tripping pipe on a workover rig pricelist

are prominent in every aspect of drilling the well, manual handling of tubular and tools, making up or breaking out during making connections or tripping pipe. The position is responsible for the processes ...

of the Floorhand include: Ensure the Rig is kept clean and tidy; housekeeping activities on and about the rig including cleaning, washing, chipping, painting, and garbage disposal Always keep all stairs ...

This job role will oversee the inspection, maintenance and repair of equipment implementing company procedures. The Floorhand will also assist all operational activities around the rig floor, or any other ...

and Accountabilities Works in a safe, healthy, and environmentally protective manner Assists Driller, Derrickhand, & Motorhand, while rigging-up, nippling-up, tearing out, & rig maintenance while drilling ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Crew Pusher and/or TRS Lead in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated by ...

of the Floorhand include: Assisting the Derrickhand, Motorhand and Driller on the drill floor while making trips; Operating manual tongs and slips to connect and disconnect drilling pipe and drilling ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

including maintenance and repair of rig equipment, and he/she is a general all-around worker on the rig. The normal workstation of a Floor Hand is the rig floor. There are usually two Floor Hands on a ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

The Driller is responsible for ensuring that the work in and around the drill floor and BOP as well as the rig up and rig down procedures and the drilling operations occurs in a safe and effective manner ...

and decisive manner. Other duties asrequired by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations ...

and decisive manner. Other duties asrequired by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations ...

and decisive manner Working above the drilling floor, on the monkey board, guiding the drill pipe during the tripping-in/tripping-out process, ensuring to wear proper safety equipment. Other ...

and decisive manner Working above the drilling floor, on the monkey board, guiding the drill pipe during the tripping-in/tripping-out process, ensuring to wear proper safety equipment. Other ...

and decisive manner Working above the drilling floor, on the monkey board, guiding the drill pipe during the tripping-in/tripping-out process, ensuring to wear proper safety equipment. Other ...

Operate and perform first line maintenance on rig floor drilling equipment Maintain drilling equipment, tubulars, handling equipment etc as per rig specific procedure Examine all safety equipment on the ...

Company Overview Nabors is a leading provider of advanced technology for the energy industry. With operations in about 20 countries, Nabors has established a global network of people, technology and equipment ...

May 27 (Reuters) - U.S. energy firms cut oil and natural gas rigs this week for the first time in 31 weeks, but the rig count rose for a record 22nd month in a row even.

Theweekly rig count decline comes as some U.S. publicly traded firms continue to focus more on returning money to shareholders and paying down debt rather than boosting output.

The U.S. oil and gas rig count, an early indicator of future output, fell by one to 727 in the week to May 27, energy services firm Baker Hughes Co said in its closely followed report on Friday. , ,

For the month, the oil rig count rose for a record 21 months in a row, while the gas rig count was up for a ninth month in a row, the most since May 2017.

Even though the rig count has climbed every month since August 2020, weekly increases have mostly been in single digits and oil production is still below pre-pandemic record levels as many companies focus more on returning money to investors and paying down debt rather than boosting output.

Since Moscow invaded Ukraine on Feb. 24, the U.S. government has urged drillers to produce more oil and gas to reduce domestic prices and help allies break their dependence on Russia energy.

U.S. crude production was on track to rise from 11.2 million barrels per day (bpd) in 2021 to 11.9 million bpd in 2022 and 12.9 million bpd in 2023, according to federal energy data. That compares with a record 12.3 million bpd in 2019. read more

But with oil prices up about 53% so far this year after soaring 55% in 2021, a growing number of energy firms said they plan to boost spending for a second year in a row in 2022 after cutting drilling and completion expenditures in 2019 and 2020.

The Attorneys at Spurgeon Law Firm know what it’s like to spend countless hours tripping pipe on a drilling rig. Stephen and Sam both have experience working on drilling rigs where they have roughnecked on Kelly and rotary drilling rigs.

Running in the hole or pulling out of the hole (aka tripping pipe) is one of the most labor intensive job tasks a worker will engage in while on a drilling rig. Long hours of throwing the slips in, breaking or making connections, and racking back stands of pipe in the derrick is mentally and physically exhausting whereby your brain will start to populate abnormal thoughts. Your mind will start to drift due to fatigue and exhaustion and thus cause you to lose focus on the job at hand. Because of this, people are more susceptible of making mistakes, which in turn will cause injury to themselves or someone else. This is why it is imperative that companies have adequate personnel on the job and to allow that personnel to take breaks as needed. Your safety should be priority and always put your health first and the company’s profit second.

All oilfield workers have the right to work in a safe environment. The oilfield is governed by rules, laws, and guidelines to keep workers safe. However, these rules and laws are not always followed and often lead to serious injury. If you have sustained injuries in the oilfield contact our experienced oilfield lawyers at 318-224-2222. Attorneys, Stephen and Sam, have both worked in the oilfield and know the ins and outs. Prior to becoming an attorney, Stephen worked offshore as a Petroleum Engineer gaining valuable experience which he uses to get his clients maximum compensation. Their experience can make the difference when it comes to getting the payment you deserve. Contact Spurgeon Law Firm today for a free consultation.

Please make sure your browser supports JavaScript and cookies and that you are not blocking them from loading. For more information you can review our Terms of Service and Cookie Policy.

Drilling and completion technologies have helped US shale plays to gain more attention than even a few years ago. Vertical wells used to be the name of the game in some oil-rich areas such as the Niobrara shale in the Denver-Julesberg basin in parts of Colorado, Wyoming, Kansas and Nebraska. Very few horizontal wells had been drilled in the Niobrara until a few years ago.

Drilling contractors have helped the boom by building fit-for-purpose rigs with enhanced drilling capabilities that reduce operational cycle times and costs. Rigs built for the Bakken are winterized, and most also have skidding capabilities for pad drilling. Better fracturing and completion techniques allow operators to drill longer horizontal laterals to optimally drain the formation without having to drill additional wells.

Unit Drilling Corp owns and operates 122 rigs and is active in virtually all US shale plays, from Haynesville, Barnett and Eagle Ford in Texas to the Woodford, Cana Woodford, and the Mississippi and the Marmaton plays in Oklahoma.

“The interesting thing about the Mississippi and Marmaton plays is that both are targeting shallow formations between 5,000 and 7,000 ft before going horizontal,” saidJohn Cromling, executive vice president for Unit Drilling. “That opens up a new area for another class of rigs, 1,000-hp rigs that are equipped for horizontal drilling.”

“Shale plays have progressed from vertical wells to highly deviated wells to horizontals, and horizontals with long laterals,” Mr Cromling said. “Drilling rigs evolved accordingly.”

He listed five key technologies that helped rigs to successfully drill the various shale plays, and each has helped to reduce operational cycle time and/or improve safety.

First is top drives. Second is larger and higher horsepower mud pumps, “because hydraulics are the key to drilling horizontal wells,” he explained. “The pre-eminent factor for drilling horizontal wells, much more so than the hookload of the derrick or drawworks horsepower, is hydraulic horsepower.”

The third technology is the mud system. “During horizontal drilling with high rates of penetration and with a large volume of solids being removed during the process, a good mud system is necessary to remove the solids,” Mr Cromling explained.

Another key area is the drillstring. “We are doing things with drillstrings now that we had been taught for 50 years not to do,” Mr Cromling said. “Pipe in compression, for example, and running heavy-weight pipe instead of drill collars and running it above the drill pipe.”

The fifth technology is skidding systems. “All of the shale plays are in the development process to some extent,” he said. “Most of the rigs in the Barnett shale can skid, and a lot of wells in the Bakken are at the development stage and they are drilled with rigs that can skid over multiple well pads.”

“It could take as little as three hours to prepare for the skidding operation and another three hours to restore the unit for drilling operations, while the actual move is usually less than one hour,” Mr Cromling said.

Other equipment that helps reduce operational cycle time includes a BOP handling system, which is critical for rigs that skid from wellhead to wellhead. The system picks up the BOP in a single unit from one wellhead, suspends it in the rig’s substructure while moving and then lowers it to the next well via hydraulic winches. “All of our skidding rigs have BOP handling systems, and it is a key factor in saving a lot of time in the preparation and restoration of the rig when skidding,” Mr Cromling explained.

Some operators also prefer the hydraulically operated catwalk, not necessarily because it saves time but because it eliminates third-party service and improves safety.

It’s interesting to note that most of Unit Drilling’s rigs do not incorporate cyber chairs with joystick controls. “We have some rigs with joysticks and a lot of rigs that do not,” Mr Cromling said. “Most of our newbuild rigs do not use joystick controls. Some people are convinced that if you don’t have a joystick your rig doesn’t have all of the new technology that is available,” he continued.

When asked if using a rig without a joystick is more of an operator preference, Mr Cromling said, “That is more my preference. I think our rigs drill just as fast and efficient” as rigs with joysticks and automatic drilling systems.”

Anadarko Petroleum’s total 2011 capital expenditures are expected to be between $6.2 and $6.6 billion, with about 10% allocated to US shale plays. In the Eagle Ford, the company increased its average estimated ultimate recoveries to more than 450,000 barrels of oil equivalent per existing well. Its 200-plus planned wells for 2011 also signify a doubling of drilling activities from 2010 levels.

In the Marcellus, Anadarko plans to operate 10 rigs and participate in more than 250 wells this year. “The Marcellus will continue to be the only domestic dry natural gas field where the company will be actively drilling due to the play’s proximity to premium natural gas markets that enhance already robust economics,” the company said in a news release.

“Anadarko had nine rigs operating in the Marcellus play as of late March,” said Steve Bosworth, vice president of worldwide drilling for Anadarko, “including one rig that spuds and air-drills the vertical section of the wells from a multi-well pad to the kick-off depth to begin drilling the horizontal lateral portion.”

The company said it will continue to invest in other emerging onshore oil plays, including Bone Spring, Avalon shale and Wolfcamp in the Permian Basin, and the horizontal Niobrara play. Anadarko was operating two rigs in the Niobrara in late March and expected to increase that to three rigs by early April. “We are drilling Niobrara wells on a limited basis at the moment,” Mr Bosworth said. “It’s still early in the evaluation, but we hope to be running six operated rigs there by the end of this year.”

Mr Bosworth is convinced that, even if some line items are higher in cost than other methods resulting in the same end, operators will always save money by reducing the operational cycle times. Anadarko looks for higher-quality, higher-technology rigs for its horizontal shale drilling programs.

“The reason we feel we do as well as we have on the operational end is by utilizing these higher-quality rigs,” Mr Bosworth explained. “We look for a rig that will not compromise safety, and in fact improve safety, while improving our operational cycle time.”

He said the automatic catwalk is a safety improvement and eliminates additional third-party service personnel on location. He has similar feelings about separate crews to run casing. “Basically we are connecting two pieces of pipe,” he said. “It should not be dramatically different for a rig crew to run casing versus having a third-party casing crew and timing the logistics of that crew to the rig.”

Anadarko has been able to eliminate having a third-party casing crew about 20% of the time, but Mr Bosworth believes that will increase not only for Anadarko but across the industry. In time, a rig crew running casing will become more proficient at it, he added.

Pad drilling has also brought operational and economic benefits by allowing the company to batch together certain operations and “make it more like a manufacturing process,” Mr Bosworth said. “We are trending toward operating rigs with skidding capabilities because they are becoming more important to us from an operational efficiency standpoint by moving from wellhead to wellhead in a matter of hours rather than days.”

Mr Bosworth is not convinced that all technology is necessary from an economic standpoint. For example, while some operators often use rotary steerable systems in horizontal shale plays, “we think we do well with conventional tools depending on the particular area,” he said.

On the other hand, Anadarko’s success with rotary steering is resulting in increased use, depending on the area. “We are very encouraged by the rotary steerable wells we drilled in the Eagle Ford,” he said. “About 10% of those wells are drilled with rotary steerables, and I think we will be at about 50% during the next month or two. If you really want to get the consistent, repeatable good results, you are going to have to do that with technology.”

Helmerich & Payne has been building FlexRigs since the late 1990s and the A/C drive FlexRig3 since 2002. Today, the company boasts a 100% utilization rate of more than 200 FlexRigs in its US fleet. Most of them are working in shales.

“From our perspective, for the shale and unconventional plays, the more complex directional and horizontal wells, you need to begin with a platform that is A/C variable-frequency drive,” said John Lindsay, H&P executive vice president and COO. “We believe those rigs are the most efficient in the industry from a drilling performance viewpoint.”

The company has about 50 FlexRigs in the Eagle Ford, 21 in the Bakken, 20 in the Cana Woodford in Oklahoma, 16 in Haynesville (down from 29 last year due to low natural gas prices), and 11 rigs in the Barnett (down from about 25 rigs at the peak, also due to lower gas prices).

The FlexRig design concept is better safety and efficiency. “There are significant time savings to be gained in addition to the drilling process that benefits from lean manufacturing concepts,” Mr Lindsay said. “Only about 30% to 40% of the total well cycle is drilling; other areas for improvement include running casing, BOP nipple up and down, tripping pipe and moving the rig.”

The industry is also working on systems that will use real-time downhole data, for example, to deliver better performance based on the well that is being drilled, Mr Lindsay said. “With unconventional plays, there is a much more focused approach on factory delivery. The industry is set up much better today to look at a factory approach to exploiting reserves, which is a continuous focus on high-performance drilling.

“There also are a lot of lean techniques that go along with that – fit-for-purpose lean technology that continues to drive down drilling times by driving waste out of the process,” he continued. “After all, that’s what we are doing – we are manufacturing a hole.”

About 450 of the approximately 1,700 rigs working onshore US are A/C drive rigs, Mr Lindsay noted, and H&P owns just over 40% of those 450 units. There are also more than 700 mechanical rigs working in the US today, and it is estimated that over 200 of those are drilling in unconventional shale plays. But he added, “It’s not a function of the (mechanical) rigs not being able to drill the well. It is a function of the rigs not being able to drill the well as efficiently and economically as an A/C drive rig.

“Drilling has become more complex,” he continued. “Several years ago only 30% of the rigs working in the US were drilling horizontal and directional wells. Today, it is a direct inverse of that, with over 70% of the rigs drilling horizontal and directional wells. And the horizontal laterals have increased in length an average of 30% to 50% over the past two years.”

Those factors are why A/C variable frequency drive (VFD) technology will continue to gain market share, Mr Lindsay believes. “A/C VFD technology has enabled the deployment of the first generation of true high-efficiency multi-parameter electronic drillers,” he said.

H&P is able to drill concurrently using multiple parameters such as weight-on-bit, torque, Delta P and rate of penetration compared with a traditional auto driller that controlled only weight-on-bit. “We are just scratching the surface of what these systems will be able to do in the future.”

Many of the company’s rigs can skid over multi-well pads, and it manufactures its own skid system rather than buying from a third party. The skid system for its onshore rigs was adapted from its bidirectional skidding system used for offshore platform rigs, and in 2006 the first FlexRig4S unit was introduced in the Piceance Basin in Colorado that was capable of drilling 22 wells on a single pad. Shale development programs typically use drilling pads with between three to 10 wellheads, and this same system is being used today in the Marcellus, Bakken, Barnett and Eagle Ford.

Brigham Exploration said it will increase its operated fleet to 12 rigs this year in the Williston Basin’s Bakken and Three Forks plays by adding a rig every month beginning after May, when an eighth rig joins the fleet of rigs Brigham operates. “Accelerating from eight to 12 operated rigs is anticipated to increase Brigham’s drilling pace by approximately 44 gross wells per year” when the 12-rig level is met, which is anticipated to occur by September 2012.

“We are going to drill about 11 gross wells per rig per year,” said Erik Hoover, operations manager for Brigham. That translates into about 100 wells during 2011 and increasing to about 130 wells in 2012.

“With oil prices the way they are, liquid-rich fields are king,” Mr Hoover said. “Some plays are liquid rich, but the Bakken is probably the only true oil resource shale play.”

All of Brigham’s rigs in the Bakken are Nabors rigs, and the operator recently contracted two newbuild Nabors B Series PACE rigs. “I think many of the future Williston Basin rigs will be newbuilds because we’re now in more of a manufacturing mode, and newer rigs will likely be able to ‘walk’ from location to location and therefore reduce drilling costs,” Mr Hoover said.

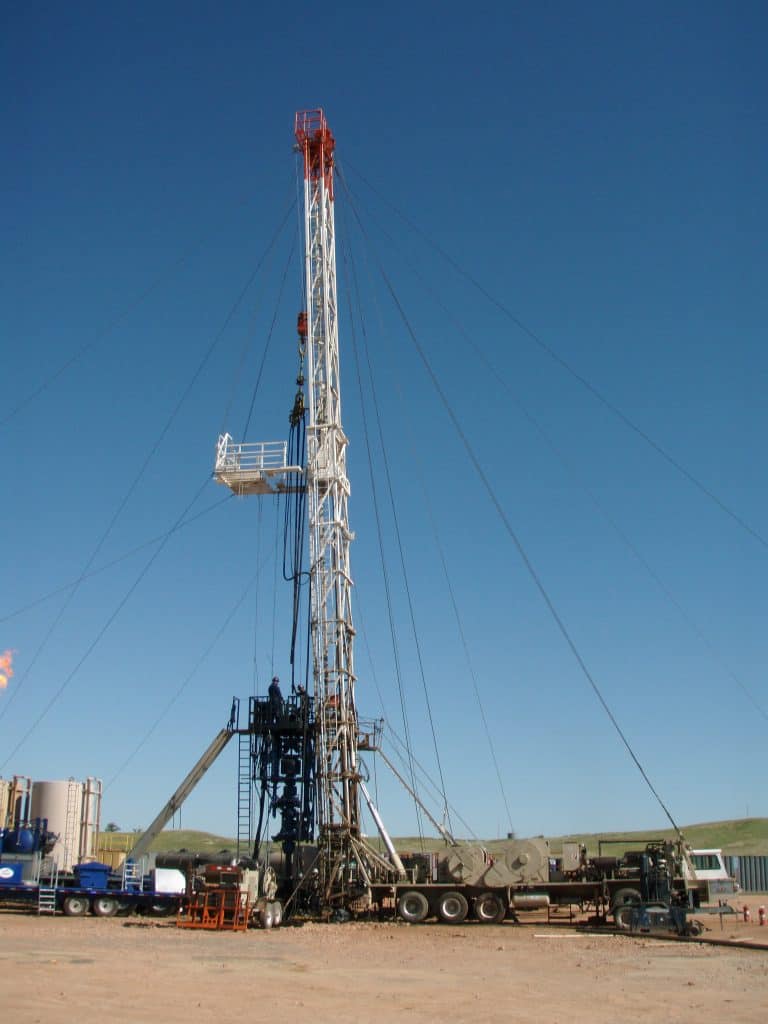

Nabors Drilling Rig 266 drilled Brigham Exploration’s Abelmann 23-14 #1H well in the Bakken Shale, which underlies Montana, North Dakota and parts of Canada. Initial production from this well was 4,169 bbl/day of oil equivalent with 33 frac stages. Nabors believes it holds the largest market share in the Bakken. Nabors photo courtesy of Jim Blecha Photography

Brigham’s wells average 17-23 days to TD, including a 10,000-ft vertical section and a 10,000-ft horizontal lateral. Three years ago, these wells took 30-35 days to drill.

Better drilling techniques account for some of the time reduction. For example, some operators who use oil-base mud in the lateral section are drilling 30-day wells. “We use oil-base mud in the intermediate section of our wells and brine water in the lateral,” Mr Hoover explained. “We typically set the bar at 20 days, but our record well was drilled in 14 days.

“With brine water we can drill up to 2,500 ft per day, but with oil-base mud we are lucky to get 1,000 to 1,200 ft per day,” he added. Most of the time, it would make sense that oil-base mud would result in a slicker downhole environment, reducing drilling time. However, when viscosity is added to the Bakken formation, it changes the drilling dynamics, Mr Hoover said. In some areas, oil-base mud is required where higher mud weights are necessary, but most of Brigham’s acreage is in normally pressured areas.

The rig and experienced drilling crews account for the faster drilling times as well. “Rigs are customized for the Williston Basin, and there are a few differentiators,” Mr Hoover noted. “One is an AC electric top drive drilling system, which is installed on virtually every Williston Basin newbuild rig.”

“New technologies and equipment on the rigs include BOP handling systems and automatic catwalks, which make these rigs more efficient,” Mr Hoover said. “There also are new drill bit technologies and directional drilling tool improvements.

“We’ve learned how to drill better, and that knowledge is combined with improved rig quality to contribute to fewer days drilling the well,” he added. “There also is a big push for safety, and some of the new technologies and equipment also increase safety on the rig.”

Nabors Drilling is active in numerous shale plays around the US and says it holds the largest market share in the Bakken shale, for which the company’s B Series PACE rig is designed. The B Series is essentially a winterized iteration of its 1,500-hp rigs for shales and conventional fields in warmer climates.

Nabors Drilling’s Rig 981, an SCR unit, drilled for Shell in the Marcellus, which underlies Ohio, West Virginia, Pennsylvania and New York. Nabors photo at right courtesy of Jim Blecha Photography

“The B series rigs with walking capability are well-suited for simultaneous operations when development drilling begins,” said Ronnie Witherspoon, senior vice president and general manager, Nabors Drilling Northern Division. “The rig can clear existing wellheads, and its skidding capability is conducive to pad layouts.”

Most new B Series units are delivered with Columbia substructure moving systems. Additionally, the rigs can be fitted with a moving system later if they are not delivered so equipped. The rigs are also equipped with technologies from CanRig, a Nabors company, including an automated catwalk, Torq-Matic floor wrench, a top drive drilling system with Soft Torque software to mitigate stick-slip and downhole vibration, and Rockit, a surface rotary steerable system that rotates the drillstring in horizontal wells to reduce downhole friction.

Nabors Rig 981, an SCR unit, is drilling a well for Shell in the Marcellus Shale. Ronnie Witherspoon, SVP and general manager for Nabors Drilling Northern Division, says the company is continuing efforts to enhance rigs, equipment and software for shale drilling. In plays such as the Marcellus, wells are often drilled in a manufacturing mode. Minimizing the number of days on a well and reducing costs are key considerations for operators, he said.

“All of our technology enhancements are geared toward optimizing drilling efficiencies while addressing the operator’s ultimate goal of minimizing the number of days on a well and shaving costs,” Mr Witherspoon said.

“When shale plays are in development, they will be in a manufacturing mode, so to speak, where well after well will be drilled from a multi-well pad,” he explained. “What we are trying to do with our rigs, equipment and software is to optimize the process and continue to drive down the number of days on a well.”

(Dow Jones) Rowan Cos.’s (RDC) fourth-quarter earnings fell 21% as the offshore drilling company reported lower contributions from discontinued operations and higher costs.

Rowan, which operates a fleet of high-specification shallow-water rigs, been transforming itself into a purely offshore driller with the help from proceeds from asset sales. In September, Rowan sold its fleet of land rigs to Ensign Energy Services Inc. (ESI.T, ESVIF) for $510 million. In May, Rowan sold its manufacturing arm LeTourneau Technologies for $1.1 billion to Joy Global Inc. (JOYG).

Rowan reported a profit of $45.1 million, or 36 cents a share, down from $57.3 million, or 45 cents a share, a year earlier. The latest period included 9 cents in income from discontinued operations, while the prior year include contributions of 17 cents. The latest period also included $3.5 million in employee separation related expenses.

Drilling a well is one the most exciting and challenging experiences for anyone involved in the oil industry. But, what happens after you drill and complete a well? You don"t just drill and leave the well alone producing oil until it dries out. Think of it like assembling a car, once someone buys the car they don"t just drive it until it"s broken, instead, every time the owner feels something is wrong with the car he takes it to the dealer to check it out. Thereby, just like a car, an oil well needs Maintenance.

Here"s when workover operations come into play. Every time a well has production problems it needs to be repaired. In this article you"re going to be reading about one particular problem in a well and what we did to solve it. If you"re a young professional in the oil industry and never had the chance to be present in a workover operation, I invite you to go through these lines, hoping they help you knowing a little more about this amazing and unpredictable world.

A few years ago, my rig team received information about the next oil well that we would be repairing. Just by reading the well"s name we immediately inferred that we were going to deal with a really old well. The job program indicated us that this well had a high water cut, this means that most of the production of the well was formation water. We needed to isolate the water producing sandstone in order to leave an upper sandstone open to production.

The well was originally drilled in the 70´s by a split drilling rig, this type of rig was used in the past for operations on shallow waters and it was not like a typical cantilever drilling barge. In this rig, the derrick was separated from the barge and it had to be armed above the foundation of the well. This type of foundation is known as Light Rig Mover foundation and it is formed by four heads with two piles each and a square metal frame 24’ x 24’ approximately. With this particular well, we recall that old saying that states: "Don’t judge a book just by its cover". Let’s move on to the seven steps

The first thing we do before working on any well is an inspection of the location before the rig move, this is very important to determine wheatear the barge can fit in the well location or not. During this well’s inspection we could see that both the well foundation and the wellhead were not in the best condition, but this was fixable and the job could be done, though it would be a real challenge. Finally, the rig was moved and positioned on the well location.

Before removing the christmas tree in order to install the BOPs, we had to secure the tubing by settling a safety valve in the upper landing nipple. In most cases we secure the well by installing a check valve in the tubing hanger, but this well did not have an extended neck hanger, instead it had a wrap around tubing hanger which made the use of slickline tools necessary. We always make a calibration trip before running anything else into a well. In this particular case the tubing string originally installed in the well was 2-7/8”, 6.5 lb/ft from surface to 11413’, and 2-3/8”, 4.7 lb/ft from 11413’ to the entry guide at 11706’. With a Baker Hughes FH Hydraulic packer at 11415’ and an Evolution R3 retrievable packer at 11697’, five gas lift mandrels, a 1.875” landing nipple at 11704’, a 2.313” landing nipple at 214’ and no sliding sleeves. We first ran a 1-27/32” gauge cutter to the bottom of the hole at 12211’ and then a 2-9/32” gauge cutter to 11413’ locating the crossover 2-7/8” x 2-3/8”. Then, before running the valve we ran a slickline tubing scratcher in order to guarantee a good setting of it. So, after a few trips, we installed the valve at 214’ and let the well secured to install de BOP and continue the operations with proper safety.

And then, the surprise began. Usually in a single packer completion we have to pull the string for several hours in order to release it, or in some cases, we must make an internal cut in the tubing with wireline tools, especially in old wells. But every time I have been involved so far in these cases with two packers, it was always necessary to make as many wireline internal cuts, as there are packers in the well completion: One cut above the upper packer and one between packers. Lucky for us, not this time; after only 25 klb of overpull both packers were released and we were able to retrieve the entire well completion joint by joint in a single tubing trip.

This saved us from all the fishing jobs, which in this type of wells is at least two fishing trips (without any complications) and perhaps a few milling trips if the tubing is somehow damaged by the wireline cutters, and this represent lots of saved rig time for the well. In general, the fishing operations take from 40% to 50% of the time needed to finish a workover job. The only thing we had to do was a quick calibration trip to 11945’ with a 4-5/8” tapered mill to guarantee a good operation in our next step.

Once we retrieve an old completion string from a well, we usually run a mechanical packer to make a casing integrity test, in this case we ran an Evolution R3 packer for 5-1/2”, 17-20 lbs/ft casing (not the same one that was retrieve from the original completion, obviously), down to 11645’, 20’ above the first perforated intervals. After successfully testing the casing, the following step was a wireline job.

The plan for this particular well was to isolate a sand formation with a high water cut, in order to start draining another sands from the same formation. This had to be accomplished by setting a bridge plug at 11930’ and also, placing 12’ of cement slurry above the plug with a dump bailer. As in the slickline jobs, we run a calibration trip before doing any wireline job, even though we had run a tapered mill before. After running a 4-9/32” gauge ring and a 3-1/8” junk basket, we ran the bridge plug with the wireline and activated the setting tool, letting the plug installed at 11930’. A final wireline trip was made in order to place the cement slurry above the plug with a Dump Bailer, this is a tool consisting of one or several cylindrical metal containers that are run in a wellbore to place small volumes of cement slurry or similar material. At the top of tool there is a hole through which the containers are filled with the material, the bottom of the tool is covered with a cap that will be removed with a small explosive charge once the tool is in position. In this well we coupled four containers into the well, placing the charge at the bottom and leaving the upper hole just above the rotary table. Then, we proceed to mix the cement slurry and filled the dump bailer, running it into the wellbore and detonating the charge at 11915’ leaving a volume of slurry enough to cover 12’ of a 5-1/2”, 20 lbs/ft casing.

As I stated before, this was a really old well, and the wellhead was pretty damaged and rusty. Hence, the next step for us was to replace the tubing head. This step required to remove the BOP, so it was necessary to run a mechanical packer along with an inside blowout preventer, setting the packer at 90’ to prevent the well from flowing uncontrollably while we worked on the wellhead. The tubing head size was 11” (bottom) x 7-1/16” (top), 5000 psi, and it was replaced with a new one with the same size and working pressure. However, this was not just removing one piece of wellhead and installing the new one, because once we started disassembling the bottom flange (11”, 5000 psi) we found that many of the bolts and nuts were highly corroded and it was impossible to remove them with the wrenches. Only 6 out of 12 bolts were removed with the wrenches, for the rest of them, we had to use a blowtorch equipment to cut and retrieve them. Finally, the new tubing head was in place, the BOP were reinstalled and we were ready for the final step of the job.

The last step of this workover job, after solving the bottom hole problem and replacing the wellhead, was to run the well completion. The equipment was ran down to 11402’ and it was composed by 368 joints of 2-7/8” 6.5 lbs/ft tubing, five gas lift mandrels, two 2.313” landing nipples, and a Weatherford Stratobar hydraulic packer, the completion was hanged in the new tubing head installed and then we performed the final slickline jobs to test the tubing string and set the hydraulic packer without any major complications.

This sums up our entire work on this well, leaving it ready for production. Yes, after more than 40 years of being originally drilled, this well is still capable of producing a very significant amount of crude oil. That’s how important workover operations are, if a well has the proper maintenance, its commercial life is longer and more productive. Besides, a workover operation is not as expensive as the drilling of a new well.

I think is only fair to say that each one of the steps I described include several activities that might need a little more detailed explanation to be completely understood, but it would be extending my writing too much. I also think it’s important to let readers know the reason why I decided to write about this particular well; if you look back in step 3, I said that the fishing activities take 40-50 % of the rig time needed to finish a workover job, the special thing about this well is that we didn’t required fishing activities since the original well completion was entirely retrieved just by pulling it out of the well. So, this is one of those cases when you get very, very lucky, and after a not quite good first impression we ended up successfully completing a job estimated to be done in 20 days in only 12.5 days, congrats for us!

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

The derrickman"s working platform. Double board, tribble board, fourable board; a monkey board located at a height in the derrick or mast equal to two, three, or four lengths of pipe respectively.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.†

8613371530291

8613371530291