how much does a workover rig cost supplier

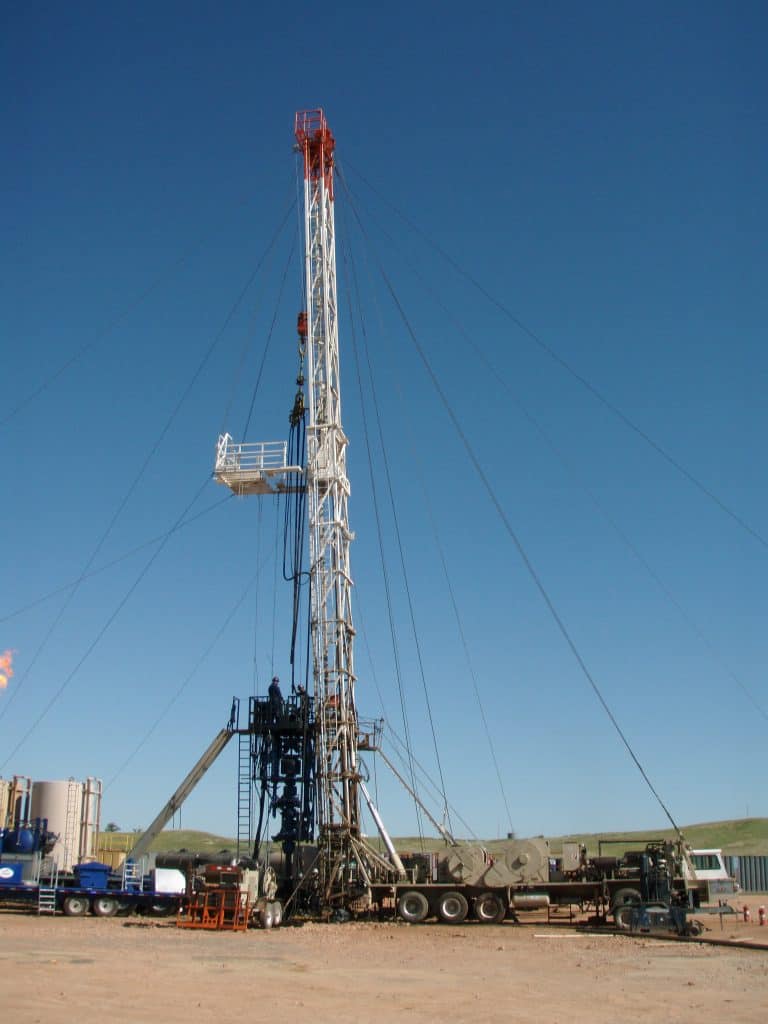

Workovers are the most common expenditure operators need on their oilfields. However, finding a service provider and getting their rates are not readily available in the industry. Operators would benefit from knowing the market average for a workover and gain reassurance they are getting a fair price for their services. This research is based on finding workover rigs for Zapata, Texas. The graph represents four service provider companies and their hourly rate for a workover rig.

It is important to note that due to slower oil development in recent years from the downturn in 2015 to the pandemic and downturn in 2020, smaller workover rig companies in Zapata, Texas have increasingly moved to the Permian Basin or have been acquired by larger service companies in the area. This has caused the workover rig service industry to be dominated by a few major servicers around Zapata. For Zapata, the ideal areas to look for servicers or workover rigs are Alice, Laredo, and Freer in Texas.

The hourly rates found are $335, $325, $375, and $360 creating an average rate of $349. Company names are replaced with Company A, B, C, and D. These companies were located in Freer and Alice for this research because the market synopsis revealed they offered more affordable rates than the servicers in Zapata.

Hourly rates for workover rigs vary and there are always competitors for services, especially for services as common as a workover rig. The market average price for a service provider is intended to provide the oil and gas operator better insight on the cost of services around their area.

An operator who wanted bids on a workover for his well requested this vendor list and decided to get connected with Company B to get the work done. He said it was a quick decision because what he was already paying for and what he was going to pay for cost more than the rates on this list.

In order to help oil and gas operators reduce operational expenditure, Petrofly researches the servicing market to provide the most economical options for your oilfield service needs. Petrofly’s platform is the complete upstream solution and leveraging the market average is one of the unique tools operators utilize to ensure lower operational costs.

Enjoy the best returns on your investment with these supreme workover rig price ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

workover rig price options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Are you looking for a wholesale workover rig price? Look no more as Alibaba.com has all sorts of pile drivers that will ease your next pile driving process. A pile-driving machine is critical equipment in constructing structures and buildings as it helps in driving piles into the soil. These piles help in providing foundation support for a structure or building under construction. In that way, you can comfortably move a load of the structure to a difficult depth without a machine. Regarding your liking workovers rig price, visit Alibcom.com as they have unlimited pile available at wholesale prices. Inther you are looking for pneumatic tools or hydraulic pipes, you will find them type at affordable prices. If you need a drill, it can advisable to have a workover r price.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Well Service | Workover Rigs - 844/80 Double drum draw works. looks to be recently rebuilt. Has new Lebus Grooving on Tubing Drum. Comes w/ 250 HP 2 speed jackshaft/RA BOX. More Info

Well Service | Workover Rigs - CARDWELL KB200B Freestanding Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Cardwell KB200B Freestanding Service Rig, 5 Axle Carrier, Detroit 8V71... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - COOPER 350 Well Service Unit p/b DETROIT 8V-92 Diesel Eng, ALLISON 750 Trans, 42X12-38x8 DRAWWORKS w/dual disc assist, 97â 200,000# Telescoping M... More Info

Well Service | Workover Rigs - CROWN 350 SERIES -- SERVICE KING 104" 205,000# DERRICK, CAT3406, ALLISON 5860,38X10 DOUBLE DRUM DRAWWORKS, CROWN SHEAVES REBUILT 2013 MAIN26âX4,SANDLINE 22â, NE... More Info

Well Service | Workover Rigs - 2008 Crown/Cabot 1058 Service unit mounted on 4 axle carrier w/Detroit 60 Power. New 5860 Drop Transmission. 72" Double rod/single tubing Derrickmast 125000# Rig is in Ex... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - FRANKS 1287-160-DTD-HT D/D Well Service Unit p/b DETROIT 8V-71N Diesel Eng, ALLISON CBT-4460-1 Trans. SERVICE KING 96" 180,000# Hydraulically Raised & ... More Info

Well Service | Workover Rigs - FRANKS 300 D/D 1287 w/hydromatic brake, Well Service Unit p/b DETROIT 8V-71 Diesel Eng, ALLISON 750 Trans, (Reman Dec 2011) FRANKS 96âH 150,000# Tri-Scope Telescopin... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b CAT 3406 Diesel Eng, ALLISON HT-750 Trans, FRANKS 96âH 180,000# 4-Leg Telescoping Mast, Hydraulically Raised & Scoped w/4-Sheave... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b Series 60 Detroit Diesel Eng, ALLISON 5860 Trans, 102âH 225,000# (on 4 line) Telescoping Mast, Hydraulically Raised & Scoped, Db... More Info

Well Service | Workover Rigs - IDECO H35 96̢۪ 210,000 MAST, DETROIT 60 SERIES ENGINE, ALLISON 5860 TRANSMISSION, REFURB 2005, IDECO DERRICK REPLACED WITH NATIONAL DERRICK, TUBING DRUM CON... More Info

Well Service | Workover Rigs - IDECO RAMBLER H-35 Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Ideco Rambler H-35 workover rig / service rig / pulling unit, 4 axle carrier, De... More Info

Well Service | Workover Rigs - 2015 INTERNATIONAL PAYSTAR 5900 Flushby Unit. C/w 2003, Refurbished in 2015, Western Fab Ltd. flushby unit, s/n 03-09-1008, 50 Ft. Mast height, 50,000 lb. pull rating, fr... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800 Flusby Unit. C/w Lash Ent. flushby unit, 47 ft mast, slant compatible, 3x5 Gardner Denver triplex pump, 5000 psi, 2005 Advance 8m3 tank, TC 406 code, P... More Info

Well Service | Workover Rigs - 2003 KENWORTH T800 Flushby Unit. c/w Online flushby unit, 47 ft. mast, slant compatible, Pullmaster HL25 wotking winch, Pullmaster PL5 catline winch, 2002 wabash two comp... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800B Flushby Unit. c/w Online flushby unit model 50-50, s/n 24641, 40 ft. mast,Salnt compatable, Pull master HL25 and PL5 winch, Gardner Denver 3x5 triplex... More Info

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The commodity price downturn is prompting price reductions among well service contractors in the greater Rockies outside the Williston Basin. In mid-January 2015, service providers report rates down about 10% quarter-to-quarter, similar to reports elsewhere in the oil patch as operators push the service sector for cost reduction. Meanwhile, larger service providers worry about further rate cutting from local, privately-held contractors. Rate reductions have not yet translated to reduction in wages for hands, although expectations are that pricing is going to drop further on the basis of lower commodity prices.

Among Survey Participants:Rig Demand Down QTQ [See Question 1 on Statistical Review]. Seven of the eight respondents said that demand had dropped in 1Q15 vs 4Q14 and all but one blamed lower oil prices for the slowing. One respondent that had seen a slowdown in demand said it was because they had finished all of their completion work. The respondent who had not seen an effect on demand said that their work was steady, but they were hearing of others slowing down.Mid-Tier Well Service Manager: “We are seeing demand slow for rigs and prices are being reduced. Operators are asking for 20% reductions, some are asking for 30% and they may get it. The greater reductions will be from people who are local because they don"t have the overhead expense. The service won’t be as good. On average, operators may get 15% of that 30% they are seeking in reductions.”

Number of Rigs Sufficient [See Question 2 on Statistical Review]. Six of the eight respondents said that the workover rig inventory is excessive for the current demand, while two said that it is sufficient but tipping toward excessive.Mid-Tier Operator: “Operators here are basically focusing on the higher production wells and going to ignore the lower ones. We have heard companies are laying down workover rigs. One company is going from 17 to 13.”

Well Service Work Weighted Toward Standard Workovers and Routine Maintenance [See Question 3 on Statistical Review]. Among all respondents, standard workover work accounts for 34% on average, routine maintenance accounts for 34%, plug and abandonment (P&A) accounts for 16% and completion work accounts for 16%.Mid-Tier Well Service Manager: “Our work slowed because we finished our completion work so the client gave us some production work to keep us steady till we finish this fracking job.”

Hourly Rates Consistent Among HP Series [See Question 5 on Statistical Review]. Most workover rig horsepower falls within the range of the 500 series. The 500 HP hourly rates average $310 to $400/hour depending on what ancillary equipment is contracted. See Table II for Average Hourly Rates.

No New Competition [See Question 7 on Statistical Review]. All respondents said that competition had not increased QTQ, and they were not anticipating it would, given lower oil prices.Mid-Tier Well Service Manager: “We worry about the small local companies undercutting prices but we are not seeing anything now.”

2015 Rates Under Pressure [See Question 8 on Statistical Review]. Five of the eight respondents said 2015 would see further reductions in demand and hourly rates and even labor rates if the price of oil did not rise. One respondent said that “iron would start laying down” if oil prices did not rise. One respondent said he expects that work demand would come back up after a couple of months as everyone adjusted.Manager for Mid-Tier Well Service Company: “As a company, we have backed off our growth budget for 2015 and our capex has been nixed. We implemented a 10% reduction in our rates. We are just going to lower rates not wages, because we can buy equipment and leave it sit, but if you do that with people, they starve.”

Hart Energy researchers completed interviews with nine industry participants in the workover/well service segment in areas of the Rocky Mountains outside of the Bakken Shale play. Participants included one oil and gas operator and seven managers with well service companies. Interviews were conducted during January 2015.

3. Looking at your slate of well service work - on a percentage basis - how much of it is workover vs. routine maintenance vs. plug & abandonment (P&A) vs. completion work?

What does it take to maintain a successful business? If you said profit, you hit the critical component to any good business. However, if you said the right equipment and team, your thought process drills deeper. I bet the rest of you were shouting, “Customers is what it takes!”

Maintaining a successful business was a top discussion point at the recent Mountain States, Maryland-Delaware, and Virginia groundwater conferences I attended as a presenter. To get a well-rounded perspective on this important topic, I interviewed a driller within our community and a custom home-builder connected to our community.

First up, Charles “Buddy” Sebastian of Sebastian and Sons Well Drilling based in Michigan is a long-time industry friend and president of the Michigan Ground Water Association. Sebastian has presented talks on job costs, company sustainability and the future of drilling companies at the MGWA’s annual conference. He also just presented at the Montana Water Well Drillers Association Convention & Trade Show.

A. The first talk I did on knowing your cost at MGWA, I had a question from the audience that said: “You have your business figured out. What"s your exit plan?” I said, the day you start your business is the day you start planning to sell your business. What I mean is, to be able to sell your business you have to be able to set your market. You can either be the market setter or market followers. You have to be able to set the market that your business is solvent. To be solvent, you have to have enough money in your profit margin to maintain, repair and replace equipment. Then, beyond sustaining the business, you can’t just work for beer and pizza. So you have to have enough profit in there to pay the team and yourself.

A. Well, we have to set the going rate for drilling in our area to have enough profit dollars to complete the job, maintain the equipment, pay the team and invest in the future.

A. We are in some dangerous times for new equipment in our industry. Rig manufacturers are for sale for the second time in less than a decade, and the latest trend is to build smaller, less expensive rigs.

A. First of all, we have to stop pricing our product according to our competitor. We fix that by knowing our cost per hour and cost per day for equipment and project. That thinking that my competitor is drilling for $18, so I need to drill for $17 needs to go away. We need to know our costs on the first job and be profitable because it isn’t going to get any better if you don’t.

A. It is based on how many wells you do a year. I figure today’s drilling equipment’s life as 10 to 15 years, and yes, some older conventional rigs had a longer lifecycle. You know I did a cost analysis of some of my older table-drive rigs to replace belts, bearings, bushing and drivelines. What I saw was [that having] bushing and bearing that were relatively cheap to repair was no longer the case. Replacement parts were not built as good as the originals; importing cost had increased and, overall, these parts were becoming obsolete due to American manufacturers no longer making them. Conventional rigs are not as easy or cheap to repair as they were. You have to take into consideration downtime versus complete replacement.

A. OK, how about an $800,000 new rig that is going to be maintained to last 15 years. I use 2,080 working hours in a year, and I take into consideration 15 years of life. That comes out to $25 an hour to operate that rig.

That’s the per-hour cost to own that rig. That’s not interest, maintenance, repairs, tires, mud pumps or wearables. It’s just the cost to own the rig. Next, you have to take into account everything to operate and maintain the rig, including the labor to repair, update and replace. A good number to start with for a new $800,000.00 rig is about $75,000 a year to own and maintain it. The best advice I can give to a new rig owner is to save $25 an hour for every hour of rig operation to replace that rig.

A. The rig payment comes from profit. If you can’t pay the rig out of profit, you are in big trouble. We must make a business that is sustainable that can attract and hire good people and, on top of that, pay ourselves. We must know our costs.

Q. How does the industry value water at a cost that makes the drilling business sustainable? How do we change the stigma that a water well must cost X but even interior amenities such as cupboards can cost so much more?

A. First, we, as an industry, must start teaching the end-user the same statement. Water is a necessity for life. We, as an industry, have more invested in equipment overhead than any other construction trade. I have quickly over a million and a half dollars invested in providing water; often the homes we drill wells for do not have that in the building materials and builder labor. We need to sell that point to our customers that we are invested in them, and they need to invest in us to be sustainable to continue to provide water.

Next, I turned to Cameron Fox, owner of Fox Custom Builders in Kalamazoo, Michigan. Fox has built custom homes in West Michigan, all requiring private water wells. He helped me visualize how customers and homebuilders view new water wells.

A. Homeowners view their water wells as a non-negotiable necessity. Our customer usually addresses this part of the contract to the extent of “how will you make sure I get exceptional water pressure.”

A. Pricing is consistent throughout our area, so pricing is not outrageous. The drilling companies’ professionalism and expertise exclusively drive my priority when choosing an installer.

A. It is all about location. Location of the well may seem like a no brainer, but choosing a site, particularly on nonconforming lots or lake homes, can be somewhat problematic. Distance from property lines, septic systems and sewage ejection pumps can often become a balancing act. A drilling company willing to work with the footprint I have is invaluable.

A. Similar to any skilled trade, you can pay a premium for a professional company to complete premium work, or you can find an inexpensive alternative and deal with the consequential headaches. You get what you pay for.

A. I have had very positive experiences with the two drilling companies I use. Both are excellent, and overall I had similar experiences. The estimates and proposals aligned, and they both researched well logs on adjacent properties to present reasonable estimated well depths. One thing that makes me use one company over the other is when they go the extra mile to educate my customers on the process and me. I have a backup drilling company just because of schedules.

A. Every homeowner has a different pricing tolerance based on what is important to them. When building a vacation home, the money will be spent to upgrade materials requiring less maintenance. Homeowners with large families are more focused on added square footage than premium kitchen cabinets or heated floors. Ultimately, each homeowner is unique, and their money is allocated toward their “must-have” items.

A. With the significant increase in the cost of wood over the last 10 years paired with the massive jump in labor costs, framing the home is typically the most expensive component of new construction. Other added costs come from the special footing or extensive land improvements/excavation.

A. We build custom homes that meet each client’s specific wants and needs. Not only do we accomplish this but at the same time we build quality homes. Energy-efficient and structurally sound homes are the starting point for our homeowners. These are our core values and a starting point from where we build to create a functional and architecturally pleasing home that exceeds our homeowners’ expectations. Building a home is like entering into a serious relationship with someone you just met. You are going to spend hundreds of hours with them, answer multiple calls a day and then respond to their weekend emails. You have to get along, or you’ll both walk away from the process drained and upset. I have found the best way to get along is to require perfection from my employees and my subs. That’s it. I do not allow mediocrity; my customers know it, and it establishes a basis for trust.

A. The entry barrier has working capital to pay subcontractors and material suppliers between bank draw. I typically need 20-25% of the contract price in liquid assets to fund the project. Then it’s about managing my project and understanding the profit I need to sustain my business, pay my employees and, at the end of the day, I need to provide for my family.

We need customers and builders, and they 100% require the drilling industry to provide water. We have to establish our message of value to our customers. The problem cannot be solved with one company or region that cannot solve our image; it will take the entire community discussing how we make the change together. In the end, we need the same thing our builder requires, to be able to recruit and pay good men and women to progress our industry, buy the right technology to be successful, and provide the consumer with a quality product that they value.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Under these rental contracts, a turnkey cost is paid by an E&P business to a middleman. This includes an insurance premium, which is returned if nothing goes wrong, but may be lost if there are difficulties. Higher specification equipment commands a larger premium.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

The International Association of Drilling Contractors (IADC) lists 547 members in the category of Land Drilling Contractors. According to Statista, the key US land drilling contractors are: Nabors Industries Ltd, Helmerich & Payne Inc, Patterson-UTI Energy Inc, Precision Drilling Corporation and Pioneer Energy Services Corp.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

Together these five companies dominate the US rental market. Other smaller but prominent contractors include: Parker Drilling, Unit Corp, Independence Contract Drilling, Seventy Seven Energy, Schramm and Ensign Drilling. Beyond these players, the market is highly fractured, with many “mom & pop” style drillers.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

This material does not amend, or otherwise affect, the provisions or coverages of any insurance policy or bond issued by Travelers. It is not a representation that coverage does or does not exist for any particular claim or loss under any such policy or bond. Coverage depends on the facts and circumstances involved in the claim or loss, all applicable policy or bond provisions, and any applicable law. Availability of coverage referenced in this document can depend on underwriting qualifications and state regulations.

All rights reserved. Travelers and the Travelers Umbrella logo are registered trademarks of The Travelers Indemnity Company in the U.S. and other countries.

Find a comprehensive report summary that describes the market size and forecast along with the research methodology.The FREE sample reportis available in PDF format

The growing demand for oil and natural gas is one of the key drivers supporting the workover rigs market"s growth. With the increase in the demand for oil and natural gas, companies will try to enhance oil and gas production to meet the demand. Oil and gas companies can increase oil and gas production in two ways. One way is to drill new oil and gas wells, while another way is to increase production from existing low-producing oil and gas wells. Workover rigs are used in both cases. Therefore, the increase in the demand for oil and natural gas will spur the need for workover rigs in oil and gas E&P activities during the forecast period.

As per Technavio, the use of laser technology in workover operations will have a positive impact on the market and contribute to its growth significantly over the forecast period. This research report also analyzes other significant trends and market drivers that will influence market growth over 2022-2026.

The use of laser technology in workover operations is one of the key workover rigs market trends contributing to market growth. The use of lasers has many advantages, such as speeding up the workover process and making it several times faster than traditional methods, and others. Downhole lasers can also be used for flow assurance applications, such as scale removal. Scale removal is a common well intervention activity, which involves a wide range of mechanical scale-inhibitor treatments and chemical treatments. Therefore, the use of laser workover systems optimizes workover operations and will fuel the growth of the market during the forecast period.

However, the emergence of rigless well intervention and abandonment technologies is one of the factors hindering the workover rigs market growth. The rigless approach is being implemented in well-abandonment applications. Rigless well abandonment can be used in a wide range of oil wells and is extremely cost-effective as it does not require a workover rig. This method complies with most well-abandonment regulatory requirements, along with a minimum footprint and quick project delivery. The use of rigless technology simplifies the equipment spread and reduces the use of costly and complex workover rigs, thereby reducing the overall cost of operations. Hence, the rigless approach to well intervention and abandonment will pose a significant threat to the market during the forecast period.

This market research report segments the workover rigs market by Application (Onshore and Offshore) and Geography (North America, Middle East and Africa, APAC, Europe, and South America).

54% of the market"s growth will originate from North America during the forecast period. The US and Canada are the key markets for the workover rigs market in North America. The numerous offshore deepwater and ultra-deepwater oil and gas projects will facilitate the workover rigs market growth in North America over the forecast period.

Companies profiledAutomated Rig Technologies Ltd., Aztec International Ltd., Bentec GmbH Drilling and Oilfield Systems, Care Industries Inc., China National Petroleum Corp., Deep Industries Ltd., Dragon Products LLC, Drillmec Spa, MAX STREICHER GmbH and Co. KG aA, Mesa Southern Well Servicing LP, Moncla Energy Services LLC, Nabors Industries Ltd., National Energy Services Reunited Corp., NOV Inc., Precision Drilling Corp., Schlumberger Ltd., Superior Energy Services Inc., Ventia Services Group Pty Ltd., Watson Hopper Inc., and Yantai Jereh Oilfield Services Group Co. Ltd.

Market DynamicsParent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID-19 impact and future consumer dynamics, and market condition analysis for the forecast period.

4 Five Forces Analysis4.1 Five forces summary4.2 Bargaining power of buyers4.3 Bargaining power of suppliers4.4 Threat of new entrants4.5 Threat of substitutes4.6 Threat of rivalry4.7 Market condition

5 Market Segmentation by Application5.1 Market segments5.2 Comparison by Application5.3 Onshore - Market size and forecast 2021-20265.4 Offshore - Market size and forecast 2021-20265.5 Market opportunity by Application

7 Geographic Landscape7.1 Geographic segmentation7.2 Geographic comparison7.3 North America - Market size and forecast 2021-20267.4 Middle East and Africa - Market size and forecast 2021-20267.5 APAC - Market size and forecast 2021-20267.6 Europe - Market size and forecast 2021-20267.7 South America - Market size and forecast 2021-20267.8 US - Market size and forecast 2021-20267.9 Canada - Market size and forecast 2021-20267.10 Saudi Arabia - Market size and forecast 2021-20267.11 China - Market size and forecast 2021-20267.12 Russia - Market size and forecast 2021-20267.13 Market opportunity by geography

10 Vendor Analysis10.1 Vendors covered10.2 Market positioning of vendors10.3 Bentec GmbH Drilling and Oilfield Systems10.4 China National Petroleum Corp.10.5 Drillmec Spa10.6 Moncla Energy Services LLC10.7 Nabors Industries Ltd.10.8 National Energy Services Reunited Corp.10.9 NOV Inc.10.10 Precision Drilling Corp.10.11 Schlumberger Ltd.10.12 Yantai Jereh Oilfield Services Group Co. Ltd.

11 Appendix11.1 Scope of the report11.2 Inclusions and exclusions checklist11.3 Currency conversion rates for US$11.4 Research methodology11.5 List of abbreviations

Technavio is a leading global technology research and advisory company. Their research and analysis focus on emerging market trends and provide actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio"s report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio"s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Dublin, May 30, 2019 (GLOBE NEWSWIRE) -- The "Global Workover Rigs Market 2019-2023" report has been added to ResearchAndMarkets.com"s offering.

The growing demand for oil and natural gas will drive the growth of the global workover rigs market during the predicted period. The global consumption of natural gas has seen a significant rise due to the increasing use of natural gas as a fuel. With the increase in the demand for oil and natural gas, companies will try to enhance oil and gas production to meet the demand.

Oil and gas companies can increase the production in two ways. One way is to drill new oil and gas wells, while another way is to increase production from existing less-producing oil and gas wells. Workover rigs are used in both cases. Therefore, the increase in the demand for oil and natural gas will spur the need for workover rigs during well E&P activities such as intervention and completion and drive the growth of the global workover rigs market during the forecast period.

The increase in oil and gas investments, as well as government support for oil and gas E&P activities, will give rise to the need for intervention and completion services. where workover rigs are required. These factors are supporting the growth of the global drilling rig count. which indicates the growth of the global workover rigs market during the forecast period.

Crude oil prices have encountered large variations over the years, which have a negative impact on the profitability and performance of upstream oil and gas companies. A large number of drilling rigs were shut down, and many employees were laid off due to the variations in global crude of prices. E&P projects are executed only when the revenue generated is high enough for upstream companies to make profits. Thus, the uncertainty and fluctuations in global crude oil prices will hamper investments in E&P projects in both onshore and offshore fields, which will, in turn, impact the global workover rigs market during the forecast period.

The market appears to be moderately fragmented. The presence of several companies including TOKAIRIKA and Valeo makes competitive environment quite intense. Factors such as the increase in global drilling rig count and the growing demand for oil and natural gas, will provide considerable growth opportunities considerable growth opportunities to workover rigs manufacturers.

DRILLMEC Spa, Nabors Industries Ltd., National Oilwell Varco Inc., Precision Drilling Corp. Schlumberger Ltd., and Yantai Jereh Oilfield Services Group Co. Ltd. are some of the major companies covered in this report.

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Savanna employees are paid every two weeks via direct bank deposit. Savanna’s compensation package includes company group health, dental and disability coverage including paramedical coverage (acupuncturist, chiropractor, massage therapist, naturopath physiotherapist and much more). Savanna also offers a competitive and rewarding retirement savings plan.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

Some well locations have sour gas (Hydrogen Sulfide or H2S) present which is extremely dangerous. All employees are required to possess a valid H2S Alive certificate regardless of whether they are working on a sour gas well. This can be obtained by signing up for and completing a one-day (8 hour) course.

Courses are available at various locations across the province. For more information, contact Energy Safety (formerly Enform) at (780) 955-7770 or visit www.enform.ca or Leduc Safety Service at (780) 955 3300 or visit www.leducsafety.com. The cost of the course is usually between $130 and $150 plus tax, and the certification is valid for three years.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Savanna is committed to providing a safe, productive and respectful work environment. As such, Savanna has Policies in place to ensure the protection of our employees, contractors, the pubic and the environment. All Savanna employees are required to acknowledge and follow the policies at all times.

Used Mainland M-32 Freestanding Service Rig, 4 Axle Carrier, Detroit 6V-71 Diesel Engine, Allison HT750 Auto Transmission, 69" Stiff Mast, 120,000 lbs. rating, 32x7 Double Drum Draw-works, 2 Auxiliary Deck Winche...

Used Cardwell KB200B Freestanding Service Rig, 5 Axle Carrier, Detroit 8V71 Diesel Engine, Allison CLBT4460 Auto Transmission, 72" Stiff Mast, 140,000lb Pull, 40 x 10 Double Drum Draw Works, 2 Auxiliary Deck Winc...

Used Ideco Rambler H-35 workover rig / service rig / pulling unit, 4 axle carrier, Detroit 8V-71 diesel engine, Allison CLT 5860-DB automatic transmission, 95" Ideco telescoping derrick, 212,000lbs hook load, 42x...

Used MR-350 Mountain Rig pulling unit / workover rig / service rig, Cat 3406T Diesel Engine, Allison CLBT-5860-2 Automatic Transmission, 104" Pemco Telescoping Double Derrick, 225,000lb Hook Load, 42x10 Double Dr...

- "Service Work" consists of using a rig to pull down hole pumps, rods, and tubing from the wellbore. Other service including cleaning and swabbing a method used to remove fluid from the well bore. Well depths range from several hundred feet to 10, 000 feet belowread more...

We are one of the leading service provider for Coring, Air Drilling, Workover and Drilling Rig Services to various Oil and Gas Companies in India. Our strength is in providing complete Rig Package with all associated equipment and services to onshore Oil and Gas Industry. We currently hold wide range of Onshore Workover Rigsread more...

Navrangpura, Ahmedabad B/507-508, Fairdeal House Near Swastik Cross road C. G. Road, Navrangpura, Navrangpura, Ahmedabad - 380009, Dist. Ahmedabad, Gujarat

Vishal Enterprise is committed to providing one-stop solution to the whole range of highest quality products in the oil machinery field. We satisfy customers’ needs of any parts in the field of oil machinery and of better quality.

JKGIT has developed strategic tie ups with rig manufacturers in China. As a team we can manage the sourcing of various rigs and their components in a cost effective manner and serve the ever growing market of Oil & gas industry in India. We are dedicated to provide a high quality oilfield products and services forread more...

We have successfully executed numerous contracts for operation and maintenance of client owned Work Over Rigs. Amongst other esteemed contractors, we have emerged as winners in the field of Safety, Best Performance, etc. Our trained technical manpower is vigilant and extremely careful with handling the equipment. For over 15read more...

We offer good quality Offshore Workover Rig. This kind of workover rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C and technical standards of RP2A-LRFD, 2Z, 14F, 14G, 500, GB3826.1, GB3836.2, GB7258, SY5202.

Ashram Road, Ahmedabad C-10, Nandanvan Complex, Opposite Town Hall Ashram Road, Ellis Bridge, Ashram Road, Ahmedabad - 380006, Dist. Ahmedabad, Gujarat

8613371530291

8613371530291