wire rope las vegas free sample

At Silver State Wire Rope and Rigging, Inc. we pride ourselves in providing you and your company comprehensive wire rope and rigging solutions. With our locations in Las Vegas and Northern Nevada, we offer a full range of conventional and custom engineered rigging products and solutions, as well as a full spectrum of tension and non-destructive testing. This testing includes magnetic field testing of wire rope tension testing of wire ropes and mining rope tension testing to CSA G-4 test protocols.

Along with general purpose and high performance wire rope, cable, slings, and specialized cables, we have a complete range of rigging hardware items and field rigging services. Silver State Wire Rope and Rigging, Inc. also offers rigging rental items for many of the projects you have.

With a primary focus on safety, Silver State Wire Rope and Rigging, Inc. is the only company of its kind in the state for wire rope and rigging solutions. With general offices, manufacturing facility and warehousing in Las Vegas and Elko, Nevada and several product divisions, we specialize in a broad spectrum of wiring and rigging-related services. About Us

Wire rope is an essential tool for safety when mining. As Nevada’s and California’s number one choice in the active mining industry, we can make sure no matter what the job is, we’ll supply full-service wire rope that meets your jobs requirements and safety standards. Learn More

The entertainment industry in Las Vegas is a shining star that brings people from all over the world. However, for the show to go on, these highly skilled professionals needs the safest wire rope money can buy. Bring any show or event to life with Silver State Wire Rope and Riggings professional and safety-first wire rope services. Learn More

Utility jobs vary from job site to job site, each having unique needs and wire rope requirements to get the job done safely and efficiently. Our wire rope is designed to fit the specific requirements on all types of utility work sites, so you can save money and be safe on the job!

Wire rope is an essential tool for safety when mining. As Nevada’s and California’s number one choice in the active mining industry, we can make sure no matter what the job is, we’ll supply full-service wire rope that meets your jobs requirements and safety standards. Learn More

Need an OSHA Rigging certified company with accreditation in Nevada and California? Silver State Wire Rope and Rigging is certified, and our training services are always on top of any new OSHA standards for wire rope, rigging. Our training services cover all types of rigging needs such as entertainment, utility, mining, and more. Learn More

Wire ropes are incredibly versatile. This versatility allows them to be utilized by many different industries. However, to meet people’s exact needs, they are constructed in different styles, weights, and sizes. Various tools help users get the most out of their wire ropes. When it comes to wire ropes, you have many choices. Continue reading…June 22, 2022

Silver State Wire Rope & Rigging first opened in 1991. Initially, our staff trained in the industrial, mining, and construction sectors. As we honed our practice and continued to expand, we quickly evolved into a full range rigging store. Now, we proudly service the entertainment and exposition sectors, as well.

Since the inception of SSWR, we have continued to innovate with the industry. Whether it was our initial foray into the entertainment industry to our continual research into cutting edge technology, to our commitment to the changing safety standards offered by OSHA — Silver State Wire Rope & Rigging is committed to giving our clients the best possible solutions.

Our website was created to be a useful reference to our clients for sourcing products and to be a resource of helpful information. We have chosen every service and product on our website on the basis of meeting our high standards for quality, availability and competitive pricing. All of the information and educational material on ourbloghas been curated to be the most helpful for anyone who may need wire rope and rigging in the mining, industrial, construction, or entertainment industries.

While the Silver State Wire Rope & Rigging website was designed to be as thorough as possible, it does not necessarily cover our entire scope of possibilities. We value personalized, bespoke solutions for each and every client. If you have a need that doesn’t seem to be addressed by our website, please feel free tocontact usand our team of professionals will get to work for you!

Manufactorer and designer of wire rope and rigging services based in Las Vegas, Nevada. The company offers a full range of conventional and custom-engineered rigging products and a full spectrum of tension and non-destructive testing which includes magnetic field testing of wire rope, tension testing of wire ropes and mining rope tension testing.

Opened in 1991 with a staff trained in the Industrial, Mining, and Construction sectors, Silver State Wire Rope and Rigging, Inc in Las Vegas, Nevada is the only company of its kind in the state. We specialize in a broad spectrum of rigging related services including: Wire Rope, Cable, Slings, and Specialized Cable Assemblies, Rigging Hardware, Safety Products and Hand and Electric Hoists.

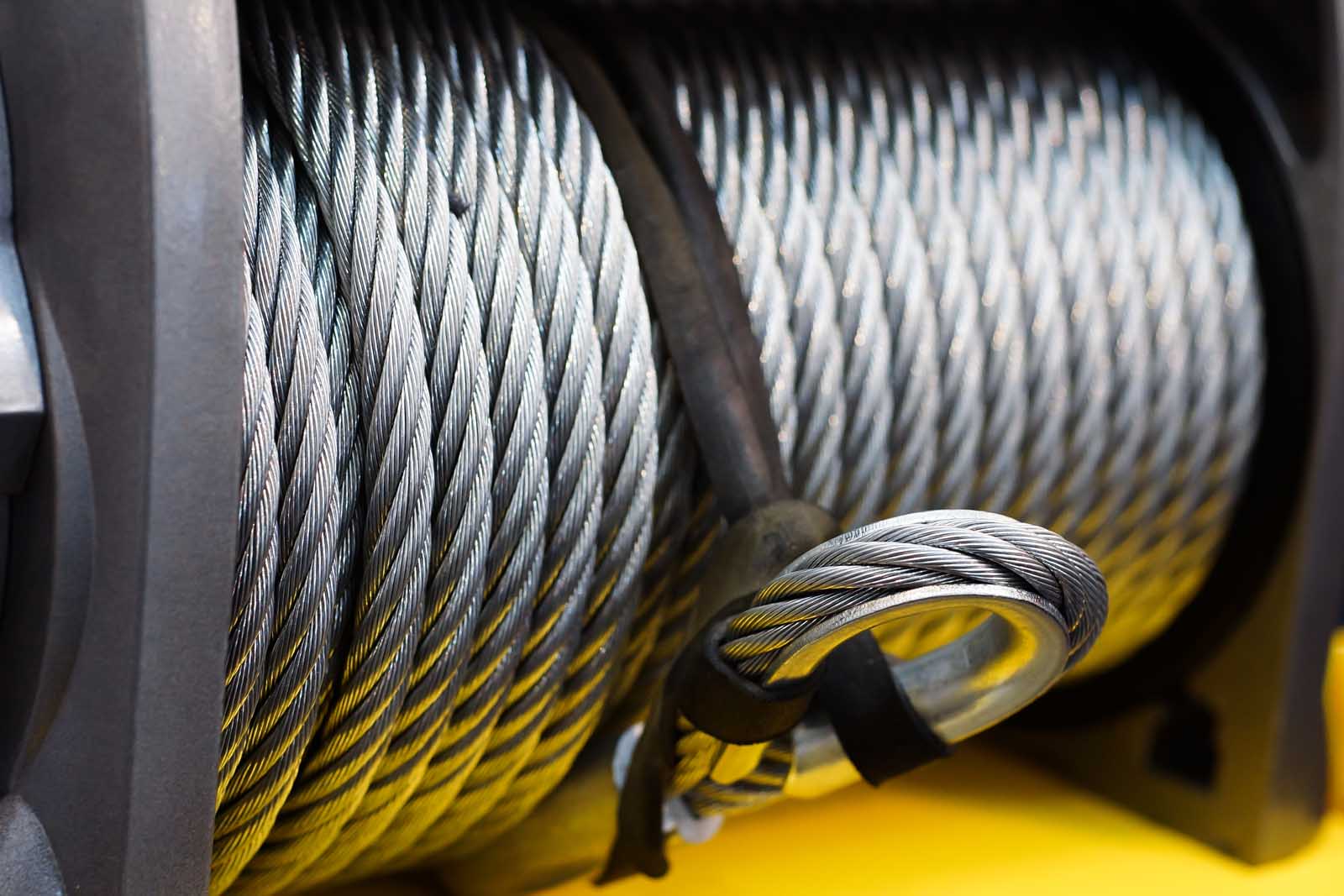

Wire rope is a complex mechanical device that has many moving parts, all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

A wire rope is a machine with many moving parts. It has a unique design consisting of steel wires that form individual strands laid in a helical pattern around a center core.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A finished wire rope is comprised of individual wires, which make up individual strands, which are then laid in a helical pattern around a synthetic or steel core.

A wire rope is a machine with many moving parts. From childhood, many of us have been conditioned to think of a machine as some device with gears, shafts, belts, cams and assorted whirring parts. Yet, by the rules of physics, an ordinary pry bar is a simple machine, even though it has only one part.

A wire rope is, in reality, a very complicated machine. A typical 6 by 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Wire rope is a complex piece of mechanical machinery with a number of different specifications and properties that can affect its performance and service life.

A finished wire rope is comprised of individual wires, which make up individual strands, which are then laid in a helical pattern around a synthetic or steel core. There are four basic components that make up the design of a finished wire rope:

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

The construction of wire rope falls into one of these strand pattern classifications. The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys,and the smaller ones on the crowns of the inner layer.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

A rope with larger diameter wires will be more crush resistant and abrasion resistant, while a rope with smaller diameter wires will be more bendable and fatigue resistant.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope. Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).

Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay – The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A fiber core can be made of natural or synthetic polypropylene fibers. Fiber cores offer greater elasticity than a steel core but are more susceptible to crushing and not recommended for high heat environments.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the same strength and weight ratings and usually the same pricing.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system. Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Some maintenance can easily be overlooked when it comes to several items. However, this can lead to serious issues. Maintenance on wire rope should be done to ensure that the rope will work for a long time. The maintenance that needs to be done when it comes to wire rope is actually quite simple. On...

A few years ago, I gave the talk at Groundwater Week in Las Vegas that this series is based on. To prepare, I talked to a few manufacturers. I asked, how often do you require inspection of the wire rope on your drills? Every one of them stated they did not have change-out, rotation or inspection schedules listed in the manuals for their units. The reasoning for this was the liability of giving these recommendations. It would put the manufacturer in the hot seat if an accident occurred and the drill crew had followed manufacturer recommendations.

This lack of guidance from manufacturers puts the liability on drillers and the companies that hire them. The driller must inspect the rig and its components each day and decide if they are safe to run. The CEO or owner must question whether the company thoroughly trains crews with safety in mind. Are our crews making the right choices? Add to this the required documentation: inspections filled out, utilized and retained to develop a company change-out, replacement or rotation schedule. After all wire rope, despite its durability and strength, eventually wears out and must be removed. Regular inspection is crucial.

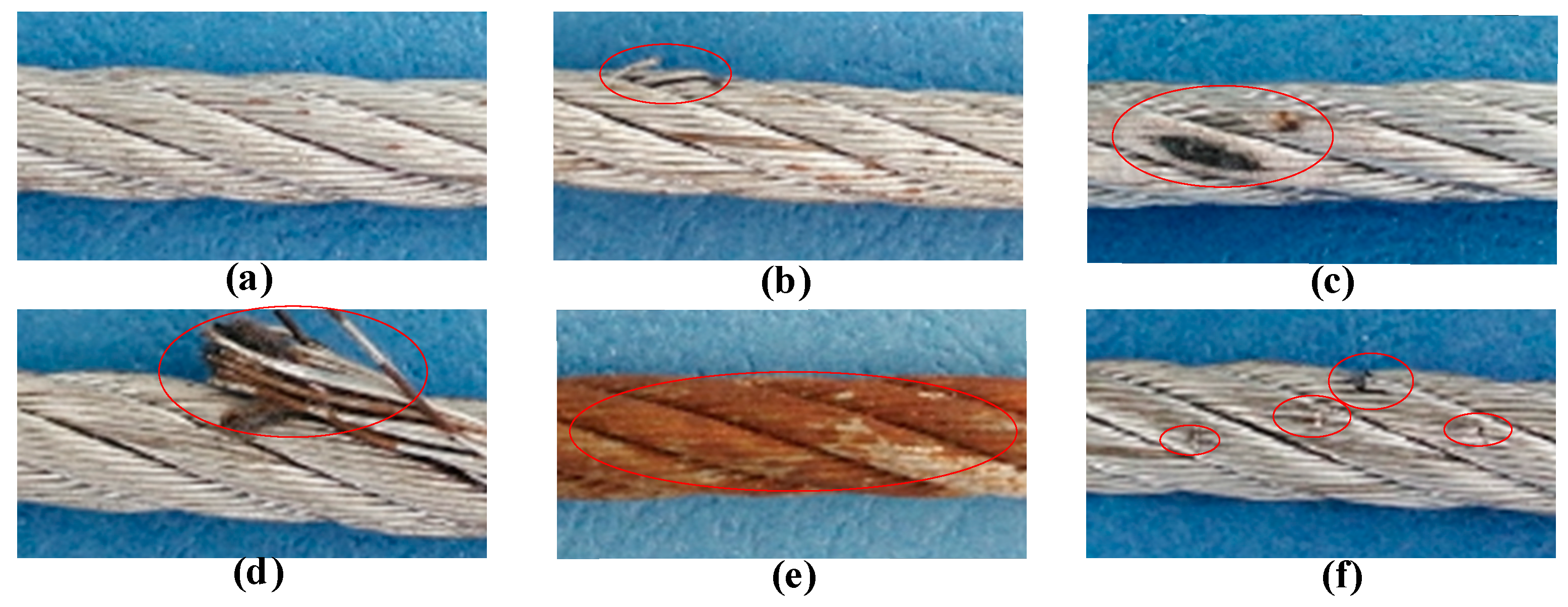

Visually inspect all hoisting lines at least once each day when in use, as is suggested by American Petroleum Institute (API) RP54 guidelines. Based on the amount of use and misuse, pay daily attention to the condition of all wire ropes. Wire rope is one of the most-used components of the drill rig or pump hoist, therefore is one of the most susceptible to constant wear and tear. Consider any damage or significant wear a potential problem. It is required to know the condition of the equipment before operating the rig or hoist.

The life of a wire rope is dictated by wear, abrasion, kinks, metal fatigue, corrosion and improper reeving. It should not take equipment failure or personal injury to find out your wire rope is deficient. Thoroughly inspect all hoisting lines monthly, making careful records of each month’s inspection.

Significant distortion: Wire rope structure concerns such as kinking, crushing, unstranding, birdcaging, signs of core failure or core protrusion between outer strands.

Improperly applied end connections or damaged end connections:Significantly corroded, cracked, bent, or worn end connections (such as from severe service or misuse).

If a deficiency in Category I is identified, an immediate determination must be made by a competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited. The wire rope must be replaced or, if the deficiency is localized, the problem corrected by severing the rope in two. The undamaged portion may continue to be used. Joining two or more lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have the minimum of two full wraps of wire when the load is in its lowest position.

Other than sand lines, remove wire ropes used as running ropes from service when broken wires meet any of the following Category II criteria:For six- and eight-strand constructions, replace when you see six randomly distributed broken wires within one lay length, or three broken wires in one strand within one lay length.

For rotation-resistant constructions, replace when you see two randomly distributed broken wires in six rope diameters – or four randomly distributed broken wires in 30 rope diameters.

When it comes to wire ropes used as standing ropes, such as guy lines, escape lines and pendant lines, remove from service after identifying any of the Category II deficiencies described above. Prohibit any operations involving use of the wire rope in question.

The employer complies with the wire rope manufacturer’s established criteria for removal from service, or a different criteria the wire rope manufacturer has approved in writing for that specific rope. Again, if a rope is shortened the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category III is identified, operations involving use of the wire rope in question must be prohibited until the wire rope is replaced! These type of deficiencies include:In rotation-resistant wire rope, core protrusion or other distortion indicating core failure.

Answers to these questions will lead you to your conclusion. Wire rope is an amazingly strong machine if we take care of it and use it properly. If we do not take care of it, it will be like that old car you may have had in high school. You never could be quite sure it would get you were you wanted it to. Until next month, stay safe and drill straight.

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbors along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero. The open spiral rope consists only of round wires. The half-locked coil rope and the full-locked coil rope always have a centre made of round wires. The locked coil ropes have one or more outer layers of profile wires. They have the advantage that their construction prevents the penetration of dirt and water to a greater extent and it also protects them from loss of lubricant. In addition, they have one further very important advantage as the ends of a broken outer wire cannot leave the rope if it has the proper dimensions.

Stranded ropes are an assembly of several strands laid helically in one or more layers around a core. This core can be one of three types. The first is a fiber core, made up of synthetic material or natural fibers like sisal. Synthetic fibers are stronger and more uniform but cannot absorb much lubricant. Natural fibers can absorb up to 15% of their weight in lubricant and so protect the inner wires much better from corrosion than synthetic fibers do. Fiber cores are the most flexible and elastic, but have the downside of getting crushed easily. The second type, wire strand core, is made up of one additional strand of wire, and is typically used for suspension. The third type is independent wire rope core (IWRC), which is the most durable in all types of environments.ordinary lay rope if the lay direction of the wires in the outer strands is in the opposite direction to the lay of the outer strands themselves. If both the wires in the outer strands and the outer strands themselves have the same lay direction, the rope is called a lang lay rope (from Dutch langslag contrary to kruisslag,Regular lay means the individual wires were wrapped around the centers in one direction and the strands were wrapped around the core in the opposite direction.

Multi-strand ropes are all more or less resistant to rotation and have at least two layers of strands laid helically around a centre. The direction of the outer strands is opposite to that of the underlying strand layers. Ropes with three strand layers can be nearly non-rotating. Ropes with two strand layers are mostly only low-rotating.

Stationary ropes, stay ropes (spiral ropes, mostly full-locked) have to carry tensile forces and are therefore mainly loaded by static and fluctuating tensile stresses. Ropes used for suspension are often called cables.

Track ropes (full locked ropes) have to act as rails for the rollers of cabins or other loads in aerial ropeways and cable cranes. In contrast to running ropes, track ropes do not take on the curvature of the rollers. Under the roller force, a so-called free bending radius of the rope occurs. This radius increases (and the bending stresses decrease) with the tensile force and decreases with the roller force.

Wire rope slings (stranded ropes) are used to harness various kinds of goods. These slings are stressed by the tensile forces but first of all by bending stresses when bent over the more or less sharp edges of the goods.

Technical regulations apply to the design of rope drives for cranes, elevators, rope ways and mining installations. Factors that are considered in design include:

Donandt force (yielding tensile force for a given bending diameter ratio D/d) - strict limit. The nominal rope tensile force S must be smaller than the Donandt force SD1.

The wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

Lifting installations for passenger transportation require that a combination of several methods should be used to prevent a car from plunging downwards. Elevators must have redundant bearing ropes and a safety gear. Ropeways and mine hoistings must be permanently supervised by a responsible manager and the rope must be inspected by a magnetic method capable of detecting inner wire breaks.

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment. There are different ways of securing the ends of wire ropes to prevent fraying. The common and useful type of end fitting for a wire rope is to turn the end back to form a loop. The loose end is then fixed back on the wire rope. Termination efficiencies vary from about 70% for a Flemish eye alone; to nearly 90% for a Flemish eye and splice; to 100% for potted ends and swagings.

When the wire rope is terminated with a loop, there is a risk that it will bend too tightly, especially when the loop is connected to a device that concentrates the load on a relatively small area. A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the cable from pinching and abrading on the inside of the loop. The use of thimbles in loops is industry best practice. The thimble prevents the load from coming into direct contact with the wires.

A wire rope clip, sometimes called a clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-bolt, a forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted to the bolt over the ropes (the saddle includes two holes to fit to the U-bolt). The nuts secure the arrangement in place. Two or more clips are usually used to terminate a wire rope depending on the diameter. As many as eight may be needed for a 2 in (50.8 mm) diameter rope.

The mnemonic "never saddle a dead horse" means that when installing clips, the saddle portion of the assembly is placed on the load-bearing or "live" side, not on the non-load-bearing or "dead" side of the cable. This is to protect the live or stress-bearing end of the rope against crushing and abuse. The flat bearing seat and extended prongs of the body are designed to protect the rope and are always placed against the live end.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound a certain distance, then bent around so that the end of the unwrapped length forms an eye. The unwrapped strands are then plaited back into the wire rope, forming the loop, or an eye, called an eye splice.

A Flemish eye, or Dutch Splice, involves unwrapping three strands (the strands need to be next to each other, not alternates) of the wire and keeping them off to one side. The remaining strands are bent around, until the end of the wire meets the "V" where the unwrapping finished, to form the eye. The strands kept to one side are now re-wrapped by wrapping from the end of the wire back to the "V" of the eye. These strands are effectively rewrapped along the wire in the opposite direction to their original lay. When this type of rope splice is used specifically on wire rope, it is called a "Molly Hogan", and, by some, a "Dutch" eye instead of a "Flemish" eye.

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform the fitting, creating a permanent connection. Threaded studs, ferrules, sockets, and sleeves are examples of different swaged terminations.

A wedge socket termination is useful when the fitting needs to be replaced frequently. For example, if the end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the termination hardware to be removed and reapplied. An example of this is on the ends of the drag ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped around a separate component called the wedge. The arrangement is knocked in place, and load gradually eased onto the rope. As the load increases on the wire rope, the wedge become more secure, gripping the rope tighter.

Poured sockets are used to make a high strength, permanent termination; they are created by inserting the wire rope into the narrow end of a conical cavity which is oriented in-line with the intended direction of strain. The individual wires are splayed out inside the cone or "capel", and the cone is then filled with molten lead-antimony-tin (Pb80Sb15Sn5) solder or "white metal capping",zincpolyester resin compound.

Donald Sayenga. "Modern History of Wire Rope". History of the Atlantic Cable & Submarine Telegraphy (atlantic-cable.com). Archived from the original on 3 February 2014. Retrieved 9 April 2014.

The new report by Expert Market Research titled, ‘Global Steel Wire Rope Market Report and Forecast 2021-2026’, gives an in-depth analysis of the global steel wire rope market, assessing the market based on types of lay, strand patterns, steel types, coating types, applications, and major regions. The report tracks the latest trends in the industry and studies their impact on the overall market. It also assesses the market dynamics, covering the key demand and price indicators, along with analysing the market based on the SWOT and Porter’s Five Forces models.

The global steel wire rope market is being driven by the increasing demand from major application sectors, such as oil and gas and heavy machinery. The Asia Pacific is one of the leading regions in the global steel wire rope industry. Steel wire rope consumption and sales are extremely high in the Asia Pacific, especially in China, Indonesia, and India. The steel wire rope industry in China has grown significantly over the last decade owing to the growing production of steel and rising investments in infrastructure activities involving lifting and motion applications. The increasing construction activities in China are expected to provide enhanced growth opportunities to the market in the forecast period.

A steel wire rope, which is composed of wires, strands, and a core made of steel and fibre, is a machinery commonly used in construction, mining, oil and gas, and marine sectors, among others. The function of the core is to sustain the external strands and protect them as they function. The wires, which are primarily made of stainless steel and high carbon steel, are twisted into strands to finally produce steel wire ropes.

The steel wire rope industry is expected to witness a healthy growth as a result of the product’s expanding applications in various sectors such as marine and fishery, and industrial and crane, among others. Steel wire ropes are light, strong, corrosion resistant, have low specific gravity and excellent elasticity, and are easy to mould. These ropes are favoured in these sectors because of their excellent impact resistance, longevity, high strength, abrasion resistance, and corrosion resistance. In the coming years, the rapid urbanisation and industrialisation and the growth of these sectors, particularly in emerging nations, are expected to drive the market growth.

The major players in the market are Cortland Limited, Anchor Industries Pty Ltd, Samson Rope Technologies, Inc., Chung Woo Rope Co. Ltd, Teufelberger Holding AG, Fasten Group, and Bekaert Group, among others. The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

8613371530291

8613371530291