wire rope locking mechanism factory

An oil impregnated sintered steel locking wedge is seated in each of two channels. Both wedges incorporate a release pin for easy adjustment. Each wedge makes contact with the wire rope using serrated teeth. These teeth press onto the wire rope and spread the load across the length of the wedge, maximizing grip strength.

Developed and manufactured in the UK by Millfield Enterprises, under ISO 9001: 2015 accreditation WIRELOCK® has a trusted track record spanning over 50 years.

Spring snap hook, swivel eye snap hook, quick link, chain, towing chain, safety rope, cable clamp, shoulder eye bolt, turnbuckle hook & eye, O ring, D ring shackle, fishing plier, etc.

The last thing you want when out and about on your bike is the nasty surprise of returning to where you parked it, only to find your bike is gone! Avoid this at all costs thanks to a wire rope lock from Alibaba.com. Choose your level of security and the shape that you prefer and you"re good to go. Secure the lock to your bike using a stand or a clamp which you can buy separately.

Some wholesale wire rope lock products give you the option of lifetime warranty if you register online. If you lose the key you can call them up and, with proof of purchase, they"ll cut your bike free. Choose from key or code based locks depending on your preference, but if you do choose a code based lock be sure to pick a memorable date to avoid any awkward circumstances.

Browse the large range of wholesale wire rope lock options at Alibaba.com. When you"ve spent so much money on your bike it"s the obvious choice to buy a lock to keep it secure. There are thousands of reputable wholesalers teamed with Alibaba.com who are there to help with your purchase, not to mention the comprehensive customer service team who are there to make sure you receive a swift and easy purchase experience.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

Our structural ropes are produced and assembled in accordance with the EU harmonization directives and are certified with CE approval. The CE certification guarantees that the marked products can be traded in the EU without restrictions. Fatzer guarantees that all requirements necessary for CE approval have been met in accordance with the relevant directives.

There has been much discussion revolving around lock wire and safety cable, and which reigns supreme. Through our own due diligence, we’ve determined that using lock wire to retain fasteners is time consuming and error prone, which makes it costly. Lockwire also requires extensive training and produces sharp ends when cut, which can cause serious injury to the technician.

Meanwhile, extensive research and testing at GE Aircraft Engine facilities revealed that the use of Bergen Safety Cable instead of lockwire resulted in a 50 percent reduction in installation time with consistently superior quality and lower assembly costs.

When traditional lock wire is removed from an application, it needs to be cut many times in order to be completely removed. This process produces numerous small fragments which are difficult to keep track of. If the scrap material cannot be fully recovered, it can cause serious damage to the aircraft and potentially its passengers as well. This is known as foreign object damage or FOD. However, when Bergen Safety Cable is removed, it produces only two pieces of scrap, making it easy to keep track of and eliminates the potential for FOD.

Using traditional lock wire requires that the operator determine how much wire to use, how many twists per inch, and many other important details. If a step is missed or completed incorrectly using lock wire, the operator must start all over. With Bergen’s Safety Cable system, all the guesswork is eliminated. The operator simply strings the cable through the fastener holes and the safety cable tool does the rest, which results in perfectly wired fasteners every time and increased production.

The cumbersome nature of applying traditional lock wire can take a very long time to master. With the streamlined method of the Bergen Safety Cable system, a new operator with zero experience can be up and running within 30 minutes.

Traditional lock wire produces very sharp ends when cut, which poses a serious threat of injury to the operator. The fused ends and flexible nature of Bergen Safety Cable removes the risk of injury 100 percent.

Other benefits include reduced inspection time, consistent cable tension on each application, and a material that is lighter than lock wire and traditional safety wire. Choosing to use Bergen Safety has a myriad of significant benefits that our customers agree improve product quality and save them time and money across the board.

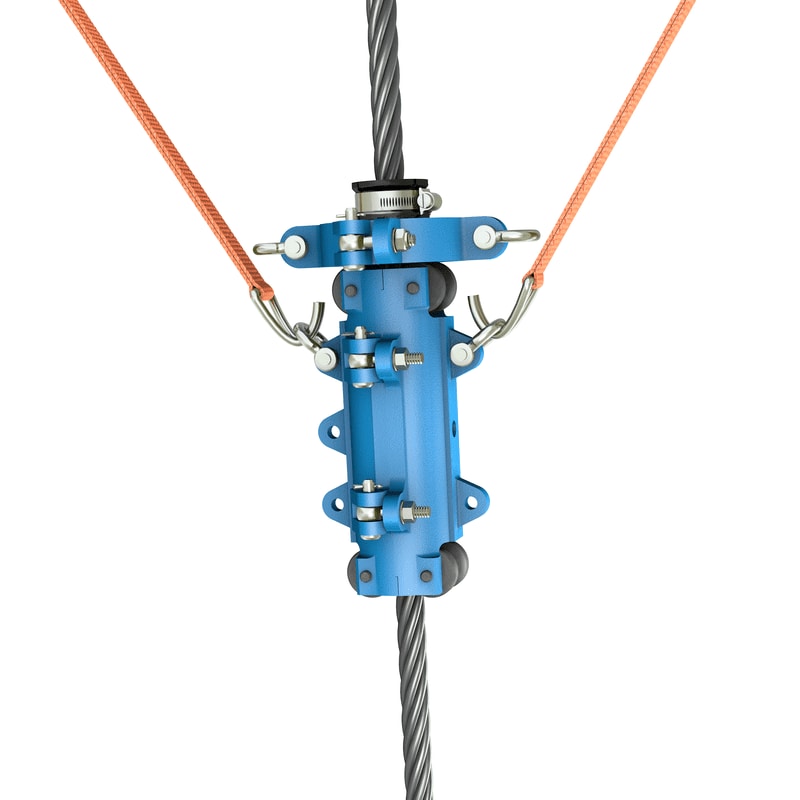

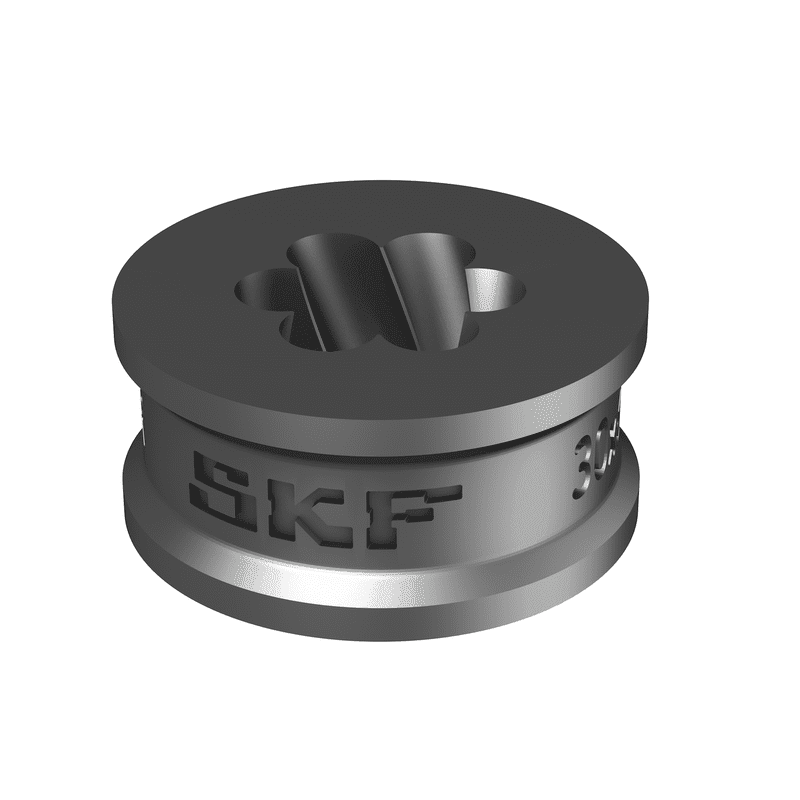

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

8613371530291

8613371530291