wire rope lubricant applicator supplier

Proper lubrication of wire rope will extend operational life and increase safety. Done correctly, it lubricates exterior surfaces as well as the inside wires and core. Proper lubrication will help reduce friction as the individual wires move over each other, and provide corrosion protection.However, lubricating wire ropes can be difficult. Manual lubrication via drip, brush, spatula or rubber glove method is a messy, time-consuming maintenance task and can be hazardous to the environment.

The Viper Wire Rope Lubricator is a much better solution. The Viper Mid MK II provides fast, effective one-pass lubrication of wire ropes from 5/16 in (8 mm) to 2 5/8 in (67 mm) in diameter, at speeds up to 6,670 ft (2,033 m) per hour. It eliminates the slow, labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing LE’s robust wire rope lubricant under high pressure (up to 5,500 psi) right to the core of the wire rope.

The Viper Wire Rope Lubricator can be used in any application where wire rope can be drawn through the collar of the lubricator, including the following typical applications:

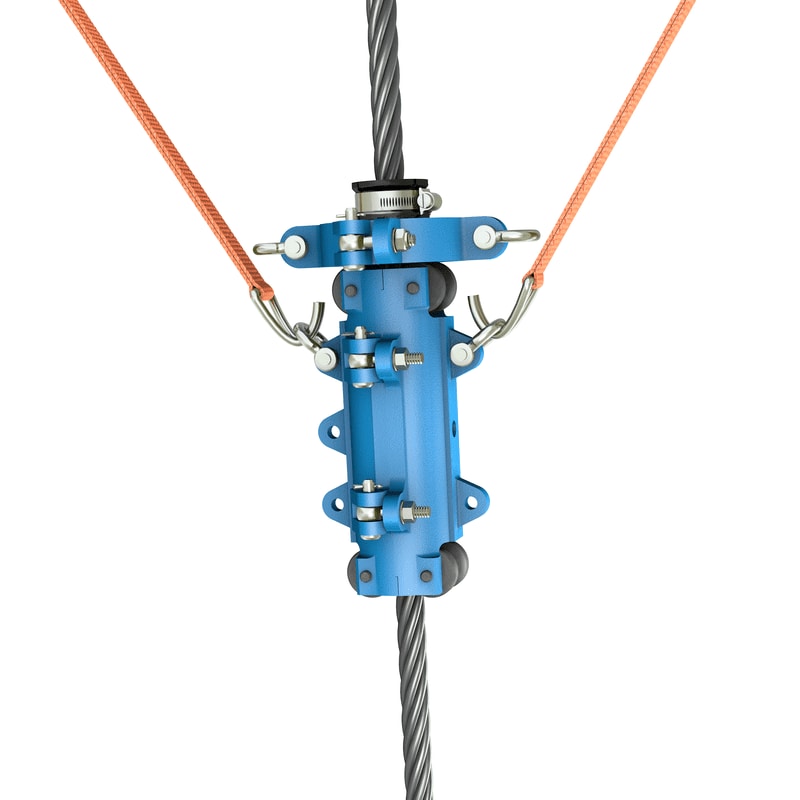

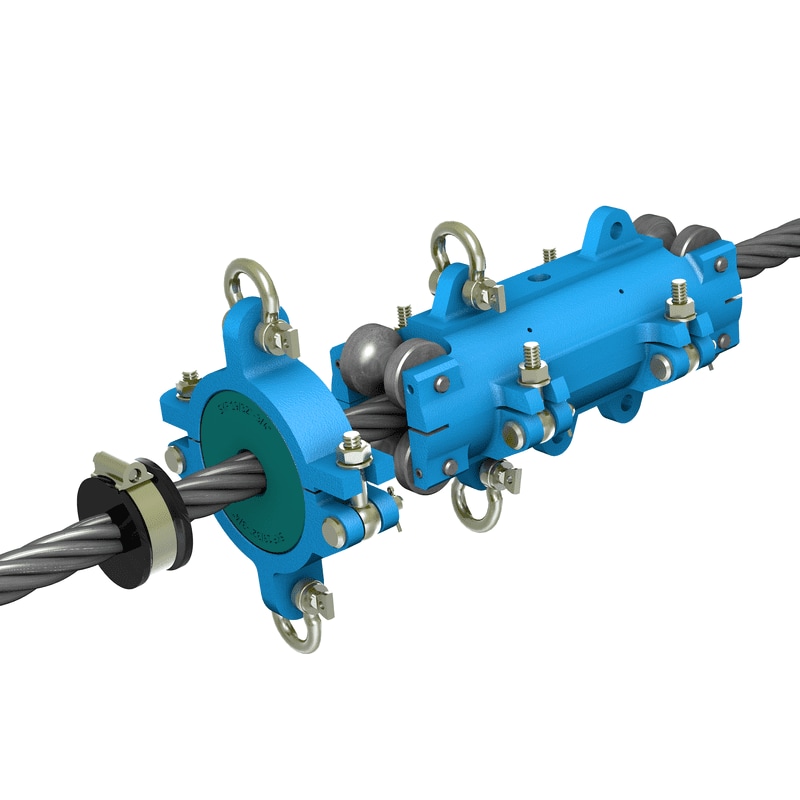

The Viper Wire Rope Lubricator consists of a lubricator collar assembly that houses polyurethane seals suited to a specific wire rope size. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar. The steel scraper plates pre-clean the rope by scraping dirt, debris and old lubricant from the rope and protect the seals from loose strands, flattening them out before new lubricant is applied.

As the lubricant is applied with the high-pressure, high-flow grease pump, it forces the lubricant between the strands to the wire rope core. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The collar is the heart of the Viper MK II. Constructed from high-grade cast aluminum with a robust protective coating, the collar is completed with stainless steel hardware to provide maximum corrosion protection. The MK II collar has built-in handles, making it easy to carry in one hand. One person can easily attach the Viper to the rope.

LE carries the complete standard kit and all necessary components for operation. Configuring the kit is simple. The selection of the seals and scraper plates is based on wire rope size. If you have more than one wire rope size, additional scrapers and seals can be purchased.

We also carry some of the best wire rope lubricants found in the market to provide you with an entire solution. We recommend that you use Wirelife® Almasol® Coating Grease (452-453) with the Viper Wire Rope Lubricator

Wirelife Almasol Grease is available in NLGI 00 (452-PL, 452-QD, 452-DR) and NGLI 0 (453-PL, 453-QD, 453-DR) grades, both of which are extremely tacky and water resistant and have exceptional penetrating ability. They provide EP protection and exceptional corrosion protection, even in underwater applications

In addition to wire rope lubrication, LE is happy to offer lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all of our items to help you make the right decision.

To learn more about the Viper Wire Rope Lubricator or about LE’s enhanced lubricants, lubricant training, oil analysis, filtration, lube rooms, breathers, sight glasses or other lubricantreliability solutions, please contact us today.

Our users can always expect excellent performance from any one of our Kirkpatrick wire rope lubrication systems. Their superb engineering provides unmatched strand lubrication and cleaning benefiting customers in any industry where wire rope maintenance is a priority. The Wire Rope Surface and groove pattern are scraped clean of penetration blocking debris and product buildup as the wire rope surface is uniformly coated with new lubricant. Every space within the wire rope open to receive the newly applied wire rope lubricant is filled.

Optimum penetration occurs as the wire rope being serviced passes through a controlled 100% pressurized immersion within the system’s internal seal lubrication chamber. This immersion displaces any entrapped surface moisture within the rope’s internal strands and replaces it with the newly applied coating product. You can trust Kirkpatrick systems’ functionality with high- and low-viscosity coatings. Higher viscosity coating products maximize fluid film support against strand rubbing that can shorten any working ropes life due to friction wear. In the event your application requires low viscosity coatings such as a mining friction hoist; our systems easily apply those products as well accommodating high wire rope travel speeds.

We will carry out lubrication on our 103 mm wire in the coming days. This will be the third time this has been conducted, and I am extremely satisfied with the results. No wastage due to drop off during application and very good penetration.

Bridon Ropes has used Masto machines in its factories for over 10 years, in cases where a special lubricant coating is required on particular wire ropes. Over the years the machines have given dependable service over a wide range of rope sizes and constructions, and have given satisfactory seal lives.

After having used the Masto unit for approximately 2 ½ years, we are more than satisfied with the unit. It is a clean and efficient way of greasing wires. Before we got the unit, greasing wires was a hard task, but now the unit is doing the work for us and the wires are greased properly and evenly.

The undersigned surveyor to Det norske Veritas was present when the “MASTO” wire lubricator was demonstrated on two wire dimentions. After being greased, the wires were split apart, and we can confirm that the grease had penetrated through the whole cross-section of the wires.

We have tested different types of wire rope lubricators and can ensure you that we are very satisfied with your product. We would definitely go for Masto lubricators should the need for such a product arise again.

I can confirm that the ‘Maesto’ wire rope lubricator has been in use on the vessels under my control for several years, during which time it has proved to be a highly effective tool to assist particularly in maintaining the wire ropes of the deck cranes in good order, despite the most ardous operating conditions.

After having used the MASTO unit for approximately one year, we are very satisfied with the unit. It is a safe and clean way of greasing wires. It has proved to be a timesaving tool, compared to brush, cloth etc.

Today we have used the Lubricator for the first time. One word: Amazing! 2 hours instead of two days, no backache, 60 Kg grease instead of 250 Kg, clean dungarees, no mess everywhere around. It’s a great advisable product. I will recommend the wire lubricator to my collegues.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE"s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

Corelube designs, engineers & manufactures state-of-the-art, wire rope lubricators/lubricator & wire rope cleaning tools. Corelube has been solving wire rope maintenance problems for over 40 years.

The key to maintaining wire ropesis protecting the interior core wires from corrosion and wear with protecting the exterior from the elements and extreme wear conditions. Corelube Equipment has designed wire rope lubrication systems that address both of these issues.

We believe there is no one size fits all solution when it comes to wire rope lubrication. With 40 years of designing wire rope lubrication systems, we believe our systems are the most advanced/environmentally friendly systems out there.

Wire rope lubricants with good penetrating properties are key to preventing internal corrosion & wear. Corelube highly recommends wire rope lubricants that transition from penetrating oil to grease.

Kirkpatrick Wire Rope Lubrication Systems are excellent for Wire Rope & Cable Lubrication/Cleaning. In only one application wire rope can have its surface and groove pattern scraped clean of product build-up and grit while at the same time new lubricant is uniformly applied to the newly cleaned surface. Coating product then fills any open spaces within the groove pattern and internal strands open to receive it. This is accomplished as the wire rope passes through a controlled 100% pressurized immersion within the internal Seal Lubrication Chamber. Surface moisture trapped within the internal strands is displaced and replaced with the newly applied wire rope coating product. Systems are functional with both low and high viscosity coatings. They can be incorporated as a Grease Applicator for tough applications where higher viscosity coatings are required to fight friction wear due to strand rubbing as well as a low viscosity oiling system required for certain Cable Cleaning & Lubrication applications.

An optional Manual Stripper is also available to be used as a rotational base for specially designed Helix Wire Rope Groove Cleaners (Not to be confused with another source’s grove cleaner). This option allows users the capability to surface clean the wire rope separate from the lubrication process. Easy visually unhindered inspection can then be performed to determine the condition of the wire rope prior to servicing or in between service dates. This process is much more effective than the use of a labor intensive cable brush cleaner that incorporates individual wires that easily gum up and require frequent cleaning.

Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Kirkpatrick Wire Rope Lubrication Systems are excellent for Wire Rope & Cable Lubrication and Cleaning. In only one application, wire rope can have its surface and groove pattern scraped clean of product build-up and grit, while at the same time new lubricant is uniformly applied to the newly cleaned surface. Coating product then fills any open spaces within the groove pattern, and internal strands open to receive it. This is accomplished as the wire rope passes through a controlled, 100% pressurized, immersion within the Internal Seal Lubrication Chamber. Surface moisture trapped within the internal strands is displaced and replaced with the newly applied wire rope coating product. Kirkpatrick Systems are functional with both low and high viscosity coatings. They can be incorporated as a Grease Applicator for tough applications where higher viscosity coatings are required to fight friction wear due to strand rubbing, as well as a low viscosity oiling system required for certain Cable Cleaning & Lubrication applications.

A great deal of time has been taken by our company to determine what characteristics our wire rope lubricants should have in meeting the stringent corrosion / wear and environmental requirements as set forth by our users of wire Dynagard™ “Blue” , Dynagard™ Blue CSS13, Dynagard™ “E” and Dynagard™ LVL are the result and are formulated to give the user the most complete coating and penetration rope possible. In addition, their environmental field performance has resulted in their use by the United States Navy, United States Coast Guard, United States Army Corps of Engineers, TVA, Bureau of Land Reclamation, NOAA and many other governmental organizations worldwide.

Kirkpatrick Wire Rope Lubrication Systems are designed so that in only one application, wire rope can have its surface and grooves scraped clean of product build-up and grit – while at the same time any new lubricant is uniformly applied to the newly cleaned surface and injected into the very core.

Moisture trapped in the internal strands is forced out and replaced with the new lubricant. All systems are compatible with low as well as high viscosity lubricants. For heavy duty applications where higher viscosity coatings are needed, it can act as a grease applicator to combat friction damage caused by strand rubbing.

The coating agent penetrates into the tiniest gaps within the groove pattern and internal strands loosen to collect it. The process is only achieved within the internal Seal Lubrication Chamber – where ropes are immersed in a controlled, pressurised environment so that confined moisture within the internal strands are expelled and replaced by the newly applied wire rope coating product.

The personal safety benefit of using the Kirkpatrick system is that it is removes personal from physical contact with the steel rope during the lubrication process.

Developing the first successful wire rope lubrication system in the world in 1982 using its own requirements, the Kirkpatrick Group Inc. has been at the forefront of wire rope lubrication industry for three decades. With an unrivalled reputation for wire rope lubrication systems and years of field experience under their belt, Kirkpatrick has positioned themselves as the leading resource and solution for any wire rope lubrication equipment problems.

Dynagard Blue CSS13 – This coating is formulated with a high viscosity base oil and engineered with a unique combination of additives to create the highest level of adhesion performance against fling off at high-speed Wire travel. It is also designed to resist water wash off in severe working marine environments.

Dynagard E – This is a revolutionary non-toxic, biodegradable wire rope lubricant that meets the performance levels of petroleum-based greases in areas of fluid film and corrosion protection of wire rope strands. Dynagard“E was the first seed oil based high viscosity grease introduced onto the world market in 1993. It also was the benchmark product used in 2002 to establish MIL-PRF18458C Type II requirements under the Environmentally Preferable Lubricants program (NSWCCD, Code 632) for the United States Navy’s Naval Sea System Command.

Dynagard LVL – This coating is an extremely tenacious wire rope dressing formulated for use in both marine and mining environments. This product is especially effective in applications where a rapidly penetrating product is required along with low fling off adhesive attributes of a much higher viscosity coating. This is particularly important for high-speed wire rope travel where fling-off is more apt to occur.

A discharge port is provided which allows some lubricant to exit the collar, taking water and other contaminates away with it. The lubricant must pass through the pressurised area before being able to drain off.

Groove cleaners act to clean the outer circumference as well as the wire rope groove pattern of contaminants that hinder the penetration of new coatings being applied inside the seal lubrication chamber.

While wire rope lubrication application is not required it can, however, increase the life of the wire rope, therefore making your purchase more cost effective in the long run. Who wouldn’t want to extend the life of their rope purchase and save money?!

Friction causes wear and tear and after awhile, the wire rope becomes unusable. Routine wire rope lubrication will reduce the amount of friction applied to each rope and will extend the life of your rope!

So, now that you know regular Wire Rope Lubrication will extend the life of your rope by reducing friction and protect the exterior, you probably want to know what products to look for, right? Don’t fret!

Want more wire rope information? Check out Industrial Rope’s blog post, “Choosing the Right Wire Rope” and make sure to check back often for more industrial rope supply tips, FAQs, and useful information!

At Northern Strands we know first-hand the importance of wire rope lubrication. It is required during manufacturing, installation, and ongoing maintenance. Different hoists and applications require different types of lubrication. We carry everything from basic asphalt lube to soap grease and no- petroleum based lubes. With Northern Strands’ knowledge of wire rope, we can recommend and supply appropriate lubrication products and suggest the best lubrication methods.

CoreLube Equipment"s Helix Groove Cleaners are designed to remove contaminants from the valleys between the strands of wire rope. The cleaner works by rotating with the helical lay of the wire rope. The Helix Groove Cleaners are designed to work with CoreLubes applicator collars or thrust block.

Wire Rope lubrication allways has been a time consuming, dirty and unefficient job. But most of all unreliable because the fact that manual greasing has no penetrating effective lubricationas a result .

The Wire Rope Lubricator is designed to lubricate steel ropes in a reliable manner , deep into the strings under high pressure. This is done in a semi-automatic way , whereas the ropes passes trough the grease applicator which is fixed. The ropes do not to be dismounted from the installations. Using the Wire Rope Lubricator , the life of the ropes as well as of the rope equipment is extended.

8613371530291

8613371530291