toy workover rig free sample

The jackup oil rig is a self-contained combination drilling rig and floating barge, fitted with long support legs that can be raised or lowered. The jackup is towed onto location with its legs up and the barge section floating on the water. Upon arrival at the drilling location, the legs are jacked down onto the seafloor and then are jacked further down. This jacking down of the legs has the effect of raising the platform, barge and drilling package. In this manner, the entire barge and drilling structure are slowly raised above the water to a predetermined height above the water, Jackup platforms are used as exploratory drilling platforms and offshore and wind farm service platforms, and they can drill in waters up to 350 feet deep.

One common piece of heavy equipment used to produce hydrocarbons from the earth is referred to as: a workover rig, a completion rig, or a pulling unit. Such a thing can do many tasks, but it is primarily used to hoist damaged tubing from a well and lower undamaged tubing into a well so that oil and gas can flow more freely. A workover rig can also be used to “complete,” repair, or swab a well to maximize its rate of fluid production.

A workover rig comprises a truck carrying a telescoping mast and a winch. In use, the truck is backed up to a well, the mast is raised, and the lifting of tubing is initiated using the winch. A typical, workover rig is used only during daylight hours. A workover rig cannot drill into the earth unless equipped with a special “power swivel” that moves up and down while turning drill pipe extending into the well.

Thousands of men in the United States work upon workover rigs and are interested in workover rigs. It is believed that many would like to own a functioning model of such a rig. Duplicating every feature of a workover rig in a mass-produced model, however, is not practical since many features would be tiny and especially costly to make. Changes are necessary in the various apparatus that: pivots the mast to its substantially perpendicular, upright orientation, telescopes the mast to its full length, and hoists tubing.

In light of the problems associated with replicating a full-size workover rig at a small scale, it is a principal object of the invention to provide a toy workover rig with means for pivoting, telescoping, and hoisting that are lifelike in operation if not exact in appearance.

It is another object of the invention to provide a toy workover rig of the type described that is radio controlled. A person with minimal experience can operate the toy workover rig without resort to prolonged training, study aids, or additional tools. An oil and gas operator can even employ my toy workover rig during a new hire"s orientation session to provide a familiarity with a rig"s working parts and function.

It is an object of the invention to provide improved elements and arrangements thereof in a toy workover rig for the purposes described which is lightweight in construction, inexpensive to make, and fully dependable in use.

The toy workover rig in accordance with this invention achieves the intended objects by featuring an extensible mast that is pivotally fastened to a wheeled truck. A remotely-controlled pivoting assembly is connected to the truck for selectively moving the mast from a horizontal, traveling position to a vertical, operating position. A remotely-controlled telescoping assembly is connected to the truck for selectively extending the mast from a retracted position to an extended position. A remotely-controlled hoisting assembly is connected to the truck for lifted selected objects within the mast.

The foregoing and other objects, features and advantages of my toy workover rig will become readily apparent upon further review of the following detailed description of the preferred embodiment illustrated in the accompanying drawings.

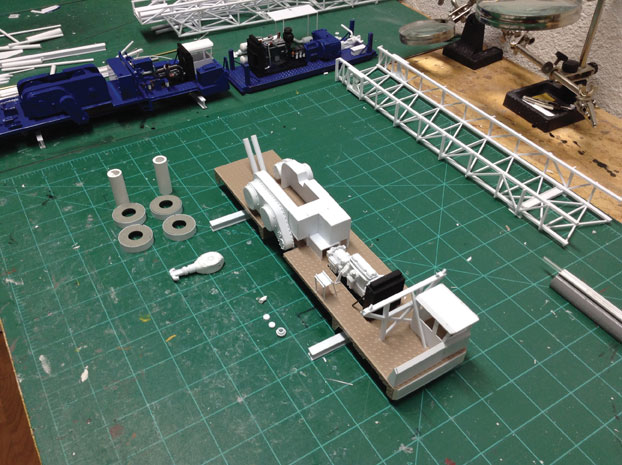

Referring now to the FIGS., a toy workover rig in accordance with the present invention is shown at 10. Workover rig 10 includes a truck 12 that carries an extensible mast 14 at its rear. Mast 14 can be selectively moved from a horizontal, traveling position to a substantially perpendicular, vertical, operating position by a pivoting assembly 16. A telescoping assembly 18 is employed to selectively extend mast 14 to its full height. A hoisting assembly 20 selectively lifts a joint of tubing 22 within mast 14. Assemblies 16, 18 and 20 of the rig 10 are operated by remote control.

Truck 12 includes an elongated body 24 that is supported above the ground by a number of rotatable wheels 26. A cab 28 is affixed to the front of body 24. A pair of upright braces 30 is affixed to the rear of body 24 for pivotally securing mast 14 thereto. Each of braces 30 has a diagonal member 32 and a vertical member 34 being connected together so as to form an inverted V-shape. The tops of braces 30 are positioned at a height that is somewhat greater than that of cab 28 and carry hinges 36 to which mast 14 is pivotally connected. A mast support 38 is affixed to body 24 behind cab 28 for holding mast 14 above cab 28 when mast 14 is pivoted downward for safe movement of workover rig 10 from place to place. A dummy motor 40 is affixed to body 24 adjacent support 38.

Body 24 is provided with a number of ground-engaging stabilizers 42 and 44 to prevent it from tipping when mast 14 is pivoted substantially perpendicular upright and telescoped. A pair of center stabilizers 42 is provided at the midpoint of body 24 with one being located on each side of body 24. Each of stabilizers 42 has a guide sleeve 46 in the bottom of body 24 and an arm 48 that fits snugly, yet slidably, within sleeve 46. Each sleeve 46 is configured such that, when a moderate pushing or pulling force is applied to the associated arm 48, arm 48 is moved within sleeve 46 along an axis that extends downwardly and outwardly from body 24. When fully extended, each arm 48 contacts the ground at a point that is not beneath body 24 thereby preventing body 24 from tipping sideways. Additionally, a pair of rear stabilizers 44 is provided at the rear of body 24 with one being located on each side of body 24. Each stabilizer 44 has a vertically oriented, guide sleeve 50 in the bottom of body 24 that is internally, helically threaded. A helically threaded rod 52 is screwed into each sleeve 50. When screwed outwardly, each rod 52 is brought into contact with the ground beneath body 24 preventing body 24 from tipping rearwardly.

Housing 54 carries several joints of tubing 22 for lifting by rig 10. Two columns of hooks (not shown) are affixed to one of side walls 60 so that the hooks of each column have horizontally positioned counterparts in the other column. The columns are set at a distance apart that is somewhat less than the length of a joint of tubing 22. Removably positioned on each pair of horizontally spaced hooks is a joint of tubing 22.

A ladder 76 is affixed to, and extends along, truss 68 l. Beneath ladder 76, an operator"s platform 78 is pivotally fastened to truss 68 l. Platform 78 has a pair of pegs 80 that carry a detachable handrail 82. Handrail 82 has a pair of pins 84 at its bottom that can be inserted into a pair of tight-fitting sockets (not shown) in the outer edge of platform 78. When mast 14 is pivoted substantially perpendicular upright, platform 78 is manually pivoted to a horizontal orientation and pins 84 are inserted into the sockets to hold the handrail 82 in a vertical orientation.

A work floor 86 is pivotally connected to bottom section 14 b. Work floor 86 comprises a U-shaped plate 88 having a pair of ground engaging legs 90 hingedly fastened thereto. One of a pair of hinges 92 pivotally connect the front of plate 88 to the bottom of lateral truss 681 and the other of hinges 92 pivotally connects the front of plate 88 to the bottom of lateral truss 68 r. A cutout (not shown) in the front of plate 88 between hinges 92 provides additional ground access for traveling block 94 and items carried thereby. When mast 14 is pivoted substantially perpendicular upright, plate 88 is manually pivoted to a horizontal orientation to the rear of mast 14 and legs 90 are pivoted downwardly to a vertical orientation to engage the ground and retain plate 88 in a horizontal orientation.

Tubing board 128 is pivotally connected to top section 14 tand extends rearwardly from it. Tubing board 128 has a U-shaped retainer 132 that is pivotally connected at its front to tubing board braces 102. Affixed to the rear of retainer 132 are a number of forwardly facing tines 134 that define spaces therebetween for racking pieces of tubing 22 lifted by traveling block 94. One of a pair of handrails 136 is rigidly affixed to each of the opposite sides of retainer 132. For compact storage when mast 14 is pivoted downwardly onto mast support 38, another handrail 138 is pivotally secured at its bottom to the rear of retainer 132.

Rod basket 130 is pivotally connected to top section 14 tand extends rearwardly from it. Rod basket 130 has a U-shaped retainer 140 from which a basket member 142 is suspended by its U-shaped top rail 144. For compact storage, retainer 140 is pivotally connected at its front to rod basket braces 106 and the rear of top rail 144 is pivotally connected to the rear of retainer 140. (The front of retainer 140 is open and configured in a manner that prevents retainer 140 from pivoting to a position more than a few degrees beyond horizontal when mast 14 is pivoted to an upright, substantially perpendicular position.) Extending sideways from the front of top rail 144 is a pair of retaining pins 146 that abut the top of retainer 140 and maintain basket member 142 in an upright, substantially perpendicular position when the mast 14 is pivoted substantially perpendicular upright.

Pivoting assembly 16 operates to swing mast 14 substantially perpendicular upright on hinges 36. Pivoting assembly 16 includes an electric motor 148 mounted atop truck body 24 between braces 30. Motor 148 drives a gearbox 150 that effectively increases torque. Gearbox 150 has a horizontal driveshaft 152 that is rotated by motor 148.

Telescoping assembly 18 operates to lift top section 14 tabove bottom section 14 bwhen mast 14 is swung to an upright orientation by pivoting assembly 16. Telescoping assembly 18 includes an electric motor 168 affixed to the bottom of bottom section 14 bbetween lateral trusses 68 rand 68 l. Motor 168 drives a gearbox 170, also affixed to the bottom of bottom section 14 b, having two meshing gears for transmitting power from the motor 168 to a driveshaft 172 extending upwardly from the gearbox 170.

A user of workover rig 10 can easily distinguish when top section 14 thas reached the upper limit of its travel. The first and easiest way to make such a determination is to see that the top portions of trusses 66, 68 rand 68 land the bottom portions of trusses 96, 100 rand 1001 line up horizontally. Another way involves an examination of tubing board 128 and rod basket 130. Their principle features should extend horizontally and vertically so that it is substantially perpendicular.

Pulleys 188 on opposite sides of workover rig 10 receive cords 184. As shown, cords 184 run under pulleys 124 and over pulleys 188. Pulleys 124 and 188 prevent cords 184 from binding and tangling while top section 14 tis being extended or retracted from bottom section 14 b.

A hook 226 is suspended from rod 216 between bells 218. Hook 226 can be employed to catch and suspend miscellaneous tools used with rig 10. Optionally, hook 226 may incorporate a swivel mechanism 228 to permit it to rotate in any direction relative to rod 216.

The operation of workover rig 10 is by three-channel, remote control. A transmitter 250 broadcasts electrical operations signals to a receiver 252 carried within truck body 24 to activate one of a number of servos 254, 256 and 258 also carried within truck body 24. Activating servos 254, 256 and 258 closes dual-throw switches 260, 262, or 264 to selectively operate motors 148, 168 and 248 to move mast 14 or traveling block 94.

When mast 14 is fully pivoted to an upright position, substantially perpendicular work floor 86 is manually pivoted away from bottom section 14 b. Then, with work floor 86 in a horizontal orientation, legs 78 are pivoted downwardly and engaged with the ground. Afterward, when play with rig 10 is complete, work floor 86 is returned to its original position against bottom section 14 band mast 14 is pivoted down upon support 38.

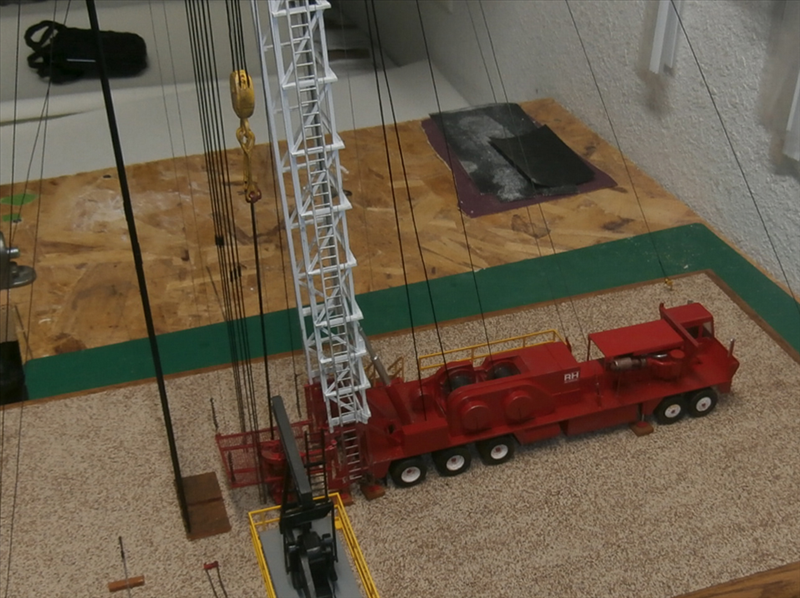

When play with rig 10 is complete, mast 14 can be returned to a compact state like that found on a real workover rig that is being driven over the road. Rig 10 is most easily stored in this condition. Others may prefer to keep mast 14 in an upright, substantially perpendicular and fully extended condition. In this manner, rig 10 makes a great display model and focal point wherever set up.

While workover rig 10 has been described above with a high degree of particularity, it will be appreciated by those skilled in making toys that modifications can be made to it. For example, wheels 26 beneath cab 28 can be made to turn via remote control to steer truck 12 and a remotely controlled motor (not shown) can be added to drive a set of wheels 26 and propel truck 12 over the ground. (Such things are, of course, commonly found in r/c cars.) Also, downwardly pivoting toolbox doors 274, sidewalks 276 and movable ladders 278 can provide added realism. So, it is to be understood that my invention is not limited solely to workover rig 10, but encompasses any and all workover rigs within the scope of the following claims.

My favorite drill rig is the Ingersoll-Rand T4W. I always wanted a model of the T4W, so I called the toy stores I knew of to see if I could find one, and no one knew what I was talking about. When I turned 5, my wish finally came true. My friend Dean Jones of Gurvis Jones Well Drilling, Bel Air, Md., brought me a model of the T4W. He was the man that was drilling the wells behind my house and knew how much rigs meant to me. He got the model from a store called Toys for Boys in Pennsylvania. It was a very delicate model, and they are now discontinued. I played with my T4W model so much that it finally broke.

Unable to find any more toys like my favorite rig, I started building my own rigs out of different block sets such as Legos, Bristle Blocks and Brios. I then decided to build models out of wood, and my first one was a T4W. After that, I built a little jetting rig out of toothpicks. One day, my dad built a model rig - a 1:16 scale rig out of wood. He used a picture that was in the phone book for the design. When I was 13 years old, I built another T4W model rig out of two separate erector sets. Mark Laibe of Versa-Drill purchased the first complete rig that I had up for sale - a Versa-Sonic.

Recently, I started building rigs out of different truck bodies and attaching wood for the booms. I paint the rigs and sell them. I have made many friends throughout the drilling industry who have purchased my rigs or have discussed their rigs with me. I will call drillers and manufacturers to talk about my favorite subject - rigs. Mike Huber of Cheasapeake Geo Systems, Baltimore, and Mark Laibe are but two of the many people whom I consider my friends. The rigs I build are fairly delicate and shouldn"t be used as toys. They look great displayed on a desk or a bookshelf. See my ad under Toys in the Marketplace.

I really like the older model rigs - I think they were built to last. I also collect pictures of rigs and would like to get some older photos of Gardner-Denver, Portadrills and Jazwell drills, and if anyone wants to send me some, I would really appreciate it. I enjoy building rigs as a hobby, but I would rather be out on the job site watching the action. My hobby keeps me out of trouble and busy doing something I really enjoy. Now that I am 16, I would like to work with a drilling crew soon to get some experience, but I need to get my driver"s license first. One day I plan on owning a water well drilling company and hiring my brother Chris, who also is interested in drill rigs.

I read all industry magazines that I can get my hands on. I have had a subscription to National Driller for years. I try and subscribe to all the magazines I can so that I can keep up with all the activities in the industry. I attended my first water well tradeshow in February - the Maryland/Delaware show. My friend Dave Kelly of Jones Well Drilling took me. I look forward to attending more trade shows when I can. I love meeting and talking to people in the industry - the stories I hear are really amazing. If anyone would like to talk to me about rigs or send me photos, hats or business cards, please get in touch with me.

Jeff amazes me with his knowledge of rigs; not only is he able to look at a rig and tell you what kind it is, he also can explain the operation of that particular rig, pointing out parts of it that he would improve.

He is one determined young man. I look for him to make his mark in this industry - either with his own well drilling company or as a rig manufacturer/designer. He has very strong love for the industry.

If you would like to know something about a particular rig, Jeff can usually tell you what you need to know. His enthusiasm is contagious; he has piqued the interest of his brother Chris about the business of well drilling.

The pressed-steel toys from the Nylint Tool and Manufacturing Company are considered by many as being among the best American toys ever made. Over the years, their line has featured dozens of models of construction equipment, trucks and cars, many of which had action features that enhanced their play value and provided countless hours of constructive fun for thousands of young boys and girls.

One toy that stands out among the group is their classic mid-1950s Michigan T-24 truck-mounted crane which became a must-have for every kid with a backyard and an imagination. With its lifelike operation and tough durability, this lattice boom crane was adored by sandbox excavators, Lincoln Log architects and playtime foremen everywhere.

The T-24 Michigan crane wasn’t born overnight. It was the result of decades of innovation by a heavy-equipment manufacturing company diversifying its product line and a second company making kitchen utensils in response to the unique demands of the post-war baby boom. Together, these companies brought out one of the most popular construction toys in history to the market.

Using the manufacturing capabilities of Ross Carrier, Clark developed a new line of rubber-tired front-end loaders and marketed them under the Michigan brand name. Clark’s Michigan lineup soon featured elevating scrapers, wheel loaders, tractor scrapers, compaction equipment, truck shovels, trench hoes and the crane that would soon become a toy legend.

Nylint already possessed modern metal-stamping facilities, so the company chose to manufacture metal toys in anticipation of the millions of soldiers who would be returning home to start families.

Nylint first made waves with the introduction of a windup toy car, a staple of toy boxes to this day. Its innovative mechanism allowed the car to start and stop, move forward or backward and turn side to side. The success of the Nylint toy car prompted a new generation of toy development.

About products and suppliers:With each new day, new learning methods are being devised. Thus, oil rig toy play an essential role in kids" learning process. They aid in building an interactive educational environment. oil rig toy are creatively manufactured objects or toys which stimulate fun learning for children. They can come in handy while tackling or handling kids. Alibaba.com lugs unlimited options of oil rig toy with assured quality.

These days, kids are pretty smart and so are their learning tools. oil rig toy intend to help a child in developing knowledge about a particular skill or subject without losing the grip of enjoyment. There are a number of educational toys available in the market, each used for separate purposes of teaching. Since oil rig toy have an artistic look, they keep the students" interests alive. They are helpful at providing lively training sessions to kids. oil rig toy come in distinct bright colors and descriptive designs.

Alibaba.com offers various categories of educational toys for babies, toddlers, preschoolers, and school-going kids. From sets of stacking cups for first-years to oil rig toy, there is not a thing which you will not find here. oil rig toy could be used by parents, teachers, or baby sitters to give practical know-how of basic skills to children. oil rig toy keep the children engaged in a learning activity for a long time.

Come and find certainly exquisite oil rig toy ranges at Alibaba.com. Browse through a phenomenal selection of educational supplies for tiny buds, accessible to all the individual customers, retailers, and wholesalers. Visit the site now to unveil exciting offers valid for short time periods.

Explore the various water well workover rigs products available for wholesale at Alibaba.com. Get a water well workover rigs for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some water well workover rigs options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

water well workover rigs options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a water well workover rigs that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

8613371530291

8613371530291