hydraulic workover rig supplier

Enjoy the best returns on your investment with these supreme hydraulic workover rig ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

The hydraulic workover rig you’ll come across at Alibaba.com are designed with the operators’ safety and comfort in mind. Advanced safety precautions such as perfect ergonomics for physical comfort, reduced noise, low dust emissions, and minimal physical hazards are notable features of the hydraulic workover rig. Operating these hydraulic workover rig is not very complicated. They have many standard features and professionally trained operators will have an easy time working with them.

Get wholesale hydraulic workover rig from global wholesalers, Alibaba. At competitive prices, you can maintain, modify, enhance or replace your machines and vehicles. From the selection of new, used, and rebuilt parts from different manufacturers, choose the suitable hydraulic workingover rig to get your construction equipment up and running in no time. The collection of hydraulic worksover rig at Alibaba.com includes parts for both mechanical and electrical systems. From transmission systems to hydraulics, engines to pumps, and brakes to wheels, Al Alibaba.com got it. You can chat with your supplier to make modifications or even get custom designs, and that’s what Alibcom. for your business needs.

A wide variety of hydraulic workover options are available to you, You can also choose from diesel, electric and gasoline hydraulic workover,As well as from energy & mining, construction works , and manufacturing plant. And whether hydraulic workover is 2 years, {2}, or {3}.

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

High quality cost-effective diesel drilling onshore large load workover rig,The rig structure is compact and well designed, highly integrated, and optimized to save working space. The power system is a hydraulic+ mechanical type with high comprehensive efficiency. A class II or self-propelled type chassis can be adopted to meet the various requirements of the end-users.

The mast is front-open type, with a single section or double-section structure, hydraulic raising and hydraulic telescoping, or mechanical telescoping.

Band brake or hydraulic disc brake can be applied as the main brake of the drawworks. The water cooling thrust plate pneumatic brake or water brake can be used as an auxiliary brake.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Sanjack has been committed to the research of automatic workover technology for many years and has a perfect automatic workover technology development, production, and manufacturing system.

In recent years, a whole set of automation technology has been formed in the automation and intelligent development of automatic workover equipment. Through the application of module design, servo drive, integrated control, electro-hydraulic compound drive and other technologies, the supporting products suitable for various types of workover equipment have been developed to meet the needs of oilfield workover equipment upgrading.

Drill floor automatic pipe arranging manipulator can replace workers to complete the placement of the column on the drill floor surface, and connect single joint, thread connection, etc., to achieve unmanned operation of the drill floor for major workover operations.

Two kinds of automatic make-up and break-down equipment with different structural forms and different characteristics replace the manual push-pull operation of hydraulic tong.

The original integrated structure of hydraulic tong and punching tong can meet the thread up and down of tubing/drill pipe at the same time. The tong head has a floating function, which can automatically compensate the center deviation between the pipe string and the jaw and reduce the damage when the tong teeth clamp the pipe body. The torque can be accurately controlled and set, and the make-up torque of pipe string meets the requirements of API. When in standby, it can rotate and give way as a whole to provide more active operation space for the drill floor. The tong head can be deflected to meet the make-up & break-down of the mouse hole string.

Instead of the traditional mechanical elevator, the hydraulic drive valve is opened and closed, and the elevator is deflected and overturned, so there is no need to lift the elevator manually.

The hydraulic station provides hydraulic power for automatic loading and unloading hydraulic clamps, hydraulic elevators, pipe string conveyors, drill floor manipulators and other equipment.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Skid mounted, Sliding mast, Rig completed by Top Drive, Hydraulic Power Tong, Rotary Table with Automatic Power Slips, Rotating Jib Crane, Hydraulic Elevators.

MarketResearch.biz delivers in-depth insights on the global hydraulic workover unit market in its upcoming report titled, “Global Hydraulic Workover Unit Market Analysis, Drivers, Restraints, Opportunities, Threats, Trends, Applications, and Growth Forecast to 2027”. The global hydraulic workover unit market is estimated to register a CAGR of X.X% in terms of value during forecast period 2018–2027. The report offers in-depth insights, revenue details, and other vital information regarding the global hydraulic workover unit market, and the various trends, drivers, restraints, opportunities, and threats in the target market till 2027. The report offers insightful and detailed information regarding the various key players operating in the global hydraulic workover unit market, their financials, supply chain trends, technological innovations, key developments, apart from future strategies, acquisitions & mergers, and market footprint. The global hydraulic workover unit market report has been segmented on the basis of installation type, service, application, and region.

Hydraulic workover units are portable pulling systems that offer various benefits for onshore and offshore installations. Hydraulic workover unit is used as an alternative to workover rigs & conventional drilling. They are mainly used in drilling, repairing, and completing wells in and around shores.

Rising energy demand in developing economies is a key factor driving growth of the global hydraulic workover unit market. In addition, increasing number of exploration activities, hydraulic fracturing, and well drilling activities are some other factors expected to boost growth of the global hydraulic workover unit market over the forecast period.

However, stringent environmental regulations are key factors restraining growth of the global hydraulic workover unit market. Additionally, lack of skilled workforce, and problems associated with use of hydraulic workover unit such as long rig-up time, and problems in transportation due to its heavy weight are some other factors anticipated to hamper growth of the global hydraulic workover unit market over the forecast period.

Increasing number of mature oil & gas fields, and rising demand for snubbing services that are part of snubbing workover operation in shale gas formation are another factors expected to boost demand for hydraulic workover units in near future, and create potential opportunities for key players in the market.

Currently, the market in North America accounted for dominant revenue share in the global hydraulic workover unit market. This dominance can be attributed to increasing production for shale gas in countries in the region. The market in Asia Pacific is projected to witness fastest growth over the forecast period, owing to rising energy demand in emerging economies such as China, India etc. Also, market in Middle East is expected to witness moderate growth over the forecast period owing to presence of large untapped energy reserves in the region.

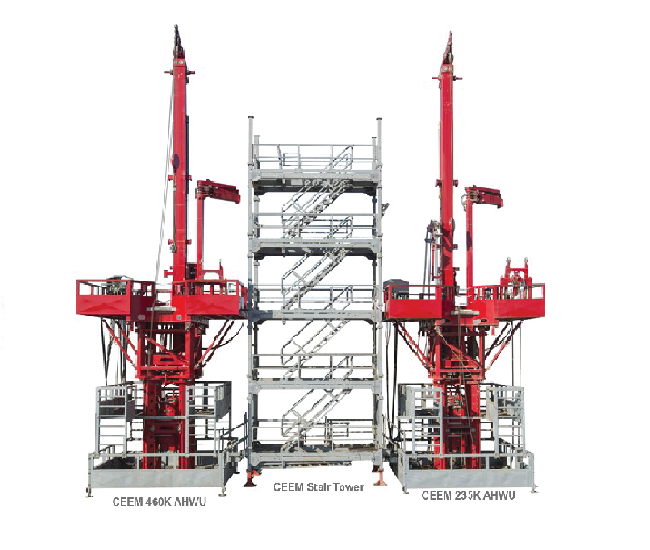

Our purpose built Advanced Hydraulic Workover packages (AHWU) are designed and manufactured in house to be rigged up as stand-alone units and used for the work over of existing wells. The rig is designed to complete all work-over functions completed by a conventional rig with the additional capability of working with pressure in snubbing and under balanced situations.

Ocean Oilfield Drilling"s AHWU and associated technologies ensure that your well continues producing at optimum rates, typically at daily operating costs much lower than those for standard drilling or workover rigs.

The global hydraulic workover unit (HWU) market size was USD 8.11 billion in 2020. The market is anticipated to grow from USD 8.59 billion in 2021 to USD 13.21 billion in 2028 at a CAGR of 6.4% in the 2021-2028 period. The global impact of COVID-19 has been unrivaled and staggering, with it witnessing a negative demand across all regions amid the pandemic. Based on our analysis, the global hydraulic workover unit (HWU) market exhibited a decline of -14.5% in 2020 compared to the average year-on-year growth during 2017-2019. The growth during the forecast period is attributable to this market"s demand and growth, returning to pre-pandemic levels once the epidemic is over.

The COVID-19 pandemic initiated by the spread of the novel coronavirus has had a damaging impact on the global industrial landscape. This industry faced significant losses and have had to reduce operations due to the imposition of rigorous lockdowns to contain the spread of the COVID-19 virus. Consequently, the outbreak of the virus has transformed the demand for HWUs.

As the hydraulic workover unit industry is majorly dependent on oil and gas activities, the decline in oil prices in a long time has significantly impacted the investment in the instrument. The imposition of lockdowns in various countries and the shutting down businesses except for essential services with minimal workforce affected the energy demand. This factor has directly impacted work in the well interventions sector.

The world is likely to derive massive oil and gas from offshore production. The more arduous production conditions in offshore locations increase the investment in more complex and newer technologies like hydraulic workover units. The onerous requirement for offshore with ease of operations is the primary market driver during the projected period.

There is a substantial increase in demand for developing a safe, versatile, and cost-effective tool for workover and well intervention operations due to the increasing number of mature oil fields. This factor bolsters the demand for HWUs globally. This equipment can be efficiently used with low setup times and are more cost-effective. Earlier workover rigs were used for similar operations, which took a lot of time and effort to be set up and used. Further, the wells had to be killed before operations, However, with newer technologies, HWUs with snubbing capabilities have made snubbing capabilities possible with newer technologies.

In 2021, MEIL, India started manufacturing a new type of HWUs with indigenous know-how, especially for the local market. The increasing demand for more effortless functioning, avoiding well-killing, secure and cost-effective well intervention units is an important trend for the hydraulic workover unit market.

A mature oil and gas field is past peak production. These oilfields account for a majority of the world"s crude oil production. With enhanced technological approaches like enhanced oil recovery (EOR), the recovery of mature oil fields has seen a tremendous increase. Increasing recovery from mature fields has necessitated prolonging the well and improving production using well interventions and workover.

With the deterioration in oil reserves, companies have increased their focus on inventing equipment required to access remaining reserves on mature wells. The prime focus is to improve recovery and prolong life. But the amplified water cut with constrained topside facilities, growing flow assurance problems, rising operating costs, and integrity issues because of the maturing facilities have made brownfield operationally and economically impractical. The increasing requirement for workover services is anticipated to bolster the market growth.

The growing population explosion and urbanization has resulted in a spike in energy requirement from the various end-user sector. As renewable energy is still in an early adoption stage of its product life cycle, the majority of power generation is handled by hydrocarbons. Due to inadequate development of other energy sources, the growing global oil and gas demand enhances well drilling and maintenance. The increase in crude oil and shale gas production capacities and an increasing number of brownfields is expected to enhance the well workover and intervention demand, fueling the market growth.

The primary factor restraining the hydraulic workover unit market growth is the consumer shift towards clean fuels. The increasing requirement of the renewable energy sector will undoubtedly decrease the investment being made in the oil and gas energy sector, which will harm the well intervention sector. The increasing proportion of power generation using renewable energy can hinder the principal investments being made for oil and gas. Also, the necessity to reduce carbon emissions has powered the acceptance of renewable energy, with government incentives being granted worldwide. Further, the developing competence of renewables for power generation with durable benefits can result in increased adoption over conventional fuels.

The services carried out by hydraulic workover units are completions, plug & abandonment, ESP completion, sand screen installations, well deepening, fishing/clean-outs, casing repairs, etc. Workover segment includes operations over dead-wells, while snubbing involves installing or removing pipes in or out of live wells. The increasing demand for dead wells" services due to the high number of brownfields is critical for the workover segment. The workover segment involves a broader range of services, making the segment significant.

Due to the high oil production from the onshore segment and the larger number of onshore oil rigs, the segment dominates the market. Moreover, most of the onshore oil rigs are mature and drive significant demand for the market.

The North American region holds a significant share in the market due to the high adoption of workover and snubbing services, coupled with demand for ease and efficiency of operations and technological advancement. Also, the rising proportion of mature oilfields in the region drives the market. Additionally, the government norms to reduce emissions led to companies finding it unviable to increase exploration and an increased necessity to prolong existing oil wells and drive the region"s market.

The competitive landscape for the hydraulic workover unit study shows that very few current companies have invested widely in research and development. The market has seen substantial recent technological advancements to keep pace with the best manufacturers. Considering all the scenarios, Balance Point Control and Halliburton are the major companies that have invested in developing HWUs. They are anticipated to continue being the key players in the future.

April 2021- Megha Engineering and Infrastructures Limited (MEIL) started manufacturing advanced hydraulic technology rigs with indigenous knowledge for the oil and gas sector. The development of HWUs commenced in the Kalol oil field near Ahmedabad, Gujarat. This manufacturing project was taken up to support the Government of India"s "Make in India" initiative.

July 2021-In its quarterly results, Norwegian Energy Company ASA announced that the Noble Sam Turner drilling program began a well workover and maintenance campaign in spring 2021 and completed three well workovers, which contributed to almost 2000 bpd bringing positive results on operating performance during the second quarter. The use of HWUs significantly contributed to the success of the campaign.

The global hydraulic workover unit market research report highlights the leading regions worldwide to understand the user better. Also, it provides insights into the latest market trends and analyzes technologies deployed rapidly with market statistics. The report highlights some of the growth-stimulating factors and restraints, helping the reader gain in-depth knowledge about the industry.

Super capacitor energy storing dual—power workover rig mainly consists of Diesel engine power unit which is made up of Diesel engine and Hydraulic transmission box, Electric power unit which is made up of Frequency conversion motor and Mechanical transmission box, Transfer case, Angle gear box, Drawworks, Mast assembly, Super capacitor energy storing and control system, Hydraulic and Pneumatic control system, Voltage transformer, Power connection box, MCC control cabinet, Frequency conversion cabinet, Electric air compressor, Electric hydraulic pump station etc.

The power of Diesel engine is used for the heavy load workover job of workover rig, such as running and jam release etc. The power of Frequency conversion motor is used for the normal trip—up and down operation

8613371530291

8613371530291