper wire contact to the drum, sheave or other objects can cause abrasion damage. Other causes include incorrect rope size, wrong fleet angle, poor spooling, and frozen rollers. Signs of this damage are worn ends as thin as the edge of a knife. Prevent this problem by ensuring proper installation and using the right wire rope size.

You would see the corroded part externally, but it would be hard to tell the extent of the damage through the naked eye, thus making it more dangerous. Some of the causes of corrosion damage are improper lubrication, exposure to substances like acid, and improper storage. Store equipment appropriately and ensure proper lubrication to prevent corrosion on wire rope. If you want to ensure that it is still safe for use, consult an expert like a service provider specialising in PM, ATLAS, and Hyva cranes. If the rope needs replacement, they can also advise the right one to use and help with proper installation.

The repetitive rubbing of the wire rope on the sheave and drum could cause damage due to fatigue. It’s one of the easiest to detect because you can immediately see it with your naked eyes. Individual wires would break, making them weak and eventually affecting the other wires, then leading to failure. Excessive rubbing may be due to vibration, worn bearings, and incorrect rope diameter. Prevent these issues to avoid premature failure due to fatigue.

The kinking of wire ropes could be due to improper unreeling of the rope, incorrect sheave size, and poor rope installation. Be sure to choose the correct sheave size that matches your rope. Moreover, ensure that you unreel and install it the right way. Looped wires also have similar causes.

Carrying a load more than its capacity can cause the wire rope to break due to tension. You will see cuts on the individual wires on one end. Consider the load limit of the rope, and ensure that you stay within that limit to extend its life.

This is characterised by the rope’s core protruding out. One of its causes is unwanted rope twists, which may occur with improper installation. Poor seizing methods and shock loading are also other possible causes.

To optimise the life of the rope and minimise the risk of failure, it needs to be carefully selected for its operating environment and must be appropriately maintained and regularly inspected. Thus, the Skuld P&I Club, in contribution with Graham Cooper, Hawkins & Associates, Singapore, has issued advisory on metal wire rope operations.

The correctly selected rope that has been appropriately operated and maintained, has not been damaged and has been regularly inspected should provide safe and trouble free service. However, it must be withdrawn from service before it becomes degraded to the point where its safety becomes compromised.

In order for the rope to work efficiently as part of a lifting or winching system, it needs to be of appropriate strength, construction and diameter. It’s very important that the rope not only has the required minimum braking strength, but is also of the correct size and construction. The diameter of the rope must be matched to the groove dimensions of the sheaves that it will be passing over and it must have appropriate flexibility, which is expressed in terms of its minimum bend radius, to suit the diameter of those sheaves.

As a rule of thumb, the greater the diameter of the rope, the greater it’s minimum bend radius. That means that a larger diameter rope cannot automatically be substituted for a smaller diameter rope, even though it may have a greater breaking strength, since its minimum bend radius may be greater than the radius of the sheaves over which it is required to operate. That will lead to over-bending of the rope, which will increase the fatigue loading on it, reducing its service life. Similarly, if the rope diameter is not correctly matched to the sheave groove dimensions, i.e. it is too large or too small, then the load on the rope will be concentrated at certain points on its circumference, rather than being spread evenly around its circumference. That will also increase the fatigue loading on the rope and so reduce its service life.

Fatigue causes individual wires to break one by one, usually over an extended period of service, rather than causing a sudden, catastrophic failure of the rope. As the number of broken wires increases, the residual strength of the rope is reduced so that it will eventually break under normal service loads. Fortunately, the tell-tale signs of fatigue damage are relatively easy to identify, since broken wires can often be seen with the naked eye or will protrude from the rope. Hence, any rope exhibiting broken or protruding wires should be treated as suspect and removed from service.

Wear and corrosion are both progressive degradation mechanisms that can be very damaging to metal wire ropes and are often the life-limiting factors. Both can be greatly reduced, but not eliminated entirely, by appropriate and regular lubrication of the rope. It is therefore very important that wire ropes are appropriately lubricated and checked on a regular basis, particularly where they are operating in arduous conditions, such as a marine environment. This is quite challenging as the method of lubrication must ensure that the interior of the rope is properly lubricated. Simple greasing of the surface is not adequate and methods such as pressurised grease application need to be used. If this is not done correctly, a rope can suffer significant internal wear, caused by the rubbing together of individual wires as the rope passes over sheaves, drums etc..

Visual assessment of the rope may indicate damage or degradation, such as wear or corrosion, in the outer layer. However, it won’t identify damage or degradation of the internal core. To evaluate the internal condition of the rope, it is necessary to use non-destructive testing techniques.

Any wire rope failure is a serious and potentially life threatening event. Fortunately, such failures are relatively rare, but if a failure does occur, it is important that it is investigated thoroughly to determine the cause and from that, identify what went wrong. To fully investigate a failure, it is necessary to gather as much information as possible at the time. That should include photographing the damage before anything is disturbed, interviewing witnesses and obtaining maintenance records etc.. The rope itself should then be examined by a specialist, which may include laboratory examination and testing, to determine the mode of failure. Once that cause of the failure has been established, it is important that lessons are learned from it and changes to working practices, maintenance procedures etc. are implemented to ensure that it does not happen again.

Wire breakshowsone end of broken wire coned, the other cupped. Necking down of the broken ends is typical of this type of break.Where tension breaks are found, the rope has been subjected to overloading, either for its original strength (new rope) or for its remaining strength in the case of a used rope. Tension breaks frequently are caused by the sudden application of a load to a slack rope, thereby setting up incalculable impact stresses.

Wire break shows broken ends worn to a knife-edge thinness.Abrasive wear obviously is concentrated at points where the rope contacts an abrasive medium, such as the grooves of sheaves and drums, or other objects with which the rope comes into contact. Unwarranted abrasive wear indicates improperly grooved sheaves and drums, incorrect fleet angle, or other localized abrasive conditions.

Wire breaksareusually transverse orsquareshowinggranularstructure.Oftenthese breaks will develop a shattered orjagged fracture, depending on the type ofoperation.Where fatigue breaks occur, the rope has been bent repeatedly around too small a radius. Whipping, vibration, slapping and torsional stresses also will cause fatigue. Fatigue breaks are accelerated by abrasion and nicking.

Easily noted by the wire"s pitted surface, wire breaks usually show evidence of tension, abrasion and/or fatigue.Corrosion usually indicates improper lubrication. The extent of the damage to the interior of the rope is extremely difficult to determine; consequently, corrosion is one of the most dangerous causes of rope deterioration.

Wirewill be pinched down and cut atbroken ends, or will show evidence of ashear-like cut.This condition is evidence of mechanical abuse caused by agents outside the installation, or by something abnormal on the installation itself, such as a broken flange.

Wire rope and cranes are joined at the hip when endeavoring to lift, move or transport materials. For centuries the combination of rope (sisal, manila, vegetable, steel, synthetic…) and a winching system have stirred the imagination of engineers and other interested persons in aiding the lifting and handling of heavy objects.

Giant strides in the development of the “crane and rope” system have led to unimaginable progress in leaps and bounds in today’s world. One thing that has remained constant over many decades is the fact that all types of rope used on cranes do eventually wear our and must be replaced.

This article focuses on actual wire rope failures, or near failures, that have occurred. The fact that all wire ropes on a crane will deteriorate over periods of operation is a universal truth, but the useful service life of wire rope will vary according to applications, operating conditions, working environment, type of crane, crane operator and other factors. Therefore, it is a necessity that proper inspection, maintenance and retirement criteria be firmly established to achieve safe and efficient working conditions.

When a wire rope on a crane fails, traumatic consequences will likely follow. At the very least, equipment damage and downtime will ensue, but more importantly lives many times are lost. These wire rope failures are mostly, not because of structural causes, but from human error, neglect, lack of training or not following known instructions. In my experience, the three main reasons for wire rope failures on cranes are misuse, abuse and overuse.

Wire ropes, pulleys, counterweights, and connecting systems are used for auto tensioning of contact wires of electric railways. A wire rope in one such auto tensioning system suffered premature failure. Failure investigation revealed fatigue cracks initiating at nonmetallic inclusions near the surface of individual wire strands in the rope. The inclusions were identified as Al-Ca-Ti silicates in a large number of stringers, and some oxide and nitride inclusions were also found. The wire used in the rope did not conform to the composition specified for AISI 316 grade steel, nor did it satisfy the minimum tensile strength requirements. Failure...

Wire ropes, pulleys, counterweights, and connecting systems are used for auto tensioning of contact wires of electric railways. A wire rope in one such auto tensioning system suffered premature failure. Failure investigation revealed fatigue cracks initiating at nonmetallic inclusions near the surface of individual wire strands in the rope. The inclusions were identified as Al-Ca-Ti silicates in a large number of stringers, and some oxide and nitride inclusions were also found. The wire used in the rope did not conform to the composition specified for AISI 316 grade steel, nor did it satisfy the minimum tensile strength requirements. Failure...

8613371530291

8613371530291