power swivel workover rig pricelist

After two years’ use of the swivel, remember to conduct crack detecting on bail, case, bail pin and central pipe. Use swivel only when confirming it meets requirements.

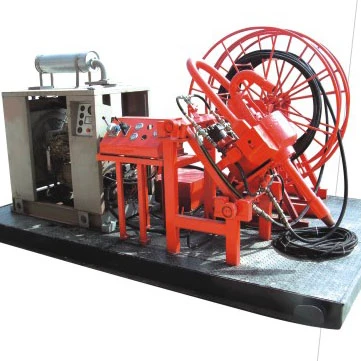

DSL-110 Power Swivel is hydraulic motor-driven swivel. It compact swivel-head design weighs 910kg. It is rated to support static load of 1100kN and dynamic load of 600kN at 100rpm.

DSL-110 Power Swivel is equipped with a hydraulic power unit with remote electric control system. All elements are set on a base seat, firm and convenient.

1. Fishing and workover operations:The power unit is ideal device to supply rotary power. It is ideally suited for use for internal or external cutting of casing or drill pipe; drilling out plugs, packers, or cement; milling operations; or scraping casing. Controlled torque is essential to eliminating the potential danger of twist-offs or damage or cutting tools.

2. Drilling applications:The compact, lightweight swivel is especially suited for drilling applications including oil and gas wells, water wells, pilings for piers and foundations. Suspending the swivel from a boom or crane eliminates a great deal of set-up time or shifts to additional locations.

3. Coring operations:When use power swivel for coring operation, any length or core may be taken. Accurate and smooth torque ensures against damage to core tools or strings.

Refer to Fig.2 and Fig.3, THT Power Swivel is powered by tow fixed displacement, piston-type, hydraulic motors. The motors are mounted on the underside of the swivel and is protected by a steel guard (11)

Two pressure hoses connect to the motor with swivel joints with quick disconnect couplers (18). The motor drain hose (14) is also fitted a self-sealing quick disconnect coupling.

The one-piece gooseneck (2) is constructed of cast steel. A 2-1/2” NPT access plug (Fig.1, 16) is located in the top. The plug may be removed to permit passage of tools with diameters smaller than 2-1/4”. The gooseneck and swivel packing are hydrostatically tested and rated at 35Mpa maximum circulating pressure.

A magnetic drain plug (65) is located on the lower cover plate (62) of the swivel assembly. A breather (47) is located on the upper cover plate. The gear housing is equipped a metal oil-leveler (46), so the operator may check oil level by watching the leveler.

Using a catline or derrick line, lift the swivel unit from the rack, and install torque rein assembly (67,Fig.2) on Swivel pinshaft. Then suspend the swivel over the wellhead. Attach one end of the safety rope of the torque rein near to pulley and the other end near to rig platform. Refer to Fig. 4. Turn the turnbuckle (7) and pull tight the rope. Secure rope in this place. Rope location should ensure the torque rein assembly geting at it at any level.

Note: If central pipe can’t be upright when lifting the power swivel, it is practicable to use a 1T hand chain hoist. Tie one end of the chain hoist in the bail and connect the other end with the rings on swivel gearbox cover. Adjust the hand chain hoist to ensure vertical location of the central pipe.

The following guidelines are intended to ensure maximum life of DSL-110 Power Swivel. These are recommendations only. Extreme peak load usage, temperature, and other variables will affect suggested service intervals.

During initial break-in, or after long period of idleness, run the Power Swivel with a reduced load at slower speed unit it reaches normal operating temperature ranging between 120o-200oF. a somewhat higher operating temperature is permissible in very hot climates, provided that it increase gradually.

6. It is practical to use thread gauge to check wearness or deformation of external and internal thread. Remaining thread top width should not be less than 3/4 of original, height not less than 4/5 of original, and worn thread number not over one and half round. If any, repair or replace right away.

If the Power swivel must be stored, it should be completely filled with gear lubricating oil to prevent oxidation. The stem should be installed with thread protector to prevent damage to the threads. Grease or dope the threads before installing the thread protector.

Enjoy the best returns on your investment with these supreme drilling power swivel ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a drilling power swivel that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. global wholesalers provide you with customization options and great after-sales services.

Are you looking for a wholesale drilling power swivel? Look no further than Alibaba.com. If you own a workshop, a drilling machine is a must-have. It is used in performing various tasks such as tapping, counterboring, spotfacing and countersinking. One of the main advantages of using a dr power powerivel is that it makes work easier and speeds up the process. Another advantage is that these machines don"t require you to put in much effort. Therefore, you can make numerous holes on various surfaces without getting exhausted. Moreover, drilling machines help you in making neat holes. Some switches have touch-sensitive glass. You can operate them using a smartphone or voice. Others have motion sensors that turn them on and off automatically.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Three (3) x 1200 HP Super Single Rigs, high level of automation, all commissioned and packed, ready to drill and excellent for Appraisal, Development, Workover, Re-entry projects.

Each rig features a 500,000 lbs Hoisting capacity + Three (3) Triplex 1600 HP Mud Pumps per Rig + 250 Ton Venture Tech Power Swivel + Pipe handler/Roughneck combo able to handle Range 3 Single DP.

These Rigs have been successfully drilling horizontal wells in West Texas and North America, and have a proven record of High performance & fast rig moves.

• Mud Pumps: 3 each National 12P160 Input power : 1600 hp with 2 Traction DC Motors Make by EMD type D79,Blower motors 10HP c) Supercharger pump 1 d) Liner cooling pump 1 Halco 1 x 1.5C Model# N 12 P 160 With 5hp motor e) Lube oil gear pump 1 (belt driven) f) Pulsation Dampner 1 Hydril 16 Gal, 5000 psi g) Pressure relief Valve 1 Retsco Reset relief valve 1500 – 5000 psi.

Power Swivels - BOWEN 120 ton 2008 US EPA Label, Cat C7 Acert 4 Cylinder 225 hp 7.2 L Diesel Engine, S3.5, Skid-Mounted, Self Contained, Power Swivel - Auction ID - 2022115 More Info

Power Swivels - BOWEN 120 ton Detroit 4 Cylinder Engine, S3.5 Power Swivel, Skid-Mounted, Self Contained, Power Swivel - Auction ID - 2022115 More Info

Power Swivels - BOWEN 150 ton Cat 3306 6 Cylinder 240 hp Engine, Skid Mounted, S150 2-Speed Power Swivel, Electric/Hydraulic, Power Swivel - Auction ID - 2022115 More Info

Power Swivels - Used Skid mounted Bowen 2.5 power swivel, powered by Detroit 453, new wash pipe and packing, remote control panel, manual hose reels, fuel and hydraulic tanks. More Info

Power Swivels - Skid mounted Bowen 2.5 power swivel, powered by Detroit 453, remote control station, diesel and hydraulic tanks. Unit runs well and we are replacing the wash pipe, packin... More Info

Power Swivels - 2.5 Bowen Power Swivel powered by Perkins Diesel engine mounted on tandem axle bumper trailer. New Washpipe, packing, and motor seal recently installed.

Power Swivels - 1999 BOWEN 85 ton Goose Neck T/A Trailer M ... Cat 3304 4 Cylinder 112 hp Diesel Engine, S2.5 Mobile, Hydraulic V Door, Self Contained, Power Swivel - Auction ID - 20221... More Info

Power Swivels - BOWEN 85 ton Goose Neck T/A Trailer M ... Cat 3304 4 Cylinder Engine, S2.5 Mobile, Hydraulic V Door, Self Contained, Power Swivel - Auction ID - 2022115 More Info

Power Swivels - NEW BOWEN 2.5 (S85) POWER SWIVEL - Powered by a new Caterpillar C4.4 diesel engine. Unit is equipped with all hydraulic controls, pumps, motors and proper filtration syst... More Info

New Skid Mounted Power Swivel with a Bowen S-150 Swivel Head, powered by a C-9 CAT engine with Sundstrand Hydraulic system, power reels with 100... More Info

Drilling Swivel is one of the main components that make a Rotary System superior to the ones that don’t have one. The swivel is the most important part of the entire rotary drilling system. The swivel is supposed to transfer the water at very high speed through the stem of the drill all the way leading to the bit. This helps both in cooling and lubricating the bit while the drilling process continues through the flushing and forcing of the cuttings straight away out of the borehole.

Drilling a well that is more than twenty to thirty feet deep will be rather hard if not completely impossible, without a swivel that has a high volume and a huge capacity. Swivel of the smaller kind are generally fitted to the common drilling rigs available in the market. Swivel of this kind are intended for drilling short 6″ to 8″ deep holes in to the concrete surfaces aimed at fitting in anchor pods and bolts for grounding purposes. This won’t really render any valuable help if you are trying to dig deep water well.

But then the question is why are such petite and low-capacity swivels used on the water well drill-rigs? The answer is quite simple. Swivel of these types are not just inexpensive but easily accessible and available in plenty as well. Developing a swivel of a superior quality along with a high volume generally takes a lot of time. They are also expensive and need thorough labor while being used in drilling.

Drilling ventures of larger kind would need a high volume twirling pivot that is characterized with a weight bearing. Such swivels are generally four times larger than the commonly available ones and also have ten times more the capacity of the common imitation counterparts. Drilling with such a machine becomes a lot easier and takes lesser time as well. This is because the water ports are large and hence gush out more volume of water that helps keep the excess mud out of the borehole. Swivel of this type is outfitted with huge heavy duty that can be replaced without any real problems.

These have seals of the packing-type which are a further resistance to the abrasion caused by the sand and the mud cuttings that are persistently forced through the system while drilling. Swivel shaft is further supported by the roller bearings, making the rotation process smooth and straight. Yet another key feature of quality swivels is the built in weight-bearing support that plays a truly advantageous role. Swivel in this way is propped up to the frame rather than lynching straight from the gear box.

Foremost designs and manufactures hydraulic and A/C top drives for a variety of applications. Foremost top drives are compact, rugged, powerful and are well suited for a variety of rig designs. Adaptable to most single and telescoping mast designs, Foremost top drives are available as a basic power swivel or complete top drivesystem.

Adaptable to most single and telescoping masts, Foremost top drives are available as a basic power swivel, or as a complete top drive system with a range of options to improve productivity and enhance operator safety.

Search our current inventory for new and used power swivels for sale. No minimum bids or reserve prices on all equipment items, including power swivels, at our Oil/Gas/Power/Utility equipment auctions. More new and used power swivels added daily! Bid in person or online in the comfort of your home.

SINOTAI Drilling mud solids control shale shaker Product Description Mud Shale Shaker for Oil Drilling.Drilling Shale shaker is the primary solids separation tool on a rig. After returning to the surface of the well the used drilling fluid flows...

Product Description DSL135 power swivel (hereinafter referred to as “this Product”), of which central pipe rotates under driving force of hydraulic variable motor through gear reduction system, is featured by compact structure and designed weight of...

SINOTAI Power Swivel Product Description Highlights 1.Power Swivel is the device installing on the derrick of servicing rig, to provide rotating power. 2.Except the use for such workover jobs as casing milling, milling, drilling cement plug and...

Product Description Main features of the swivels: Swivel has two categories, common swivel and double duty swivel. Double duty swivel is common swivel combined with spinner. With standard bails and double pin alloy steel sub. The gooseneck is...

Product Description swivel for drilling rigs Highlights 1.Swivel has two categories, common swivel and double duty swivel. Double duty swivel is common swivel combined with spinner. 2.With standard bails and double pin alloy steel sub. 3.The...

Product Description ZP series rotary table is one of the main supporting equipment of oil drilling rig and oil well workover machine. Design and manufacture according to API Spec 7K drilling equipment specification

Swivel Joints offered function I form of a threaded connection where at least one of pipes is curved at 45 or 90 degrees. With the provided connection being water-read more...

8613371530291

8613371530291