wire rope lubricant applicator quotation

While wire rope lubrication application is not required it can, however, increase the life of the wire rope, therefore making your purchase more cost effective in the long run. Who wouldn’t want to extend the life of their rope purchase and save money?!

Friction causes wear and tear and after awhile, the wire rope becomes unusable. Routine wire rope lubrication will reduce the amount of friction applied to each rope and will extend the life of your rope!

So, now that you know regular Wire Rope Lubrication will extend the life of your rope by reducing friction and protect the exterior, you probably want to know what products to look for, right? Don’t fret!

Want more wire rope information? Check out Industrial Rope’s blog post, “Choosing the Right Wire Rope” and make sure to check back often for more industrial rope supply tips, FAQs, and useful information!

Proper lubrication of wire rope will extend operational life and increase safety. Done correctly, it lubricates exterior surfaces as well as the inside wires and core. Proper lubrication will help reduce friction as the individual wires move over each other, and provide corrosion protection.However, lubricating wire ropes can be difficult. Manual lubrication via drip, brush, spatula or rubber glove method is a messy, time-consuming maintenance task and can be hazardous to the environment.

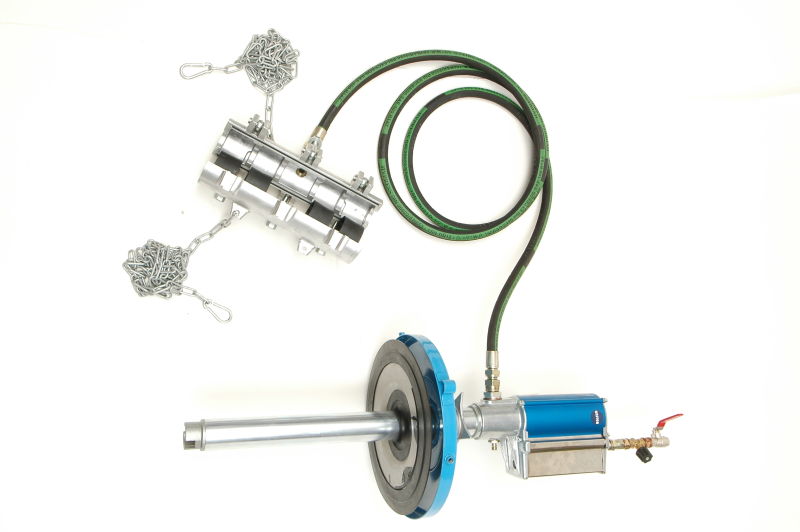

The Viper Wire Rope Lubricator is a much better solution. The Viper Mid MK II provides fast, effective one-pass lubrication of wire ropes from 5/16 in (8 mm) to 2 5/8 in (67 mm) in diameter, at speeds up to 6,670 ft (2,033 m) per hour. It eliminates the slow, labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing LE’s robust wire rope lubricant under high pressure (up to 5,500 psi) right to the core of the wire rope.

The Viper Wire Rope Lubricator can be used in any application where wire rope can be drawn through the collar of the lubricator, including the following typical applications:

The Viper Wire Rope Lubricator consists of a lubricator collar assembly that houses polyurethane seals suited to a specific wire rope size. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar. The steel scraper plates pre-clean the rope by scraping dirt, debris and old lubricant from the rope and protect the seals from loose strands, flattening them out before new lubricant is applied.

As the lubricant is applied with the high-pressure, high-flow grease pump, it forces the lubricant between the strands to the wire rope core. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The collar is the heart of the Viper MK II. Constructed from high-grade cast aluminum with a robust protective coating, the collar is completed with stainless steel hardware to provide maximum corrosion protection. The MK II collar has built-in handles, making it easy to carry in one hand. One person can easily attach the Viper to the rope.

LE carries the complete standard kit and all necessary components for operation. Configuring the kit is simple. The selection of the seals and scraper plates is based on wire rope size. If you have more than one wire rope size, additional scrapers and seals can be purchased.

We also carry some of the best wire rope lubricants found in the market to provide you with an entire solution. We recommend that you use Wirelife® Almasol® Coating Grease (452-453) with the Viper Wire Rope Lubricator

Wirelife Almasol Grease is available in NLGI 00 (452-PL, 452-QD, 452-DR) and NGLI 0 (453-PL, 453-QD, 453-DR) grades, both of which are extremely tacky and water resistant and have exceptional penetrating ability. They provide EP protection and exceptional corrosion protection, even in underwater applications

In addition to wire rope lubrication, LE is happy to offer lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all of our items to help you make the right decision.

To learn more about the Viper Wire Rope Lubricator or about LE’s enhanced lubricants, lubricant training, oil analysis, filtration, lube rooms, breathers, sight glasses or other lubricantreliability solutions, please contact us today.

Lubricating with the aid of brushes, rags, gloves, or by other means is costly, risky, and ineffective. The lubricant forms a film on the surface which water vapour can penetrate, thus becoming trapped. Temperature changes cause condensation and rust then begins to form from the inside. A wire rope can appear to be in good condition, when in fact corrosion and friction are destroying it from the inside. Its useful life is shortened and it becomes potentially dangerous. Even factory lubricated wire rope requires regular relubrication.

Only the Masto Lubricator penetrates under high pressure all types of wire rope, such as Non-rotating, Dyform, and Locked Coil with heavy grade lubricant. NB. To obtain total penetration through a compact rope the pressure must be minimum 20 bar (285 PSI) in the chamber. Even wire rope subjected to severe surface wear will have a longer life when lubricated with the Masto. Stainless steel, galvanized, and other special types of wire rope require just as much lubrication since friction is the same and corrosion can also occur.

If you start using the MASTO Lubricator, the best results are obtained with the highest quality Wire Rope Grease. If you use SWEPCO 150 Wire Rope Grease your wire ropes will be protected in an optimum way.

An impressive load wear index of greater than 75 and 4-ball weld load of 800 kg demonstrate the superiority of SWEPCO 150’s industry leading extreme pressure and anti-wear protection. The result is significantly longer service life for wire rope and wire rope system components.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

The Kirkpatrick Group, Inc., manufacturer of Kirkpatrick Wire Rope Lubrications Systems has kept very busy since their story last appeared on these pages back in 2003. Owner and President Bob Kirkpatrick points out their number one goal remains unchanged and that goal is to provide clients with innovation, safety and support for the care and maintenance of their wire ropes.

“What is unique about the testimonials we’ve received over the years is that they’ve come to us unsolicited through third parties. Their evaluations and opinions concerning the performance of our product came directly from their own successful use of it in their wire rope preventative maintenance programs.”

The use of wire rope pressure applicators has now become a main stay inmost wire rope maintenance applications worldwide since Kirkpatrick first introduced them to the world market in 1982. Wire rope pressure lubrication has changed the manner in which industries maintain their wire ropes on a worldwide basis simply because their use has established that the working life of wire rope has been extended. In addition, labor savings has proven to be as much as 50 times greater as compared to the labor costs and time spent using manually applied methods.

Since 1982, Kirkpatrick has gained a broad knowledge of what it takes to optimally apply wire rope dressings to wire rope, no matter what method is used. This a direct result of his own infield and daily troubleshooting experience over the last 33 years.

“The fact is that the most important time a wire rope can receive a coating is during the manufacturing process when every strand can be coated prior to the wire rope being closed. I always push customers to use as viscous a coating as possible. This is especially true in the mining industry. It may be a little more expensive; however, the rewards of a longer wire rope life more than justifies it.

“Protection against friction wear and strand rubbing is guaranteed with heavier viscosity wire rope lubricants marrying well to the original lay-up material. Our systems will apply any viscosity product including oils. Therefore, my opinion is not generated from its shortcomings in the application of different consistencies. We can perform with them all if they are able to be pumped. That is in a range of NLGI Grade 3 greases.

“In the case of oils used on working ropes where friction wear is of high concern and adequate fluid film protection between the strands is a must, those oils only apply microscopic layer protection against strand rubbing. They can also serve to emulsify and wash out the original layup material. By analogy, would you oil your car wheel bearings or grease them? In the event that oils are used, it is necessary to treat the rope more often because once the original lay-up material is gone; the oils must take its place.”

Currently, most wire rope contractors are being required to pressure lube their customers’ wire ropes in offshore field applications or prior to delivery to the drill ships or rigs. There is also so much out there yet to be learned. The growth Kirkpatrick has experienced has resulted in the fact that they have a data base of more than 10,000 clients involved to some degree in wire rope preventative maintenance.

“I sit at my desk every day and find that I have to send troubleshooting emails out around the world. I thoroughly enjoy the process. I am exposed to every industry where wire rope is used as well as to so many different cultures. They all have their own style of doing business. However, they all have one thing in common: They need follow through and support to analyze their applications and then after sale support to make the use of our systems successful for them. I feel we definitely have the know-how.”

During pressure lubrication wire rope passes through a 100% pressurized and controlled immersion many times faster than manual applications. This in turn reduces labor costs, improves safety as well as increases the working life of the wire ropes being treated. The outer surface and groove pattern is wiped clean of water and contaminants which then allows optimal penetration of coating; there is less lubricant waste and more fluid film support between the strands, helping out in reducing friction wear.

Kirkpatrick likes to remind those he deals with of the facts regarding pressure lubrication, as well as straighten out the numerous misconceptions. “There is this idea that the pressure inside the collar may go has high as 5,000 psi. We tested a competitor’s system on a one inch six strand with their lubricant and the internal pressure was approximately 10 psi. Using our system with the competitor’s coating product, we had an internal pressure of 100 psi. In either case it is a far cry from the 5,000 psi which came up in discussion, an impossibility because no lubricator is a closed hydraulic system.

“The reason for this is that the lubricant moves through and around the wire rope in the stationary pre-travel mode and then as the wire rope travels through the seals more pressure is released as the wire rope removes the lubricant feeding into the seals. In any event the amount of internal pressure is dependent on the strand density and the configuration of the wire rope it has to penetrate.

Ninety-nine percent of the time the lubricant is not going through the core, according to Kirkpatrick. If the pressure lubricator is constructed correctly, it will fill every open space in the rope that is available to receive the load. The other way to do it is to surface coat the wire rope with a rag.

The Naval Air Systems Command – Chief of Naval Operations Pre-production Evaluation Final Report concluded that the Kirkpatrick Model SU35B Wire Rope Lubricator evaluated during the project appeared to have significant potential for reducing material usage and waste disposal costs. Significant labor savings were found to be possible due to the reduced labor required to perform cable cleaning and lubricating events.

“Of equal importance, the wire rope lubrication system is a safer alternative than the previous method used because it does not require personnel to place grease on their gloves and wipe the crane cable. The cost analysis showed a 10-year return on investment (ROI) of approximately $135,900.60 and a breakeven point of .41 years,” according to the Navy’s report.

The Navy Public Works Department, San Diego found the Kirkpatrick Model SU35B Wire Rope Lubricator system to increase productivity and reduce costs. Their results were that the automated wire rope lubrication system extends the life span of wire rope, reducing the costs of removing and disposing of worn out wire rope and the purchase and installation of replacement rope.

“Operating costs are also reduced, because cranes are less frequently taken out of service to be refitted with new wire rope. The automated system cleans and lubricates wire rope at a rate of 100 feet per minute as compared to the manual rate of approximately one foot per minute.

“Cleaning and lubricating wire ropes on cranes using the old manual method took approximately five eight-hour workdays per crane. Using the automated system, wire rope on a crane can now be cleaned and lubricated in one eight-hour day. This represents significant savings in labor costs. The automated wire rope lubricator has reduced PWC San Diego’s annual cost of cleaning cables from about $320,000.00 a year to approximately $34,000.00, a yearly generating savings of approximately $286,000.00.”

Navy maintenance practices require that crane cables be periodically cleaned and lubricated. The cables are constructed of multiple wire ropes that have been twisted together. Cleaning and lubricating provides corrosion resistance and extends the service life of the cable. Cable performance is improved by eliminating additional drag caused by the buildup.

The first step of crane cable maintenance involves cleaning the cable to remove any accumulation of dirt, marine growth, old grease, rust, and small particles of metal from between the wire ropes that form the cable. After cleaning the cable, grease is reapplied to allow the crane cable to achieve its top operating speed and hauling ability. Metals that are scraped off during the cleaning process are disposed of as hazardous waste.

reduce the generation of wastes (degreaser, rags, grease) during cleaning and lubricating, provide a safer working environment and improve the efficiency of wire rope cleaning and lubricating as well as reduce the amount of hazardous material (grease) applied to the cables.

The site arranged for the WRL to be temporarily attached to a forklift in order to achieve an angle for the lubrication collar to operate properly. The ability of any given site to mount the lubrication collar in such a manner is dependent upon available equipment resources. It is also important to optimize the speed at which the cable is pulled through the lubrication collar and the pressure with which the grease is applied.

Bob Kirkpatrick feels that his firm has designed the most efficient wire rope lubrication system available today. “We understand what is required to provide those we serve with the right system for their specific application prior to purchase and then to maximize the customer’s use of that system once it is received.

Smart businesses look to safely extend the life of their wire ropes with the right specialized lubricant. But even that approach can have unwanted and unfortunate consequences because the lubricants that historically excel at extending the life of wire ropes are not environmentally acceptable.

That was the complex problem presented to Klüber Lubrication by Redaelli Tecna, a global leader in the production of steel wire ropes with over 200 years of experience. They needed an EAL (Environmentally Acceptable Lubricants) solution with a high drop point and a reasonable price point.

Klüberbio AM 92-142 is an environmentally acceptable lubricant that combines excellent load-carrying capacity, good anti-wear protection and strong anticorrosive properties to extend the life of your wires. It also exhibits excellent adhesion to metal surfaces and good water resistance, reducing lubricant consumption and labor.

It was developed as an effective EAL lubricant option for steel wire ropes operating under harsh conditions. Especially those application seen in the marine and offshore industry where wire ropes contact sea water, are exposed to extreme cold or hot climate conditions and the extreme loads experienced during active heave compensation operations.

The partnership was so successful, Redaelli Tecna now recommends Klüberbio AM 92-142 for initial and relubrication of their own steel wire ropes. Klüber Lubrication NA LP is looking for partners within North America that use EAL wire rope lubricants in their marine operations but are not getting the desired results.

KEMTREE LUBRICANT APPLICATOR is a simple mechanical device that significantly improves the carryover of Dry Drawing Lubricants on Steel and Stainless Steel wires.

A Lubricant Applicator is a spring-loaded device with 3 rollers. The rollers are made of high-quality alloy steel and carefully hardened for optimum performance.

The Applicator fits in all Standard Die Boxes of a Wire Drawing Machine. It is to be clamped on the wire without cutting it, thus avoiding the cumbersome process of threading the wire on the machine.

Smart businesses look to safely extend the life of their wire ropes with the right specialized lubricant. But even that approach can have unwanted and unfortunate consequences because the lubricants that historically excel at extending the life of wire ropes are not environmentally acceptable.

That was the complex problem presented to Klüber Lubrication by Redaelli Tecna, a global leader in the production of steel wire ropes with over 200 years of experience. They needed an EAL (Environmentally Acceptable Lubricants) solution with a high drop point and a reasonable price point.

Klüberbio AM 92-142 is an environmentally acceptable lubricant that combines excellent load-carrying capacity, good anti-wear protection and strong anticorrosive properties to extend the life of your wires. It also exhibits excellent adhesion to metal surfaces and good water resistance, reducing lubricant consumption and labor.

It was developed as an effective EAL lubricant option for steel wire ropes operating under harsh conditions. Especially those application seen in the marine and offshore industry where wire ropes contact sea water, are exposed to extreme cold or hot climate conditions and the extreme loads experienced during active heave compensation operations.

The partnership was so successful, Redaelli Tecna now recommends Klüberbio AM 92-142 for initial and relubrication of their own steel wire ropes. Klüber Lubrication NA LP is looking for partners within North America that use EAL wire rope lubricants in their marine operations but are not getting the desired results.

Light-bodied oil · provides the ability to penetrate to the core of wire rope · wire ropes are cleaner and easy to inspect · penetrates the interstices between wires and strands · high film strength · prevents wear · resists oxidation and corrosion · self-healing film former · excellent in acid or alkali and pollutants’ environment · high polarity promotes creeping and re-lubrication of areas forced dry of oil.

Field lubrication for wire ropes in service. All sizes of standing and running ropes as used on suspension and lift bridges, tramways and cableways. All types of cranes, escalators, derricks, masts and chimneys. Also on hoist ropes, draglines, conveyors and material handling equipment. Major industries served include surface and underground mining, construction, towing, marine, gas and petroleum, on and off shore drilling, to name a few.

RXSOL Wire Rope Lubricant has been tested and proven directly compatible with Crosby RXSOL Wire Rope Lubricant Spray Applicators (see Crosby Catalog). The use of RXSOL Wire Rope Lubricant in Crosby RXSOL Wire Rope Lubricant Spray Applicators is recommended. Other methods of application include manual by brush, swab, drip, pour, automatic drip or spray systems and automatic pressure wire rope lubricators. This product is also available in an aerosol can.

The de-watering fluid is designed for complete lubrication and corrosion protection in environmentally sensitive locations, in wet and hostile applications. It is a multipurpose lubricant for use on wire ropes, chains, pulleys, springs, nuts and bolts.

BIOGEN Fluid demonstrates industry leading corrosion protection, guarding wire ropes and other equipment from the onset of degradation. It also has excellent penetration abilities and will naturally search its way between strands and cavities.

• BIOGEN Fluid is ideal for lubrication of all types of wire ropes and armoured ROV umbilicals. It is also ideal for equipment such as winches, hoists, drag lines, large chains, tethers and chains.

Digging, dredging, hauling and pumping equipment require metal surfaces to be lubricated properly and be free of water and dirt to maximize operational life. Equipment used in the sand and gravel industry is subject to extremes in temperature, moisture, dust and dirt, all of which can be detrimental to lubricant performance and lead to premature equipment failure and expensive parts replacement. Dutylex has been serving customers in the sand and gravel industry for many years, and our expert lubrication consultants and onsite service can make an instant impact on your operation.

Electric motor replacement can be expensive and time-consuming, and electric motors need to run reliably to keep dredges, water pumps, conveyor belts and screens operating. Dutylex’s superior electric motor grease will outlast most competitive lubricants, keeping your electric motors running efficiently. Dutylex also provides the tools necessary for proper application of the grease, whether you perform manual application or prefer today’s automatic lubricators to improve consistency and reduce labor costs.

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with Dutylex’s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE can supply a full range of protective lubricant solutions. We even supply wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation of your wire rope.

We provide your company with the highest level of innovation, safety, and support for the care, and maintenance of your Wire Ropes. This generates longevity for your Wire Rope that no manual method used can achieve.

Since 1982, when we first introduced our products to the world market, we have consistently created the most advanced, safe, and well-supported method for Wire Rope Preventative Maintenance. Over the years since, our continued leadership has proven to make our Customers’ job much easier and cost effective on the broadest possible scale. In honor of this three-decade tradition, we will continue to announce further innovations, with several Patent Pending design features on the horizon. We never stop looking for improved design opportunities based on our own as well as our Customers’ first hand field experience.

Kirkpatrick Wire Rope Lubrication System’s integrated design provides the most efficient way to field dress any configuration of Wire Rope in any Preventative Maintenance Schedule. Our Lubrication Systems accomplish this by scraping a Wire Rope’s Groove Pattern and outer circumference clean of debris while simultaneously applying a new coat of Wire Rope Lubricant under pressure to the surface and into the internal strands. This process is all accomplished in one pass, generating tremendous savings in time, labor costs, and Wire Rope Lubricant usage. Scraper Plates and Groove Cleaners used with the Kirkpatrick System are calibrated to fit the specific Diameter and match the number of outer strands and lay pattern of the Wire Rope for which they are used. An accurate fit to the Groove Pattern efficiently removes product build-up and debris within each distinct Groove Pattern. Our revolutionary proprietary laser created tooling makes the finished Groove Cleaners as close to a perfect fit as is possible.

Consequently, Dynagard™ Environmental Wire Rope Lubricants are uniformly applied to the newly cleaned surface, penetrating into any open spaces within the Grooves and inner strands that allow them to do so. The goal in this process is to maintain the structural integrity of the original factory applied lay-up material for as long as possible. Therefore, using a lubricant coating product such as Dynagard™ that marries well to the initial lay-up material substantially increases the working life of the layup material as well as the Wire Rope. Superior Wire Rope Maintenance happens because of the aforementioned and as the Wire Rope passes through a 100% pressurized immersion within the Lubrication Collar’s Seal Center Chamber. Surface and internal moisture (trapped within the strands) is displaced as the pressurized Wire Rope Lubricant coating is being applied. Our Wire Rope Lubrication Systems are functional with both low and high viscosity coatings.

Centraline Lubro-Tech Engineers Pvt Ltd offers an automatic Wire Rope Lubrication System. This unique system benefits end users and wire rope manufacturers with considerable cost and time savings in lubricating their wire ropes automatically. Manual lubrication of wire ropes via the drip, brush, spatula or rubber glove method has always been a difficult and time consuming maintenance task. Typically messy asphaltic or “blackjack†type products are employed which have coating abilities but very little lubrication or penetration properties. The Centraline wire rope lubricator provides fast and effective one pass lubrication of wire ropes from 5/16†(8 mm) to 2-5/8†(67 mm) in diameter at speeds up to 6670 feet (2,000 meters) per hour, it eliminates the slow and labour-intensive task of manual lubricant application, at the same time achieving more thorough results by forcing quality lubricant under high pressure right through to the core of the wire rope. The wire rope lubrication system package consists of: high strength collar; grease lube pump; air regulator with PG and air control valve; high pressure lube delivery hose and QDC; high pressure lubricant control valve; excess lubricant drain hose; retaining ratchet straps and shackles; carry strap for the collar; robust aluminium storage case; highly durable polyurethane seals (to be selected and ordered separately); aluminium scrapers (to be selected and ordered separately); wire rope cleaner (to be selected and ordered separately). Features and benefits: no more manual greasing; stops corrosion/protects ropes; penetrates to the wire rope core; less waste and mess; fast and efficient – at speeds up to 6670 feet (2,000 metres) per hour; high pressure – high pressure operates up to 6,000 PSI; and lubricates ropes from 5/16†(8 mm) to 2-5/8†(67 mm) in diameter.

We will carry out lubrication on our 103 mm wire in the coming days. This will be the third time this has been conducted, and I am extremely satisfied with the results. No wastage due to drop off during application and very good penetration.

Bridon Ropes has used Masto machines in its factories for over 10 years, in cases where a special lubricant coating is required on particular wire ropes. Over the years the machines have given dependable service over a wide range of rope sizes and constructions, and have given satisfactory seal lives.

After having used the Masto unit for approximately 2 ½ years, we are more than satisfied with the unit. It is a clean and efficient way of greasing wires. Before we got the unit, greasing wires was a hard task, but now the unit is doing the work for us and the wires are greased properly and evenly.

The undersigned surveyor to Det norske Veritas was present when the “MASTO” wire lubricator was demonstrated on two wire dimentions. After being greased, the wires were split apart, and we can confirm that the grease had penetrated through the whole cross-section of the wires.

We have tested different types of wire rope lubricators and can ensure you that we are very satisfied with your product. We would definitely go for Masto lubricators should the need for such a product arise again.

I can confirm that the ‘Maesto’ wire rope lubricator has been in use on the vessels under my control for several years, during which time it has proved to be a highly effective tool to assist particularly in maintaining the wire ropes of the deck cranes in good order, despite the most ardous operating conditions.

After having used the MASTO unit for approximately one year, we are very satisfied with the unit. It is a safe and clean way of greasing wires. It has proved to be a timesaving tool, compared to brush, cloth etc.

Today we have used the Lubricator for the first time. One word: Amazing! 2 hours instead of two days, no backache, 60 Kg grease instead of 250 Kg, clean dungarees, no mess everywhere around. It’s a great advisable product. I will recommend the wire lubricator to my collegues.

8613371530291

8613371530291