wire rope inspection standards factory

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

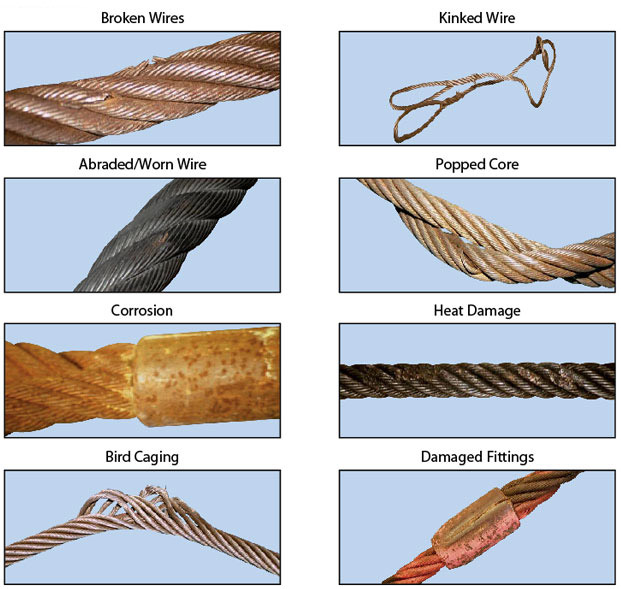

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

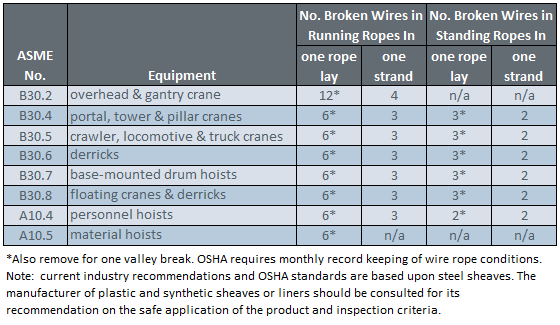

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Do you know who is supposed to be inspecting your lifting slings? More importantly, do you know how often they’re inspecting them? OSHA and ASME have different inspection requirements, frequencies, and removal criteria for each type of sling—including alloy chain slings, synthetic slings, metal mesh slings, and wire rope slings.

At Mazzella, we understand the amount of effort and coordination it takes to stay current on industry standards and to develop an inspection program that keeps your business in compliance. Because of this, we have a dedicated business unit made of up highly-trained and qualified inspectors and technicians that focus only on rigging equipment inspections, industry compliance, and sling testing and repair.

In this article, our goal is to help you understand what is required to inspect wire rope slings to meet ASME standards, which in turn, will help to ensure the safety of the users,help extend the service life of the slings, and help reduce unnecessary equipment repair costs and loss of production due to equipment downtime.

As a starting point, the same work practices which apply to all “working” wire rope apply to wire rope which has been fabricated into a sling. Therefore, a good working knowledge of wire rope design and construction will not only be useful, but essential in conducting a wire rope sling inspection.

There are two industry standards that exist to provide the end-user with guidelines for inspection and criteria that warrants removal from service: OSHA 1910.184 and ASME B30.9.

Initial Inspection (prior to initial use): Best practice is to inspect the wire rope sling upon receiving it from the manufacturer. Double-check the sling tag to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements.

Frequent (daily or prior to use): Designate a Competent Person to perform a daily visual inspection of slings and all fastenings and attachments for damage, defects, or deformities. The inspector should also make sure that the wire rope sling that was selected meets the specific job requirements it’s being used for.

Users can’t rely on a once-a-day inspection if the wire rope sling is used multiple times throughout the day. Damage to wire rope can occur on one lift and best practice is to perform a visual inspection before any shift change or changes in lifting application. Because shock loads, severe angles, sharp edges, and excessive heat can quickly cause damage to a lifting sling, the user should inspect the sling prior to each lift.

Periodic Inspection: A periodic inspection is performed by either a professional service provider, or by a Qualified Person, every 12 months (at a minimum) and monthly to quarterly in more severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:Frequency of use

Depending on the severity of the operating environment and frequency of use, your business may decide to inspect wire rope slings more often than the minimum yearly requirement.

Per ASME B30.9, the wire rope sling tag on all new slings shall be marked by the manufacturer to include:Rated load for the types of hitches (single-leg vertical, choker, and basket) and the angle upon which they are based

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use. When inspecting wire rope slings, daily visual inspections are intended to detect serious damage or deterioration which would weaken the sling.

This inspection is usually performed by the person using the sling in a day-to-day job. The user should look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion, etc. Any deterioration of the sling which could result in appreciable loss of original strength should be carefully noted and determination made on whether further use would constitute a safety hazard.

2. Broken Wires: For strand-laid grommets and single-part slings, ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay. For cable laid, cable laid grommets and multi-part slings, use the following:

3. Distortion: Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope.

7. Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light surface rust does not substantially affect strength of a sling.

9. Unbalance:A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

10. Kinks: Are tightened loops with permanent strand distortion that result from improper handling when a rope is being installed or while in service. A kink happens when a loop is permitted to form and then is pulled down tight, causing permanent distortion of the strands. The damage is irreparable and the sling must be taken out of service.

11. Doglegs: Are permanent bends caused by improper use or handling. If the dogleg is severe, the sling must be removed from service. If the dogleg is minor, (exhibiting no strand distortion) and cannot be observed when the sling is under tension, the area of the minor dogleg should be marked for observation and the sling can remain in service.

The best lifting and rigging inspection program is of no value if slings, which are worn out and have been retired, are not properly disposed of. When it is determined by the inspector that a sling is worn out or damaged beyond use, it should be tagged immediately DO NOT USE.

If it’s determined that the wire rope will be removed from service, we suggest cutting it down into more manageable sizes before discarding. This extra effort will help to accommodate the needs of most recycling facilities that will accept the damaged wire rope and also help to make sure that it cannot be used any further. Keep the following in mind when disposing of wire rope slings and wire rope cable:Cut into approximately 3’ to 4’ sections

OSHA does not provide clear guidelines on how to properly and adequately inspect wire rope slings. It is up to the designated inspection personnel to know the requirements of the sling inspection standards, and to develop a comprehensive inspection protocol. Wire rope inspection should follow a systematic procedure:First, it is necessary that all parts of the sling are readily visible. The sling should be laid out so every part is accessible.

Next, the sling should be sufficiently cleaned of dirt and grease so wires and fittings are easily seen. This can usually be accomplished with a wire brush or rags.

The best way to help extend the life of a wire rope sling, and help to ensure that it stays in service, is to properly maintain it during and in-between each use. Inspections are easier to perform—and probably more thorough—when slings are easily accessible and organized, kept off of the ground, and stored in a cool and dry environment.Hang slings in a designated area where they are off of the ground and will not be subjected to mechanical damage, corrosive action, moisture, extreme temperatures, or to kinking.

Like any other machine, wire rope is thoroughly lubricated at time of manufacture. Normally, for sling use under ordinary conditions, no additional lubrication is required. However, if a sling is stored outside or in an environment which would cause corrosion, lubrication should be applied during the service life to prevent rusting or corroding.

If lubrication is indicated, the same type of lubrication applied during the manufacturing process should be used. Your sling manufacturer can provide information on the type of lubricant to be used and provide the best method of application. We recommend a wire rope lubricant that is designed to penetrate and adhere to the wire rope core.

Proper inspection of your wire rope slings for damage or irregularities, prior to each use, is the best way to help keep everybody on the job site safe. Keep in mind that you’re planning to lift valuable and expensive equipment, and if a failure were to occur, it would not only cause unnecessary equipment repair costs and costly downtime, but also potentially jeopardize the lives of workers on site.

At Mazzella, we offer a variety of services including site assessments, rigging and crane operator training, sling inspection and repairs, overhead crane inspections and so much more. Our rigging inspection program is its own dedicated business unit with a team of inspectors that are certified through Industrial Training International to meet OSHA 1910.184 and ASME B30.9 requirements for sling inspection.

Wire ropes are largely used in marine environment or for rigging purposes. They receive considerable loads and thus suffer a great deal of mechanical damage throughout their service life. Moreover, research has shown that the major cause of wire rope failure is excessive deterioration and corrosion, lack of maintenance and inspection, and wrong usage resulting in early discarding, reduced safety and replacement cost increase.

Sometimes damage can be easily detected, while in other cases fractured wires may occur on the inside. Hence, wire ropes should be inspected and maintained by the right person (competent person assigned by the company), to assure they’re in perfect condition. Regular inspectionsensure high rope performance, long service lifetime , safety of personnel and equipment, and reduced operating costs.

All ropes (synthetic, high modulus and wire ropes) should be inspected before and after an operation. This guideline ensures maximum safety for both a ship’s personnel and equipment. Even though it’s difficult to determine the exact service life span of ropes, there is a way to have a more precise estimation about their efficient lifecycle. Calculating the exact time ropes have been in use (e.g mooring time, mooring conditions, weather and tidal conditions) is the answer. All in all, rope inspections should occur at least once a year.

Inspecting wire ropes in particular, comes with great responsibility. Inspection results should be recorded, and any defects noticed have to be reported and addressed properly. Some defects can be repaired, while in some cases replacing a wire rope is inevitable.

Periodical inspections ofvessel deck equipment is also crucial for maintaining the good condition of wire ropes. The condition of the drum, chocks, bitts, rollers, sheaves, cable clamps and other end fittings, affect the rope’s performance, threads and cords. Make sure to mark these parts during your overall inspection.

In order to help marine officers and staff conduct successful wire rope inspections – and keep an up-to-date record of them – we have created an inspection solution that helps in maintaining and monitoring a ship’s ropes and deck equipment.

When calculating mass using F = Minimum Breaking Force, according to the wire rope’s diameter, you can determine the Minimum Breaking Massand therefore the wire’s max strength. When calculating mass using F = Safe Load according to the wire rope’s diameter, you can determine the Safe Load Mass,which is the advised load for this rope diameter.

The strands of a wire rope absorb the majority of the tensile force applied on the rope. Their design and manufacturing standards affect the level of fatigue resistance and resistance to abrasion. An easy way to understand which rope design is suitable for each purpose, is the wire rope classification.

Wire ropes are classified according to the number of strands in each construction and the number of wires in each strand. For example, a classification of 6X19 means that a wire rope of this type always has six strands, but its wires could be 15-26 per strand. This is because 19 is not the exact number of wires, but the classification of a wire number range.

Visual inspections are a common and fast way to assess wire rope condition. Both the standard and rotation resistant wire rope inspectionprocesscomply with the same four steps of examination. A ship’s crew can perform them as follows:

Steel wire rope distortion is obvious in most cases and can easily be identified by the inspector or the ship‘s crew. It usually occurs if load is suddenly applied or abruptly released (shock loading), or even if swift torque is forcefully induced.

Although not all of these deformations make the rope absolutely dangerous to use, they all may cause ropes to wear unevenly in time. This means inspections should take place more often, and distorted ropes should be handled with caution.

The rag and visual inspection is a good method for regular inspection intervals. The inspector pulls a rag along the rope trying to find broken wire cords. If the rug gets snagged by the rope, the inspector has to stop and assess the wire rope’s condition. Extreme caution should be exercised during the visual inspection, and under no circumstances should this method be the only one used to inspect wire ropes.

Tip: When you encounter a protruding wire end, bend it back and forth manually, until it separates from the wire. This will protect neighboring wires from wearing out.

Diameter reduction is a critical factor in steel wire rope wear and if not properly taken care of, it can result in rope breakage. Excessive abrasion, loss of core mass, corrosion or inner wire failure are all factors that contribute to diameter reduction.

To get an accurate measurement of the rope’s diameter, measure the rope at three different points at least 5 feet apart. Take the average of these three measurements to determine the true diameter.

Any measurements showing a reduction of ⅓ or more, indicate that a replacement should follow without delay. A diameter reduction of less than 1/3 still requires attention, and the inspector or the ship’s crew should be on guard in the next scheduled wire rope inspection.

Failure from abrasion or corrosion is a result of deficient deck equipment inspection or insufficient wire rope lubrication respectively. Internal corrosive damage is more difficult to identify than any other types of degradation. In most cases, the damage has progressed more than the external signs suggest.

Wire rope storage plays a significant role in the rope’s operation life.Wire rope corrosion and pitting can be avoided if ropes are safely stored in a clean, cool, dry and well-ventilated place. Steel wire ropes should not by any means rest on the floor, and should be protected from water, dust or any chemical fumes. Long term storage requires periodic greasing, turning the reel upside down for preventing grease dripping and possibly re-winding to another reel with larger inner tube diameter.

Wire ropes should be maintained with periodical lubrication. In order to prevent internal corrosion, a pressure lubricator is suggested to be used. In this case, a small amount of grease is used to lubricate the rope internally, while the deck stays grease-clean. Pressure lubricators clean the rope before they grease it so that the new grease enters a clean rope. The type of grease used is very important for maximum protection and greasing efficiency.

Steel wire ropes exposed to dirt, grime and other contaminants, have to be cleaned with a wire brush and petroleum (unless a pressure lubricator is used). Optimal cleaning of wire ropes can extend their service life and guarantee safe operations.

The reeling process is of high importance for the longevity of wire ropes. To protect them from being damaged, it is important that the surface of the drum is clean, smooth and dry. Improper reeling may cause wire-rope strands to spread or get flattened, when in contact with one another, as successive layers are being spooled and upper layers apply pressure on the lower ones.

Katradis S.A. offers a wide range of top quality wire ropes for shipping (mooring and hoisting operations), fishing and construction purposes. Our wire ropes have greater resistance to fatigue, and they distribute tension force equally among the rope strands. They are less likely to kink, providing higher staff safety and assuring operation success.

A specific procedure for sling inspection is the best safeguard against injury, death and property damage. It is important that you employ a three stage level of inspection to ensure that slings are inspected with appropriate frequency. It is also important that all inspections must be done by trained and qualified personnel.

To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. If necessary, remove dirt and grime so wires and components are visible. Look for any of the conditions listed in the Removal from Service Criteria. The following example depict some of the types of damage, but note that they are relatively extreme examples provided for illustration purposes only.

If you identify ANY of these types of damage, remove slings from service immediately, even if the damage you see is not as extensive as shown. Slings that are removed from service must be destroyed and rendered completely unusable. Never ignore sling damage or attempt to perform temporary field repairs of damaged slings. It is very important that slings are regularly and properly inspected. If you are not sure whether or not a sling is damaged, DO NOT USE IT.

Wire rope is extremely sturdy and can be used in many different applications. In order to withstand harsh conditions, wire rope has basic guidelines of inspection it must meet. Continue reading to find out the guidelines of inspection for wire rope.

Abrasion damage is usually caused by the rope making contact with an abrasive surface. It can also be caused by simply passing over the drum and sheaves during regular, continued use. To minimize this risk, all components should be in proper working condition and be of appropriate diameter for the rope. Badly worn sheaves or drums will cause serious damage to a new rope and will greatly diminish the integrity of the rope quickly.

Corrosion is hard to assess but is more problematic than abrasion. Corrosion is usually the result of the lack of lubrication. It will most likely take place internally before there are any apparent signs on the rope’s surface. One telltale sign of corrosion is a slight discoloration, which is generally the result of rusting. This discoloration indicates a need for lubrication which should be dealt with as soon as possible. Failure to attend to this situation will lead to severe corrosion which will cause premature fatigue failures in the wires and strands. If this occurs, the rope will need to be removed immediately.

Diameter reduction is an extremely serious deterioration factor and can occur for several reasons. The most common reasons for diameter reduction are excessive abrasion of the outside wires, loss of core diameter/support, internal or external corrosion damage, or inner wire failure.

Examining and documenting a new rope’s actual diameter when under normal load conditions is critical. During the life of the rope, the actual diameter of the rope should be regularly measured at the same location under similar loading conditions. If this protocol is followed correctly, it should divulge a routine rope characteristic—after an initial reduction, the overall diameter will stabilize, then gradually decrease in diameter during the course of the rope’s life. This occurrence is completely natural, but if diameter reduction is confined to a single area or happens quickly, the inspector must quickly identify the source of the diameter loss and make the necessary changes if possible. Otherwise, the rope should be replaced as soon as possible.

Crushing or flattening of wire rope strands can happen for many reasons. These issues usually arise on multilayer spooling conditions but can also develop just by using the wrong wire rope for the specific application. Incorrect installation is the most common cause of premature crushing/flattening. Quite often, failure to secure a tight first layer, which is known as the foundation, will cause loose or “gappy” conditions in the wire rope which will result in accelerated deterioration. Failure to appropriately break-in the new rope, or even worse, to have no break-in protocol whatsoever, will also result in poor spooling conditions. The inspector must understand how to correctly inspect the wire rope, in addition to knowing how that rope was initially installed.

Another potential cause for the replacement of the rope is shock loading (also known as bird-caging). Shock loading is caused by the abrupt release of tension on the wire rope and its rebound culminating from being overloaded. The damage that ensues can never be amended and the rope needs to be replaced immediately.

There are several different instances that might result in high stranding. Some of these instances include the inability to correctly seize the rope prior to installation or the inability to maintain seizing during wedge socket installation. Sometimes wavy rope occurs due to kinks or very tight grooving issues. Another possible problem arises from introducing torque or twist into a new rope during poor installation methods. In this situation, the inspector must assess the continued use of the rope or conduct inspections more often.

There are a lot of guidelines for troubleshooting wire rope. At Silver State Wire Rope and Rigging, Inc., we take these guidelines seriously, and so should you. All of our products are tested and guaranteed to be the best fit for your specific needs. We can also help you with your troubleshooting needs. Contact us today!

If required UNIROPE® provides ON SITE INSPECTION SERVICE. Our factory trained inspection personnel will provide you with a full WRITTEN inspection report and a complete LISTING of all inspected slings in service at your plant or construction site. Where necessary we will proof-load the slings and issue a PROOF TEST CERTIFICATE. This service not only covers slings made from wire rope, but also slings made from chain and synthetic fibers.

The goal of a sling inspection is to evaluate the remaining strength in a sling, which has been used previously, to determine if it is suitable for continued use.

Specific inspection intervals and procedures are required by local safety regulations (e.g. in Ontario see OHSA) and by ASTM B30.9. The responsibility for having the inspection done is placed upon the SLING USER.

As a starting point, the same work practices which apply to all “working” wire ropes also apply to wire rope slings. Therefore, a good working knowledge of wire rope design and construction will not only be useful but essential in conducting a wire rope sling inspection.

Since a wire rope is a rather complex “machine”, no precise rules can be given to determine exactly when a wire rope sling should be replaced. There are many variables, and all must be considered.

Broken Wires: For 6-strand wire rope slings, 10 randomly distributed broken wires in one rope lay, or five broken wires in one strand of one rope lay. For Gator-Flex® and Tri-Flex® slings these same rules apply to each of the component ropes.

Metal Loss: Wear or scraping of one-third the original diameter of outside individual wires. This is quite difficult to determine on slings and you require some experience to perform this evaluation.

Distortion: Kinking, crushing, birdcaging, or other damage which distorts the rope structure. The main thing to look for are wires or strands that are pushed out of their original position in the rope. Slight bends in a rope where wires or strands are relatively in their original position would not be considered serious damage. But good judgment is indicated.

Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacement. Light rusting usually does not affect the strength of a sling.

Mechanical Damages: One of the most common causes of damage is the kink which results from pulling the sling body through the loop (choker hitching), thus causing wires or strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

Disposition: The best inspection program available is of no value if slings, which are worn out and have been retired, are not disposed of properly. Retired slings should be tagged DO NOT USE to prevent any further usage. The sling should be destroyed as soon as possible by cutting the eye and fittings from the rope.

Inspect the bearing point of the eye. Check for deformation and wear of sleeve, thimbles, and all attached hardware. Check for broken wires where the rope enters the sleeve or socket.

Both ASTM B.30.9 and most Provincial Regulations require that wire rope slings receive two types of inspections: a PRIOR TO USE visual inspection, and additional inspections where severe conditions warrant.

Daily inspections are intended to detect serious damage or deterioration which would weaken the sling. Look for obvious things, such as broken wires, kinks, crushing, broken attachments, severe corrosion.

Additional inspections must be carried out by a designated person who must have good knowledge of wire rope. The frequency of these regular inspections should be based on:

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

Wire rope is a collection of metal strands that have been twisted and wound to form the shape of a helix with the purpose of supporting and lifting heavy loads and performing tasks that are too rigorous for standard wire. On shipping docks, rigging, and load bearing equipment, wire rope is attached to swivels, shackles, or hooks to lift a load in a controlled, even, and efficient manner.

The uses for wire rope include adding support to suspension bridges, lifting elevators, and serving as additional reinforcement for towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

Individual designs of wire rope involve different materials, wire, and strand configurations as a means for supporting and assisting in the completion of lifting or supportive applications.

The term wire rope encompasses a wide range of mechanical tools that are made to perform heavy and extreme lifting jobs. Wire rope is a complicated and complex tool with multiple moving parts capable of moving in unison. A 6 by 25 wire rope has 150 outer strands that move as one in an intricate pattern supported by a flexible core.

An essential part of the design of wire rope is the required clearance between the strands to give each stand the freedom to move and adjust when the rope bends. It is this unique feature that differentiates wire rope from solid wire and other forms of cable.

The basic element of wire rope is wire that is used to configure, shape, and form the rope. Typically, steel, stainless steel, and galvanized wires are the first choice with aluminum, nickel alloy, bronze, copper, and titanium being second possibilities. The choice of wire is dependent on the type of work the wire is going to be used to perform with strength, flexibility, and abrasion resistance being the major determining factors.

Stainless steel wire rope has all of the basic qualities of galvanized and general wire rope with the added benefits of corrosion and rust resistance; this makes it the ideal choice for harsh and stressful conditions.

Steel wire rope is classified as general purpose wire rope and comes in a wide variety of sizes, diameters, and strengths. It is the most common type of wire rope and is used for several industrial, manufacturing, and construction applications.

Before going further into the discussion of how wire rope is made, it is important to understand the numbers used to describe each type. All wire ropes have a core around which wires are wound. The various styles of cores vary according to the construction and design of the requirements of the wire rope that is being produced.

Wire rope is classified by the number of strands it has as well as the number of wires in each strand. The most common classification is a seven wire rope that has one strand in the center and six around its circumference. This type of wire rope is lightweight with a very simple construction. The majority of wire ropes are more complex and intricate with multiple intertwining strands and wires.

What must be understood about wire rope is that it has a complicated configuration. It is actually wires wrapped around wires to form bundles that are wrapped around other bundles. In the case of a seven wire wire rope, the core has bundles of wires wound around it; this can be seen in the image below.

The first step in wire rope creation is the production of wire strands where wires are wound around a single core wire. The number of wires included in the strand is dependent on the specified strength, flexibility, and size requirements of the rope. Once the strand is completed, it is straightened before being moved to wire rope construction.

Like wire ropes, strands have different patterns; patterns are the arrangements of the wires and their diameters. Though most strands have a core, there are strand patterns that have three or four wires without a core that are referred to as centerless strands. The design of each strand pattern is meant to enhance the strength of the wire rope and improve its performance.

For a multiple layer strand, the layers of wire are placed over one another in successive order. The placement of the wires on top of each other must be such that they fit smoothly and evenly.

The Warrington pattern is like the multiple layer pattern with one variation. Like the multiple layer pattern, the inner wires and the core are the same and have the same diameter. The difference is in the outer layer, which has wires of alternating sizes of large and small with larger diameter wires laying in the valleys of the inner wires.

All of the wires of a filler pattern are the same size. What makes this pattern unique is the insertion of small wires in the valleys of the inner wires to fill the gap between the inner and outer layer.

The flattened strand pattern is also known as the triangular strand, which can be triangular or oval. Three round wires form the core. The outer flattened surface has a greater sectional metallic area; this makes this pattern stronger and longer lasting.

The core of a wire rope runs through the center of the rope and can be composed of a variety of materials, which include synthetic fibers, natural fibers, a single strand, or another wire rope. The core supports the wound strands, helps maintain their position, is an effective lubricant carrier, and provides support.

Wire ropes with fiber cores are restricted to light loads and are not used in severe, harsh, or stressful conditions. Polypropylene and nylon are types of synthetic fiber cores and can be used in conditions where there is exposure to chemicals.

Cores made of wire are classified as independent wire cores. The core of a wire rope with a wire core is actually a wire rope with another wire rope serving as the core, as can be seen in the diagram below. These types of wire ropes are used where the rope will be exposed to exceptional resistance and crushing.

A strand, or wire strand core, is exactly like the rest of the strands of the wire rope with wires of the same diameter and size as the other strands.

The choice of core and creation of the strands are the simplest yet most essential parts of wire rope construction. Wire rope lays, the method used to wind the strands, is more complex and involves several choices.

Lay is a term used to describe three of the main characteristics of wire rope: direction, relationship, and linear distance. The strands can be wrapped around the core going right or left. Right or left refers to the direction of the strands wrapped around the core and the wires within the strands. The linear distance is how far a strand moves when it is making a revolution around the core.

In a regular lay, the wires and strands spiral in opposite directions. With a right hand regular lay, the wires spiral to the left and the strands to the right. In the left hand regular lay, the wires spiral to the right and the strands to the left. This type of lay is easy to handle but wears out quickly because the crown wires are in contact with the bearing surface.

In the Lang, or Albert, lay, the wires and strands spiral in the same direction with right hand lay being the most common. The wires in a Lang lay appear to run parallel to the center line of the rope. The difficulty with Lang lay wire ropes is handling since they tend to kink, twist, and crush.

Wire rope is an exceptionally strong tool that has been configured and designed to withstand the stress placed upon it through rigorous and continual use. In most applications, wire rope has to endure extreme stress and strain. It is for these reasons that coatings have been developed to protect wire rope from abrasions, corrosion, UV rays, and harmful and damaging chemicals.

Three main types of coatings are used to protect wire rope: polyvinyl chloride (PVC), polypropylene, and nylon. Of the three types, PVC is the most popular.

In cases where there are severe and hazardous working conditions, polypropylene is the recommended choice since it is capable of protecting wire rope against corrosion and chemical leaching. Additionally, it is resistant to impact damage and abrasion. Polypropylene is a tough, rigid, and crystalline thermoplastic that is made from a propene monomer and is resilient as well as inexpensive.

Braided wires are electrical conductors made up of small wires that are braided together to form a round tubular braid. The braiding and configuration of braided wire makes them very sturdy such that they do not break when flexed or bent. Braided wires are widely used as conductors, are commonly made from copper due to copper"s exceptional conductivity, and can be bare or coated depending on the application.

Braided wire can be round and tubular or flat. Round tubular braids fit in most spaces where flat braided wire will not. Flat braided wire begins as round braided wire which is flattened on a capstan. They are exceptionally strong and designed for medical and aircraft applications.

Metals used to make wire rope are various grades of stainless steel, bright steel, and galvanized steel. Though the majority of wire rope manufacturers use these three metals, other metals such as copper, aluminum, bronze, and monel are also used on a limited basis.

The most important aspect of wire rope is the wire and the metal from which it is made. The strength and resilience of wire rope is highly dependent on the quality of metal used to make it, and these are essential factors to be considered when purchasing it.

Bright steel wire does not have a coating and is rotation resistant, (designed to not rotate when lifting a load). It is drawn from hot rolled rods that are put through a die to match its specific dimensional tolerances, mechanical properties, and finish. Bright wire is used as a single line in conditions that require a rope that will resist cabling.

Galvanized steel has a zinc coating for corrosion resistance and has the same strength and durability as bright steel. Environmental conditions determine the use of galvanized steel. In mildly severe and slightly harsh conditions, galvanized steel wire is an economical replacement for stainless steel.

In the manufacturing process, galvanized wire goes through the process of galvanization, a method of coating steel wire with a protective and rust resistant metal. Galvanized wire is exceptionally strong, rust resistant, and flexible enough to meet the needs of a variety of applications.

Wire rope made from copper is mostly used for electrical applications due to its exceptional electrical characteristics. The benefits of copper wire rope are its durability, flexibility, and resilience compared to standard copper wire. The strength of copper wire rope is seen in its use in applications where there are vibrations and shaking.

The wire rope lubrication process begins during its fabrication and continues during its use. Lubrication of wire rope is designed to lower the amount of friction it endures and provide corrosion protection. Continued lubrication increases the lifespan of wire rope by preventing it from drying up, rusting, and breaking.

The types of lubricants for wire rope are penetrating or coating with coatings covering and sealing the outside of the rope. Penetrating lubricants go deep into the rope and seep into the core where they evaporate to form a thick coating or film.

The application of the lubricant is dependent on the type of core. Fiber cores absorb the lubricant and serve as a reservoir that retains the lubricant for an extended period of time. With metal cores, the lubricant is applied as the wire is twisted into strands to give complete saturation and coverage of the wires.

There are several types of greases that are used as wire rope lubricating agents and are made up of oil, a thickener, and additives. The essential components are the base oil and additives, which influence the behavior of the grease. The thickener holds the base oil and additives together. The amount of base oil in a grease is between 70% and 95% with an additive of 10%.

The additive in grease enhances the positive properties of the oil and suppresses the negative properties. Common additives are oxidation and rust inhibitors as well as pressure, wear, and friction reducing agents.

Of the many choices for lubricants, vegetable oil is the easiest to use and penetrates the deepest. The design of the additives for vegetable oils gives them the necessary qualities required to penetrate deep into a wire rope. The exceptional penetration provides protection against wear and corrosion. Since vegetable oil is a fluid, it helps in washing the wire rope to remove external abrasive contaminants.

Wire rope is widely used in machines, structures, and varied lifting applications. Its type, size, and requirements are determined by how it will be used. Regardless of its use, wire rope guarantees exceptional strength and provides high quality and excellent performance.

The lifting of heavy loads for centuries involved the use of hemp rope or chains, neither of which was a guaranteed or substantial method. Early in the 18th Century, between 1824 and 1838, Wilhelm Albert, a German mining engineer, combined the twisting of hemp and strength of chains to create today‘s wire rope.

The most common use of wire rope is as a part of a crane hoist wherein it is attached to the hook of the hoist and wrapped around a grooved drum. The tensile strength and durability of wire rope makes an ideal tool for lifting and keeping loads secure. Though it is used in several industries, it is very popular for production environments wherein materials need to be lifted quickly and efficiently.

In addition to its many lifting applications, the strength and stability of wire rope is useful in other applications, especially in the aerospace industry. Pedals, levers, and connectors in the cockpit of an aircraft are connected with wire rope. The wires provide for the passage of power between systems and mechanisms; this allows control of the aircraft. Wire rope is used to control propeller pitch, cowl flaps, and the throttle. It also assists in lowering and minimizing vibrations.

Tires are reinforced with wire rope to increase their durability and strength. All automotive production environments make use of wire ropes for supplying materials, moving heaving loads, and positioning equipment. Wire rope can be found in the production of steering wheels, cables, exhausts, springs, sunroofs, doors, and seating components.

As surprising as it may seem, the place that wire rope has the greatest use is in the home, where its strength, long life, endurance, and resilience provide guaranteed protection and performance. The main reason wire ropes are so popular for home use is cost.

Inexpensive, easy to obtain, easy to install, and easy to maintain, wire ropes provide an additional method for performing home repairs and structural support. Their excellent flexibility and sturdiness combined with their invisibility has made wire rope an ideal solution to several home maintenance issues. It is used to support staircases, fences, decks, and hang plants.

The search and production of crude oil has relied on wire ropes for centuries to lift drill bits, insert shafts, and support oil rigs on land and the water. When equipment, machinery, and tools have to be lowered into the depths of the earth and sea, wire ropes are the tool that the oil industry relies on to do the job.

Many of the tasks of oil production require tools that are capable of enduring severe and harsh conditions. Wire ropes have to withstand enormous pressure, extraordinary stress, and a wide range of temperatures. The use of wire rope includes maintaining oil rig stability and moorings for offshore rigs.

Wire rope has long been a standard component for the transportation industry, from the cable cars of San Francisco to the lift chairs for ski resorts. For many years, cable cars have relied on heavy duty cables (wire ropes) to be pulled by a central motor from multiple locations. It is a method of transportation that has existed for centuries.

In Europe, funiculars use cables that hang from a support to move cars up and down a mountain with cables moving in opposite directions. The word funicular is from the French word funiculaire, meaning railway by cable. The terms wire rope and cable are used interchangeably when discussed by professionals. The first part of funicular, or funiculaire, is from the Latin word "funis," meaning rope.

The major use for wire ropes in the food and beverage industries is as a means for lifting and moving heavy loads. Wine barrels and containers full of ingredients are lifted and placed through use of cranes and wire ropes. They are also part of conveyor systems that move products from one station to another.

From the beginnings of amusement rides up to the present, wire ropes have been an essential part of attraction construction and safety. They pull cars on roller coasters, hold cabins that swing, and move carriages through haunted houses. The main concern of amusement parks is safety. The strength, stability, and guaranteed performance of wire ropes ensures that people who attend amusement parks will have a good time and stay safe.

The rigging used to complete the stunts in modern movies depends on wire rope for safety. Much like in amusement rides, wire ropes protect performers from injury and harm as they hang above a scene or carry out an impossible move.

The live theater industry uses wire ropes to raise and lower curtains, support overhead rigging, and hold backdrops and scenery pieces. During a production, rapid and efficient movement is a necessity that is facilitated by the use of wire ropes.

Wire rope is a tool that we tend to envision as indestructible, unable to succumb to any form of damage. Though it is exceptionally sturdy and strong as well as capable of enduring constant use, it is just as susceptible to breakdown as any other tool.

To avoid serious harm and damage, wire ropes should be scheduled for regular inspections. There are situations that can damage or break a wire rope; these should be understood prior to the problem arising.

Guide rollers have the potential to damage and cause abrasions on wire rope if they become rough and uneven. Of the various elements of a crane and lift, guide rollers have the greatest contact with the mechanism‘s wire rope. Regular inspection of guide rollers will ensure they are not damaging the rope or causing abrasions.

Bending is normally a regular part of wire rope usage; this occurs repetitively as the rope passes through a sheave. As a wire rope traverses the sheave, it is continually bent and develops cracks or breaks. The cracking and breaking are exacerbated by movement on and off the groove of the drum. Normally, the breakage happens on the surface and is visible. Once it appears, it accelerates to the core of the rope.

A bird cage is caused by a sudden release of tension and a rebound of the rope. This type of break requires that the rope be replaced since the place of the break will not return to its normal condition.

Wire ropes are multi-layered; this makes them flexible and torque balanced. The layering inside and outside creates flexibility and wear resistance. Relative motion between the wires causes wear over time, which leads to internal breakage. The detection of these breaks can be indicated by an electromagnetic inspection that calculates the diameter of the rope.

Kinked wire rope is caused by pulling a loop on a slack line during installation or operation; this causes a distortion in the strands and wires. This is a serious condition that necessitates rope replacement.

Corrosion damage is the most difficult cause of wire rope damage to identify, which makes it the most dangerous. The main reason for corrosion is poor lubrication that can be seen in the pitted surface of the rope.

The types of damage and problems listed here are only a small portion of the problems that can be caused if a wire rope is not regularly lubricated and inspected. Various regulatory agencies require that wire ropes be inspected weekly or monthly and provide a list of factors to examine.

As with any type of heavy duty equipment, wire rope is required to adhere to a set of regulations or standards that monitor and control its use for safety and quality reasons. The two organizations that provide guidelines for wire rope use are the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA).

All wire rope manufacturers and users closely follow the standards and guidelines established by OSHA and ASME. In the majority of cases, they will identify the specific standards they are following in regard to their products.

OSHA‘s regulations regarding wire rope fall under sections 1910, 1915, and 1926, with the majority of the stipulations listed in 1926 under material handling, storage, use, and disposal.

"Running rope in service shall be visually inspected daily, unless a qualified person determines it should be performed more frequently. The visual inspection shall consist of observation of all rope that can reasonably be expected to be in use during the day‘s operations. The inspector should focus on discovering gross damage that may be an immediate hazard."

"The inspection frequency shall be based on such factors as rope life on the particular installation or similar installations, severity of environment, percentage of capacity lifts, frequency rates of operation, and exposure to shock loads. Inspections need not be at equal calendar intervals and should be more frequent as the rope approaches the end of its useful life. Close visual inspection of the entire rope length shall be made to evaluate inspection and removal criteria."

ASTM A1023 covers the requirements for steel wire ropes with specifications for various grades and constructions from ¼ in. (6 mm) to 31/2 in. (89 mm) manufactured from uncoated or metallic coated wire. Included are cord products from 1/32 in. (0.8 mm) to 3/8 in. (10 mm) made from metallic coated wire.

United States Federal Spec RR W 410 covers wire ropes and wire seizing strands but does not include all types, classes, constructions, and sizes of wire rope and strands that are available. The purpose of Spec RR W 410 is to cover more common types, classes, constructions, and sizes suitable for federal government use.

Wire rope and wire seizing strand covered by United States Federal Spec RR W 410 are intended for use in general hauling, hoisting, lifting, transporting, well drilling, in passenger and freight elevators, and for marine mooring, towing, trawling, and similar work, none of which are for use with aircraft.

API 9A lists the minimum standards required for use of wire rope for the petroleum and natural gas industries. The types of applications include tubing lines, rod hanger lines, sand lines, cable-tool drilling and clean out lines, cable tool casing lines, rotary drilling lines, winch lines, horse head pumping unit lines, torpedo lines, mast-raising lines, guideline tensioner lines, riser tensioner lines, and mooring and anchor lines. Well serving wire ropes such as lifting slings and well measuring are also included in API 9A.

Wire rope is a collection of metal strands that have been twisted and wound to form the shape of a helix with the purpose of supporting and lifting heavy loads and performing tasks that are too rigorous for standard wire.

Individual designs of wire rope involve different materials, wire, and strand configurations as a means for supporting and assisting in the completion of a lifting or supportive task.

All wire rope slings shall be tagged with name or trademark of manufacture, rated loads for the types of hitches used and the angle upon which it is based and the diameter or size.

Any sling that is not standard, an in-house break test shall be performed and the results recorded and placed in the proper binder. If the test proves unsatisfactory, the sling shall not be manufactured until such time that necessary changes are made and the assembley meets all requirements.

Before being released to the customer, the fabricator and second inspector shall sign The New Product Fabrication Form that they have met these standards in the manufacturing, testing and packaging process.

In this article, the reader will find all the information for a conscious use of the MRT equipment, perfectly in compliance with the ISO4309 regulation. We hope that this short read will help the rope technicians to evaluate autonomously how to behave during an inspection. This article has been written with the intent of clarifying misinterpretations of the ISO4309 but it cannot substitute in any case the regulation. Each rope technician is highly invited to read ISO4309 before performing any rope inspection.

The magneto-inductive method was born at the beginning of the 20th century in the ropeways sector, where safety criteria have always been the strictest. In the following years the technology evolved, devices became smaller, lighter and cheaper and around the 80’s they arouse the interest of the heavy lifting sector. Since the early 2000s, the methodology began to be used widely, especially in the offshore sector, where ropes operate in a very harsh environment.

The usefulness of the method is so relevant that in the ISO 4309: 2010 it was indicated as a valid aid to visual inspection (chapter 5.6), but at the end of 2017 the new version of the standard (ISO 4309: 2017) was finally released, introducing the magneto-inductive test in the assessment methods table for rope status evaluation. New discard criteria were specially defined. The magneto-inductive method officially became an aid to the visual inspections and the preferred solution for performing internal rope inspections.

The MI method must always be associated with a visual inspection. The competent person detects visible defects and fill out a correct report; if defects are not visible but highlighted by the MRT, the operator rates the severity of the deterioration, as defined by the regulation.

For all these modes of deterioration the competent person must express a severity rating, which is the result of the relative assessment method. For example, regarding the reduction in diameter the measurement is necessary, whilst, regarding the number of visible broken wires, counting is the appropriate method.

Inspectors must evaluate wear and corrosion inside and outside the rope. Furthermore, they must evaluate the loss of metallic section caused by internal and external broken wires.

It is well known that some specific defects generate in the inner part of the rope. In this case it is almost impossible to perform a visual inspection. For this reason, ISO4309 assesses the Magnetic Rope Test as the preferred method for “Loss of metallic area caused by broken wires”, “Loss of metallic area caused by mechanism other than broken wires” and for “Corrosion (external, Internal and fretting)”. Thanks to this specific methodology the competent person is able to inspect the modes of deterioration as prescribed by the regulation.

In the European Communities ISO4309 is harmonized in EN12385. Every rope commercialized in Europe must follow EN12385, and it should be written on the specific rope “Use & Maintenance Manual”. The compliance with this latter regulation provides a presumption of conformity with the relevant essential requirements of the directive 98/37/EC. For this reason, the rope manufacturers have two options:

It could happen that the manual is not available. In this case, it is mandatory to follow the related regulation, for example ISO4309 for ropes. In any case, you must follow the laws of the country where you’re performing the inspection.

The competent person must be aware of how he’s performing the inspection, because he must keep himself and the plant safe, he must always follow the ISO4309 regulation to be in compliance with the correct inspection procedure. To hasten the efficiency of the MRT method, we highly suggest the reader to check our article: “The visual Inspection and the MRT”. For the most interested readers we recommend the articles listed in the bibliography.

[4] V. Cacciatore, A. Canova, A. Vallan and B. Vusini, “Experience and technologies in NDT of ropes”. KEY ENGINEERING MATERIALS, (2007), vol. 347, pp. 627-632.

[5] A. Canova, B. Vusini, “Magnetic analysis of non-destructive testing detectors for ferromagnetic ropes”, COMPEL: The International Journal for Computation and Mathematics in Electrical and Electronic Engineering, Vol. 27 No. 4, 2008, pp. 869-878.

[6] A. Canova, F. Degasperi, F. Ficili, M. Forzan, B. Vusini “Experimental and numerical characterisation of ferromagnetic ropes and non-destructive testing device”, Proc. of OIPEEC Conferebce 18th – 20th March 2009, Stuttgart, Germany, pp. 289-298.

[8] H.R. Weischedel, (1999), “Electromagnet

8613371530291

8613371530291