wire rope inspection pdf free sample

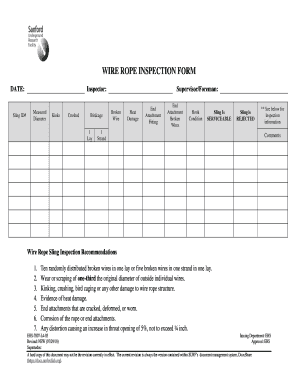

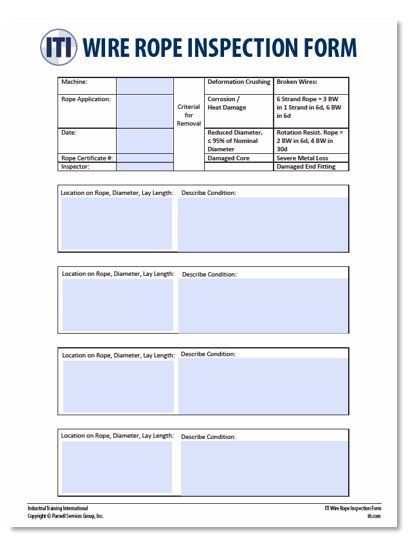

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

(3) Operational aids. Operations must not begin unless operational aids are in proper working order, except where the owner or lessee meets the specified temporary alternative measures. See WAC 296-155-53412 for the list of operational aids.Note:All accredited crane certifiers must meet and follow the requirements relating to fall protection, located in chapter 296-880 WAC, Unified safety standards for fall protection.

(a) Wire ropes must meet the crane or wire rope manufacturer"s specifications for size, type and inspection requirements. In the absence of the manufacturer"s specifications, follow the requirements for removal criteria located in this section, including Table 1.

Derricks63Consult rope mfg.Consult rope mfg.32*Also remove if you detect 1 wire broken at the contact point with the core or adjacent strand; so called valley breaks or evidence from any heat damage from any cause.Note:xd means times the "diameter."

(b) The accredited crane certifier must perform a complete and thorough inspection covering the surface of the working range plus 3 additional wraps on the drum of the wire ropes.

(ii) If the deficiency is localized, the problem is corrected by severing the wire rope; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited.

(e) Replacement rope must be of a compatible size and have a strength rating at least as great as the original rope furnished or recommended by the crane manufacturer.

(a) Sheave grooves must be free from surface defects that could damage the rope. The cross-sectional radius at the bottom of the groove should be such as to form a close fitting saddle for the size of rope used. The sides of the groove must be tapered outward and rounded at the rim to facilitate entrance of the rope into the groove. Flange rims must run true about the axis of rotation.

(a) A safe test area must be selected and all traffic and unauthorized personnel and equipment must be cleared from test area. This test area must be roped off or otherwise secured to prevent entry of unauthorized personnel and equipment;

8613371530291

8613371530291