wire rope inspection standards supplier

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

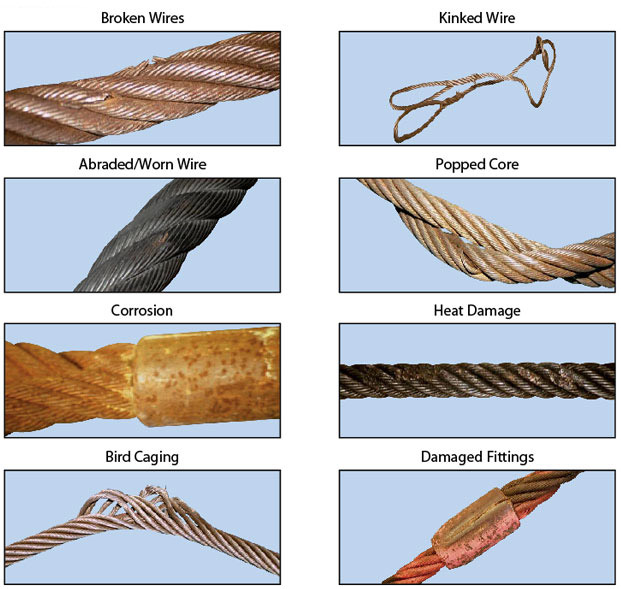

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

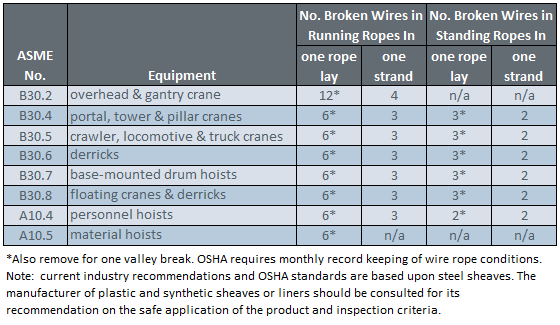

All wire ropes will wear out eventually and gradually lose work capability throughout their service life. That"s why periodic inspections are critical. Applicable industry standards such as ASME B30.2 for overhead and gantry cranes or federal regulations such as OSHA refer to specific inspection criteria for varied applications.

You should thoroughly inspect all wire ropes at regular intervals. The longer it has been in service or, the more severe the service, the more thoroughly and frequently it should be inspected. Be sure to maintain records of each inspection.

Inspections should be carried out by a person who has learned through specialized training or practical experience of what to look for and who knows how to judge the importance of any abnormal conditions they may discover. It is the inspector"s responsibility to obtain and follow the proper inspection criteria for each application inspected.

Figure 1is what happens when a wire breaks under tensile load exceeding its strength. It"s typically recognized by the "cup and cone" appearance at the point of failure. The necking down of the wire at the point of failure to form the cup and cone indicates failure has occurred while the wire retained its ductility (the ability to change form without breaking).

Figure 2is a wire with a clear fatigue break. It is identified by the square end perpendicular to the wire. This break was produced by a torsion machine that"s used to measure the ductility. This break is similar to wire failures in the field caused by fatigue.

Figure 3 is a wire rope that has been subjected to repeated bending over sheaves under typical loads. This fatigue results in breaks in individual wires - these breaks are square and usually in the crown of the strands.

Figure 4 is an example of fatigue failure of a wire rope subjected to heavy loads over small sheaves. The breaks in the valleys of the strands are caused by "strand nicking." There may be crown breaks, too.

Figure 5 is a single strand removed from a wire rope subjected to "strand nicking." This condition is a result of adjacent strands rubbing against one another. While this is normal in a rope"s operation, the nicking can be accentuated by high loads, small sheaves or loss of core support. The ultimate result will be individual wire breaks in the valleys of the strands.

Do you know who is supposed to be inspecting your lifting slings? More importantly, do you know how often they’re inspecting them? OSHA and ASME have different inspection requirements, frequencies, and removal criteria for each type of sling—including alloy chain slings, synthetic slings, metal mesh slings, and wire rope slings.

At Mazzella, we understand the amount of effort and coordination it takes to stay current on industry standards and to develop an inspection program that keeps your business in compliance. Because of this, we have a dedicated business unit made of up highly-trained and qualified inspectors and technicians that focus only on rigging equipment inspections, industry compliance, and sling testing and repair.

In this article, our goal is to help you understand what is required to inspect wire rope slings to meet ASME standards, which in turn, will help to ensure the safety of the users,help extend the service life of the slings, and help reduce unnecessary equipment repair costs and loss of production due to equipment downtime.

As a starting point, the same work practices which apply to all “working” wire rope apply to wire rope which has been fabricated into a sling. Therefore, a good working knowledge of wire rope design and construction will not only be useful, but essential in conducting a wire rope sling inspection.

There are two industry standards that exist to provide the end-user with guidelines for inspection and criteria that warrants removal from service: OSHA 1910.184 and ASME B30.9.

Initial Inspection (prior to initial use): Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. Double-check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements.

Frequent (daily or prior to use): Designate a Competent Person to perform a daily visual inspection of slings and all fastenings and attachments for damage, defects, or deformities. The inspector should also make sure that the wire rope sling that was selected meets the specific job requirements it’s being used for.

Users can’t rely on a once-a-day inspection if the wire rope sling is used multiple times throughout the day. Damage to wire rope can occur on one lift and best practice is to perform a visual inspection before any shift change or changes in lifting application. Because shock loads, severe angles, sharp edges, and excessive heat can quickly cause damage to a lifting sling, the user should inspect the sling prior to each lift.

Periodic Inspection: A periodic inspection is performed by either a professional service provider, or by a Qualified Person, every 12 months (at a minimum) and monthly to quarterly in more severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:Frequency of use

Depending on the severity of the operating environment and frequency of use, your business may decide to inspect wire rope slings more often than the minimum yearly requirement.

Per ASME B30.9, the wire rope sling tag on all new slings shall be marked by the manufacturer to include:Rated load for the types of hitches (single-leg vertical, choker, and basket) and the angle upon which they are based

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use. When inspecting wire rope slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. The user should look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion, etc. Any deterioration of the sling which could result in appreciable loss of original strength should be carefully noted and determination made on whether further use would constitute a safety hazard.

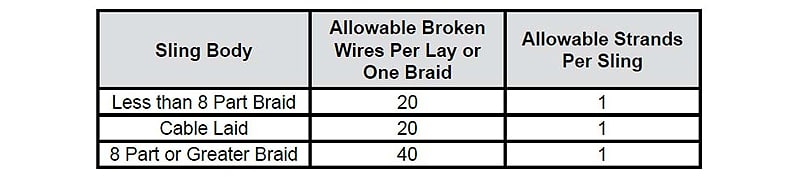

2. Broken Wires: For strand-laid grommets and single-part slings, ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay. For cable laid, cable laid grommets and multi-part slings, use the following:

3. Distortion: Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope.

7. Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light surface rust does not substantially affect strength of a sling.

9. Unbalance:A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

10. Kinks: Are tightened loops with permanent strand distortion that result from improper handling when a rope is being installed or while in service. A kink happens when a loop is permitted to form and then is pulled down tight, causing permanent distortion of the strands. The damage is irreparable and the sling must be taken out of service.

11. Doglegs: Are permanent bends caused by improper use or handling. If the dogleg is severe, the sling must be removed from service. If the dogleg is minor, (exhibiting no strand distortion) and cannot be observed when the sling is under tension, the area of the minor dogleg should be marked for observation and the sling can remain in service.

The best lifting and rigging inspection program is of no value if slings, which are worn out and have been retired, are not properly disposed of. When it is determined by the inspector that a sling is worn out or damaged beyond use, it should be tagged immediately DO NOT USE.

If it’s determined that the wire rope will be removed from service, we suggest cutting it down into more manageable sizes before discarding. This extra effort will help to accommodate the needs of most recycling facilities that will accept the damaged wire rope and also help to make sure that it cannot be used any further. Keep the following in mind when disposing of wire rope slings and wire rope cable:Cut into approximately 3’ to 4’ sections

OSHA does not provide clear guidelines on how to properly and adequately inspect wire rope slings. It is up to the designated inspection personnel to know the requirements of the sling inspection standards, and to develop a comprehensive inspection protocol. Wire rope inspection should follow a systematic procedure:First, it is necessary that all parts of the sling are readily visible. The sling should be laid out so every part is accessible.

Next, the sling should be sufficiently cleaned of dirt and grease so wires and fittings are easily seen. This can usually be accomplished with a wire brush or rags.

The best way to help extend the life of a wire rope sling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.Hang slings in a designated area where they are off of the ground and will not be subjected to mechanical damage, corrosive action, moisture, extreme temperatures, or to kinking.

Like any other machine, wire rope is thoroughly lubricated at time of manufacture. Normally, for sling use under ordinary conditions, no additional lubrication is required. However, if a sling is stored outside or in an environment which would cause corrosion, lubrication should be applied during the service life to prevent rusting or corroding.

If lubrication is indicated, the same type of lubrication applied during the manufacturing process should be used. Your sling manufacturer can provide information on the type of lubricant to be used and provide the best method of application. We recommend a wire rope lubricant that is designed to penetrate and adhere to the wire rope core.

Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. Keep in mind that you’re planning to lift valuable and expensive equipment, and if a failure were to occur, it would not only cause unnecessary equipment repair costs and costly downtime, but also potentially jeopardize the lives of workers on site.

At Mazzella, we offer a variety of services including site assessments, rigging and crane operator training, sling inspection and repairs, overhead crane inspections and so much more. Our rigging inspection program is its own dedicated business unit with a team of inspectors that are certified through Industrial Training International to meet OSHA 1910.184 and ASME B30.9 requirements for sling inspection.

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

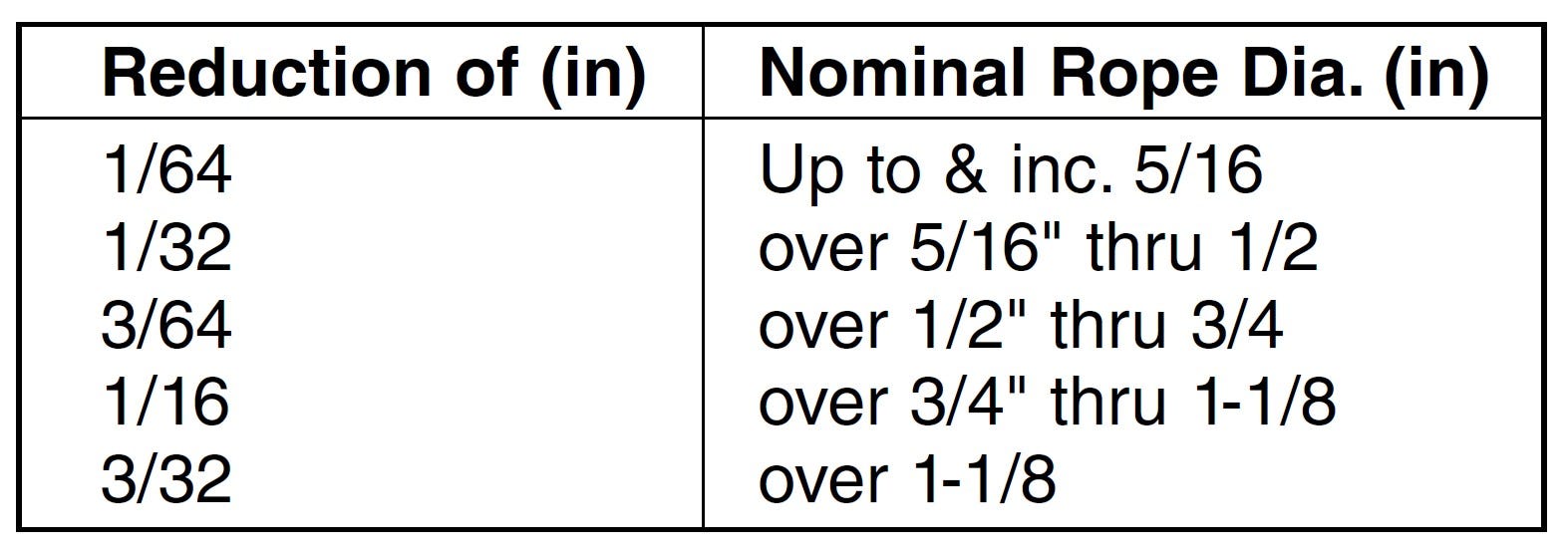

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

(a) Original equipment wire rope and replacement wire rope shall be selected and installed in accordance with the requirements of this section. Selection of replacement wire rope shall be in accordance with the recommendations of the wire rope manufacturer, the equipment manufacturer, or a qualified person.

(b) Wire rope design criteria: Wire rope (other than rotation resistant rope) shall comply with either Option (1) or Option (2) of this section, as follows:

(2) Option (2). Wire rope shall be designed to have, in relation to the equipment"s rated capacity, a sufficient minimum breaking force and design factor so that compliance with the applicable inspection provisions in Section 1613.10 (Inspections - Wire Rope) will be an effective means of preventing sudden rope failure.

(A) Type I rotation resistant wire rope (“Type I”). Type I rotation resistant rope is stranded rope constructed to have little or no tendency to rotate or, if guided, transmits little or no torque. It has at least 15 outer strands and comprises an assembly of at least three layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

(B) Type II rotation resistant wire rope (“Type II”). Type II rotation resistant rope is stranded rope constructed to have significant resistance to rotation. It has at least 10 outer strands and comprises an assembly of two or more layers of strands laid helically over a center in two or three operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

(C) Type III rotation resistant wire rope (“Type III”). Type III rotation resistant rope is stranded rope constructed to have limited resistance to rotation. It has no more than nine outer strands, and comprises an assembly of two layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

(C) Type I shall have an operating design factor of no less than 5, except where the wire rope manufacturer and the equipment manufacturer approves the design factor, in writing.

(A) A qualified person shall inspect the rope in accordance with Section 1613.10(a). The rope shall be used only if the qualified person determines that there are no deficiencies constituting a hazard. In making this determination, more than one broken wire in any one rope lay shall be considered a hazard.

(C) Each lift made under subsection (e)(3) shall be recorded in the monthly and annual inspection documents. Such prior uses shall be considered by the qualified person in determining whether to use the rope again.

(B) Rotation resistant ropes may be used as boom hoist reeving when load hoists are used as boom hoists for attachments such as luffing attachments or boom and mast attachment systems. Under these conditions, all of the following requirements shall be met:

3. The requirements in ASME B30.5-2004 sections 5-1.3.2(a), (a)(2) through (a)(4), (b) and (d) except that the minimum pitch diameter for sheaves used in multiple rope reeving is 18 times the nominal diameter of the rope used (instead of the value of 16 specified in section 5-1.3.2(d)).

4. All sheaves used in the boom hoist reeving system shall have a rope pitch diameter of not less than 18 times the nominal diameter of the rope used.

6. The operating design factor for these ropes shall be the total minimum breaking force of all parts of rope in the system divided by the load imposed on the rope system when supporting the static weights of the structure and the load within the equipment"s rated capacity.

(f) Wire rope clips used in conjunction with wedge sockets shall be attached to the unloaded dead end of the rope only, except that the use of devices specifically designed for dead-ending rope in a wedge socket is permitted.

(h) Prior to cutting a wire rope, seizings shall be placed on each side of the point to be cut. The length and number of seizings shall be in accordance with the wire rope manufacturer"s instructions.

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

Cranes must meet periodic inspection criteria as defined in the OSHA standard. All cranes must also meet the design, construction, and testing criteria as set forth in 29 CFR 1926.1433 through 1926.1441. If a manufacturer’s inspection criteria exceed the requirements as defined in the OSHA standard, the crane must be inspected to meet the criteria of the manufacturer. Prior to beginning work on the site, the crane subcontractor must verify the following inspections:

Periodic Monthly Inspections by a competent person. If equipment has been idle for 3 months or greater, a monthly inspection must be conducted by a competent person prior to use on the site.

Deficiencies identified in any wire rope inspection must be documented, categorized, and corrected as indicated in the standard before any work can begin.

Wire rope slings have played a critical role in applications like lifting, rigging, and hoisting. They are usually made from galvanized or un-galvanized steel wire strands, which are woven into ropes with end terminations. The end terminations can be loops or hooks.

Several industries, such as mining, manufacturing, shipping, and power generation, use wire rope slings because they are easy-to-use, cost effective, and reliable. Depending on the type of load and crane, you can use an assembly of wire rope slings for lifting, rigging, and hoisting.

Although they are extremely strong and durable, wire rope slings require regular maintenance and inspection. They must be inspected to ensure safety and prevent economic losses. In this short guide, we will take a look at wire rope sling inspection, maintenance, and replacement.

As mentioned before, the purpose of wire rope sling inspection is to identify any damage or excessive wear before it leads to a disaster. Two leading organizations in the US, OSHA, and ASME have published inspection and maintenance guidelines to ensure wire rope slings safety and functionality.

The two standards governing the criteria and guidelines of wire rope sling inspection are OSHA 1910.184 and ASME B30.9. As per these guidelines, there are three types of inspections.

This inspection should be carried out immediately after receiving the wire rope slings. During this inspection, make sure to check the sling identification tags. These tags will bear the product information, its rated load capacity, and other specifications. Check if they are what you ordered and what you need.

The second type of wire rope sling inspection is to be carried out daily or prior to use. As wire rope slings are used in a wide range of applications, it is always better to inspect them before each use. In other words, if you are going to use a sling three times a day, you should inspect it three times.

As wire rope slings can get damaged during a loading or rigging application, this inspection is extremely critical. You can have designated personnel, usually a competent crew member, to inspect wire rope slings before each use.

Only a certified professional or service provider can carry out periodic inspections. You also need to document each periodic inspection and maintain records, as per the ASME B30.9 guidelines. The schedule of periodic wire rope sling inspection depends on factors like frequency of use, the severity of work conditions, type of lifting or rigging, and experience gained on the service life of wire rope slings used in similar applications.

Even though it’s usually a visual inspection, you have to be thorough with it. Neither OSHA nor ASME has specified any fixed sling inspection process. You need to set up a process of your own based on your requirements, rope sling usage, and other factors.

Usually, a proper wire rope sling inspection process should include the following steps:Make sure to lay down the sling on a flat surface in such a way that all its areas are visible and easily accessible.

If possible, maintain a detailed record of all your sling inspections. Well-kept records make it easier to identify slings that are nearing the end of their service life or are damaged.

Sling tag identification is the most critical step in sling inspection. These tags help you identify the usage specifications of the slings. So, make sure to maintain the tags in excellent condition throughout the lifespan of the slings. If the tag is damaged or illegible, remove the sling from use immediately.

If you come across any of the following scenarios during your sling inspection, you will need to remove the slings immediately. Furthermore, if you are unsure of the potential damage, discontinue the use of slings.

While the structure and specifications of wires vary greatly, wire rope slings often have the following four key components:Core: The core is made from steel, synthetic, or natural fibers. The function of the core is to provide strength and support to the wires.

Wires: Wires are made from materials like steel, iron, bronze, and stainless steel. Wires surround the core, and they come in different sizes and strengths.

The guidelines for allowable broken wires are as follows:Single Part Body Slings and Strand Laid Grommets:5 broken wires in one strand in one rope lay

Distortion constitutes damages like kinking, crushing, and birdcaging, among others. If you see any such damage or wires and strands pushed out of their original positions, you need to replace the wire rope sling immediately.

Wire rope damage due to heat results in metallic discoloration, fusing of wires, or loss of lubricant. Make sure to replace the sling if there is heat damage.

While light surface rust will not affect the strength of wire rope slings, you will need a replacement if the corrosion has caused pitting or binding of wires.

When using wire rope slings, pulling through a loop can push out wires and strands from their original positions, pushing the slings out of balance. If you see this damage, replace the slings immediately.

Kinks are nothing but loops with permanent wire and strand distortions. As this type of damage is irreparable, you need to replace the slings right away.

Improper use of wire rope slings can cause doglegs, which are permanent bends. If the slings have minor doglegs with no strand distortion or if you can’t see them when the sling is under tension, you can continue using the sling. However, replacement is necessary if the doglegs are severe.

Make sure to discard the damaged wire rope slings in an eco-friendly manner. You should label the slings “Do Not Use” to avoid accidental use. Then, you should cut the eye and fittings from the rope, cut the rope into 3’ to 4’ sections, and send them for recycling.

The third most important step is wire rope sling maintenance. You should keep the following points in mind to ensure regular and comprehensive maintenance:Always keep the slings off the ground, in hanging position, and in a dry and cool environment.

Wire rope slings play a critical role in a wide range of industries such as mining, manufacturing, and shipping, among others. Although they are strong and have a long lifespan, rope slings do need regular inspection and maintenance to ensure safety and longevity. Hopefully, this guide will help clear all your doubts regarding wire rope sling inspection, replacement, and maintenance. If you need help with any rigging equipment inspection, maintenance, and replacement, feel free to reach out to our team at Holloway Houston Inc.

For over 40 years, Kennedy Wire Rope & Sling Company has supplied construction and industrial sites throughout the world with top quality, reliable lifting and rigging solutions. We tailor our clients’ rigging, lifting, and fall protection equipment to meet the demands of each job, fabricating every wire rope, synthetic, and chain sling to exacting industry standards. Additionally, we offer equipment inspection and repair, including a variety of onsite services as well as rigid proof testing to ensure the fitness of lifting or rigging systems with respect to the job to which they are commissioned.

8613371530291

8613371530291