wire rope lubricants suppliers manufacturer

Manufacturer of wire rope & cable lubricants including grease. Specifications of wire rope & cable grease include pour point of minus 25 degrees F, flash point of 120 degrees F, viscosity of 3.28 at 100 degrees F & 12.8 at 40 degrees F, & specific gravity of 0.89. Wire rope & cable grease capacities include ability to penetrate wire rope, evaporate & leave a film of molybdenum disulphide in the core to lubricate each wire strand. Wire rope & cable grease can be applied by spraying, brushing or dipping in a in-line tank with no heating requirements. Grease is available in 25 lb. pail or 55 gal. drums. Compliant with ASTM standards.

Manufacturer of chain, wire rope & cable grease. Available as coating grease. Features include soft, semifluid formulation & water-resistant. Coating grease contains a wear-reducing additive that protects against premature wear & shields metal against corrosive attack. Available in three NLGI grades in red/gold colors. Services include equipment reliability assessment, oil analysis, lubricant storage, handling & transfer, contamination exclusion, contamination removal, education & training & design, implementation & support.

Manufacturer and distributor of grease for chain, cable and wire rope applications. Products include conventional grease, aerosol grease, food grade aerosol grease, liquid aerosol grease, food grade white grease, biodegradable grease, bearing grease, heavy duty multipurpose grease and heavy duty aluminum complex multipurpose grease. Grease for use in asphalt plant, bottling/canning, construction, fleet maintenance, marine transport, paper/lumber mill, plastics manufacturing, power generation and printing applications are available. JIT delivery available.

Manufacturer of wire rope and cable grease. Types include biodegradable and marine and automotive grease. Resistant to fresh and salt water. Services include designing, product development, plant surveys and lubricant inventory consolidation, lubrication maintenance, oil or fluid and grease analysis and training. Markets served include food, beverage and pharmaceutical. NSF/H-1 registered.

Manufacturer of synthetic multi-purpose PTFE ( lubricants & grease, low temperature torque, high temperature performance. Magnalube-G protective & lubricating film on metal parts, water resistant specialty lubricant for industrial engineers. Magnalube GX with molybdenum disulfide for extreme pressure environments. All product applications include machining, construction, gears, bearings, hydraulics & pneumatic mechanical functions.

Manufacturer of biobased professional-grade greases and lubricants. Products reduce friction, heat and wear. Contain no VOCs and mix with petroleum-based greases. Non-flammable with high flash points. Non-toxic, biodegradable formulations recommended for environmentally sensitive areas near waterways. For use on chains, slides, rollers, hinges, pivot points, gears, cables, metal-to-metal contact areas, oil lubricated bearings. For industries including industrial, hardware, marine, automotive and agricultural markets, as well as many industries requiring professional-grade greases.

Manufacturer of wire rope and cable grease. Nuclear grade bearing, silicone brake and silicone dielectric greases are available. Used in cable connections, battery and parking break cables applications. Available in tubes, cartridges, pails, cans and drums. RoHS and REACH compliant. NSF, USDA, and FDA certified.

Distributor of cable & wire rope grease. Product range includes telecom tools, batteries, digging/trenching tools, drill bits, electrical connectors, cord & terminals, fasteners/anchors, powertools, screwdrivers/nutdrivers & tool kits for telecom & cable companies.

Distributor of rope grease including rust preventive products. Contains three performance rust preventives covering a range of applications including storage and inter-operational activities. Intended for protection cold-rolled sheet and coiled steel in the metal industry. Available in weight of 40.00 lbs., rope grease can be used as protective coatings for cold-rolled sheet and coiled steel, coatings for precision machined parts and instruments for storage and die lubricant in light duty pressing operations.

Manufacturer of wire rope & cable lubricants including grease. Specifications of wire rope & cable grease include pour point of minus 25 degrees F, flash point of 120 degrees F, viscosity of 3.28 at 100 degrees F & 12.8 at 40 degrees F, & specific gravity of 0.89. Wire rope & cable grease capacities include ability to penetrate wire rope, evaporate & leave a film of molybdenum disulphide in the core to lubricate each wire strand. Wire rope & cable grease can be applied by spraying, brushing or dipping in a in-line tank with no heating requirements. Grease is available in 25 lb. pail or 55 gal. drums. Compliant with ASTM standards.

Broadline distributor of electronic components, including heat sink products: aluminum heat sinks, cable & wire grease, wire rope & cable grease, fiber optics heat sinks, & printed circuit board heat sinks.

Distributor of gear, wire rope and cable greases for marine industry. Other products include oils, lubricants, fluids, inhibitors, and coolants. Also offers turnkey lubricant services.

Manufacturer of cable and wire rope grease. Suitable for lubricating wire ropes, cables, flexible couplings, chains, open gears, and partly open gears. Blending, product development, packaging, transloading, warehousing, and distribution services are also available.

Manufacturer of wire rope and cable lubricants for marine industry. High-performance and biodegradable lubricants and water resistant and extreme-pressure greases are available. Offered in different specifications.

Manufacturer of braided products & accessories, using synthetic yarns & wires. Products include ropes for commercial fishing, utilities, sailing & proprietary applications. Weighted, dynamic, static & float lines, shock cords, specialty & rescue lines & custom products using high-tech materials such as Kevlar®, spectra & Dyneema®.

Distributor of O-ring greases for cable, wire, chain and rope applications. Features friction, wear and corrosion-resistant properties with a variety of operating temperature ranges. Available in tubes, pails and aerosols. Also offers oil and gel lubricants. Materials worked with include PTFE and silicone.

Manufacturer of calcium sulfonate and lithium grease for wire ropes, trolley wires, and cables. Specifications include 94 and 96 viscosity index and 9.25 and 8.29 lbs. per gal. density. Available with various features such as smooth and semi-fluid textures, oxidation and water resistance, thermal stability, and rust and corrosion protection. Also offers trailer axle, machinery, and coupling grease.

Distributor of abrasives & lubricants including cable, wire, rope & wire rope grease. Services include vendor managed inventory & process improvement. Markets served include electronic, foundries, aerospace, automotive, woodworking, metal working & ship repair industries.

Manufacturer of biodegradable and non-biodegradable corrosion resistant grease for sealing wireline, wire rope and cables. Biodegradable sealing grease is available in 235 to 314 cSt viscosity. Automotive, heavy duty fleet, off-road, aviation, environmental, extreme pressure, water resistant, high temperature and synthetic grease also available. Reduces friction and protects against corrosion from hydrogen sulfide (H2S), brine water, carbon dioxide (CO2), acids, caustics, chemicals, saltwater, drips and splatters. Suitable for food-grade, aircraft, sports, engine and drive train applications. Private labeling services and customized chemical solutions are also offered.

Distributor of abrasives & lubricants including cable, wire, rope & wire rope grease. Services include vendor managed inventory & process improvement. Markets served include electronic, foundries, aerospace, automotive, woodworking, metal working & ship repair industries.

Manufacturer of standard and custom wire rope and cable lubricants, specifically greases. Available in silicone and non-silicone dielectric grease types with temperature ranges of -40 degrees C to 200 degrees C. Synthetic and damping greases are also offered. Other products available are silicone fluids, compounds, and grease removers. Contract packaging and filling services are also offered. Serves the automotive, electrical, medical, oil and gas, marine, and food processing industries. ISO/TS 16949:2009 certified.

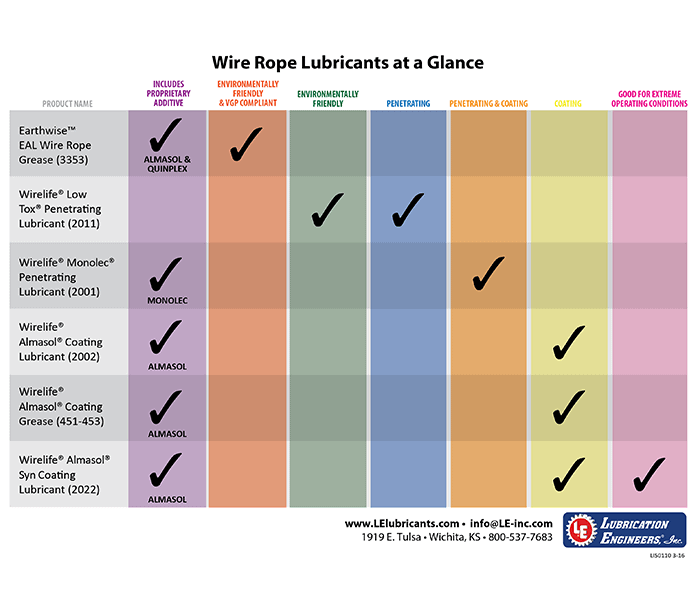

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions, including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Most wire ropes are lubricated during the manufacturing process, but this lubricant will not last the entire life of the rope. When looking for a lubricant to relubricate your wire rope, choose one that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, can penetrate between wires and strands, has high fluid film strength, resists oxidation and remains pliable. It is important to remember that most wire ropes fail from the inside out. Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

Because most wire ropes fail from the inside, it is critical to ensure the center core receives sufficient lubricant. LE recommends a combined regimen in which a penetrating lubricant is used to saturate the core, followed by a coating lubricant to seal and protect the outer surface. LE offers several penetrating and coating type wire rope lubricants to suit your specific needs.

Penetrating lubricants contain an evaporative solvent that facilitates migration of the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film that protects and lubricates each strand.

Wirelife Almasol Coating Grease (451-453) is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Wirelife Almasol Coating Lubricant (2002) is a fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust – even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

Wirelife Almasol Syn Coating Lubricant (2022) is an extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength. Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol, LE’s exclusive wear-reducing additive.

Wirelife Monolec Penetrating Lubricant (2001) has excellent corrosion resistance and high load-carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core. Available in bulk sizes or in an aerosol version.

Typical Applications: All stationary or moving wire ropes or cables under heavy loads; chains of all sizes; mining and construction applications such as standing and running lines, draglines, cranes and derricks; marine applications such as cranes, hoists and drilling rigs; any other application that requires excellent rust protection for steel parts.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife Low Tox Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Earthwise EAL Wire Rope Grease (3353) is recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation.

Typical Applications: Applications near or around waterways including: Wire rope; chain links, pins and bushings; cable sheave bushings, bearings and strands; open and closed silent and roller chains. Ideal for use in automatic lubrication systems.

LE is happy to offer industrial lubricant and reliability recommendations for a variety of applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our wire rope lubricants, wire rope lubricators as well as our other enhanced lubricants and lubricant reliability products, please

![]()

Crosby’s Vitalife®products are the preferred wire rope lubricants in the industry because of their ability to penetrate into wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope.Available in a variety of container sizes.

Whitmore’s Wire Rope Lubricant products also coat these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions, which eliminates flaking and peeling.Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope, as well as chains, leaf springs and other applications where penetrating oil is needed. It may be applied by hand or automatic lube system.

Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

The Kirkpatrick Group, Inc. has been the Original Equipment Manufacturer of Dynagard™ Environmental Lubricants and Wire Rope Lubrication equipment for over 30 years. We developed the first successful Wire Rope Lubrication System

Specialises in:Air Lubrication Systems, Environmentally Acceptable Lubricants (EAL), Environmentally Safe Lubricants, Lubrication Equipment and Wire Rope Maintenance Equipment

Full Sail Marine maintains offices around the world to offer quick response services to our clients in the Commercial, Government, Cruise and Offshore industries. With locations throughout North America and Europe, we stand ready

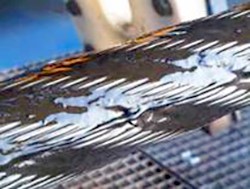

Our users can always expect excellent performance from any one of our Kirkpatrick wire rope lubrication systems. Their superb engineering provides unmatched strand lubrication and cleaning benefiting customers in any industry where wire rope maintenance is a priority. The Wire Rope Surface and groove pattern are scraped clean of penetration blocking debris and product buildup as the wire rope surface is uniformly coated with new lubricant. Every space within the wire rope open to receive the newly applied wire rope lubricant is filled.

Optimum penetration occurs as the wire rope being serviced passes through a controlled 100% pressurized immersion within the system’s internal seal lubrication chamber. This immersion displaces any entrapped surface moisture within the rope’s internal strands and replaces it with the newly applied coating product. You can trust Kirkpatrick systems’ functionality with high- and low-viscosity coatings. Higher viscosity coating products maximize fluid film support against strand rubbing that can shorten any working ropes life due to friction wear. In the event your application requires low viscosity coatings such as a mining friction hoist; our systems easily apply those products as well accommodating high wire rope travel speeds.

The PANOLIN Group emerged from PANOLIN AG, founded in 1949. The Group is an independent Swiss family business domiciled in Madetswil near Zurich, with an own production facility at the same location. The development, production and marketing of lubricants are certified to ISO 9001 and ISO 14001 as well as ABS (American Bureau of Shipping). Innovation, flexibility, competence and close relations with our customers make the PANOLIN Group a high-performance partner for all your lubricant requirements.

Light-bodied oil · provides the ability to penetrate to the core of wire rope · wire ropes are cleaner and easy to inspect · penetrates the interstices between wires and strands · high film strength · prevents wear · resists oxidation and corrosion · self-healing film former · excellent in acid or alkali and pollutants’ environment · high polarity promotes creeping and re-lubrication of areas forced dry of oil.

Field lubrication for wire ropes in service. All sizes of standing and running ropes as used on suspension and lift bridges, tramways and cableways. All types of cranes, escalators, derricks, masts and chimneys. Also on hoist ropes, draglines, conveyors and material handling equipment. Major industries served include surface and underground mining, construction, towing, marine, gas and petroleum, on and off shore drilling, to name a few.

RXSOL Wire Rope Lubricant has been tested and proven directly compatible with Crosby RXSOL Wire Rope Lubricant Spray Applicators (see Crosby Catalog). The use of RXSOL Wire Rope Lubricant in Crosby RXSOL Wire Rope Lubricant Spray Applicators is recommended. Other methods of application include manual by brush, swab, drip, pour, automatic drip or spray systems and automatic pressure wire rope lubricators. This product is also available in an aerosol can.

LUBEGARD Wire Rope Lubricants are patented, aquatically non-toxic & biodegradable. They contain a unique blend of corrosion inhibitors, thickeners and wear reducers. Both are ideal for all types of wire ropes and chains in a variety of services and environments.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

8613371530291

8613371530291