wire rope inspection osha for sale

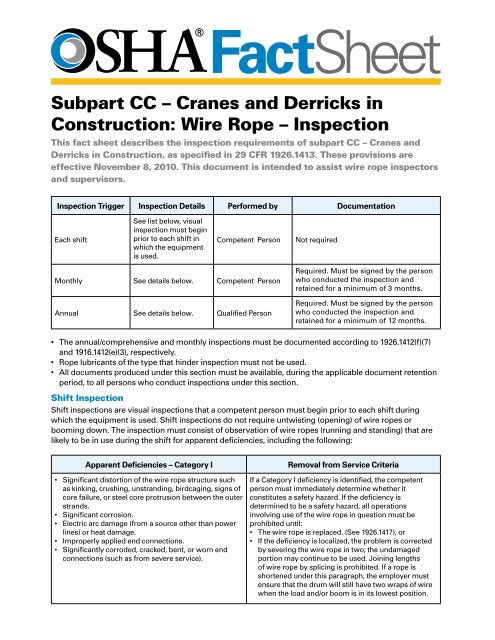

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

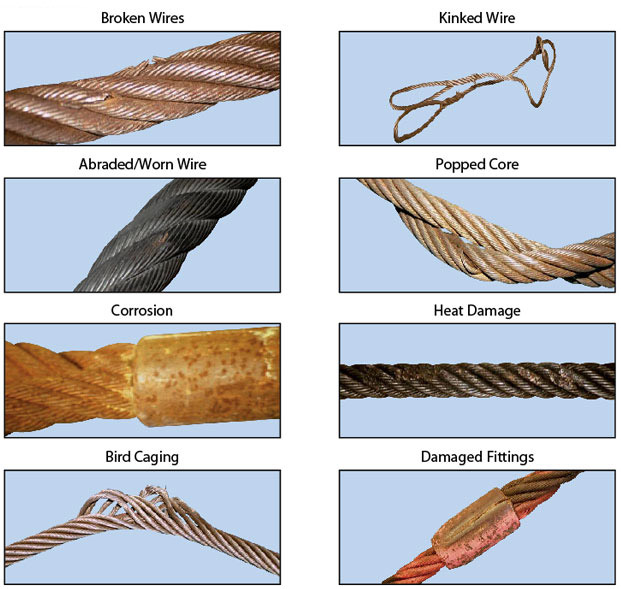

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Cable laid endless sling-mechanical joint is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

Cable laid grommet-hand tucked is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

Cable laid rope sling-mechanical joint is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

Master link or gathering ring is a forged or welded steel link used to support all members (legs) of an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

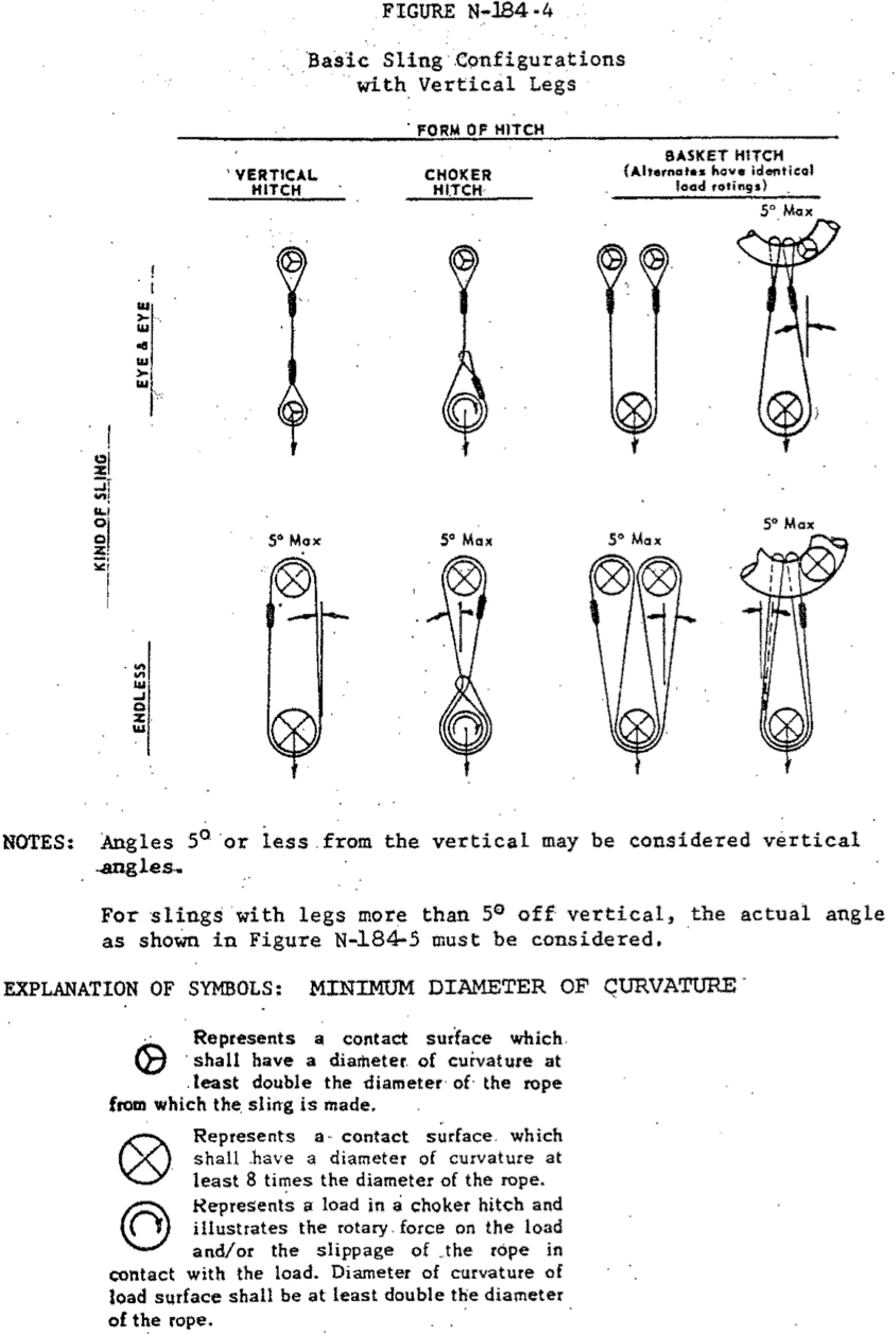

Diagram indicates Forms of Hitch and Kind of Sling. Eye&Eye Vertical Hitch. Eye&Eye Choker Hitch. Eye&Eye Basket Hitch (Alterates have identical load rations). Endless Vertical Hitch. Endless Choker Hitch. Endless Basket Hitch (Alternateve have identical load ratings). Notes: Angles 5 deg or less from the veritcal may be considered vertical angles. For slings with legs more than 5 deg off vertical, the actual angle as shown in Figure N-184-5 must be considered. Explanation of Symbols: Minimum Diameter of Curvature. Represents a contact surface which shall have a diameter of curvature at least double the diameter of the rope from which the sling is made. Represents a contact surface which shall have a diameter of curvature at least 8 times the diameter of the rope. Represents a load in a choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface shall be at least double the diameter of the rope.

Strand laid endless sling-mechanical joint is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Inspections. Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of

experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.

The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.

Sling use. Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

Sling use. Employers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F to plus 180 °F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

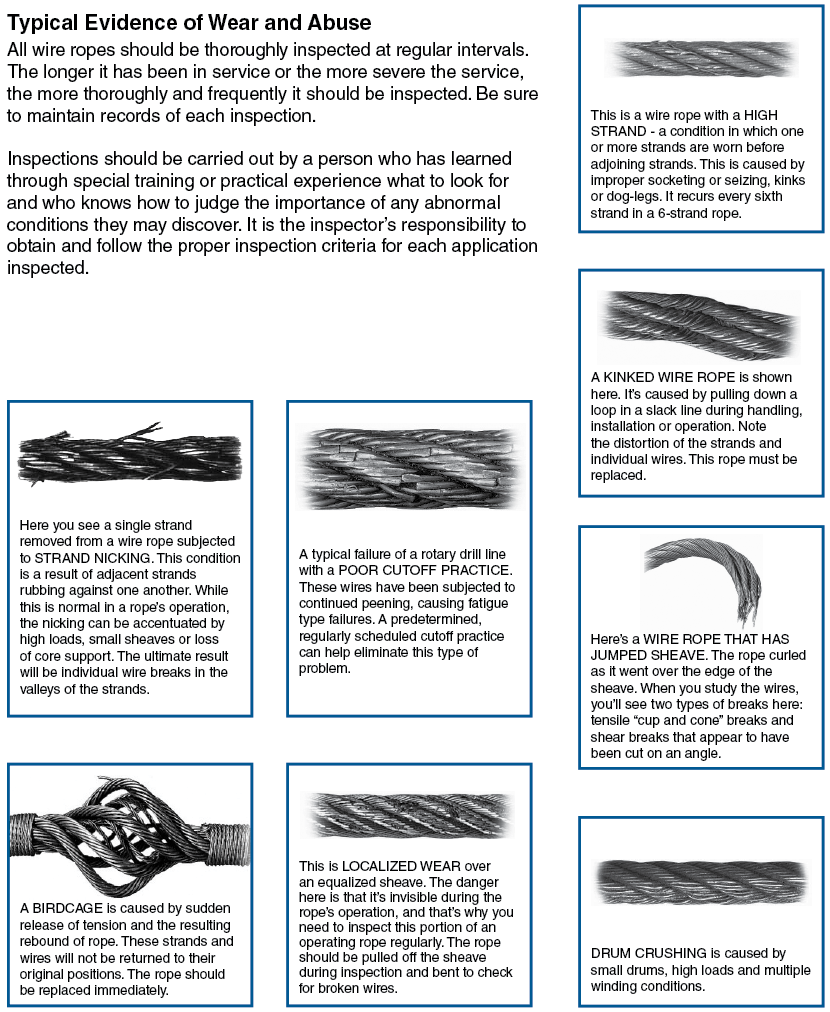

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

In order to maintain your safety and the safety of others, your equipment should be routinely inspected to assure that it is safe for use. This includes wire rope, slings, hardware, and hoists.

At Coca Sales, we take your rigging and subject it to a thorough inspection check list, checking for any major damage or flaws, to make sure it is safe for continued use. We follow OSHA and ANSI guidelines for removal criteria. All items that pass the visual inspection are given serial numbers, pull-tested and, upon your request, receives a new certification paper/proof of test.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

Wire rope lifting slings, bridles and assemblies provide great durability and high tensile strength for lifting heavy loads. In addition, wire rope lifting slings are lighter in weight and more cost efficient than chain slings. Wire rope slings, sometimes referred to as wire slings, or cable lifting slings, are constructed using a variety of different styles and sizes of steel wire rope. Every style and size of wire rope offers different properties and benefits such as:

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel IWRC (independent wire rope core) core.

Wire rope lifting slings, bridles and assemblies are highly customizable, so if you are unable to find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

The durability of steel cable lifting slings is also put to the test in the harsh environments seen in steel mills and forging facilities. Every steel wire rope configuration will offer different properties and will be better equipped to handle certain applications. Generally, a smaller number of large outer wires will provide more wear, corrosion and abrasion resistance. Conversely, a larger number of smaller outer wires will provide better flexibility and fatigue resistance.

After you decide what construction and size of wire rope fits your application, you must configure the entire sling. Wire rope bridles and assemblies are available in single-leg, double-leg, triple-leg, and quadruple-leg configurations. They most commonly have 2 eyes and are constructed using a mechanical flemish splice. Wire rope lifting slings can be used in vertical, choker and basket hitches. They can also be equipped with a variety of attachments and fittings to accommodate almost any overhead lifting application.

Although wire rope sling fittings and attachment can be reused, the wire rope itself is not repairable. If a wire rope sling fails an inspection, it is to be properly destroyed and disposed of

It is important to inspect wire rope slings regularly and to keep a record of all sling inspections. At Tri-State Rigging Equipment we offer a full range of rigging inspection and repair services. The standards that govern wire rope sling inspection are OSHA 1910.184 and ASME B30.9. It is recommended that wire rope rigging slings first undergo an initial inspection when you receive the lifting sling from the manufacturer. The purpose of this initial inspection is to:

Wire rope slings, bridles and assemblies should also be inspected by a designated and qualified individual every day before use to make sure that the sling is in working condition and will lift its rated capacity. The person performing the inspection should examine all the wire rope, fastenings and attachments on the wire rope sling. The inspector is looking for visual indications of any defects, deformities and general damage that might affect the integrity of the sling.

Depending on your application, it may be recommended that you perform these visual inspections more than once a day. If the wire rope sling is used many times throughout the day, by multiple individuals, across multiple shifts, it is imperative that the sling be inspected before every shift change and before any change in lifting application.

ASME standards further require a thorough periodic inspection to be performed at least once a year by either a professional service provider, or by a Qualified Person. In addition, written records must be kept until the next periodic inspection. The rejection criteria for periodic wire rope sling inspections are as follows:

10 or more randomly distributed broken wires in one rope lay, or 5 or more broken wires in one strand in one rope lay, for strand-laid grommets and single part slings.

If your wire rope sling shows any of the rejection criteria above, you must remove the sling from service, and it must be destroyed. Properly destroying rigging equipment is imperative because you can be held accountable for damage done by people who find and use your discarded slings. Therefore, lifting slings deemed not suitable for service must be destroyed beyond use and beyond repair. The process for destroying a wire rope sling is as follows:

The purpose of daily and periodic wire rope sling inspections is not to get anyone in trouble but rather to gain knowledge of the frequency of use, severity of conditions, and nature of lifts, and consider how all these factors affect your wire rope sling. The most important reason to perform daily and periodic wire rope sling inspections, however, is to keep you and your coworkers safe.

Tri-State Rigging Equipment is a custom manufacturer, service provider and distributor for all wire rope lifting slings serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

Wire ropes are designed to be extremely strong and durable to safely lift and secure heavy items. Wire ropes are commonly used with overhead lifting and rigging equipment to hoist loads – so when things go wrong, it can be extremely dangerous.

Wire rope hazards have caused hundreds of injuries and even fatalities on construction sites. According toone report, more than 60 people were killed over 15 years due to a wire rope breaking.

When wire rope is handled or stored incorrectly, it can tremendously increase the likelihood of a safety hazard. Some of the most common safety issues with this piece of industrial equipment include broken strands, corrosion, crushed wires, or fatigue that causes the rope to slip, stretch, or snap.

At Elite Sales, we have fulfilled lots of orders forwire ropesto replace broken or damaged equipment. So, take our advice with these tips to reduce wire rope hazards through proper handling.

OSHA requires that all overhead lifting and rigging equipment be carefully inspected before use. Certified crane operators are typically responsible for this task – but all workers interacting with wire ropes should know how to conduct an inspection.

First, the wire rope should be visually inspected to note any of the most common signs of wear and tear. This includes crown or valley breaks in the exterior strands or any kinks in the wire rope.

Any visible rusting, loose wires, kinking, or damaged fitting should be noted immediately. The wire rope should be replaced or repaired before it is used, as even a few broken wires could compromise its strength and durability.

Dryness or dust forming on the wire rope is an indication that hasn’t been recently lubricated. This can cause the wire rope to break far more easily, so this must be taken into consideration during the inspection as well.

Wire ropes are commonly damaged when they are being moved as the strands can get caught, broken, or bent. Correctwire rope installation and handlingare crucial for extending the life and use of this equipment. So, all employees who handle wire ropes should receive adequate training for proper handling.

Special care should be taken when the wire rope is unreeled or uncoiled. The strands can easily get kinked or crushed during this process. The best practice is to pull the wire rope in a straight line off of the reel or mount it on a revolving stand to ensure that the rope does not look or kink.

All wire ropes should be routinely re-lubricated as well. This helps to reduce wear from friction and movement and also protects the wires from corrosion.

Additionally, all handlers should be aware of practices that can damage wire ropes and avoid them at all costs. For instance, battening down the wire rope sling to secure it can crush and break the strands. This is unfortunately a fairly common practice on construction sites – so supervisors should strictly enforce correct handling.

Wire rope can get damaged during storage, too. All wire ropes must be completely dried and stored in a cool, temperature-controlled space. It is also best to avoid stacked coiled wire rope directly on the ground and instead stack it on cement or metal.

As an industrial hardware supplier, we understand that it is not just the way that these materials are handled – but also the quality of the equipment that lowers safety risk. Cheap wire rope will rust or wear down quickly, which increases the likelihood of it breaking.

First, be sure that you only purchase wire rope made with improved plow steel (IPS), extra improved plow steel (EIPS), or even extra-extra improved plow steel (EEIPS). This means that the wire rope is made of stronger steel than mild plow steel (MPS).

You should always double-check that you are using the correct wire rope for your application. There are many different styles, constructions, and patterns available which are optimized for certain uses.

For example, some are designed to berotation resistantwhich is best for overhead lifting. The central core of the wire rope is also an important factor to consider. A fiber core is best for applications where elasticity and stretch are needed – but it is not ideal for high heat or heavy loads. Wire strand cores on the other hand are best when additional stability is needed for securement.

Working with a trusted and experienced industrial wire rope supplier can be extremely beneficial here. Not only will this give you access to a wide range of wire rope options, but you can receive advice and guidance from professionals.

Here at Elite Sales, we’ve worked with construction companies and industrial manufacturers for years to provide top-rated equipment. We carry a great selection of wire rope in many styles, lengths, diameters, and constructions to meet nearly all applications. Plus, our team of experts is just a phone call away.

Reducing the risk of wire rope hazards on the job site needs to be a top priority. Any mistakes with wire rope installation, transportation, or storage can lead to major safety issues. One of the easiest ways to do this is enforcing proper handling of top-quality wire rope equipment throughout the organization.

If you are looking to purchase high-quality wire rope for your business, be sure to check out our selection. Elite Sales is proud to carry top-rated industrial hardware. Our team is available to answer any questions and direct you to the exact types you need for any application.

(a) Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this Part. The types of slings covered are those made from allow steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

“Cable laid endless sling-mechanical joint” is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

“Cable laid grommet-hand tucked” is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

“Cable laid rope sling-mechanical joint” is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

“Master link” or “gathering ring” is a forged or welded steel link used to support all members (legs) or an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

“Strand laid endless sling-mechanical joint” is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

“Strand laid grommet-hand tucked” is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

“Strand laid rope” is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Inspections. Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of (A) frequency of sling use; (B) severity of service conditions; (C) nature of lifts being made; and (D) experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.

1910.184(e)(3)(iii) The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.

Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service

INSPECTIONSIn addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of (A) frequency of sling use; (B) severity of service conditions; (C) nature of lifts being made; and (D) experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.

The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.

SLING IDENTIFICATION Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

MINIMUM SLING LENGTHSCable laid and 6×19 and 6×37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

SAFE OPERATING TEMPERATURESFiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200°F. When nonfiber core wire rope slings of any grade are used at temperatures above 400°F or below minus 60°F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

REMOVAL FROM SERVICEWire rope slings shall be immediately removed from service if any of the following conditions are present:Ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay.

SLING IDENTIFICATIONEmployers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

SAFE OPERATING TEMPERATURESNatural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20°F to plus 180°F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer’s recommendations shall be followed.

SPLICINGSpliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

REMOVAL FROM SERVICENatural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:Abnormal wear.

Using wire rope slings is one of the most reliable ways to secure a load to lifting equipment. Wire rope slings are light, strong, and durable, and they can be used in a variety of ways for many different kinds of lifts.

Because crane operators rely on wire rope slings for so many lifting operations, they must be kept in good condition for safe operation, and they should be inspected routinely for any damage or excessive wear. To ensure that all wire rope slings are properly inspected, it is important to know who should perform the inspections, how frequently inspections should be performed, and what criteria should be examined to pass an inspection. OSHA and ASME provide inspection requirements and guidelines that can be used to ensure that all wire rope slings are inspected correctly and safe for material handling operations.

How often wire rope slings are inspected depends largely on how frequently those slings are used. However, there are a few universal rules for when to inspect all slings. First, every wire rope sling should be inspected upon receipt from the manufacturer. Check slings for any manufacturing flaws and that the sling received is the correct sling and meets your application’s requirements.

Next, all wire rope slings should also be inspected before using. Regardless of how frequently a sling is used, it should always be inspected prior to use, as damage to the sling could have occurred during the previous use or in the time between uses. Inspecting a sling before every use ensures that a sling that has been damaged isn’t used if the damage wasn’t noticed or reported at the time.

In addition to these universal guidelines, wire rope slings should also be inspected routinely by a Qualified Person based on how frequently and how severely they are used. ASME guidelines require periodic sling inspections by a Qualified Person yearly for normal, occasional use and monthly to quarterly for severe, frequent use. ASME B30.9 also requires these periodic inspections to be documented and kept on-record.

The person inspecting the wire rope sling will be different depending on the circumstances of the inspection. Wire rope slings must be inspected prior to every use, and this inspection should be done by the operator in preparation for the lift. The operator should be a competent person, as defined by OSHA, with the necessary knowledge to perform inspections. For monthly to yearly inspections, a professional service provider or Qualified Person, as defined by OSHA, should conduct the inspection.

The inspection process is not specifically defined by OSHA or ASME, so it is the responsibility of the inspector to know and understand how to inspect the sling properly and what to look for. First, the sling should be laid out so that the entire sling is visible and easily accessible. Then the sling should be cleaned with a rag or wire brush to make the wires and fittings more visible.

Next, the sling should be inspected thoroughly along its full length, with special attention given to fittings and end attachments. Identify any points with significant wear and determine if the sling is still suitable for service. If the sling is not suitable for service, it should be removed immediately. Label slings that have been inspected and keep records of inspection dates and sling conditions.

There are several factors that should be examined when inspecting a wire rope sling. OSHA 1910.184(f)(5) describes several conditions that require a sling to be removed from service if they are identified. These conditions include:

OSHA 1910.184(f)(2) also states that wire rope slings must have “permanently affixed and legible identification markings.” These markings provide information regarding the maximum safe working load at various angles for different types of hitches, the size of the sling, and the manufacturer. If the identification markings on a sling are missing or illegible during inspection, the sling should be removed from service.

ASME B30.9 provides several inspection standards in addition to OSHA requirements. If eye splices show evidence of slipping or if tucked strands have moved, the sling should be removed from service. Any cracked, bent, or broken end fittings also indicate that a sling is not suitable for use. Any severe corrosion of the rope or end attachments that cause the wires to bind will require a sling to be removed from service, but light surface rust will not substantially affect a sling’s strength.

Properly inspecting wire rope slings and removing unsafe slings from service helps keep material handling operations safe. If a sling fails during operation, equipment can be damaged, leading to long downtime and costly repairs, and workers can be put at high risk of serious injury or even death. Routinely inspecting and maintaining wire rope slings is a simple, effective way to ensure that all material handling operations are completed safely.

8613371530291

8613371530291