wire rope maintenance pdf for sale

The Wire Rope Users Manual, Fourth Edition, December 2005, is published by the Wire Rope Technical Board and is the culmination of a joint effort by the domestic wire rope industry. This 160 page manual is a comprehensive and convenient source of reference data covering areas such as wire rope components; identification and construction; handling and installation; operation, inspection and maintenance; and physical properties. The information provided helps establish sound practices in rope selection and application. In addition, the fourth edition includes a section to serve as guidance for the safe use of rope and sling products: Wire Rope and Wire Rope Sling Safety Bulletin and Wire Rope Inspection Form.

The Minimum Breaking Strength should be considered the straight line pull with both rope ends fixed to prevent rotation, which will ACTUALLY BREAK a new, UNUSED, rope. The Minimum Breaking Strength of a rope should NEVER BE USED AS ITS WORKING LOAD.

To determine the working load of a wire rope, the MINIMUM or NOMINAL Breaking Strength MUST BE REDUCED by a DESIGN FACTOR (formerly called a Safety Factor). The Design Factor will vary depending upon the type of machine and installation, and the work performed. YOU must determine the applicable Design Factor for your use.

For example, a Design Factor of “5” means that the Minimum- or Nominal Breaking Strength of the wire rope must be DIVIDED BY FIVE to determine the maximum load that can be applied to the rope system.

WIRE ROPE WEAR OUT. The strength of a wire rope slightly increases after the break in period, but will decrease over time. When approaching the finite fatigue life span the breaking strength will sharply decrease. Never evaluate the remaining fatigue life of a wire rope by testing a portion of a rope to destruction only. An indepth rope inspection must be part of such evaluations.

NEVER overload a wire rope. This means NEVER use the rope where the load applied is greater than the working load determined by dividing the Minimum Breaking Strength of the rope by the appropriate Design Factor.

NEVER ‘SHOCK LOAD’ a wire rope. A sudden application of force or load can cause both visible external damage (e.g. birdcaging) and internal damage. There is no practical way to estimate the force applied by shock loading a rope. The sudden release of a load can also damage a wire rope.

Lubricant is applied to the wires and strands of a wire rope when manufactured. This lubricant is depleted when the rope is in service and should be replaced periodically.

Regular, periodic INSPECTIONS of the wire rope, and keeping of PERMANENT RECORDS SIGNED BY A QUALIFIED PERSON, are required by OSHA and other regulatory bodies for almost every rope installation. The purpose of inspection is to determine whether or not a wire rope may continue to be safely used on that application. Inspection criteria, including number and location of broken wires, wear and elongation, have been established by ISO, OSHA, ANSI, ASME and other organizations.

Every wire rope user should be aware of the fact that each type of fitting attached to a wire rope has a specific efficiency rating which can reduce the working load of a rope assembly or rope system, and this must be given due consideration in determining the capacity of a wire rope system.

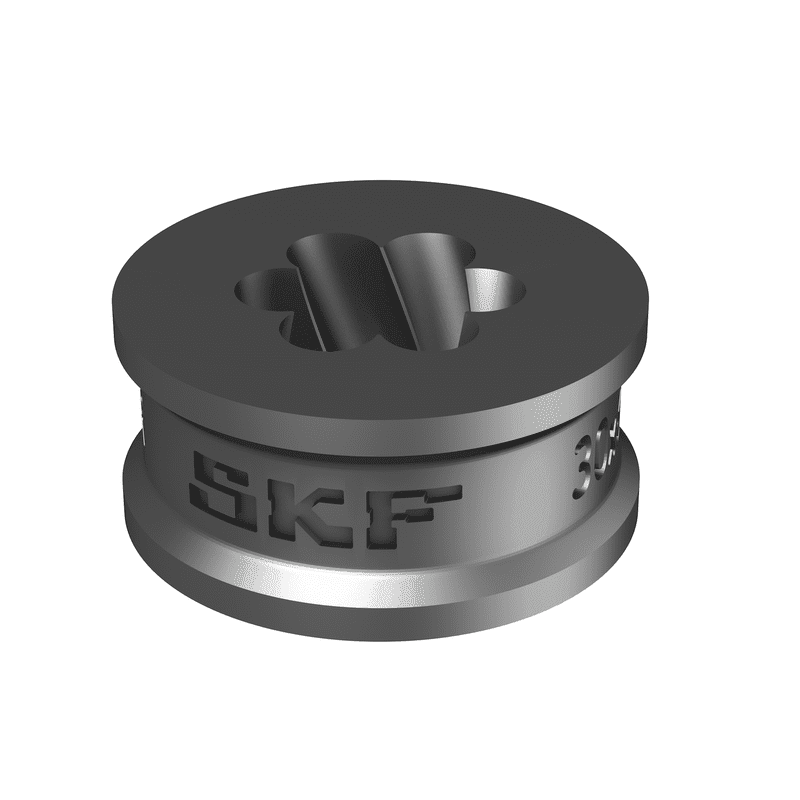

The Viper MKII Wire Rope Lubricator range provides fast and effective cleaning and lubricating of wire ropes. Wire ropes from 8 mm (5/16” ) to 165 mm (6-1/2”) in diameter can be automatically greased at speeds up to 2,000 mt per hour.

The Viper MKII with the new cast Aluminium collar is 32% lighter and combined with the unique inbuilt carry handles and shoulder strap enables single person wire rope lubrication. Ideal for use on all cranes, towing lines and mooring lines, the Viper MKII eliminates the HS&E risks associated with manual lubrication. Use of the Viper MKII provides improved wire rope lubrication by forcing wire rope lubricant under pressure into the wire rope.

Other lubricators just coat the surface of the ropes but the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer. This longer dwell time means greater lubricant penetration which leads to increased rope life and extended re-lubrication intervals.

Mandatory wire rope and sheave replacement intervals have been extended from 8 to 12 years, provided the total number of machine hours does not exceed 7,000*. For select machines, this means a significant savings for fleet owners, as a typical wire replacement job can cost anywhere from $2,000 to $7,000.

When you do replace wire rope sheaves, use JLG wire rope kits to streamline your service and reduce downtime. Order wire rope kits via Online Express.

Extending wire rope sheaves replacement intervals is another reduction to total cost of ownership for JLG. If you have any questions about this change or how to get the right parts for your job, contact your Regional Sales or Service Manager or

8613371530291

8613371530291