snubbing unit vs workover rig manufacturer

Snubbing units have evolved into one of the most capable and efficient well servicing tools in the oil & gas industry. In the 1920"s, the need for a rig to work with pressures at surface drove the invention of the snubbing unit. The first snubbing unit was primarily designed to work in well control situations to "snub" drill pipe and or casing into, or out of, a well bore when conventional well killing methods could not be used. The first snubbing unit relied on the draw works of the companion rig to supply its" power. A series of sheaves, cables and counter weights were rigged up so that as the rig"s traveling blocks hoisted up, the snubbing unit would snub in the hole. Conversely, when the traveling blocks on the rig were lowered, the snubbing unit would snub out of the hole. As you can imagine, this required close communication with several different contractors in order to perform the work safely and efficiently.

One of the main components of a snubbing unit is the slip. Stationary and travelling slips are operated in sequence to grip the pipe as it is snubbed into the well. Typically, a minimum of four slip bowls are used in snubbing operations. Two slip bowls are designated for "pipe light" operations. Pipe light is when the well bore forces are greater than the tubular weight in the well bore. The other two slip bowls are designated for "pipe heavy" operations. Pipe heavy occurs when either enough pipe has been snubbed into the well bore and fluid weight inside of the pipe is greater than the snub forces acting against the pipe in the well bore.

While snubbing into the hole, there is a transition point the tubular goes through from being pipe light, to pipe heavy. This transition is an equilibrium typically referred to as the "balance point". The balance point occurs when there is enough pipe weight in the wellbore to equal the snub forces generated against the pipe. In certain instances, thousands of feet of pipe can be moved with minimal effort since the pipe weight is at an equal state with the snub forces. Snubbing contractors calculate this snub force and add in a friction factor from the BOP and wall contact on either a casing or tubing string. If done correctly, the snubbing contractor can predict when this balance point will take place and can properly prepare for it.

Modern snubbing units are powered by sophisticated hydraulic systems. These hydraulic units typically supply all power required by the components of a snubbing operation. With a better understanding of hydraulics and modern advances, companies have been able to harness this hydraulic energy to develop precision controlled snubbing units. These units move tubulars into and out of a well bore by use of a "multi cylinder jack"; a snubbing jack comes in many sizes depending on the task at hand. They are usually denoted in size by the snubbing unit description (i.e. 460K, 340K, 200K, etc). The 460K snubbing unit has the ability to lift 460,000 LBS and a snubbing capacity of 230,000 LBS. Most snubbing units can typically snub half of their lift rating. Assume you had a well with 10,000 PSI at surface and wished to snub in a string of 2 3/8" tubing. The snubbing contractor can calculate the snub force, add in their respective friction calculations and project the snub force to overcome will be approximately 51,000 LBS. This would put a 120K snubbing unit to close to its maximum capacity of 60,000 LBS snub loading. The safest bet would be a 150K or 235K snubbing unit.

Well control is taken very seriously by snubbing contractors. The BOP is the only barrier between the well bore and personnel. Depending upon well conditions, pressures and work performed, the BOP stack configuration varies greatly; there can be a minimum of three BOP"s and in some cases, up to ten. All of this is determined in the pre-job phase of the operation.

Pipe handling is performed by the snubbing units "gin pole" and "pipe winches". The gin pole is typically telescoped out in excess of 40ft above the snubbing unit. With the use of dual tubing winches, multiple joints of pipe can be handled simultaneously, speeding up the operation.

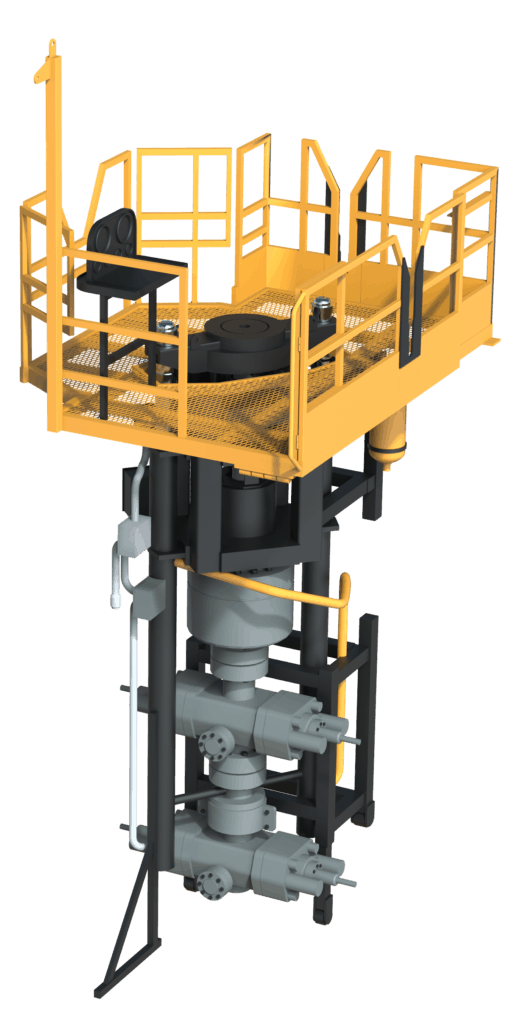

The snubbing "basket" is the platform where the snubbing personnel work. The basket contains all of the necessary hydraulic controls to operate all the features of the snubbing unit, as well as a large bank of BOP"s and hydraulic valve controls.

Today"s snubbing units can be employed to provide a wide range of services. In essence, a snubbing unit is a hydraulic rig that can do everything a rig can do, plus it can perform under pressure in an under balanced live well state. This is especially critical to the operators in the Haynesville Shale, which is known for HPHT wells. With the use of the snubbing units" hydraulic rotary, the unit can be employed for fishing, milling, drilling, side tracking or any task needed to remove bridge plugs, cement or deepen wells.

The industry has become more aware of damages caused by heavy kill weight fluids and mud. This has helped make snubbing units more popular in a completion and workover role, versus its" traditional use as a well control response tool. With the advances in drilling technologies in the unconventional shale market, the benefits of snubbing units have become very apparent. These types of completions often have laterals extending out thousands of feet. With costly stimulations used to help extract the gas more efficiently, operators often times do not wish to turn around and load the well with heavy fluids to complete the well dead.

Coiled tubing has its limitations in reach, due to wall to wall mechanical friction in horizontal wells. Often times the coiled tubing units cannot reach TD or supply the needed weight on bit to mill up composite plugs typically used in completions.

Another clear advantage to using a snubbing unit is its" small footprint, which is critical on the tight locations in the unconventional shale"s. Moreover, the small size and ease of mobilizing is especially useful and cost effective with offshore wells.

In conclusion, with the snubbing unit"s size, ability to handle pressure, rotary capabilities, rigidity of jointed tubing and minimal wall contact, snubbing units have become the chosen resource for these types of completions.

Snubbing is a type of heavy well intervention performed on oil and gas wells. It involves running the BHA on a pipe string using a hydraulic workover rig. Unlike wireline or coiled tubing, the pipe is not spooled off a drum but made up and broken up while running in and pulling out, much like conventional drill pipe. Due to the large rigup, it is only used for the most demanding of operations when lighter intervention techniques do not offer the strength and durability.drilling and completions operations, snubbing can be performed with the well still under pressure (not killed). When done so, it is called hydraulic workover. It can also be performed without having to remove the Christmas tree from the wellhead.

A snubbing rigup is a very tall structure. It consists of a hydraulically powered snubbing unit, which provides the force on a pipe, above a string of multi-layered pressure control components.

At the top of the snubbing unit is the basket, which serves as the control post for the rigup. Below the basket are the hydraulic jacks, which power the pipe into and out of the hole. It consists of two mechanisms for applying force to the pipe in either direction. Each mechanism consists of travelling and stationary slips. The travelling slips are used to move the pipe, while the stationary slips are used to hold the pipe while the travelling slips are repositioned between strokes.

Unlike coiled tubing or wireline, where the wire or tubing is always the same diameter allowing for a single unmoving primary barrier (stuffing box or stripper), snubbing uses a pipe, which will have an enlarged collar at the connection between the joints. Therefore, the pressure control system must be able to accommodate this variable diameter. The stripping rams accomplish this. The first stage of lowering a collar through the stripping system is to close the lower rams so as to seal off the mechanism above from wellbore pressure. The space between the rams can then be bled off allowing the upper rams to be opened. The collar can then pass through the opened upper rams. Once the collar is in between the rams, the upper rams are closed and pressure is equalised either side of the lower rams. The lower rams are then safely opened and the collar is lowered through the rams.

Because snubbing is normally done under pressure, initially, the weight of pipe in wellbore is less than the force due to the wellbore pressure. This is described as light-pipe: downward force is required on the pipe to force it in against resistance. Once a sufficient amount of pipe has been run into the hole, the weight becomes sufficient to overpower the wellbore pressure and the pipe naturally wants to fall in the hole; this is heavy-pipe. At this point, the snubbing mechanism is changed over to the one which provides upward force to hold the pipe and lower it controllably into the well.

The more complex method of pressure control, as compared to coiled tubing and wireline, naturally invites more opportunity for things to go wrong. One such peril was seen in June 2007 on the Shearwater platform. Snubbing was being used to clean out large pebble, which had entered the well through a collapsed liner. While pulling out of hole, one stripping ram was not opened sufficiently and a collar on the pipe string caught on the ram. The excessive force applied to the pipe caused it to break apart, dropping the string below the failure into the well. In the time it took to prepare to fish out the pipe, the pebbles in the process of being circulated out, settled on the pipe, preventing successful fishing.

Not all Snubbing units are large and time consuming to rig up. In the Canadian oilfield many companies use small "Stand Alone" snubbing units which can be broken down and rigged up in less than 3hrs. These Units consist of 4 segments which can be placed onto 4 separate trucks. These 4 segments consist of the following:

Units varies in strength, there are 95K, 120K, 150K, 170K, 225K, 340K, 460K, 600K The number indicates their working strength in pulling force, and 150K means the unit is capable of pulling maximal 150000 pounds. This is based on the hydraulic force acting on the size of the unit"s piston size. Also are there more complex special built unit to find as the CSU 160 a special build rig assist unit, and stand alone units like

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The rig assist unit was installed on top of the rig’s Bops. A landing joint was lowered into the stack and screwed into the tubing hanger. The snubbing Bops were tested using the rig pump to 35mpa

The stack was equalized using the snubbing unit equalize line to well bore pressure. The hanger hold-down screws were backed out and the tubing hanger staged out using the snubbing units annular and stripping rams

Once the lift force from the well overcame the weight of the string, the snubbing unit took over pipe movement. The tubing connections were still staged out and the pipe continued to be racked in the derrick

The joint was gently snubbed up until the fill/flow sub was above the snubbing unit annular element. The operator continued to raise the tubing until the lower connection of the 3m pup joint engaged the bottom side of the stripping rams. The rams were locked and the chamber between the stripping rams and annular was re-equalized

Pumping services tend to get more expensive offshore, because of the degree to which the equipment must be assembled on location. Wire based services still require assembly, but because the parts are smaller can usually be mobilized in larger ‘chunks’ thus requiring less assembly on location. On land, fluid pumping equipment is much more readily portable on trucks or trailers. Workover rigs on land are incredibly cheap in most places as measured on a per diem basis. Part of their advantage is that they arrive to location with most of their key components already assembled in/on one truck. This advantage disappears offshore where the rig must be assembled on site first.

Paying for a drilling rig or intervention vessel is the price of gaining physical access to the well. Everything else must be added to it to get physical access to the general area and then gain access to the well. There is no need for various forms of standalone pumping services because the vessel or rig will already have a cementing unit and/or the mud pumps available for that sort of work.

Performing the same operation over and over again has significant cost savings attached to it. Once the correct housing and supply arrangements are in place, and all the necessary people and equipment have been assembled, continuing to use it altogether ‘as is’ can save an enormous amount of money compared to dispersing it all and starting over again later. For land operations, this is most pronounced in areas where reservoir, surface, and operational practices allow for grouping wells together in relatively small areas, and for clustering well pads. Depending on what work is being done to the wells and how close together they are it may be possible to ‘hop’ from one well to the other without ever moving the equipment on a road or doing a complete rig-down.

Deepwater operations can benefit from this too, but not as much as ‘traditional’ fixed or surface access facilities, because the overall day rate of the rig or intervention vessel is often much higher, and the process of switching between wells is often much lengthier.

On land, you hire the unit and crew, and a small diem fee is added to the cost of employing them so they can stay in a hotel and get food when they are not working. The crews will transport themselves to and from the well and move the equipment to and from the well also.

The costs of conducting business in each of these 3 areas tend to scale very roughly in factors of 10. 100 wells making 50 bbls of oil each on land is a cash cow. Offshore that is a disaster, because the cost of servicing those wells is prohibitive. A more reasonable scenario is 10 wells making 500 bbls of oil each. In deepwater, a well making 500 bbls of oil a day is an abandonment candidate, if indeed it got that far along before abandonment. One well making 5,000 bbls a day is more. The direct cost of hiring (for example) a snubbing unit do not scale by factors of 10, but the overall cost of employing a snubbing unit do. As a result, different types of well servicing make sense in one area which may not make sense in another. On land in areas with ordinary access to infrastructure (not the Sahara or Alaska) operations like slickline are often so cheap that they are a routine procedure, with preventative or predictive maintenance schedules to scrape away paraffin or remove small amounts of scale. By contrast, it is completely cost prohibitive to try and attempt to perform similar work in deepwater – you either design and operate the well in such a way that paraffin and scale do not build up in the wellbore at appreciable rates, or you P&A the well. The cost of routine mitigation is simply too high. The relative cheapness of most workover rigs on land is another major factor. Many types of operations which could in theory be carried out in some other way are done with a workover rig simply because it is the most cost-effective technique, even if other methods might be faster, or involve fewer people. The relatively high cost of a rig for offshore facilities means that in most cases every effort short of getting a rig is tried first. Then a catalogue or list of operations to be conducted by a rig at a given facility will be gradually built up over time until they reach a critical level. At that point, a rig will be sent out to conduct all the operations which only it can perform, moving from one well another to save costs by making the work repeatable.

Snubbing is a process that controls the pressure of oil or gas in order to run or pull tubing, drill pipe, or casing. These applications use the standard snubbing unit to complete or re-complete wells in a “live well” condition. Any type of workover application can be performed utilizing quick jacks.

Snubbing units are often used in place of workover units for offshore applications. Snubbing can offer the same services at a greatly reduced cost to the customer. Snubbing can be performed on live and dean wells. Milling operations can be faster and more precise with snubbing units due to infinite control of torque and speed of the rotary mounted on the snubbing jack. Snubbing is versatile alternative that can overcome the limitations of other workover systems - wireline, coiled tubing and conventional workover rigs. It eliminates the use of kill fluids that can damage the producing formation and require costly disposal. Snubbing is also a faster solution. Snubbing units can often have the task completed before a conventional workover operation is even rigged up.

Snubbing is your best choice when conventional draw works are absent. The self-contained equipment requires little space and can finish the job quickly. The hydraulic system"s precise control over force protects against overload and allows responsive tool manipulation.

In this video, Matt Tourigny from Deep Well Services shows us how their company is utilizing virtual reality to help train their staff (and even us) on the simple (yet critical) steps of snubbing operations. Snubbing is when you enter a pressurized well with pipe. Snubbing is commonly required to bring a well into production once it has been hydraulically fractured. This is because the plugs used for zonal isolation during the frac needs to be drilled out.

The big difference between this type of flush-by rig and conventional flush-by unit is drawworks. Mechanical drawworks are adopted on ourflush-by rig.

Mitey Titan (MT) is one of the first manufactures of CM HWO or Snubbing Units. Our first CM Unit was mounted on a 1-Ton truck, designed and manufactured starting in 2005. MT is a leading designer and manufacturer of these units at present, leading the snubbing industry in innovation, safe performance, and user friendly HWO equipment. Mitey Titan HWO equipment is built to high quality standards and has earned a near-perfect reputation for its performance and design worldwide.

The most critical factors in snubbing is knowing how much pipe can be pushed in a hole at a time without buckling and how much collapse and burst pressure the pipe can handle.

To most longtime oil and gas field professionals, the word "snubbing" means trouble. It means a well somewhere is dangerously close to being out of control. "Everyone connected it with that forever," said Cudd Pressure Control vice-president, Ron Jackson. "Twelve to fourteen years ago a snubbing unit was the last thing you wanted to see come on your location."

"[Snubbing units] are used in situations such as when you are off bottom with drill pipe and you take a kick in the hole, particularly in an oil mud where the kick is not going to migrate so you have to get the pipe back to bottom," explained Larry Flak, Engineering Manager of well control specialists and well firefighters, Boots & Coots.

Once the kick is under control, that is being flowed harmlessly to a pipeline or flare in what is often referred to as a diverted blowout, the drill pipe must be sent back to bottom before the crew can regain complete control. It is the classic snubbing unit task because often the upward pressure of the flowing well is greater than the downward force created by the available drill pipe weight.

"If you are pipe light, meaning you don"t have enough weight for the drill pipe to combat the pressure, you may have to get a snubbing unit rigged up on the well to push it back in the hole because it won"t fall."

"With snubbing you have the ability to work on the well without killing it with heavy fluid that can be damaging to the formation," Jackson said. "So we can do workovers and completions without killing the well."

So popular has the practice become that Jackson estimates more than 80% of all snubbing jobs performed today are planned workovers, completions, or other type well interventions performed to protect the formation from fluid damage.

"Well control [snubbing] activities are very unusual," said Flak. "If [snubbing companies] had to depend on diverted blowouts to earn a living today, they would go bankrupt."

Offshore, doing a workover operations with a snubbing unit rather than a traditional rig is referred to as a "hydraulic workover", likely because of the old connotations industry veterans associate with the term snubbing. In the US Gulf of Mexico, it has become a common practice for the same reason underbalanced drilling has become popular in many onshore applications—re-entering depleted or partially depleted reservoirs.

While avoiding damage to older formations is a prime driver of the proliferation of hydraulic workovers, Jackson says the growing popularity of underbalanced drilling just naturally raises demand for underbalanced completions. "Brand new wells are good candidates [for snubbing completions] because they don"t have any damage yet," he said. "A lot of wells are drilled underbalanced with a little positive flow. But just because you drilled underbalanced, if you can"t complete it underbalanced you really haven"t accomplished as much as you might. We can run casing, cement, and perforate underbalanced and never hurt the formation. We can run up to 13-in. casing and handle a hook load of 600,000 pounds."

Snubbing"s reputation as a dangerous way to make a living, say today"s proponents of the process, has also been mitigated by changing technologies and applications when indeed the call does come for a well control situation. Much as operators now routinely drill in a situation once considered highly dangerous, so have they come to view completions and workovers done under pressure as not only safe, but as optimum and even routine under the proper circumstances and when properly planned.

As with so many older technologies, computer software is being brought to bear on the planning and executing of snubbing operations. The most critical factors in snubbing is knowing how much pipe can be "grabbed" and pushed in the hole at a time without buckling and how much collapse and burst pressure that pipe can handle. Cudd is in the midst of refining their proprietary program to better define those numbers and will possibly make them commercially available in the future.

"If you are on a well with 5,000 psi, and you are injecting tubing into it, you have to know the maximum unsupported length [of tubing] you can stuff in at a time and the forces exerted on the tube," said Jackson, explaining the theory behind the computer program. "You put in all the known parameters such as type of unit and power pack size, and it tells you the hydraulic settings and the maximum [length of tubing] you can take."

In addition to the immediate savings on high-cost jackups, when working over a well under pressure, there are costs savings in heavy muds and their handling. (Heavy kill muds with exotic additives designed to protect producing formations are often expensive to recycle and transport in the environmentally sensitive offshore.) Also, rig up and down is faster than with traditional workover rigs and production can be brought back on line more reliably and quicker when muds need not be cleaned from the well bore first—an operation that can take several days.

While some of the traditional snubbing market such as wellbore fluids clean-out or spotting acid or cement in live wells, have in recent years become the province of coiled tubing, demand for the staid old units is likely to remain high. For one thing, CT units have size limits, snubbing units do not. Above about a 3 ½-in diameter, particularly offshore, their weight and space requirements are a liability. And CT is not available in production casing sizes, which are often the section operators are most intent on protecting from fluid invasion.

And finally, one of the most prolific areas of development in the world today, is in the older fields of the US Gulf of Mexico, where independent operators are re-entering partially depleted zones to recover hydrocarbons left behind by majors seeking bigger targets. The depleted nature of these zones means they are highly susceptible to fluid invasion damage during recompletion and workover operations, in many cases the least expensive, most efficient method for handling them: hydraulic workovers.

When your well requires Hydraulic Workover Services, the trained professionals at Cudd Energy Services can engineer, plan, and execute the job safely and efficiently. With extensive experience in land, marine, desert, and other difficult to access locations around the world, Cudd Energy Services is a recognized industry leader and innovator in Hydraulic Workover Services.

Cudd offers a variety of hydraulic workover / snubbing solutions to enhance production and/or restore the mechanical integrity of your well. We can provide conventional stand alone, conventional stand alone with racking and skidding capabilities, hydraulic rig assist, or Quick Jack options to accommodate all well intervention situations.

Cudd Energy Services hydraulic stand alone unit is a preferred choice when pressure, space, accessibility and rig availability are concerns. The stand alone package includes a work basket, hydraulic jack, stationary and traveling slip bowls, power pack, work window with walk arounds, and gin pole. Pump support is available for all applications.

For expedient and efficient operations, Cudd Energy Services revolutionary "Space Saver" snubbing unit brings the advantages of hydraulic snubbing to conventional drilling or workover operations.

The self-contained, 170K Space Saver unit is configured with a low-profile snubbing stack located between the hydraulic jack legs. This shortens the operating height for more efficient tubular handling and faster trip times. With only one flange connection to the existing BOP stack, the hydraulic rig assist unit can be rigged up in less than 60 minutes.

Cudd Energy Services 150K Quick Jack™ is a modular stand alone hydraulic workover unit configured for rapid rig ups (2-3 hours). The Quick JackT is an economical alternative to high pressure coil tubing or a space saver workover rig combination.

Cudd"s hydraulic workover professionals are continuously examining our processes to create job efficiencies for our customers. One result of these efforts is the Rack Jack® and/or skid systems used independently or in tandem. The Rack Jack® feature enables crews to standback the workstring improving trip times in and out of the well. The skid system allows movement between wells without rigging down the unit or BOP stack. Used in tandem, the Rack Jack® skidding system allows the user to move between wells without laying down the workstring.

Major players in the hydraulic workover unit market are Archer limited, Basic Energy Services, Inc. , Canadian Energy Equipment Manufacturing FZE, Cudd Energy Services, Easternwell Group, Elnusa, Halliburton Company, High Arctic Energy Services Inc, Key Energy Services, LLC, NOV Inc.

New York, March 24, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Hydraulic Workover Unit Global Market Report 2022" - https://www.reportlinker.com/p06247583/?utm_source=GNW

The global hydraulic workover unit market is expected to grow from $8.65 billion in 2021 to $9.58 billion in 2022 at a compound annual growth rate (CAGR) of 10.7%. The growth is mainly due to the companies resuming their operations and adapting to the new normal while recovering from the COVID-19 impact, which had earlier led to restrictive containment measures involving social distancing, remote working, and the closure of commercial activities that resulted in operational challenges. The market is expected to reach $12.40 billion in 2026 at a CAGR of 6.7%.

The hydraulic workover unit market consists of sales of hydraulic workover unit services by entities (organizations, sole traders, and partnerships) that utilize versatile, cost-saving, and safe techniques for the repair and maintenance of all types of wells.Hydraulic workover is a well intervention technique used for installing or removing tubes (pipes) in and out of dead wells (the well with zero surface pressure).

The main services in the hydraulic workover unit are workover and snubbing.The snubbing services are used to install or eliminate tubular from a well while the well is pressurized.

Snubbing has the advantage of allowing work to be done without dying the well, which eliminates reservoir formation damage and costly stimulation procedures.The various installation types include skid mounted, trailer mounted and has a capacity in different ranges such as 0-50 tonnes, 51-150 tonnes, above 150 tonnes.

North America was the largest region in the hydraulic workover unit market in 2021. The regions covered in this report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

The increasing shale gas production is projected to propel the growth of the hydraulic workover unit market in the coming years.Shale gas is natural gas generated from a type of sedimentary rock called shale that is formed from clastic origins such as sedimentary rock or siltstone.

The most adaptable technology available in the upstream oil and gas industry is the snubbing unit, which is a type of hydraulic workover unit. According to the United States Energy Information Administration, shale gas production in the USA is expected to increase from 27.90 trillion cubic feet in 2021 to 32.50 trillion cubic feet by 2025. Therefore, the increasing shale gas production drives the growth of the hydraulic workover unit market.

The introduction of multiphase projects is a key trend gaining popularity in the hydraulic workover unit market.Major players operating in the hydraulic workover unit sector are launching multiphase projects in collaboration with technology players to set a new offshore snubbing unit or hydraulic workover world record.

For instance, in September 2020, SBS Energy Services (SBS), a US-based provider of snubbing, hydraulic workover services entered into a strategic partnership with Helix Solutions to complete a multi-phase project that deactivates roughly 29,000 feet of 10 inches by 6 inches insulated pipeline in the Gulf of Mexico.

In April 2019, High Arctic Energy Services Inc., a Canada-based drilling oil and gas wells company acquired assets of snubbing services equipment from Precision Drilling for $8.5 million. The acquisition provides the High Arctic with additional quality snubbing equipment and access to experienced personnel and crews. Precision Drilling is a Canada-based drilling rig contractor involved in offering snubbing services, oil field rental, and supplies.

The countries covered in the hydraulic workover unit market report are Australia, Brazil, China, France, Germany, India, Indonesia, Japan, Russia, South Korea, UK and USA.

When considering workover operations, our clients have to make choices. In other words, they can opt for the cheap and straightforward well intervention method that would be most suitable for them. However, they can opt for complicated and expensive remedial operations. Various workovers cure enhanced recovery or tubular (and cement) integrity issues. Saltel Patch is one of the best alternatives to reach such objectives. Saltel Patch guarantees the best internal diameter (ID) post-setting. Likewise, it extends the lifespan of the well. The Patch is now a reliable, field-proven solution to troubleshoot downhole erosion and corrosion issues. It is not uncommon for operators to include us in their workover strategy in order to maximize the life cycle of their wells.

Moreover, Saltel Patch, once set, brings a strong added-value to the well production. It is a drastically cost-effective alternative in the workover process. It combines smooth entry – tapered ends, with Max. ID for better flow rates when the well is back to production.

The patch has extended the options for workover in order to make it more convenient. As a result, the scope of the project has been widened to include aging assets, mature wells, and new well applications. In other words, the Patch now covers damaged completion modules requiring max ID. Damaged frac ports, open and blocked sliding sleeves, damaged DV tools, ICD, sand screen sections.

8613371530291

8613371530291