parts of a workover rig quotation

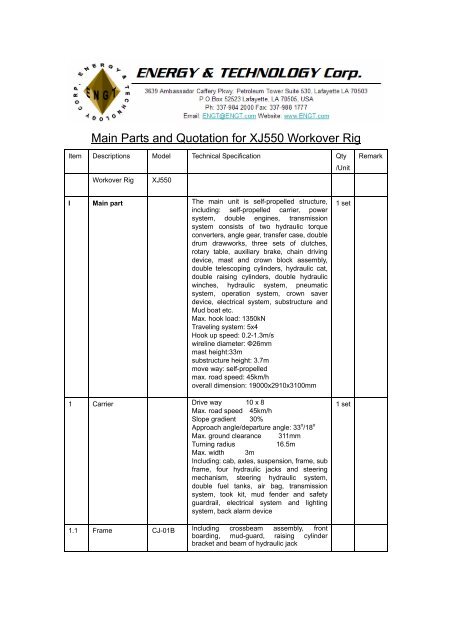

Main Parts and Quotation for XJ550 Workover RigItem Descriptions Model Technical Specification Qty/UnitWorkover Rig XJ550RemarkI Main part The main unit is self-propelled structure,including: self-propelled carrier, powersystem, double engines, transmissionsystem consists of two hydraulic torqueconverters, angle gear, transfer case, doubledrum drawworks, three sets of clutches,rotary table, auxiliary brake, chain drivingdevice, mast and crown block assembly,double telescoping cylinders, hydraulic cat,double raising cylinders, double hydraulicwinches, hydraulic system, pneumaticsystem, operation system, crown saverdevice, electrical system, substructure andMud boat etc.Max. hook load: 1350kNTraveling system: 5x4Hook up speed: 0.2-1.3m/swireline diameter: Φ26mmmast height:33msubstructure height: 3.7mmove way: self-propelledmax. road speed: 45km/hoverall dimension: 19000x2910x3100mm1 Carrier Drive way 10 x 8Max. road speed 45km/hSlope gradient 30%Approach angle/departure angle: 33 o /18 oMax. ground clearance 311mmTurning radius 16.5mMax. width 3mIncluding: cab, axles, suspension, frame, subframe, four hydraulic jacks and steeringmechanism, steering hydraulic system,double fuel tanks, air bag, transmissionsystem, took kit, mud fender and safetyguardrail, electrical system and lightingsystem, back alarm device1 set1 set1.1 Frame CJ-01B Including crossbeam assembly, frontboarding, mud-guard, raising cylinderbracket and beam of hydraulic jack

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

DrillingParts.com is in no way affiliated with the companies referenced in this website. References and/or mention of company names or the accompanying computer code are for ID purposes only and are not Trade Marks or Trade Names used by or affiliated with DrillingParts.com. Although under affiliate program agreements, DrillingParts.com may earn on qualifying purchases completed through third party associates such as Amazon, eBay and our marketplace vendors.

Workover rigs without guyline are designed for small-scale and fast workover operations. Since it is not necessary to install external windload guylines, operating efficiency is greatly enhanced. They can work at 60 kn of wind in adjustment mode, and 35 kn of wind in operating mode, and are suitable for shallow wells in various oilfields.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Workovers rank among the most complex, difficult and expensive types of wellwork. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

Before any workover, the well must first be killed. Since workovers are long planned in advance, there would be much time to plan the well kill and so the reverse circulation would be common. The intense nature of this operation often requires no less than the capabilities of a drilling rig.

The workover begins by killing the well then removing the wellhead and possibly the flow line, then installing a B.O.P commonly known as a blowout preventer, then lifting the tubing hanger from the casing head, thus beginning to pull the completion out of the well. The string will almost always be fixed in place by at least one production packer. If the packer is retrievable it can be released easily enough and pulled out with the completion string. If it is permanent, then it is common to cut the tubing just above it and pull out the upper portion of the string. If necessary, the packer and the tubing left in hole can be milled out, though more commonly, the new completion will make use of it by setting a new packer just above it and running new tubing down to the top of the old.

Although less exposed to wellbore fluids, casing strings too have been known to lose integrity. On occasion, it may be deemed economical to pull and replace it. Because casing strings are cemented in place, this is significantly more difficult and expensive than replacing the completion string. If in some instances the casing cannot be removed from the well, it may be necessary to sidetrack the offending area and recomplete, also an expensive process. For all but the most productive well, replacing casing would never be economical.

Drilling calls for complex, carefully engineered equipment — and inevitably this equipment can wear down over time and require replacement. That’s where a workover rig comes in. Workovers are among the most expensive and complicated tasks in the drilling industry, so here are a few things you should understand about them.

A workover is a complex maintenance task that involves pulling completion hardware out of a well in order to extend the life of the well. A workover rig is a specially designed rig that makes it easier to take out or insert tubing into a well.

To complete a well servicing, the well is first killed. This halts the flow of fluids in the reservoir. The wellhead and flow line will then be removed and the completion hardware will begin to be pulled out of the well using the workover rig. Replacement parts will then be lowered into the hole accordingly.

Because workovers are involved in time-consuming processes, through-tubing workovers might be initiated, which can occur without forcing teams to kill a well and do a full well servicing. This might be considered first before deciding on a full well servicing.

A workover rig is needed when a well is no longer suitable for the drilling job it was originally built for. Maybe the production tubing has incurred damage over time or downhole tubing has stopped functioning correctly. Or perhaps the contents of the reservoir that the tubing is drawing from has changed and requires adjusted tubular components. In any case, the well is unable to perform efficiently and could even compromise the safety of those working on the well. At that point, its components must be replaced and a workover rig must be constructed.

You always want your well to perform to expectations. Katch Kan can help thanks to our zero-spill installation system, which ensures your well servicing operations will proceed safely and efficiently. We offer a wide array of well servicing solutions, which are designed to prevent fluid spills, keep workers safe, lower clean-up costs and reduce operation time.

Due to aggressive automated scraping of FederalRegister.gov and eCFR.gov, programmatic access to these sites is limited to access to our extensive developer APIs.

If you are human user receiving this message, we can add your IP address to a set of IPs that can access FederalRegister.gov & eCFR.gov; complete the CAPTCHA (bot test) below and click "Request Access". This should only be necessary once for each IP address you access the site from.

If you want to request a wider IP range, first request access for your current IP, and then use the "Site Feedback" button found in the lower left-hand side to make the request.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

The 844 TD-HD Workover Rig by Franks has a 3/4″ Tubing Line, Air Clutches and is powered by a Detroit Diesel 6V71 Motor & Allison CLT 4460 transmission. The 844 TD-HD Workover Rig is in excellent working condition, has a current OK Tag and clean Title.

Franks 844 TD-HT draw works with 3/4″ Tubing Line. New Air Clutches have been added to the draw works and it is powered by a Detroit Diesel 6V71 Motor & Allison CLT 4460 transmission.

Performance proven main drum draw works assemblies are modular construction for versatile rig assembly. Designed to allow maximum parts interchangeability and easy add-on features to customize this for your specific operation.

The mast is constructed with an 8 X 10 Double Pole design with 70 ft height. The mast design and construction aids the operator in quick and easy set up on site and keeps a lower profile while moving down the road for transport.

Includes tubing tongs, elevators, McKissick block and basic tools. Unit is in excellent working condition, has a current Oklahoma Registration Tag and clean Title.

This unit is mounted on a Cabot Explorer carrier designed specifically for oilfield equipment. Rugged walking beam suspension, double reduction rear tandem with Bendix powered air brakes.

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

BEAUMONT, TX—In Australia, a unique project is underway in which an energy company is working with the native Aboriginal community of Noonkanbah, in the Kimberley region of Western Australia. Prior to and throughout the hydraulic fracturing program on Noonkanbah Station, there was significant engagement to ensure everyone was satisfied with the project.

Not only were meetings and tours held for local residents to better understand the process, many locals were hired to work on site. Drug and alcohol abuse has become rampant and caused numerous deaths among the Aboriginal population. With the energy company’s zero tolerance policy regarding drugs and alcohol, not only have the young people learned a marketable skill, they have good reason to stay sober and healthy. Good jobs and good earning potential gives the local community elders reason to be optimistic that the lives of the younger generation can be turned in a positive direction. Communication and cultural understanding were key to the success of this partnership.

According to Mandy Raps of Dragon Products, “we are proud to see Dragon hydraulic frac equipment being put to good use for a worthy cause with positive social outcomes.” Dragon builds complete frac spread equipment including mobile frac pumps, blenders and cementing equipment. The collaboration between industry and community brings social and economic benefits to everyone involved.

Dragon Products, Ltd is a leading manufacturer of mission critical products serving the energy and industrial industries. Based in the United States, and family owned and operated for more than 50 years, the Dragon name is synonymous with “severe duty engineered” equipment for a broad range of applications including well servicing, bulk storage, liquid and solids hauling, and a variety of pumping and mud solutions. Their equipment portfolio includes tanks and trailers; roll off equipment; pumps and stimulation equipment; mobile workover rigs; and surface production equipment. To learn more visit http://www.dragonproductsltd.com.

Workover rig drillout operations can be some of the most costly and important activities in the life cycle of a well. Through the expanded collection of operation-specific data, operators and service companies alike can increase operational efficiency, improving both cost and predictability of a given operation. Within the workover rig completion space, this has allowed for more in-depth analysis to be conducted in a previously data-scarce part of the industry. Acquisition and analysis of this data has opened the door for further operational efficiency improvements as well as more consistent and predictable execution.

This paper will focus on three examples that examine the value extracted from analytics conducted on data that has been captured in real time. These include: 1) Establishing baselines for key performance indicators (KPIs), 2) Developing best practices for frac plug milling operations, and 3) Optimal plug selection.

Analysis and implementation of these data-driven solutions have already resulted in significant improvements in the workover rig completion space. Using these techniques to set performance targets for rig personnel, several operators have seen improvements in well-to-well transitions, mobilization and connection times, as well as overall plug milling performance. Data behind several milling practices shows that top performances require the combination of higher average weight on bit, a bit as close to drift ID as possible, and the use of tools that allow pump rate to be maximized. Milling performance recorded on a sample size of over 25,000 plugs provides confirmation of optimal plug selection options in each basin for drillout purposes.

The collection and analysis of data across the industry continues to present opportunities to quantify and implement strategies that have resulted in improvements across the board. Incorporating analytics to stick pipe operations has resulted in comprehensive benchmarking of operations and improved execution of workover rig drillouts.

The College of Earth and Mineral Sciences is committed to making its websites accessible to all users, and welcomes comments or suggestions on access improvements. Please send comments or suggestions on accessibility to the site editor. The site editor may also be contacted with questions or comments about this Open Educational Resource.

The College of Earth and Mineral Sciences is committed to making its websites accessible to all users, and welcomes comments or suggestions on access improvements. Please send comments or suggestions on accessibility to the site editor. The site editor may also be contacted with questions or comments about this course.

8613371530291

8613371530291