wire rope inspection osha brands

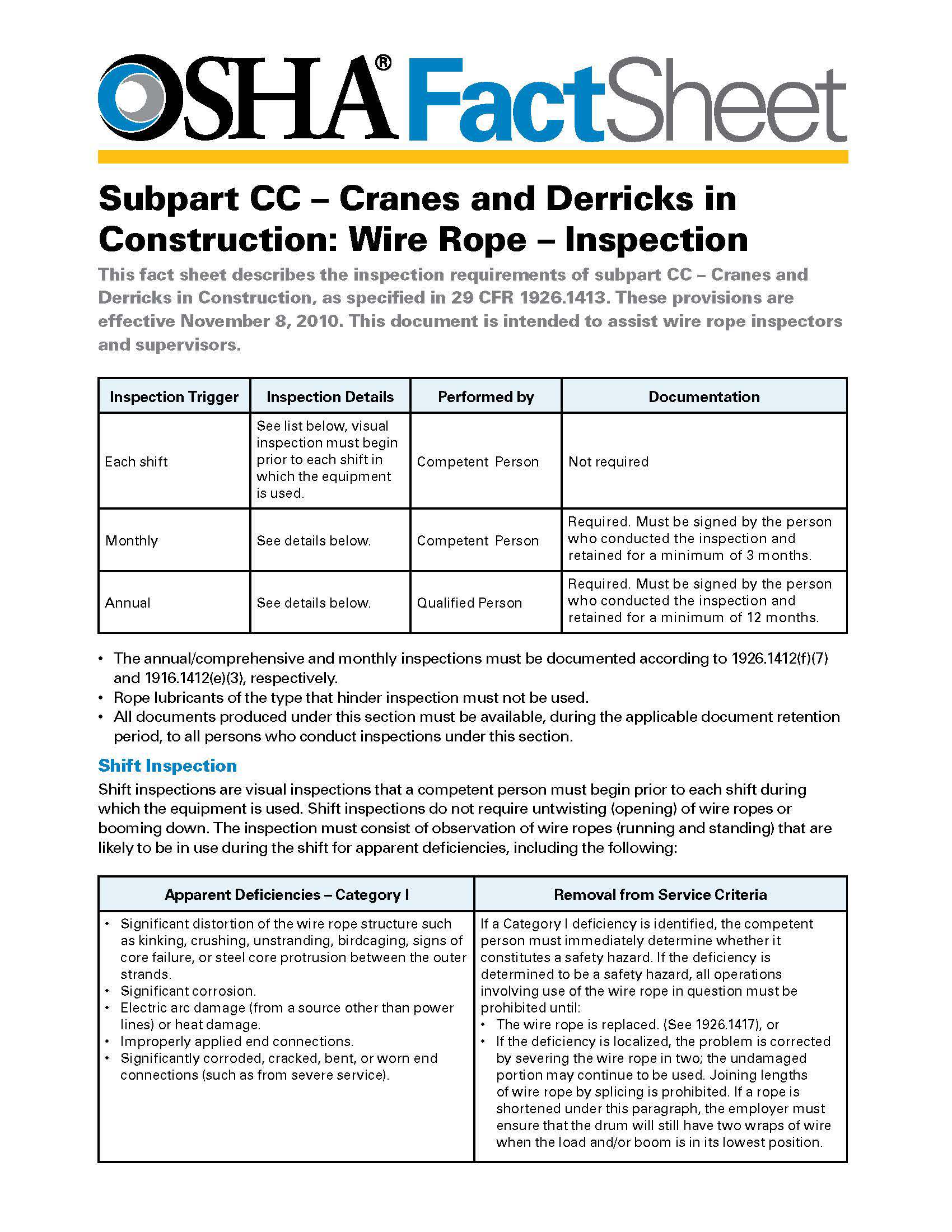

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

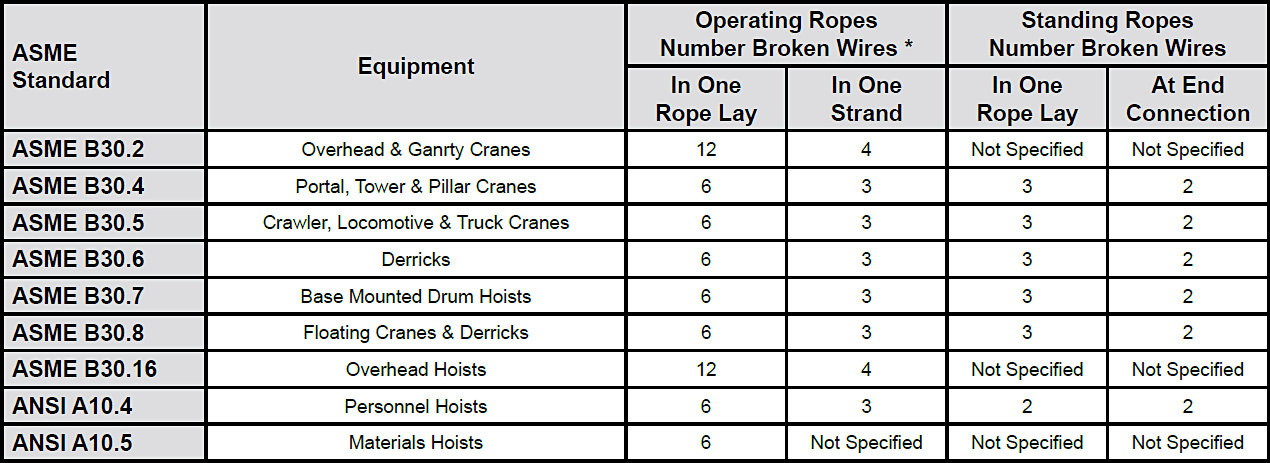

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Inspections. Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

In addition to the inspection required by other paragraphs of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of (A) frequency of sling use; (B) severity of service conditions; (C) nature of lifts being made; and (D) experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.

Employers must not use improved plow-steel wire rope and wire-rope slings with loads in excess of the rated capacities (i.e., working load limits) indicated on the sling by permanently affixed and legible identification markings prescribed by the manufacturer.

An eye splice made in any wire rope shall have not less than three full tucks. However, this requirement shall not operate to preclude the use of another form of splice or connection which can be shown to be as efficient and which is not otherwise prohibited.

Except for eye splices in the ends of wires and for endless rope slings, each wire rope used in hoisting or lowering, or in pulling loads, shall consist of one continuous piece without knot or splice.

Wire rope shall not be used if, in any length of eight diameters, the total number of visible broken wires exceeds 10 percent of the total number of wires, or if the rope shows other signs of excessive wear, corrosion, or defect.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F (93.33 °C). When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F (204.44 °C) or below minus 60 °F (15.55 °C), recommendations of the sling manufacturer regarding use at that temperature shall be followed.

Wire rope slings shall have permanently affixed, legible identification markings stating size, rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, and the number of legs if more than one.

Employers must not use natural- and synthetic-fiber rope slings with loads in excess of the rated capacities (i.e., working load limits) indicated on the sling by permanently affixed and legible identification markings prescribed by the manufacturer.

In manila rope, eye splices shall contain at least three full tucks, and short splices shall contain at least six full tucks (three on each side of the centerline of the splice).

In layed synthetic fiber rope, eye splices shall contain at least four full tucks, and short splices shall contain at least eight full tucks (four on each side of the centerline of the splice).

Strand end tails shall not be trimmed short (flush with the surface of the rope) immediately adjacent to the full tucks. This precaution applies to both eye and short splices and all types of fiber rope. For fiber ropes under 1-inch diameter, the tails shall project at least six rope diameters beyond the last full tuck. For fiber ropes 1-inch diameter and larger, the tails shall project at least 6 inches beyond the last full tuck. In applications where the projecting tails may be objectionable, the tails shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F (-28.88 °C) to plus 180 °F (82.2 °C) without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under 1 inch (2.54 cm) in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope 1 inch (2.54 cm) in diameter and larger, the tail shall project at least 6 inches (15.24 cm) beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Employers must use natural- and synthetic-fiber rope slings that have permanently affixed and legible identification markings that state the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Original equipment wire rope and replacement wire rope must be selected and installed in accordance with the requirements of this section. Selection of replacement wire rope must be in accordance with the recommendations of the wire rope manufacturer, the equipment manufacturer, or a qualified person.

Wire rope design criteria: Wire rope (other than rotation resistant rope) must comply with either Option (1) or Option (2) of this section, as follows:

Option (1). Wire rope must comply with section 5-1.7.1 of ASME B30.5-2004 (incorporated by reference, see § 1926.6) except that section"s paragraph (c) must not apply.

Option (2). Wire rope must be designed to have, in relation to the equipment"s rated capacity, a sufficient minimum breaking force and design factor so that compliance with the applicable inspection provisions in § 1926.1413 will be an effective means of preventing sudden rope failure.

Type I rotation resistant wire rope ("Type I"). Type I rotation resistant rope is stranded rope constructed to have little or no tendency to rotate or, if guided, transmits little or no torque. It has at least 15 outer strands and comprises an assembly of at least three layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type II rotation resistant wire rope ("Type II"). Type II rotation resistant rope is stranded rope constructed to have significant resistance to rotation. It has at least 10 outer strands and comprises an assembly of two or more layers of strands laid helically over a center in two or three operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type III rotation resistant wire rope ("Type III"). Type III rotation resistant rope is stranded rope constructed to have limited resistance to rotation. It has no more than nine outer strands, and comprises an assembly of two layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type I must have an operating design factor of no less than 5, except where the wire rope manufacturer and the equipment manufacturer approves the design factor, in writing.

A qualified person must inspect the rope in accordance with § 1926.1413(a). The rope must be used only if the qualified person determines that there are no deficiencies constituting a hazard. In making this determination, more than one broken wire in any one rope lay must be considered a hazard.

Each lift made under § 1926.1414(e)(3) must be recorded in the monthly and annual inspection documents. Such prior uses must be considered by the qualified person in determining whether to use the rope again.

Rotation resistant ropes may be used as boom hoist reeving when load hoists are used as boom hoists for attachments such as luffing attachments or boom and mast attachment systems. Under these conditions, all of the following requirements must be met:

The requirements in ASME B30.5-2004 sections 5-1.3.2(a), (a)(2) through (a)(4), (b) and (d) (incorporated by reference, see § 1926.6) except that the minimum pitch diameter for sheaves used in multiple rope reeving is 18 times the nominal diameter of the rope used (instead of the value of 16 specified in section 5-1.3.2(d)).

The operating design factor for these ropes must be the total minimum breaking force of all parts of rope in the system divided by the load imposed on the rope system when supporting the static weights of the structure and the load within the equipment"s rated capacity.

Wire rope clips used in conjunction with wedge sockets must be attached to the unloaded dead end of the rope only, except that the use of devices specifically designed for dead-ending rope in a wedge socket is permitted.

Prior to cutting a wire rope, seizings must be placed on each side of the point to be cut. The length and number of seizings must be in accordance with the wire rope manufacturer"s instructions.

Government regulations are specific on when to inspect. Both ASME Standard B30.9 and OSHA require that wire rope slings receive two types of inspections: a daily visual inspection, and additional inspections where service conditions warrant.

Daily visual inspections are intended to detect serious damage or deterioration which would weaken the sling. This inspection is usually performed by the person using the sling in a day-to-day job. The user should look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion, etc.

Additional inspections should be performed at regular intervals based on, (1) frequency of sling use, (2) severity of service conditions. (3) nature of lifts and (4) prior experience based on service life of slings used in similar circumstances.

It is required that these additional inspections be carried out by a designated person who must have good knowledge of wire rope. An accurately written and dated record of all conditions observed shall be maintained. Any deterioration of the sling which could result in appreciable loss of original strength should be carefully noted and determination made on whether further use would constitute a safety hazard.

When an eye is formed in a sling, the rope is formed into a relatively sharp bend to form the eye. This bend increases the clearance between the strands on the outside of the eye and, in some cases, this clearance accumulates between two strands. This is not a reason for concern in a new sling, and the sling is acceptable for use.

Precisely how to make proper, adequate inspections is not detailed by OSHA—yet it is in the knowledge of the inspector that the big difference between a good inspection and something less becomes apparent.

Inspection should follow a systematic procedure:First, it is necessary that all parts of the sling are readily visible. The sling should be laid out so every part is accessible.

Next, the sling should be sufficiently cleaned of dirt and grease so wires and fittings are easily seen. This can usually be accomplished with a wire brush or rags.

A knowledgeable inspector will also insist on proper storage for out-of-use slings—to make his job easier, if not for the good of the slings. Inspections are much easier—and probably more thorough—when slings are available for inspection in an orderly arrangement, out of the weather and away from heat and dirt.

Like any other machine, wire rope is thoroughly lubricated at time of manufacture. Normally, for sling use under ordinary conditions, no additional lubrication is required. However, if a sling is stored outside or in an environment which would cause corrosion, lubrication should be applied during the service life to prevent rusting or corroding.

Do you know who is supposed to be inspecting your lifting slings? More importantly, do you know how often they’re inspecting them? OSHA and ASME have different inspection requirements, frequencies, and removal criteria for each type of sling—including alloy chain slings, synthetic slings, metal mesh slings, and wire rope slings.

At Mazzella, we understand the amount of effort and coordination it takes to stay current on industry standards and to develop an inspection program that keeps your business in compliance. Because of this, we have a dedicated business unit made of up highly-trained and qualified inspectors and technicians that focus only on rigging equipment inspections, industry compliance, and sling testing and repair.

In this article, our goal is to help you understand what is required to inspect wire rope slings to meet ASME standards, which in turn, will help to ensure the safety of the users,help extend the service life of the slings, and help reduce unnecessary equipment repair costs and loss of production due to equipment downtime.

As a starting point, the same work practices which apply to all “working” wire rope apply to wire rope which has been fabricated into a sling. Therefore, a good working knowledge of wire rope design and construction will not only be useful, but essential in conducting a wire rope sling inspection.

There are two industry standards that exist to provide the end-user with guidelines for inspection and criteria that warrants removal from service: OSHA 1910.184 and ASME B30.9.

Initial Inspection (prior to initial use): Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. Double-check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements.

Frequent (daily or prior to use): Designate a Competent Person to perform a daily visual inspection of slings and all fastenings and attachments for damage, defects, or deformities. The inspector should also make sure that the wire rope sling that was selected meets the specific job requirements it’s being used for.

Users can’t rely on a once-a-day inspection if the wire rope sling is used multiple times throughout the day. Damage to wire rope can occur on one lift and best practice is to perform a visual inspection before any shift change or changes in lifting application. Because shock loads, severe angles, sharp edges, and excessive heat can quickly cause damage to a lifting sling, the user should inspect the sling prior to each lift.

Periodic Inspection: A periodic inspection is performed by either a professional service provider, or by a Qualified Person, every 12 months (at a minimum) and monthly to quarterly in more severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:Frequency of use

Depending on the severity of the operating environment and frequency of use, your business may decide to inspect wire rope slings more often than the minimum yearly requirement.

Per ASME B30.9, the wire rope sling tag on all new slings shall be marked by the manufacturer to include:Rated load for the types of hitches (single-leg vertical, choker, and basket) and the angle upon which they are based

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use. When inspecting wire rope slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. The user should look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion, etc. Any deterioration of the sling which could result in appreciable loss of original strength should be carefully noted and determination made on whether further use would constitute a safety hazard.

2. Broken Wires: For strand-laid grommets and single-part slings, ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay. For cable laid, cable laid grommets and multi-part slings, use the following:

3. Distortion: Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope.

7. Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light surface rust does not substantially affect strength of a sling.

9. Unbalance:A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

10. Kinks: Are tightened loops with permanent strand distortion that result from improper handling when a rope is being installed or while in service. A kink happens when a loop is permitted to form and then is pulled down tight, causing permanent distortion of the strands. The damage is irreparable and the sling must be taken out of service.

11. Doglegs: Are permanent bends caused by improper use or handling. If the dogleg is severe, the sling must be removed from service. If the dogleg is minor, (exhibiting no strand distortion) and cannot be observed when the sling is under tension, the area of the minor dogleg should be marked for observation and the sling can remain in service.

The best lifting and rigging inspection program is of no value if slings, which are worn out and have been retired, are not properly disposed of. When it is determined by the inspector that a sling is worn out or damaged beyond use, it should be tagged immediately DO NOT USE.

If it’s determined that the wire rope will be removed from service, we suggest cutting it down into more manageable sizes before discarding. This extra effort will help to accommodate the needs of most recycling facilities that will accept the damaged wire rope and also help to make sure that it cannot be used any further. Keep the following in mind when disposing of wire rope slings and wire rope cable:Cut into approximately 3’ to 4’ sections

OSHA does not provide clear guidelines on how to properly and adequately inspect wire rope slings. It is up to the designated inspection personnel to know the requirements of the sling inspection standards, and to develop a comprehensive inspection protocol. Wire rope inspection should follow a systematic procedure:First, it is necessary that all parts of the sling are readily visible. The sling should be laid out so every part is accessible.

Next, the sling should be sufficiently cleaned of dirt and grease so wires and fittings are easily seen. This can usually be accomplished with a wire brush or rags.

The best way to help extend the life of a wire rope sling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.Hang slings in a designated area where they are off of the ground and will not be subjected to mechanical damage, corrosive action, moisture, extreme temperatures, or to kinking.

Like any other machine, wire rope is thoroughly lubricated at time of manufacture. Normally, for sling use under ordinary conditions, no additional lubrication is required. However, if a sling is stored outside or in an environment which would cause corrosion, lubrication should be applied during the service life to prevent rusting or corroding.

If lubrication is indicated, the same type of lubrication applied during the manufacturing process should be used. Your sling manufacturer can provide information on the type of lubricant to be used and provide the best method of application. We recommend a wire rope lubricant that is designed to penetrate and adhere to the wire rope core.

Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. Keep in mind that you’re planning to lift valuable and expensive equipment, and if a failure were to occur, it would not only cause unnecessary equipment repair costs and costly downtime, but also potentially jeopardize the lives of workers on site.

At Mazzella, we offer a variety of services including site assessments, rigging and crane operator training, sling inspection and repairs, overhead crane inspections and so much more. Our rigging inspection program is its own dedicated business unit with a team of inspectors that are certified through Industrial Training International to meet OSHA 1910.184 and ASME B30.9 requirements for sling inspection.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

Removal criteria for wire rope, wire rope slings, synthetic web/round slings, chain slings, rigging hardware, and below-the-hook lifting devices is the focus here. Personnel qualification is available.

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

The United States Department of Labor, with OSHA, put out a report on sling safety that is intended to be an informational booklet that gives a generic overview of safety standards for using a sling. It is designed to assist operators in understanding and complying with OSHA regulations.

Our team of engineers can help you answer any questions you have about rigging supplies,wire rope sling and safety. Reach out today to find out more information.

Wire rope slings are essential pieces of rigging hardware, especially for industrial sites, and designed to lift and hoist heavy objects. The lifting device remains connected to those slings with several different configurations. While these slings are generally durable, proper inspection and maintenance are required to keep up their integrity. Damages from wear and tear are likely without detailed inspection. According to ASME and OSHA standards, users must inspect wire rope slings regularly and correctly to operate them safely. Continue reading for more information regarding the inspection of wire rope slings.

According to OSHA guidelines, inspections on wire rope slings should be conducted at a regular interval. The frequency of the inspections will largely depend on the frequency of use. However, you should stick to these general recommendations when it comes to wire rope sling inspections:Inspect slings immediately after receiving them from the manufacturers

Before using your wire rope slings, it’s essential to inspect them properly. An inspection will allow you to detect the damage that may have been caused during your previous use. Be sure to take appropriate steps to solve the issues if you come across them.

Visual inspections should be conducted daily. An inspection can be as simple as the person who is using the sling to identify any signs of deterioration. Even the most minor of damage can potentially weaken the wire rope sling. The user should attempt to identify defective wires, crushing potentials, corrosion, and faulty attachments.

It is also imperative to conduct an annual inspection. This inspection should include every part of the sling, including the fittings, end attachments, and splices.

A certified and qualified person should be conducting the inspections on your wire rope slings. If you’re only using the slings occasionally, a yearly inspection may suffice. However, for severe use, a quarterly inspection would be optimal. Consider contracting an inspection service.

The inspector will look for the damaged and worn-out parts of the wire rope sling. The inspector will also label the parts that were already inspected.

You may find some signs of damages after the inspection. However, that doesn’t mean it’ll be easy to decide between repair and replacement of the damaged slings. This is a guide that might help you determine when it’s time to replace those damaged slings.Deteriorated wires: Five damaged wires in a strand indicate that it’s time for a replacement if you are using single-part slings. If you’re using a multi-part sling, ten randomly damaged wires in a rope lay should warrant replacement.

Metal loss: The loss of metal may be indicated by the outer diameters of wires showing wear and tear signs. In this case, you should strongly consider replacing the sling.

Severe rope corrosion is a sign that you should replace your slings. However, light rusting will only reduce the strength of your slings. In this case, whether you replace them or not is entirely up to you.

You need to cut the fittings and eye of the sling first. Then label them properly to avoid accidentally using them. It is imperative that you do not use those slings at all.

Remember that proper inspections will prevent you from using damaged wire rope slings. It’s strongly recommended that you hire professionals to inspect your slings. Checking and maintaining wire rope slings throughout the year can help you avoid costly repairs.

Proper maintenance and upkeep will help make sure you get the most out of your wire rope slings. It’s also imperative to understand the correct ways to store your slings while they aren’t in use. As a general rule, you should keep slings away from heat, liquids, sprays, and corrosion. With proper maintenance and care, you can easily use your wire rope slings for several years.

AtSilver State Wire Rope and Rigging, we know everything there is to know about wire ropes and rigging. If you have any questions about wire rope slings, inspections, or anything else regarding wire ropes, feel free tocontactone of our professional staff members.

Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.”

Contact IBT to schedule a Sling Safety Seminar. The Sling Safety Seminar will be tailored to your facility’s needs. Let IBT and Lift-All train your employees to be compliant with the new OSHA regulation for wire rope slings.

Let us know if you would like your facility inspected or retagged. IBT and Lift-All will perform sling inspections according to the latest regulations. They will identify slings that are not in compliance and can retag slings that lack identification but otherwise would have passed inspection. Lift-All’s Tuff-Tags are the best solution for difficult tagging applications.

OSHA regulations require that all chain slings and numerous other items receive an in depth inspection at least once a year by a competent person. All-Way, Inc. provides the opportunity for you to have a thorough, documented, fully traceable inspection performed by trained technicians.

Chain slings, wire rope slings, web slings, round slings, wire mesh slings,and numerous other below the hook lifting devices can all be inspected in one survey by a representative of a company that furnishes them all. All-Way, Inc. has sold and serviced these lifting devices throughout the country and we are familiar with the current regulations and standards that apply to a professionally conducted survey. Additionally, we utilize an RFID Field ID Inspection and Asset Tracking system to provide the most accurate, advanced survey while saving you and your company valuable time.

All reports and product data can be traced online at your convenience whenever the need should arise. Our detailed reports allow you to view inspections, load tests, repairs, and track equipment locations easily and efficiently with less time out of service. Should you need to print or review these documents, Instant-Access to your inspection reports and test certificates is available on our secure All-Way, Inc./N4 Field ID website 24/7.

Our heavy duty sling and chain tags carry the statutory capacity, serial number and load limit information longer than standard metal tags and interface electronically with our chain hoist inspection and tracking system for time saving future rigging hardware and wire rope sling inspections or necessary data retrieval.

On top of the inspection services, All-Way, Inc. offers in-house and on-site load testing services which is also traceable through our Field ID system. Wire rope slings, chain slings, synthetic slings, fittings, hardware, hoists, load beams, and numerous other items are routinely tested by our trained technicians.

If you or your company currently utilizes our rigging inspections or testing services, you may login or request online access to your account by clicking the All-Way Field IDbutton on this page.

If you are running a business where Fall Protection Gear is used, there is a lot you need to know about OSHA standards. While the need to keep high quality, well inspected Fall Protection Equipment should be a no-brainer, you need to know what is expected of you to keep your workplace compliant.

“One who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.” [OSHA 29 CFR 1926.32(f)]

In many cases companies may hire an outside, third party person to inspect gear. This can sometimes add extra validity to the process and also offers a fresh set of eyes for inspections. In some cases, it may also be a more cost effective way to perform inspections.

Universally all Fall Protection Equipment should be inspected before and after each use and at the start of each 8 hour shift. In addition to these visual inspections, all gear must be given a more formal and documented inspection by a Designated Competent Person at least once every 12 months.

While performing daily inspections, there are some things you should look out for in particular. Arc burns, chemical damage, heat damage, and minor cuts are all things to look out for.

One of the more obscure OSHA standards is in regards to harnesses. When not in use, harnesses must be stored in a cabinet to avoid additional exposure to light and UV Rays.

If a Competent Person observes discoloration from UV Rays in a harness during an inspection, you should expect that they will deem the harness to be unfit for use. This may seem trivial, but if a harness has been put through enough exposure to show discoloration it will also show a reduction in strength and integrity.

Authorized Repair Service Departments from manufacturers are the only people or institutions accepted by OSHA standards for restoring Fall Protection Gear and there are significant limits to what they can do.

The obvious and most important reason to be concerned about meeting OSHA regulations for Fall Protection Equipment is workplace safety. The reasons that these standards are so stringent and black & white are all related to the fact that workers’ lives are on the line.

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

8613371530291

8613371530291