hydraulic workover rig manufacturer

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Enjoy the best returns on your investment with these supreme hydraulic workover rig ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

The hydraulic workover rig you’ll come across at Alibaba.com are designed with the operators’ safety and comfort in mind. Advanced safety precautions such as perfect ergonomics for physical comfort, reduced noise, low dust emissions, and minimal physical hazards are notable features of the hydraulic workover rig. Operating these hydraulic workover rig is not very complicated. They have many standard features and professionally trained operators will have an easy time working with them.

Get wholesale hydraulic workover rig from global wholesalers, Alibaba. At competitive prices, you can maintain, modify, enhance or replace your machines and vehicles. From the selection of new, used, and rebuilt parts from different manufacturers, choose the suitable hydraulic workingover rig to get your construction equipment up and running in no time. The collection of hydraulic worksover rig at Alibaba.com includes parts for both mechanical and electrical systems. From transmission systems to hydraulics, engines to pumps, and brakes to wheels, Al Alibaba.com got it. You can chat with your supplier to make modifications or even get custom designs, and that’s what Alibcom. for your business needs.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

Skid mounted, Sliding mast, Rig completed by Top Drive, Hydraulic Power Tong, Rotary Table with Automatic Power Slips, Rotating Jib Crane, Hydraulic Elevators.

High quality cost-effective diesel drilling onshore large load workover rig,The rig structure is compact and well designed, highly integrated, and optimized to save working space. The power system is a hydraulic+ mechanical type with high comprehensive efficiency. A class II or self-propelled type chassis can be adopted to meet the various requirements of the end-users.

The mast is front-open type, with a single section or double-section structure, hydraulic raising and hydraulic telescoping, or mechanical telescoping.

Band brake or hydraulic disc brake can be applied as the main brake of the drawworks. The water cooling thrust plate pneumatic brake or water brake can be used as an auxiliary brake.

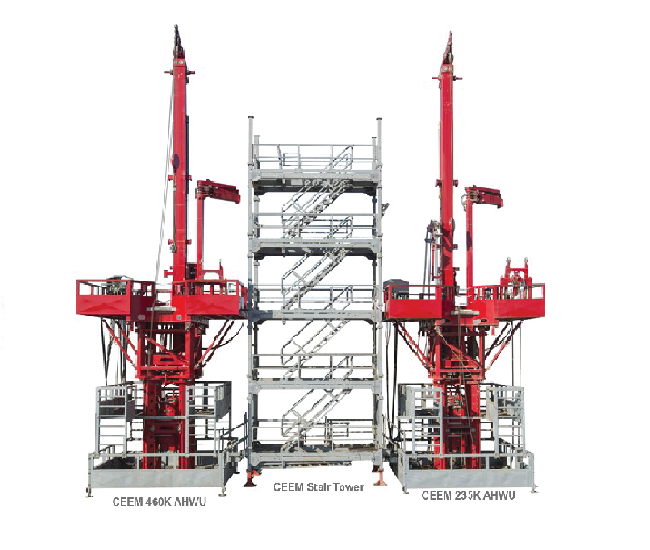

The hydraulically-driven Snubbing and Workover units have lift-force capacities ranging up to 460,000 lbs, and are capable of performing a wide range of Workover services. There are only a few companies that provide these units, such as Halliburton, Cudd Energy in Australia. With this unit, we have just completed an ENEXD ensures safe and reliable performance from the most experienced team of personnel from around the world, adhering strictly to API, OEM, DNV, and other operating and governing body standards.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The hydraulically-driven Snubbing and Workover units have lift-force capacities ranging up to 460,000 lbs, and are capable of performing a wide range of Workover services. There are only a few companies that provide these units, such as Halliburton, Cudd Energy in Australia. With this unit, we have just completed an ENEXD ensures safe and reliable performance from the most experienced team of personnel from around the world, adhering strictly to API, OEM, DNV, and other operating and governing body standards.

The HWO unit uses hydraulic cylinders to lift tubulars in or out of the well. Using hydraulic cylinders allows for perfect control over tubular movements and eliminates the use of a large mast construction which is present on conventional drilling rigs.

Hydraulic cylinders can generate large pull and push forces and provide the HWO unit with a small footprint and configuration. These properties are beneficial for offshore operations where space can be limited and where harsh weather conditions are present. In general, the running speed of a HWO unit is lower than a conventional workover rig.

Major players in the hydraulic workover unit market are Archer limited, Basic Energy Services, Inc. , Canadian Energy Equipment Manufacturing FZE, Cudd Energy Services, Easternwell Group, Elnusa, Halliburton Company, High Arctic Energy Services Inc, Key Energy Services, LLC, NOV Inc.

New York, March 24, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Hydraulic Workover Unit Global Market Report 2022" - https://www.reportlinker.com/p06247583/?utm_source=GNW

The global hydraulic workover unit market is expected to grow from $8.65 billion in 2021 to $9.58 billion in 2022 at a compound annual growth rate (CAGR) of 10.7%. The growth is mainly due to the companies resuming their operations and adapting to the new normal while recovering from the COVID-19 impact, which had earlier led to restrictive containment measures involving social distancing, remote working, and the closure of commercial activities that resulted in operational challenges. The market is expected to reach $12.40 billion in 2026 at a CAGR of 6.7%.

The hydraulic workover unit market consists of sales of hydraulic workover unit services by entities (organizations, sole traders, and partnerships) that utilize versatile, cost-saving, and safe techniques for the repair and maintenance of all types of wells.Hydraulic workover is a well intervention technique used for installing or removing tubes (pipes) in and out of dead wells (the well with zero surface pressure).

The main services in the hydraulic workover unit are workover and snubbing.The snubbing services are used to install or eliminate tubular from a well while the well is pressurized.

North America was the largest region in the hydraulic workover unit market in 2021. The regions covered in this report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

The increasing shale gas production is projected to propel the growth of the hydraulic workover unit market in the coming years.Shale gas is natural gas generated from a type of sedimentary rock called shale that is formed from clastic origins such as sedimentary rock or siltstone.

The most adaptable technology available in the upstream oil and gas industry is the snubbing unit, which is a type of hydraulic workover unit. According to the United States Energy Information Administration, shale gas production in the USA is expected to increase from 27.90 trillion cubic feet in 2021 to 32.50 trillion cubic feet by 2025. Therefore, the increasing shale gas production drives the growth of the hydraulic workover unit market.

The introduction of multiphase projects is a key trend gaining popularity in the hydraulic workover unit market.Major players operating in the hydraulic workover unit sector are launching multiphase projects in collaboration with technology players to set a new offshore snubbing unit or hydraulic workover world record.

For instance, in September 2020, SBS Energy Services (SBS), a US-based provider of snubbing, hydraulic workover services entered into a strategic partnership with Helix Solutions to complete a multi-phase project that deactivates roughly 29,000 feet of 10 inches by 6 inches insulated pipeline in the Gulf of Mexico.

In April 2019, High Arctic Energy Services Inc., a Canada-based drilling oil and gas wells company acquired assets of snubbing services equipment from Precision Drilling for $8.5 million. The acquisition provides the High Arctic with additional quality snubbing equipment and access to experienced personnel and crews. Precision Drilling is a Canada-based drilling rig contractor involved in offering snubbing services, oil field rental, and supplies.

The countries covered in the hydraulic workover unit market report are Australia, Brazil, China, France, Germany, India, Indonesia, Japan, Russia, South Korea, UK and USA.

When your well requires Hydraulic Workover Services, the trained professionals at Cudd Energy Services can engineer, plan, and execute the job safely and efficiently. With extensive experience in land, marine, desert, and other difficult to access locations around the world, Cudd Energy Services is a recognized industry leader and innovator in Hydraulic Workover Services.

Cudd offers a variety of hydraulic workover / snubbing solutions to enhance production and/or restore the mechanical integrity of your well. We can provide conventional stand alone, conventional stand alone with racking and skidding capabilities, hydraulic rig assist, or Quick Jack options to accommodate all well intervention situations.

Cudd Energy Services hydraulic stand alone unit is a preferred choice when pressure, space, accessibility and rig availability are concerns. The stand alone package includes a work basket, hydraulic jack, stationary and traveling slip bowls, power pack, work window with walk arounds, and gin pole. Pump support is available for all applications.

For expedient and efficient operations, Cudd Energy Services revolutionary "Space Saver" snubbing unit brings the advantages of hydraulic snubbing to conventional drilling or workover operations.

The self-contained, 170K Space Saver unit is configured with a low-profile snubbing stack located between the hydraulic jack legs. This shortens the operating height for more efficient tubular handling and faster trip times. With only one flange connection to the existing BOP stack, the hydraulic rig assist unit can be rigged up in less than 60 minutes.

Cudd Energy Services 150K Quick Jack™ is a modular stand alone hydraulic workover unit configured for rapid rig ups (2-3 hours). The Quick JackT is an economical alternative to high pressure coil tubing or a space saver workover rig combination.

Cudd"s hydraulic workover professionals are continuously examining our processes to create job efficiencies for our customers. One result of these efforts is the Rack Jack® and/or skid systems used independently or in tandem. The Rack Jack® feature enables crews to standback the workstring improving trip times in and out of the well. The skid system allows movement between wells without rigging down the unit or BOP stack. Used in tandem, the Rack Jack® skidding system allows the user to move between wells without laying down the workstring.

EEST Energy provides multi-capacity Hydraulic Workover Units (HWU) for projects onshore and offshore. A Hydraulic Workover Unit (HWU) is gaining global recognition in performing the same well-servicing applications as conventional well intervention activities, especially when dealing with critical limitations such as space and deck-loading problems.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291