tripping pipe on a workover rig made in china

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

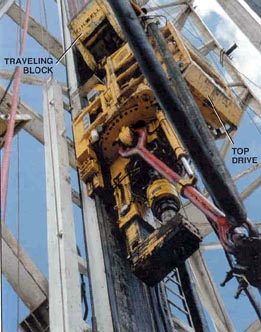

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

The derrickman"s working platform. Double board, tribble board, fourable board; a monkey board located at a height in the derrick or mast equal to two, three, or four lengths of pipe respectively.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.†

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

Each part of the device has different structural forms and can be selected arbitrarily for personalized configuration according to the needs of users.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

In addition to its main function of suspending the pipe string, it also has the functions of automatic tubing mouth match, make-up and break-out, and is also equipped with a guide device bearing reverse torque, which can realize the functions of automatic well washing, sand flushing, drilling, grinding and milling.

Main function: connect to the wellhead flange and clamp the pipe string. Slip teeth are common with other manufacturers for easy replacement. The hydraulic cylinder is clamped and the pipe string is forced to be centered. The clamping is reliable and convenient for automatic operation. Open and close state detection, and realize safety interlock with other equipment.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

The hydraulic system includes hydraulic source, wellhead automatic operation device control valve group, hydraulic elevator, hydraulic slip valve group, conveyor control valve group and pipeline, etc.

Subsequent to writing that article I happened to read an excellent book with the title Salt: A World History, written by Mark Kurlansky. I highly recommend it to anyone with an interest in history and human affairs, along with Kurlansky’s other books, Cod: A Biography of the Fish that Changed the World, and The Basque History of the World. The three books’ themes are interrelated in a most entertaining way. But to get back to Salt, in one chapter an ancient salt producing industry involving sophisticated drilling techniques and coproduction of brine and natural gas in China’s Sichuan province, far pre-dating western efforts, is detailed. I was tremendously interested by this, and immediately felt that this topic would make a great follow up to my first one, as it involved hydrocarbon exploitation, and better still, was ideal nourishment for the bee in my bonnet – it involved another culture, from long ago, whose exploits and achievements are frequently overlooked by us in the west.

Through a little research I discovered the existence of a museum dedicated to Sichuan’s ancient brine / salt / gas industry. Called The Salt Museum, it is located in Zigong City, named after two of its famous salt wells, about three hours’ drive south of the provincial capital Chengdu (figure 1). I resigned myself to the fact that it was highly unlikely I’d be close to China in the near future, let alone Zigong. Then earlier this year, out of the blue, a business-related trip to Chengdu materialized, and I was determined to visit The Salt Museum while over there. It all worked out, and this article is the result. My aim is to provide interested readers with an understanding of the fascinating achievements of these people hundreds of years ago. As with my previous article this is not a scholarly analysis, but rather an amateur’s efforts to share his enthusiasm, and provide entertaining and stimulating reading.

When a break in our work responsibilities allowed it, I and my Geo-X colleagues, Bo Li and Andrew Royle, set off to Zigong, with our generous and gracious hosts from the Sichuan Geophysical Company (S.G.C.), Gang Lin and Zhirong Li. To drive through rural Sichuan is interesting, as one gets a sense of the intensity of human development in one of China’s richest regions. The heavily populated portion of Sichuan is a large basin, flanked by the Himalayan Plateau to the west, the Long Men Mountains to the north, and the Hua Ying Mountains to the south. The Yangtze River flows along the southern edge of the basin, and numerous tributaries drain south through the rich agricultural lands and into the Yangtze . With its fertile, well watered soil, and mild climate, Sichuan is one of China’s most productive farming regions. Since ancient times, Sichuan has been called “heaven country” within China. The most common crops include wheat, canola, rice, cotton, barley, corn, yams, tobacco, fruits and vegetables. On higher, less fertile ground, huge areas are devoted to the cultivation of mulberry bushes (figure 2), which feed one of the world’s oldest and biggest silk producing industries.

Naturally, with such attractive conditions for human habitation, Sichuan has been occupied by humans since the early dawn of our existence. The countryside has been worked by the human hand for so long, that it is hard to spot a single wild area in the basin proper. Even steep hillsides are terraced for farming, and ancient family crypts hewn into rock cliff outcrops can be spotted frequently from the highway. The contrast between the luxury cars speeding along the modern 6-lane highways, and the ancient terraces, tombs and irrigation systems is startling, but one can easily imagine one long continuous evolution of human technology here, from thousands and thousands of years ago, to the present. Many of China’s ancient technical accomplishments came from this region, including sophisticated irrigation techniques, and what I am particularly interested in, their drilling technology.

My reaction on arriving in Zigong was typical for a westerner first visiting China – yet another city of, what - half a million, one, two million people? - that I had never heard of, with big boulevards, high buildings, people everywhere, construction cranes sprouting willy-nilly. The scale of development in modern China is simply staggering.

After a visit to Zigong’s Dinosaur Museum, on par with our Tyrell Museum in Drumheller, and the requisite banquet of incredibly delicious Sichuan food, we arrived at the Salt Museum. The museum is housed in the former Shanxi Guildhall, built in 1736–1752 AD by salt merchants from Shanxi Province to the north (figure 3). The museum and the building housing it easily exceeded my expectations, as this is truly a world class exhibition. The fact that this historical building and the museum itself are still in existence today can be largely attributed to patriarchal leader Mr. Deng Xiaoping, who proposed and promoted this museum in the 1950s.

The earliest evidence of wells in China, in Zhejiang Province, comes from the era when humans were first turning to agriculture in this region, some 7,000 years ago. Approximately 5,000 years ago Chinese coastal people were boiling sea water to produce salt. As high density human settlement penetrated further and further inland and increasingly relied on farming, salt, critical to human survival as a vital food supplement and preservative, became a valuable commodity. The first recorded salt well in China was dug in Sichuan Province, around 2,250 years ago. This was the first time water well technology was applied successfully to the exploitation of salt, and marked the beginning of Sichuan’s salt drilling industry. From that point on, wells in Sichuan have penetrated the earth to tap into brine aquifers, essentially ground water with a salinity of over 50g/l. The water is then evaporated using a heat source, leaving the salt behind.

At some point around 2,000 years ago the leap from hand and shovel dug wells to percussively drilled ones was made (figure 4). By the beginning of the 3rd century AD, wells were being drilled up to 140m deep. The drilling technique used can still be seen in China today, when rural farmers drill water wells. The drill bit is made of iron, the pipe bamboo. The rig is constructed from bamboo; one or more men stands on a wooden plank lever, much like a seesaw, and this lifts up the drill stem a metre or so. The pipe is allowed to drop, and the drill bit crashes down into the rock, pulverizing it. Inch by inch, month by month, the drilling slowly progresses. It has been speculated that percussive drilling was derived from the pounding of rice into rice flour. When I read of this technique in Salt, I imagined a fairly crude technology. I had no idea how sophisticated these drilling methods became, to the point where these people really had developed most of the tools and techniques one might see on a modern drilling rig, albeit on a smaller scale and without the benefits of modern machining methods.

At regular intervals in the drilling, the crushed rock and mud at the bottom of the hole needed to be removed. The drill stem would be pulled from the hole using a large wheel, somewhat similar in appearance to that on a modern flexible cable down hole tool truck. A length of hollow bamboo with a leather foot valve would then be lowered to the bottom of the hole. When the tube was lifted, the weight of the mud inside would keep the valve closed, and the contents could be brought to the surface. Drilling would then recommence.

Figure 5. A series of diagrams showing the steps taken to repair a well bore cave in. The first four steps establish the top and bottom depths of the caved in zone; in the fifth step straw is inserted ~ 1m below the zone, where it expands as it soaks up water and plugs the hole; in step six a material is tamped down above the straw to plug the hole more securely; in step seven repair cement (tong oil + lime) is forced into the cave in zone; finally in step 8 a guided bit drills down through the centre of the repaired zone to reopen the well bore.

The drilling method on its own is impressive, especially when considering that the rest of the world had nothing comparable in the earlier centuries. But even more impressive are all the techniques the Sichuan drillers developed to overcome common drilling problems – cave ins, lost tools, deviated wells, and so on (figures 5 & 6). A huge variety of tools and techniques evolved to handle well repair issues (figure 7). Many different drill bits were also developed, with different sizes, shapes and compositions, to deal with the different rock types encountered, and the many different drilling requirements. For example, opening the hole at the wellhead required a large heavy bit (3m long, 150-250 Kg) called the “Fish Tail” (figure 8); the “Silver Ingot” drilled the well bore rapidly, but roughly; the “Horseshoe” bit drilled slowly, but achieved round, smooth, high quality well bores. Hollow logs were used in the near surface as casing.

Figure 7. A variety of down hole tools on display at the Salt Museum. Upper left a re tools designed to repair the surface of the well bore wall, by scraping off salt build up, reestablishing the correct diameter, etc. Bottom and middle left are lost tool retrieval tools. The rest are drill bits and miscellaneous tools.

A major breakthrough was achieved around 1050 AD, allowing deeper wells, when solid bamboo pipe was replaced by thin, light, flexible bamboo “cable” (figure 9). This dramatically lowered the weight that needed to be lifted from the surface, a weight that increased with the depth being drilled. By the 1700s Sichuan wells were typically in the range of 300 – 400m deep, and in 1835 the Shenghai Well was the first well in the world to exceed 1,000 metres of depth. In comparison, the deepest wells in the U.S. at that time were about 500m deep. The Sichuan salt producing industry was centred around Zigong, and early photographs show hundreds of producing derricks (“heaven carts”; figure 10), salt stove operations, and the Fuxi River jammed with salt trading boats (figure 11). Brine and natural gas were transported through 100s of kilometres of bamboo pipeline (figure 12).

Figure 9. Museum model of flexible down hole bamboo cable and the wheel from which it would be deployed. Deeper wells used a large cylinder with a vertical axis and driven by oxen to deploy cable.

Figure 10. A photo of Zigong early in the 20th century showing many of the derricks used to drill and produce brine and gas wells. Some of these "Heaven Carts" were over 100m tall!

The fuel used initially in the evaporation process was of course wood. Sources of wood became scarce due to the scale of the salt production industry. Some energy saving techniques were used during evaporation: spreading the brine on tree branches under the sun to increase the salt concentration before boiling, and putting several boiling pans on the same chimney path to use residual heat. There are instances of oil and gas production and use in China going back as far as 61 BC, but it appears as if the salt and hydrocarbon industries were separate for a long time. Fortuitously, at some point in the 16th century, techniques to harness the natural gas encountered during drilling for brine were developed, and this allowed natural gas to be burned beneath the big salt pans. It was the coexistence of brine and gas that pushed Zigong’s salt production into the industrial scale. Once wells were able to reach down to 700-800m, they were able to produce both brine and gas from the Jialingjiang group Triassic formations. Annual salt production in Zigong in the 1850s was about 150,000 tons. The Chinese population was about 0.45 billion at that time. The salt industry was a huge economic driver, and many large cities in Sichuan were established, and flourished, because of the lucrative salt trade.

A key technological advance was the introduction of the “Kang Pen” drum at the end of the 18th century (figure 13). This drum sat on top of the wellhead, and the pressure within the drum was controlled such that gas and brine could simultaneously be produced, and efficiently separated. One bamboo pipe line would take away the brine, and others the gas. The 2,000 year plus Sichuan salt industry has drilled approximately 130,000 brine and gas wells, and 10% of those were in the immediate Zigong area. Zigong has a cumulative gas production over this period of over 30 billion cubic metres. The area continues to be a major salt producer, and many of the historical wells are still in production.

One minor detail I found interesting. When I had first read of bamboo pipelines, I wondered how the barriers separating the segments within the bamboo were dealt with. Did they drill holes through these compartment walls with long augur bits to create pipe? My curiosity was satisfied by one of the displays depicting the process of turning bamboo into pipe. Each length of bamboo was cut in half, down its length. The segment walls were removed, and the insides of the bamboo further hollowed out to create a smooth inside surface of constant interior diameter. The two sections were then put back together and bonded with a glue made from a mixture of lime and tree seed oil. It was further bound together with twine inset into grooves in the outside surface of the bamboo, to prevent fraying, especially for down hole use where the hole’s rock walls would scrape against the exterior surface of the bamboo pipe as it was repeatedly lifted and lowered during drilling and production operations. Similar glue and twine techniques were used to link and splice pipe line sections together end-to-end in an airtight fashion. As recently as the 1950s there was still over 95km of bamboo pipeline in operation in the Zigong area.

Figure 13. An ancient sketch originally fro m "The Annals of Salt Law of Sichuan Province". A "Kang Pen" drum is seen in the centre foreground, with gas pipes directly feeding the salt stoves on the right. At the top, brine from a remote well is being carried in buckets by men, who feed it into a bamboo pipeline that runs down to the stoves. One of the carriers is being paid at top left, and it appears that a blow out is depicted on a new well being drilled in the left foreground; maybe the men operating the drill rig have run away, as tragically happened at a Chongqing, Sichuan sour gas well, late 2003.

Being earth scientists, Andrew, Bo and I were naturally curious about the geology of the region, and the knowledge the ancient drillers had of the subsurface. Did they practice geology, or geophysics, in some form? Did they draw diagrams of the sub-surface and choose new drilling locations based on geological models? This is one area the museum displays do not touch on. However, it is known that well locations were chosen based on the distribution of existing gas and brine wells, and on a variety of surface clues. Brine and gas seeps were obvious indicators of a good location. The salt drillers looked for a salt “frosting” on the surface rocks, or the smell of brine. Yellow brine wells (high in ferric chloride) were usually drilled into yellow sandstone outcrops, while black brine wells (containing hydrogen sulfide) were drilled into cracked sandstones with a black crust. Brine only wells were usually drilled on hillsides, while gas producing wells were usually drilled on hilltops, suggesting that the topography reflected the underlying geological structures. However, surface clues would not have revealed much about targets down towards 1000m depth, so we’re left to speculate on whether geological skills advanced along with the drilling technology.

My brief visit to Sichuan left me intrigued, fascinated, and eager to learn more about China’s ancient technical accomplishments. I can highly recommend the region as a place to visit, not only for its interesting historical sites, but also for its natural beauty (most of Sichuan is mountainous and unpopulated, especially the west, with bamboo forests, and panda bears), its rich culture with many interesting ethnic minorities, its delicious food, great shopping, and its wonderful, friendly people. However, the highlight of my trip was the visit to the Salt Museum, and I hope I have passed on my enthusiasm for this topic to readers.

Tripping pipe (or "Making a round trip" or simply "Making a trip") is the physical act of pulling the drill string out of the wellbore and then running it back in. This is done by physically breaking out or disconnecting (when pulling out of the hole) every other 2 or 3 joints of drill pipe at a time (called a stand) and racking them vertically in the derrick. When feasible the driller will start each successive trip on a different "break" so that after several trips fresh pipe dope will have been applied (when running back in the hole) to every segment of the drill string.

The most typical reason for tripping pipe is to replace a worn-out drill bit. Though there are many problems that occur to warrant the tripping of pipe. Downhole tools such as MWD (measurement while drilling), LWD (logging while drilling) or mud motors break down quite often. Another common reason for tripping is to replace damaged drill pipe. It is important to get the pipe out of the wellbore quickly and safely before it can snap.

Drill bits wear and tear like most any other piece of equipment. Once a bit becomes too worn to drill at an adequate rate or make a full-gauge hole, or if the bearings are thought to be near failure, a trip is undertaken to replace the bit. A trip is not considered a bit trip when the purpose of replacing the bit is to change sizes. This is only done when the crew "sets surface, intermediate or longstring" as appropriate.

A fishing trip is when a crew is forced to trip pipe to retrieve loose items in the wellbore. This can result from something being dropped in the hole, i.e. a tool, that would cause damage to the bit if the crew attempted to drill with it on bottom.

Another major cause is known as a "twist off". Twisting off is when the drill string parts by failing catastrophically under the torsional stress. This may happen if the drill string below is pinched in the wellbore, or as the result of a structural weakening of the pipe caused by a washout or a crack in a threaded connection member.

When pipe snaps or a part of the bit breaks off, the crew has to recover all of the separated items from the wellbore. Recovering snapped pipe usually involves placing a specialized tool (an "overshot") with grips set inside of it over the broken pipe in an attempt to capture it. The grip works in a manner similar to Chinese fingercuffs. Sometimes the jagged top of the fish must be milled back to a round outside shape before the overshot can slip over it. The overshot contains a packoff device to make a pressure seal so circulation can be reestablished through the bit to facilitate recovery of the fish. For a broken bit, a magnet is commonly used to remove all of the broken parts.

A cracked pipe can lead to a broken string. Extra care is taken when tripping for one so that too much pull does not cause the cracked pipe to snap. Cracked pipes (i.e., washouts) are usually noticed by a sudden drop in pressure. The crew will usually pump "fastline" (small lengths of manila rope taken from unraveled catline) down the drill string to make a temporary plug and time the pressure to see when it rises back to normal. This enables the crew to know how far down to expect the cracked pipe to be within a few stands; also strands of these rope segments may be seen at the point of washout. Most trips for a cracked pipe are not complete trips like a fishing trip or a bit trip. These can be as simple as only going a few stands down, to pulling the drill collars.

Logging of the open hole may take place at various depths while drilling, and almost always at the end of the drilling operation. The drill string will be removed from the wellbore to allow a logging crew to conduct a survey of the well. After the logging is completed at total depth, the crew will run the drill string back into the well and then proceed to lay it down when coming out of the hole prior to installing the final set of casing (the "production casing").

These trips are routinely expected by the crew. Setting surface occurs after the wellbore is drilled to the predetermined surface depth (e.g., after drilling below fresh water strata). The crew will remove the entire drill string to allow surface casing to be emplaced. The procedure is similar for setting intermediate, only that it typically involves a much longer drill string to be removed. Setting longstring is usually a one time operation combining both surface and intermediate casing. This saves the time of only having to undertake one pipe trip as opposed to two pipe trips.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Powerful CAT engines and a custom-made chassis that can be equipped with single wheel full suspension enable well service operations in even the most remote areas.

Suited for corrosive environments: All steel parts are specially protected against corrosion through the application of multiple layers of ship paint. The same coating process is used in marine shipbuilding.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Tripping refers to the process of removing and/or replacing pipes from the well when it is necessary to change the bit or other piece of the drill string, or when preparing to run certain tests in the well bore.

Operators working in shallow resource plays, such as shallow oil, unconventional shale gas and coalbed methane (CBM), just can’t get enough of a good thing. At their request, rig manufacturers are expanding the operating and mobility features of the industry’s rigs to a new level of sophistication – the highly or ultra-mobile rig. Highly mobile drilling rigs bring increased agility, automation, safety focus and cost savings, and are being used in deeper oil plays to perform top-hole work. Additionally, highly mobile rigs are carving niches for themselves in workover operations from offshore platforms, as well as geothermal applications.

Mobile and highly mobile rigs are different from their predecessor, the heliportable rig, which is used to access locations where no infrastructure exists, such as Siberia and the Amazon region. Heliportable rigs, which first appeared about 30 years ago, are capable of being broken down into a minimum number of loads, with each load weighing three tons, depending on the type of rig.

“Ironically, the helirig concept has not evolved very much, I suppose due to low-volume demand for these units. However, modular highly portable rigs have taken off, and the demand is very high for the foreseeable future,” Ray Pereira, vice president of North America sales for Drillmec, said.

For the purpose of this article, highly or ultra-mobile rigs are defined as small or medium-size self-driving rigs with wheels, mounted on either a substructure or trailer, and quite often their substructure and mast are self-erecting. How is this different from mobile rigs? According to rig manufacturers, features such as a heightened ability to be broken down and reassembled and still retain full functionality, increased use of automation for added safety and operational ability, and a reduction in crew size all set highly mobile rigs apart from mobile rigs.

“A fully engineered drilling system is even more important in highly mobile rigs given the trend toward more factory-styled well construction and automated drilling,” Eric Quinlan, LOC product manager for Huisman, commented. “The complete integration of third-party equipment into the rig design will further reduce the number of loads required, the rig-up and rig-down times, as well as improve on automation.”

“High mobility allows more wells to be drilled in a year,” he continued. Particularly for pad drilling in the shale plays, rigs must not only be able to skid or walk but also move quickly and safely to the next pad.

“There is a stronger focus on self-erecting components in highly mobile designs, for instance slingshot-type substructure and self-elevating or self-erecting masts,” Thomas Janowski, sales manager for Herrenknecht Vertical, said. The advent of portable top drives, iron roughnecks, as well as casing-running tools, have added to efficiencies of highly mobile rigs, he noted.

The design and construction of these highly mobile rigs have become very sophisticated, as with the case of the Drillmec HH Series rig, where the main rig components, such as the mast and part of the drill floor, are fused to the specially designed trailer. This allows the top drive and iron roughneck to be transported without being removed from the mast. The trailer concept has improved the mobility of mud pumps, mud tanks, variable frequency drive houses and pipe bins for the automatic racking system.

“A key limitation to current rigs is the available resources (people, trucks, etc) that enable the rig move. Location of the wells also plays a role and adds constraints, both geographic and regulatory,” Mr Quinlan said.

Therefore, there is a major push to reduce load weights and dimensions of all modules that are required to erect a highly mobile rig on location while at the same time reducing the number of loads required to fully assemble the rig on site, according to Mr Pereira.

It all comes down to the challenge of how to rethink components, such as a 40-ton mud pump, to make them more easily and economically transportable. “There is no standard solution at all,” Mr Janowski said. “How do you make 40 tons highly mobile? You can put wheels on it, but there are limits as to weight and size of components. It is challenging to design the components on the one hand lighter by using different compound materials like glass-reinforced plastic, and on the other hand, these heavy components like mud pumps, diesel generators and electrical cabinets and steel structures, such as the mast and substructure, have to be able to be broken down into smaller pieces but retain the same operational features.”

Equipment advances have brought challenges to highly mobile rig designs as well. “We are seeing a lot more wires and sensors being installed along with measurement equipment and video cameras,” Mr Quinlan remarked.

According to Atlas Copco, mobile rigs got their start in the energy industry when operators started using water-well rigs to drill for oil and gas. “The industry sort of evolved into using mobile rigs for oil and gas drilling rather than actually beginning at a definitive time. The Atlas Copco RD20 rig was borne out of the need for a mobile rig designed specifically for oil and gas drilling,” Alex Grant, well drilling product line manager for Atlas Copco, recalled. The rig was conceived from the T4 water-well rig and has received several technology upgrades since it was introduced in 1986.

The 120,000-lb hookload RD20 rig now has a sister rig, the highly mobile 200,000-lb hookload Predator, which took five years to develop and is just now finishing field trials. The first production unit is expected to begin work in September this year in a Texas shale play.

“We saw a definite need to get into the bigger fields with the bigger players. That’s where Predator came in. We took a clean sheet of paper and asked the question, ‘What does the oil and gas market need?’ ” Mr Grant said. “Because we desired to have an API 4F rating, we probably spent about two years getting our suppliers lined up…. Structures are designed to three times the loading capacity; that’s something you can’t just evolve from a rig that you already have. In 2010, we built two prototypes and put them in the field in an extensive testing program.”

Recognizing that more operators are performing directional drilling, Atlas Copco also added more pullback capacity to the Predator design. The RD20 rig had a pullback capacity of about 5,500 ft; the Predator has about 8,000 ft to 10,000 ft of pullback capacity.

For Drillmec, the Drillmec HH Series rig saw its evolution from a simple hydraulic rig for water wells upgraded to oil well standards in 1990. The first built-for-purpose HH rig was delivered to Eni in 1994. Since then, each generation of the rig has been improved to include enhanced automatic controls for the pipe handler using programmable logic controllers (PLCs) and advances to the hoisting and hydraulic systems. The latest generations include joystick controls and cyber control touchscreen features. The company offers up to 375-ton HH Series rigs for land applications and up to 600-ton rigs for offshore platforms.

Also on the HH Series rig, the vertical pipe-racking system is assembled in a semi-circular array around the rig floor to contribute to quick rig-up and rig-down. Further, containers can be transported and handled full of drill pipe to save time and to reduce risks associated with pipe handling.

“For us, the challenge in the beginning was to develop a rig that provided very safe working conditions for the crew, a small environmental footprint and a high level of operating efficiency,” Mr Pereira said. “Our extensive knowledge of hydraulics enabled us to effectively use a purpose-made cylinder for the hoisting aspect of the rig, thereby eliminating the need for mechanical drawworks and the operational and transport complexities that it brings. The rigs do not have a conventional mast structure nor drawworks and long wires or traveling equipment as the hydraulic cylinder replaces those items and is the main hoisting element of the rig.”

Safety has become a paramount driver alongside economics for highly mobile rigs. “Try to remove personnel from unsafe areas is what we’ve done,” Atlas Copco’s Mr Grant said.

“From a mechanical standpoint to achieve safety, we’re getting into more computer-controlled systems, such as a wireless pipe-handling system where the operator can stand away from the whole operation, observe from a distance and still control the unit. We’re bringing computers more into it. It’s the same with the driller; with the use of electronics, we’re able to stand away from the drill table, stand back in the doghouse even and operate the rig from back there, out of the area where injuries typically occur,” Mr Grant said.

“Drillmec uses single 45-ft joints of range 3 drill pipe that is transported in pipe bins and ready to be used,” Mr Pereira said. “There are no delays waiting to make up stands and set them in fingerboards. Stand-building operations can take days. With the HH Series rig, there is no need to touch the pipe, thereby increasing safety parameters.”

The LOC 250, Huisman’s first highly mobile rig, is a containerized rig, meaning that all elements of the rig fit into standard ISO containers, and has casing-while-drilling capabilities. Since introducing the LOC 250 in 2005, the company has upgraded its design to include AC drive, a higher hookload and an expanded mud system, and the LOC 400 was introduced in 2009. The next generation of the LOC 400, to be introduced in late 2012 or early 2013, will feature a higher level of automation, even quicker rig moves and enhanced skidding capabilities.

“We’re conducting a study on rig moves, finding the weak links and engineering the process to improve it, and preparing recommendations for field personnel to accomplish rig moves quicker,” Mr Quinlan said.

Increased rig safety features desired by operators have brought about another benefit – a reduction in the number of crews needed to run the rig. “The more features you have, such as self-erecting masts, self-erecting substructures and highly mobile components, the less the risk of accidents related to these activities. In Herrenknecht Vertical’s case, a high level of automation, together with the concept of mobility, eliminates almost all of the dangerous jobs on the rig,” Mr Janowski explained. “The number of people involved in tripping pipe in and out is limited to two persons.”

The Drillmec HH Series rig advanced automation concept requires few crew members as well. The concept “allows it to perform most of the routine drilling operations, including tripping in and out the drill string, with an almost unmanned drill floor where worker presence is basically limited to thread doping and handling the bottomhole assembly,” Mr Pereira said. “No one is exposed to direct contact with rotating tubulars, tongs and wrenches or to falling objects.”

“With the latest Atlas Copco rig, the Predator, we’ve got it down to the minimum amount where we can have three people operating a rig as opposed to the six or seven people that would be on a conventional rig,” Mr Grant said.

With Herrenknecht Vertical’s Terra Invader rig, only two people are involved in tripping pipe in and out. The rig came onto the work scene in a geothermal application in Germany in 2006, just one year after the company was established. This rig, which has a box-on-box substructure, is tailored to the Western European market, where cranes are readily available.

“The design criteria are different in that the situation regarding cranes and heavy trucks in Europe is slightly different from the rest of the world,” Mr Janowski noted. “It’s cheaper to install a crane because it’s available and you can rig-up in two days with a crane.”

“There has always been a demand for high mobility in this industry, but the higher the costs are for drilling and transportation, the higher the demand to make the equipment more mobile than before,” Mr Janowski noted. According to him, exploration drilling in remote places, on artificial islands, in the Brazilian Amazonas region and in Siberia has prompted the increased demand for highly mobile units. Crane and truck load capacities are limited. Cost levels are quite high, and the need to reduce crew cost is an issue.

An economic boost has been a huge plus for operators choosing highly mobile rigs. In addition to the shale plays in North America, key markets are North Africa and the Middle East. “In the Middle East, you have only to drill 700 to 900 meters (2,297 to 2,953 ft) to access resources. Drilling takes only five or six days,” Mr Janowski commented. “There must be a relation between the drilling time and the moving time. When you drill five days, no one would accept a rig move time of five days.”

“It is not just the rig design that enables high portability,” Mr Quinlan remarked. “The contractor must also have the right procedures and systems in place and have a dedicated rig-moving team that knows the rig and how to move it. It’s no use having a rig that can move in two days and be waiting for trucks for three days before it can move.”

“With the Huisman LOC rigs, we wanted a rig that could be moved anywhere on the planet with the same ease as moving a few miles on the road. In this regard, we have been very successful. To move the LOC rigs overseas is very cost effective and can be cheaper than rig moves over land.”

Also regarding improved economics, Mr Grant pointed out that “in addition to the rig’s ability to be broken down into manageable pieces that can be rolled down the road to the next site, the pieces are smaller and the capital outlay is a lot less to achieve the same result as that achieved by drilling with a conventional rig. We run less crew; staff overhead is a lot less. Ultimately, if you’re going for the shallower stuff, the overall cost of ownership is a lot less … roughly two-thirds of the cost of a big conventional rig.”

Rig manufacturers believe there is savings to be realized from use of a highly mobile rig to drill the top-hole section when an operator is targeting deeper reserves. The conventional rig doesn’t need to stay on-site as long. There’s also savings to be realized from reducing nonproductive time.

“It’s about decreasing nonproductive time and increasing safety,” Mr Pereira remarked. “The correct application of a fast-moving or portable rig can save the operator days in mobilization and demobilization between wells. Depending on the distance to the next well location, the Drillmec HH Series rig can be ready for drilling within 72 hours. A well-trained crew can do it in less than 48 hours.”

According to Drillmec, one of its expanded rig capabilities as a result of the design was for the rig to become an integral part of the substructure. “We figured, wouldn’t it be great if you could run the hydraulics of the substructure from the rig itself and offer connections on the substructure to quickly connect an air or mud pump system and reduce the downtime for setup,” Mr Grant said. “The other part was to have the pipe-handling on the back of that.” The Drillmec rigs have the main rig components fused to the specially designed trailer.

With Atlas Copco, Mr Grant said they’re expanding the operational ability of their highly mobile rigs by taking manual labor out of the scenario where possible. For example, “with the Predator rig, the driller has the more accurate ability to dial-in to a computer what he is trying to accomplish; for instance, establish weight on bit by dialing it in,” Mr Grant said. “Before, the driller had to watch the pressure gauge and dial-in weight-on-bit information as the formation changed.”

Highly mobile rigs are meeting diverse global drilling requirements as well. Drillmec’s HH Series rigs are currently operating in shale plays in North America, in the deserts of Egypt and the Middle East, in remote locations in Peru, Colombia, Venezuela and Australia, as well as in geothermal projects in Iceland and Chile. Further, the company recently announced the sale of 25 hydraulic rigs, with an option for an additional 125 rigs, to Chinese drilling company Greka Drilling. The units will work in CBM and shale-gas applications in China’s Shanxi Province.

Huisman’s LOC rigs have drilled oil, gas and geothermal wells in the US and Europe. Although the LOC rigs were designed for onshore drilling, the company has developed a concept and performed basic engineering on a LOC rig for offshore application.

“We have worked on a very interesting concept for using our LOC rig as a modular platform rig with a unique installation procedure onto the platform. This solution would see platform installation in a few days as compared with the several weeks required for similar modular rigs,” Mr Quinlan said.

In addition to shallow-resource development, Atlas Copco has found success using its highly mobile units to do top-hole drilling and set the casing so that conventional double or triple rigs can go in later to drill the deeper sections.

“We can use a top head drive to push the head down onto the drill bit to create weight on bit,” Mr Grant said. “The conventional rigs are not top head drive; they’re relying on collars and sticks of steel to give them weight on bit, making it harder there at the top of the hole.”

As operators expand their search for resources across the globe, rig manufacturers are keeping pace, delivering innovations in operation and transportability.

With more advances already on the drawing board, rig manufacturers are confident that the next generation of highly mobile rigs will continue to meet operator expectations.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Annular BOP: A Bop with a full opening elastomer element that has the ability to seal on virtually any shape, as well as seal on itself in and emergency situation.

Balance Point: This term refers to the condition during a trip in or out of the hole where the pipe weight and the lift force exerted by the well acting on the cross-sectional area of the pipe being tripped is at or near equal.

BHA: Bottom hole assembly. Describes the production or workover tools used for completion or workover operations. (i.e. packers, bridge plugs, fishing tools, etc).

BOP stack: A series of blow out preventers stacked together using an equalizing and bleed of spool. Stack normally consists of an annular; equalize spool and a set of stripping rams. In snubbing operations the BOP stack is considered a secondary BOP. When working in conjunction with a workover, service or drilling rig the rig supplies the primary BOP’s.

Counter Balance Winches: A winch that can hydraulically counter balance the weight it is picking up. This gives the winch the ability to automatically feed off should the load placed upon it become greater than the actual weight being held via the hydraulics. Typically the snubbing unit will have two of these winches.

Equalize line: High pressure line pipe, chick sans (swivels) and valves for use during a snubbing operation to equalize or bleed off pressures within different chambers in a snubbing BOP stack.

Equalize spool: A ported spool for use in a snubbing operations allowing the operator the ability to equalize or bleed off certain sections of the BOP stack.

Gas well snubbing: Workover or completion work on a gas well which is either live or underbalanced with a rig assist or self-contained snubbing unit. Many gas well formations are fluid sensitive making a snubbing operation ideal for maximum production of the well. Eliminates the need for expensive kill fluids.

Guide Tube: Any arrangement of support system that prevents columnar buckling of the pipe being snubbed. Typical arrangements can be telescopic or static depending on the design of the snubbing unit structure.

Hydraulic Workover Unit: A unit that competes directly with conventional work over rigs. By utilizing hydraulic cylinders instead of a traditional draw-works arrangement, the unit maintains a small footprint allowing rig up in tight areas such as on offshore platforms.

Live well completions: A well condition where tubulars and tools are pulled or inserted into a well with the use of a rig assist snubbing unit or self-contained snubbing unit. The well has surface pressure from the down hole formations. Wells can be either gas or oil.

Live well workovers: Describes the condition of a gas or oil well is in when tubulars are snubbed in or out of well. There is pressure at surface in these wells making them ideal candidates for snubbing operations.

Lower snubbing basket: The work floor area which allows access to the snubbing crew to the BOP stack components and stationary snubbing and heavy slips.

Passive Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary must be driven with an external force be it by hand or with a power swivel rigged above the unit.

Pipe Heavy: In regards to snubbing, this is a pipe condition in which the tubing has sufficient string weight to overcome the forces acting on its cross-sectional area. Once the weight is sufficient, it overcomes the force applied by the pressure in the well and will fall under its own weight into the well.

Pipe Light: In regards to snubbing, this term describes the condition when the well bore forces acting on the cross-sectional area of the pipe being snubbed are greater than string weight; if tubing is not controlled, the snubbing unit will eject itself from the well.

Power-Pack: This is the prime mover that provides the force needed to turn hydraulic pumps which allow the operation of the snubbing jack and BOP systems. Diesel engines are the most common form, although electric drives are also utilized in special circumstances.

Powered Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary is driven with hydraulic motors, allowing the unit to perform string rotation without external support equipment.

Rig assist snubbing: A mobile snubbing unit, either truck-mounted or skid-mounted, that works in conjunction with a workover, service or drilling rig for workover or completions work on a live well or underbalanced well. Unit is capable of running or pulling tubulars and tools under pressure.

Scalloped spool: A spacer spool modified for snubbing to allow well bore pressures to equalize or bleed off around the tubing hanger when landing or pulling the hanger.

Self contained snubbing:A snubbing unit which stands alone by itself with no need of a service, workover or drilling rig. A self-contained unit is capable of workover or completion work on a live well or underbalanced well or indirect.

Snubbing: A procedure in which tubing is run or pulled from a well, which is in an underbalanced or live well condition. Snubbing units have specialized pressure control devices which permit them to deliver drilling, completion and workover services while there is pressure in the wellbore. Snubbing units eliminate the need to neutralize well pressure prior to servicing and therefore avoid the formation damage which neutralizing pressure can have on a well’s ability to produce.

Snubbing Assistant: This person’s position is primarily focused on taking direction from the snubbing operator, and entails routine maintenance, pipe handling and power tong operation.

Snubbing jack: The structure of the unit designed to withstand engineered ratings for both the pipe weight and the force applied by the unit’s hydraulic cylinders. The hydraulically operated equipment which enables crews to work on underbalanced or live well.

Snubbing Operator:Equivalent to a driller position, the snubbing operator physically operates the snubbing unit and takes direction from the snubbing supervisor. The operator is responsible for managing the daily activities of the rest of the snubbing crew, and ensuring that the equipment is functioning as designed.

Snubbing slips: A set of hydraulically actuated slips which can be run either inverted or right side up to control the movements of pipe in conjunction with a snubbing jack to insert or extract tubulars under live well or underbalanced conditions.

Snubbing Supervisor:Equivalent to a rig manager or tool push, the snubbing supervisor is responsible for all aspects of the snubbing unit and its operations. He/she is the direct liaison to the oil company representative he/she is working for. All members of the snubbing crew are subordinate to the snubbing supervisor. Typically the supervisor will have in excess of 10 years’ experience in snubbing operations.

Snubbing unit: A hydraulically actuated unit with slips, BOP stack and hydraulic jack for inserting or pulling tubing and BHA’s from underbalanced or live well conditions.

Staging tubing: Is the process of moving tubing into or out of a live or underbalanced well by using different sections of the BOP stack to insert or extract tubing connections or larger diameter tool assemblies. I.e. annular and a set of stripping pipe rams or two sets of stripping rams. The preventers are closed and opened in sequence allowing for tubing connections or larger diameter tools to be staged in with at least one preventer being closed to contain well bore pressures.

Stand alone snubbing (see self contained unit): Use of a snubbing unit by itself without the aid of a service, workover or drilling rig. Unit is capable of workover or completion work on a live well or underbalanced well.

Stationary snubbing slips: A set of snubbing slips that are typically mounted on top of a BOP stack which will hold pipe that is in a pipe light or neutral state.

Stripping: : During snubbing operations this is the procedure where you move pipe through a closed preventer (pipe rams or annular) on a live or underbalanced well containing pressure from the well bore with a closed preventer.

Stripping on: : The procedure in which a snubbing unit is rigged onto a service, workover or drilling rig, which is holding the pipe heavy tubing string with their tubing slips and not with a tubing hanger landed.

Stripping Ram: A hydraulically operated ram style BOP used during snubbing and stripping operations. Typically the ram front insert is a sacrificial material that is easily replaced for extended stripping. Materials for the inserts can be custom ordered for the application at hand.

TEP: A type of tubing plug developed for snubbing to control well bore pressures inside the tubing. Only viable for snubbing in operations. The plug is a machined collar with a removable disc and “o” ring. Once the tubing string has been snubbed in, the disc can be knocked out by equalizing the tubing string and flowing the casing. Once an overbalanced condition has been achieved inside the tubing string, the disc will fall out. Disc may also be removed by sand line or wire line tapping down on the disc once tubing string has been equalized with casing pressures.

Traveling plate: The plate which connects the rods from the hydraulic cylinders together on a snubbing unit where the traveling and heavy slips are attached. There are many cylinder configurations and stroke lengths possible depending on job requirements.

Traveling snubbing slips: A set of slips mounted upside down on a snubbing jacks traveling plate, which controls the movement of tubing in or out of a well. Slips will hold tubing only when tubing is in the pipe light state.

Underbalanced:A term to describe the pressure conditions in a well. Formation pressure is greater than the hydrostatic pressure of fluid, mud, etc… exerted on the formation causing pressure to migrate to surface in a well. A well in an underbalanced state is a prime candidate for snubbing.

Underbalanced completions: The condition of a well when completion services such as snubbing are performed. Formation pressure is greater than the hydrostatic pressure inside the well bore causing pressure to be at surface in the well. Underbalanced completions are prime candidates for snubbing. Typically wells have been perforated before snubbing unit arrives and the unit snubs in a production string to allow the well to be produced.

Underbalanced drilling: This term describes the condition of the well when drilling operations are ongoing. Snubbing units are used to snub out drill strings, i.e. bit changes and then snub in the drill string again or run productions strings.

Underbalanced workovers: The well is live with pressure to surface when workover operations are performed. Rig assist snubbing or self-contained snubbing units are used for the running or pulling of tubulars and BHA’s. Typically the snubbing unit pulls pipe from the well, the original zone is worked over, abandoned, or a new zone perforated and the snubbing unit snubs the production string back into the well.

Well control:In regards to snubbing, well control is the operation of containing well bore pressure with the use of a blowout preventer stack and tubing pressure by the use of a plugging system.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The work on the drilling floor of the PaceR801 rig revolves around a stout robot methodically picking up sections of pipe and moving them precisely over the drilling center to rapidly connect the pipe.

While it is one of many technological advances on the rig Nabors bills as “the world’s first fully automated land rig,” the robot is the one “that gets most people interested and excited,” said Travis Purvis, senior vice president, global operations for Nabors Industries Ltd.

As of 18 October, the PaceR801 had completed the first well on an ExxonMobil pad and was drilling the lateral on the second well of the three-well pad. After the third is done, the extended test will move to the next pad.

It is risky to announce who came in first in a competitive race in a secretive business. But Nabors stands out because the PaceR801 has an automated drilling floor, a range of other automated functions above and below ground, and most significantly, it is the only one using its rig to drill producing wells for a customer.

Jason Gahr, operations manager for unconventional drilling at ExxonMobil, said the research collaboration “demonstrates the ability to optimize drilling using the combined power of robotics, automation, computing, and data.”

The companies’ interests range from automating more drilling functions by retrofitting rigs, to wanting to hire the rig, whose name is frequently shortened in conversations to R801.

There is only one PaceR801 and it is going to be tied up for a while. “We expect to drill multiple test wells on multiple pads and continue to work on the technology” with ExxonMobil, Purvis said.

It was created to show off the fruits of a 5-year drive to create a totally automated version of its Pace high-specification rig. Nabors likens it to the concept cars built by automakers to show off their vision of the future and to promote innovation within the company.

In this case, it is a vision of the near future. While the automated drilling floor is new, much of the rest is recently proven technology. Two of the drilling automation programs used—Nabors’ SmartSLIDE and SmartNAV—are already on 30% of the Nabors fleet, said Austin Groover, director of operations for smart products at Nabors. Those applications, which manage drilling of the curve and directional drilling, plus a third that automates drilling a stand of pipe, SmartDRILL, have been used by ExxonMobil for 2 years.

Maximizing the performance of a rig with multiple proven technologies plus a new one such as a robotic drilling floor required developing a system that coordinates the movements of those apps and the rig hardware while drilling.

“There is a human in the driller’s cabin turning the system on and hitting ‘play.’ From that point, the system is doing all the orchestrating,” Groover said. This mechanical symphony is conducted by a program called the “sequencing engine.”

A rig floor video would show the robot reaching over to pick up the next piece of hardware—normally a 45-ft segment of pipe that had been measured and its threads doped previously by the system. The arm then moves it over the well center and holds it vertically in place while other machines recognize the thread pattern and spin the pipe to connect it with the right level of torque. Then another application takes over to lower the drillstring to the bottom and resume drilling according to ExxonMobil’s specifications.

The number of steps actually required is far greater than one wordy, oversimplified paragraph can express. ExxonMobil is now working with Nabors to see if the innovation will translate into improved performance.

Speed is an obvious, required measure of performance. Better-executed well plans are also a goal, but that is much more difficult to measure, as is the impact of hole quality on future production.

Occidental Petroleum’s goal for automation is to “capture knowledge,” said John Willis, vice president for drilling and completions for onshore and carbon sequestration for Occidental, in in his keynote address at the recent IADC Advanced Rig Technology Conference (ART) covered by the IADC Drilling Contractor.

Willis was referring to capturing the most efficient way of doing a task in the control system so that a lower-skilled driller could perform at the same level as a more highly skilled driller by relying on automation to apply the lessons learned to drill a well faster and better.

The industry has been working toward this point for more than a decade. Work on Nabors’ drilling floor robot dates to 2008 when Equinor initially funded a Norwegian startup, Robotic Drilling Systems AS. Nabors acquired it in 2017 after the equipment was evaluated

8613371530291

8613371530291