wire rope inspection osha quotation

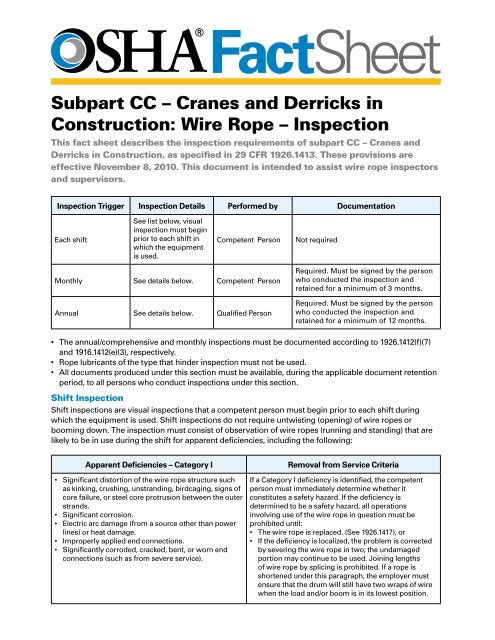

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

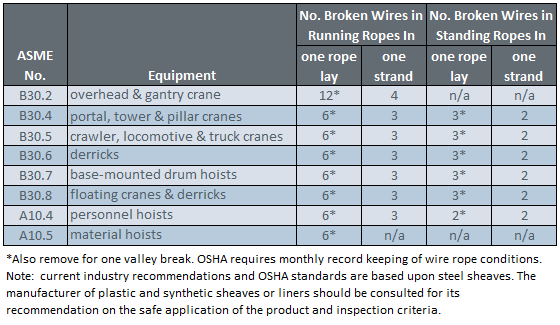

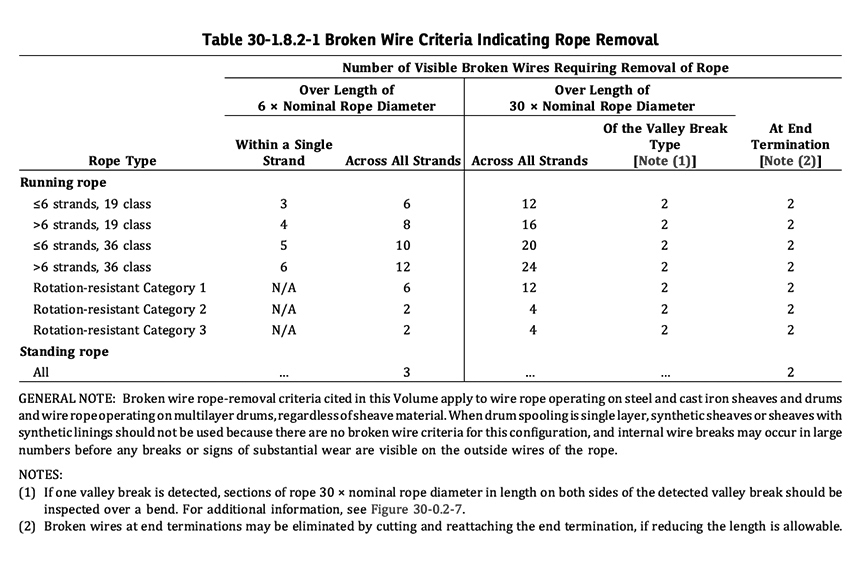

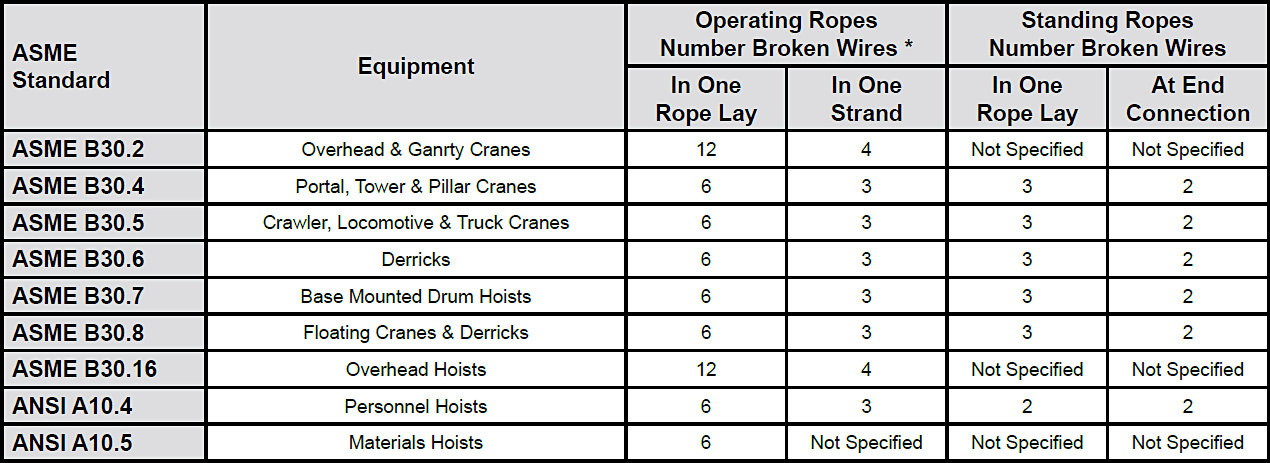

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

On June 29, 2013, Employee #1 was performing as a Battle Spearmen Warriors in a mock battle scene. The Employee wore a twist disk metal harness attached to a wire rope and an overhead winch to ascend and descend the length of a sand cliff deck while it was in a vertical position. Employee #1 was lining up across the deck, preparing to fly up to an overhead forest grid catwalk backwards in a horizontal position facing downwards, but the employee was approximately 8 ft above the other employees. A coworker, a rigger, assigned to assist the employee avoid striking the grid while she was ascending by pushing her wire rope away from the grid, noticed that the employee had started to lineup so he proceeded towards a self, retracting lifeline to tie off. The employee flew up at a higher rate of speed than normal towards the grid without tucking in her feet or legs. The coworker tied off to the lifeline, heard a loud bang noise, turned around, and grabbed the wire rope with his left gloved hand to breast the wire rope away from the forest grid. As the coworker grabbed the wire rope, Employee #1 had already struck the bottom of the grid from the back of her legs to her waist. This caused a shock load to the winch; the wire rope came out of the sheave/pulley and scraped against a shear point cutting numerous wires in the wire rope. The wire rope broke apart causing the employee to fall 94 ft to the level 5 lower basement, and landing on the harness. Employee #1 was transported to UMC Trauma Center, where she was pronounced dead.

Removal criteria for wire rope, wire rope slings, synthetic web/round slings, chain slings, rigging hardware, and below-the-hook lifting devices is the focus here. Personnel qualification is available.

Atlantic Crane"s OSHA inspection experts take the guesswork out of OSHA regulations and what is needed to keep your cranes operating safely and in compliance.

Don"t take the risk of non-compliance. Our technicians will ensure that your overhead material handling systems meet the following OSHA crane regulations and more.

Required OSHA InspectionsComplete inspection of overhead cranes at intervals of at least every 12 months, and as often as every month depending upon the activity, severity of service and environment. OSHA 1910.179(j)(3)

Inspection and load testing prior to initial use of all new and altered cranes to ensure compliance of all functions of hoisting and lowering, trolley travel, bridge travel, limit switches, locking and safety devices. OSHA 1910.179(j)(k)

Inspection of cranes not in regular use. A crane which has been idle for a period of one month or more, but less than six months, shall be given an inspection conforming with requirements of OSHA 1910.179(j)(m)(2).

Monthly hook inspection with certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial or ID number of the chain inspected. OSHA 1910.179(2)(iv)

Monthly wire rope inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial or ID number of the rope inspected. OSHA 1910.179(m)

Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.”

Contact IBT to schedule a Sling Safety Seminar. The Sling Safety Seminar will be tailored to your facility’s needs. Let IBT and Lift-All train your employees to be compliant with the new OSHA regulation for wire rope slings.

Let us know if you would like your facility inspected or retagged. IBT and Lift-All will perform sling inspections according to the latest regulations. They will identify slings that are not in compliance and can retag slings that lack identification but otherwise would have passed inspection. Lift-All’s Tuff-Tags are the best solution for difficult tagging applications.

American Wire Rope & Sling wants to make sure your training needs go beyond the canned versions that most companies offer. All of our Rigging Trainers are Crosby-Certified to conduct any level of rigging training you might need. We work with your company to learn how you are using your rigging, and then we create a custom training plan that not only educates your people on general rigging requirements, but also dives deeper into the things your employees use the most at your facility. We offer training in one-hour increments and up to four-hour full scope rigging trainings. We offer trainings at our rigging service centers or at your facility, jobsite or corporate office. If you want the best rigging training in the business, it only comes from one place: American Wire Rope & Sling.

Daily operation wears on critical crane components. Over time, this may lead to breakdown and even catastrophic failure—particularly without regular inspections. Through regular inspections, crane users can spot potential problems so they can perform maintenance and repairs that may preclude employee injury and costly interruptions in service.

Konecranes offers training for users of all makes of overhead lifting equipment. This includes hands-on instruction in performing frequent inspections of critical crane components that are subject to daily wear.

Inspection procedure for cranes in regular service is divided into two general classifications based upon the intervals at which inspection should be performed. The intervals in turn are dependent upon the nature of the critical components of the crane and the degree of their exposure to wear, deterioration, or malfunction. The two general classifications are herein designated as "frequent" and "periodic" with respective intervals between inspections as defined below:

The following items shall be inspected for defects at intervals as defined in paragraph (J)(1)(ii) of this section or as specifically indicated, including observation during operation for any defects which might appear between regular inspections. All deficiencies such as listed shall be carefully examined and determination made as to whether they constitute a safety hazard:

Hooks with deformation or cracks. Visual inspection daily; monthly inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial number, or other identifier, of the hook inspected. For hooks with cracks or having more than 15 percent in excess of normal throat opening or more than 10 twist from the plane of the unbent hook refer to paragraph (L)(3)(iii)(a) of this section.

Hoist chains, including end connections, for excessive wear, twist, distorted links interfering with proper function, or stretch beyond manufacturer"s recommendations. Visual inspection daily; monthly inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier of the chain which was inspected.

Our CARE Preventive/Predictive Maintenance program has been designed to improve your equipment safety and productivity with preventive maintenance inspections, compliance inspections and routine maintenance.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

8613371530291

8613371530291