wire rope inspection course quotation

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

Troubleshooting: Please double-check your spelling and try again OR Visit our Featured Courses page for popular courses OR Try a similar but different search item, like FOET instead of F.O.E.T. OR The course may be unavailable in the country you have chosen OR Contact your local training centre for help.

Objective: This training is aimed at persons who directly or indirectly come into contact with wire ropes and should always be available to them. They should ease the proper handling of wire ropes and convey the necessary expertise. Compliance with the instructions in the training should ensure the safe handling of wire ropes and help to prevent dangers and minimize repair costs and downtimes.

EN10264-2: 2012-3 Steel wire and wire products - Steel wire for ropes - Part 2: Cold-drawn non-alloy steel wire for ropes for general applications. Changes to the machine as well as non-observance of the regulations from

Rigging inspector training has been provided by ITI for 30 years. The training curriculum heavily focuses on wire rope inspection, hoist rope inspection, chain sling inspection, and hardware inspection.

The original Rigging Gear Inspector Course is designed to build or enhance the skills of the student to become a qualified, in-house rigging gear inspector. The three-day course includes classroom workshops and multiple hands-on inspection activities.

Participants learn hands-on with detailed study of rigging gear compliance and rejection criteria so they are capable of recognizing damaged gear and removing it from service before it creates an unsafe condition. Personnel learn how to perform periodic inspections that includes how the accumulation of minor issues may result in unsafe equipment.

This training includes nearly a hundred slings and rigging components with varying degrees of deficiencies. Each inspector candidate will learn hands-on how to inspect and document all the deficiencies found on each component. Technical training ensures each inspector has the knowledge required to perform a comprehensive inspection.

To ensure that rigging gear and sling inspectors have the knowledge and skills required to recognize equipment deficiencies during a periodic inspection.

To ensure that all personnel with inspection responsibilities are knowledgeable of required standards and manufacturer’s information necessary for a comprehensive inspection.

We provide an impartial inspection service for ropes courses and adventure parks and pride ourselves on our wealth of experience and knowledge within the industry. Having been instrumental in developing the recognised European standards (EN-15567 Part 1 &2) & UK Ropes Course Guide 2015, we provide reputable, reliable and referenceable information and impartial support that can help you optimise the operations of your ropes course.

Whether it is an existing course requiring an annual inspection, or guiding you through the inaugural inspection process of a newly built ropes course, we have the professional & personable team to help you through the process.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

We offer you a wire rope inspection course which is especially designed for the working field of ropes courses. The course was developed in the UK, because there had been nothing comparable in the industry.

The 2-day course will provide attendees with sufficient theoretical and practical knowledge to inspect cable in a ropes course and to understand when wire ropes should be retired. On day one, a more theoretical session will be delivered covering such topics as types of wire rope construction, wire rope fatigue, wire rope abrasion, wire rope corrosion, lightening and other damage. The second day will reflect inspection of wire rope in a more practical way and according to the ISO 4309: 2013 with its criteria for retiring cable.

We will provide you with a script. There is an assessment at the end of the course. After the course a certificate will be issued to all those who successfully complete the written and practical assessments.

This course is part of our pre-conference trainings, so please only use the Online Registration Form. This registration form will enable you to book pre-conference training courses, to register for main conference presentations & workshops, to order meals, reserve a seat in a shuttle bus and to send a room reservation inquiry – all within a single form.

Objective: The training is intended to provide personnel with good theoretical and practical basic training in the use and maintenance of steel ropes.

The course provides a thorough introduction to knowledge about steel ropes, the correct use / choice of steel ropes and what requirements are set for those who use and control steel ropes.

Anyone who is to use work equipment as mentioned in §10-1 and §10-3, must have practical and theoretical training that provides knowledge of construction, operation, use properties and area of use, as well as maintenance and control.

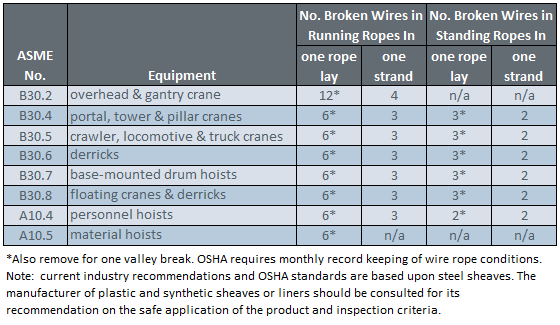

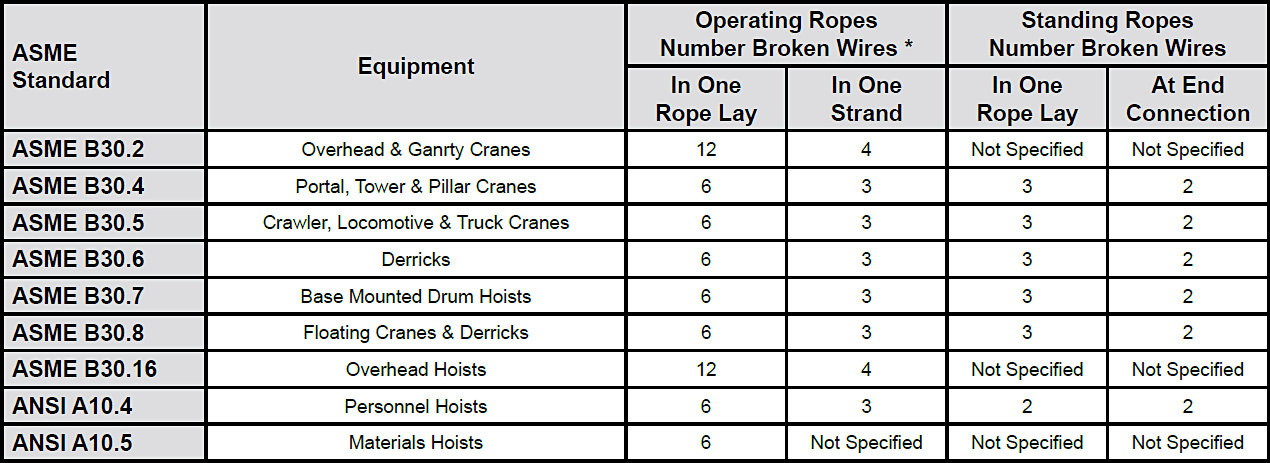

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

The Rigging Box, Inc. has developed a basic rigging safety and inspection course in order to insure a safe and productive work place for your organization. The purpose of this course is to communicate fundamental skills critical to safe rigging and material handling safety. The course will cover lecture, PowerPoint’s, video, practical applications and can be tailored to cover your rigging techniques relevant to your operation. We have tactfully combined OSHA 1926.251 and EM-385 section 15 in order to keep your employees up to date on current regulations. Please be advised that OSHA 1926.251 and ANSI B.30.9 are now requiring individuals involved with the use of rigging and rigging hardware to be trained in the proper use and inspection criteria.

8613371530291

8613371530291