what does a workover rig do pricelist

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

The commodity price downturn is prompting price reductions among well service contractors in the greater Rockies outside the Williston Basin. In mid-January 2015, service providers report rates down about 10% quarter-to-quarter, similar to reports elsewhere in the oil patch as operators push the service sector for cost reduction. Meanwhile, larger service providers worry about further rate cutting from local, privately-held contractors. Rate reductions have not yet translated to reduction in wages for hands, although expectations are that pricing is going to drop further on the basis of lower commodity prices.

Among Survey Participants:Rig Demand Down QTQ [See Question 1 on Statistical Review]. Seven of the eight respondents said that demand had dropped in 1Q15 vs 4Q14 and all but one blamed lower oil prices for the slowing. One respondent that had seen a slowdown in demand said it was because they had finished all of their completion work. The respondent who had not seen an effect on demand said that their work was steady, but they were hearing of others slowing down.Mid-Tier Well Service Manager: “We are seeing demand slow for rigs and prices are being reduced. Operators are asking for 20% reductions, some are asking for 30% and they may get it. The greater reductions will be from people who are local because they don"t have the overhead expense. The service won’t be as good. On average, operators may get 15% of that 30% they are seeking in reductions.”

Number of Rigs Sufficient [See Question 2 on Statistical Review]. Six of the eight respondents said that the workover rig inventory is excessive for the current demand, while two said that it is sufficient but tipping toward excessive.Mid-Tier Operator: “Operators here are basically focusing on the higher production wells and going to ignore the lower ones. We have heard companies are laying down workover rigs. One company is going from 17 to 13.”

Well Service Work Weighted Toward Standard Workovers and Routine Maintenance [See Question 3 on Statistical Review]. Among all respondents, standard workover work accounts for 34% on average, routine maintenance accounts for 34%, plug and abandonment (P&A) accounts for 16% and completion work accounts for 16%.Mid-Tier Well Service Manager: “Our work slowed because we finished our completion work so the client gave us some production work to keep us steady till we finish this fracking job.”

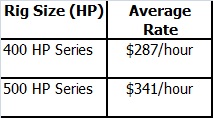

Hourly Rates Consistent Among HP Series [See Question 5 on Statistical Review]. Most workover rig horsepower falls within the range of the 500 series. The 500 HP hourly rates average $310 to $400/hour depending on what ancillary equipment is contracted. See Table II for Average Hourly Rates.

No New Competition [See Question 7 on Statistical Review]. All respondents said that competition had not increased QTQ, and they were not anticipating it would, given lower oil prices.Mid-Tier Well Service Manager: “We worry about the small local companies undercutting prices but we are not seeing anything now.”

2015 Rates Under Pressure [See Question 8 on Statistical Review]. Five of the eight respondents said 2015 would see further reductions in demand and hourly rates and even labor rates if the price of oil did not rise. One respondent said that “iron would start laying down” if oil prices did not rise. One respondent said he expects that work demand would come back up after a couple of months as everyone adjusted.Manager for Mid-Tier Well Service Company: “As a company, we have backed off our growth budget for 2015 and our capex has been nixed. We implemented a 10% reduction in our rates. We are just going to lower rates not wages, because we can buy equipment and leave it sit, but if you do that with people, they starve.”

Hart Energy researchers completed interviews with nine industry participants in the workover/well service segment in areas of the Rocky Mountains outside of the Bakken Shale play. Participants included one oil and gas operator and seven managers with well service companies. Interviews were conducted during January 2015.

3. Looking at your slate of well service work - on a percentage basis - how much of it is workover vs. routine maintenance vs. plug & abandonment (P&A) vs. completion work?

The Workover Rigs market will remain attractive over the forecast period owing to rising consumption of petroleum products. As a result, the Exploration and Production (E&P) located globally will increase their investment due to increasing demand and positive outlook of the oil and gas market.

The ongoing rise in oil prices can be regarded as new phase for the companies operating in the sector. Adding to this, the participants are looking to attain growth through domestic and international expansion as well as adding new production related services. As Workover Rigs providers play important role in the production operation making them key segment in the reviving upstream sector and hold massive share in the overall spending of the companies.

Moreover, the investment from government as well as private sector in the drilling activities is also expected to rise and surge in shale gas production is expected to fuel the growth of the Workover Rigs market in the coming years. The oversupply of Workover Rigs in the cyclical oil & gas market is one of the major restraint to the market.

However, the industry has recovered successfully from the recent oil price crisis and industry outlook will remain positive in the coming years. One of the major trend in the market will use of environment friendly Workover Rigs. The government authorities are directing energy companies to decrease carbon footprint that will shift the focus of the companies towards use of components that run renewable energy in the coming years.

Workover rigs are specialized oil rigs utilized in the process of pulling and replacing production to extend the life of the well. They are also called completion rigs or pulling units. They are used in various operations such as handling rod & tubing work and other associated activities to improve the well output and perform plug & abandonment services. Moreover, oil & gas companies have shifted to workover operations to increase their oil & gas output from mature oilfields. Workover rigs are preferred in onshore and offshore applications. They provide high mobility, which allows companies to move them across oilfields. The stability in oil prices is expected to increase the demand for workover rigs due to increase in production activities across the globe. The rise in demand for oil and natural gas is expected to propel the growth of the workover rigs market over the forecast period.

Oil & gas industries are adversely affected due to the coronavirus outbreak. With decrease in oil prices, many companies are facing financial crisis, which is one of the major factors that reduce the demand for workover rigs over the forecast period. Similarly, the worldwide lockdown has suspended travel privileges, thereby decreasing the fuel consumption across the globe. The lockdown has disrupted the supply chain and forced many companies to shut down their power plants to prevent the spread of the virus. This has further reduced the demand for workover rigs across the globe.

The workover rigs market is expected to grow vigorously due to rise in demand for oil and natural gas. Rise in population and rapid urbanization have increased the demand for these fuels. Increase in demand for oil and natural gas is expected to make companies to enhance oil and gas production to meet the demand. Moreover, increase in oil & gas investments and government support for oil & gas E&P activities are anticipated to increase the requirement for intervention and completion services. Rise in well E&P activities, such as intervention and completion, is expected to boost the growth of the workover rigs market during the forecast period. However, uncertainty and fluctuations in crude oil prices are expected to reduce investments in E&P projects, which, in turn, may impact the workover rigs market over the forecast period.

Digitalization of workover rigs is one of the major trends observed. Automated workover rigs provide better safety and higher precision in operations as they use remotely operated robotic equipment. Integrated software system provides precise data to the operators for future decision making. This technological advancement in the workover rigs market is expected to boost the market growth over the forecast period.

Furthermore, huge investment from government and other private companies to drilling activities is also expected to propel the workover rigs market over the forecast period.

By region, the global workover rigs market is segmented into North America, Latin America, Western Europe & Eastern Europe, Asia-Pacific, and the Middle East & Africa. The Middle East & Africa is expected to become the market leader during the forecast period. High investments and increased current production activities contribute to the market growth in the region. North America is also expected to grow, owing to its increased shale field activities,

Key benefits of the report:This study presents the analytical depiction of the workover rigs market along with the current trends and future estimations to determine the imminent investment pockets.

Key Market Players Mesa Southern Well Servicing, Sun Well Service, Inc., Nordic Gulf, Drillmec Drilling Technologies, Automated Rig Technologies Ltd, Moncla Companies, San Antonio International, Eastern Well Services, MBI Energy Services, Superior Energy Services

Oil rig equipment is expensive due to the size and operations carried out by such large machinery. Purchasing a newly constructed drill rig is a huge investment.

As such, you’ll want to be sure you have the right expectations before you begin searching for one to complete your assignment. This article will discuss just what a drill rig does and the estimated costs involved in the drilling process.

As one of the industry leaders, TAFS assists trucking companies to increase cash flow with some of the lowest factoring rates in the industry and 1-Hour Advance option.

When you need a machine powerful enough to bore through the earth’s crust to retrieve minerals, gas, or any other natural resources, a drill rig will get the job done. Each rig is designed for the environment they’re operating in and the product being extracted. Those two factors greatly affect the cost of the rig you’re looking to purchase.

A standard land rig with 1,500 to 1,700 horsepower will cost between $14 million and $25 million to own. An offshore oil rig cost is much higher, starting at $20 million and going as high as $1 billion. Owning your drill rig will save you money in the long run, especially when considering the daily cost of operations.

Your daily rate depends on the rig type, distance from shore, drilling depth, and water depth. Onshore drilling rates range from $200,000 to $310,000 each day. Offshore drilling can cost between $600,000 to $800,000 per day.

Several factors impact the oil rig cost, including construction, including materials, market conditions, equipment prices, and more. We’ll cover the basics, so you have a realistic expectation when searching for a rig price.

Cost and demand go hand-in-hand. When there is a high demand for building new rigs, the cost rises because a limited number of shipyards can provide the service.

For example, in the early 2000s, there wasn’t a demand for new rig construction, so rates were low. In the mid-2000s, demand increased, and prices rose, but after the 2008 recession, demand decreased. But the prices didn’t drop significantly as the recession wasn’t expected to last long.

The materials used in making a drill rig are a key component in construction costs. The material used most, steel, comes in various strengths, and the stronger the steel, the higher it’s priced. When steel prices are low, rigs will be cheaper to produce; when steel prices rise, so do the costs of the rigs.

Concrete is another material that will raise production costs. It’s often used in environments containing salt water as a way of avoiding corrosion and rusting. Concrete usually costs about 7% to 10% more than steel.

The cost of additional services needed for constructing wells will begin to add up. Phone bills and fees for transferring data are part of your communication cost. For those working offshore, rig positioning will be another fee.

The cementing equipment and engineer have to be paid for their services also. Other services are wire line logging, drilling measurement, mud engineering, downhole motors, mud logging, and surveying the hole.

There are two types of oil rigs, jackups, and floaters. Floaters aren’t attached to or resting on the seafloor. Jackups have support legs that allow the rig to be raised or lowered. Each type has different equipment to assist with the drilling process.

The engines, generators, cranes, and other oil rig components are purchased from a third party and assembled by the rig builder. Non-drilling related equipment is about 30% to 60% of the total cost.

Since most of the parts used are made from steel, the fluctuations in the steel market will influence the rig’s price. Demand for the additional equipment to fit on the rig will also play a part in costs.

Where your rig is built impacts the labor costs, which affect the price of the drill rig. It’s estimated that labor is 10% to 15% of the total cost of the rig is built internationally. While the U.S. and Korea have similar costs, Singapore charges three times less.

Each dollar spent on labor in the U.S. generates $3 in revenue, while in Singapore and South Korea, every dollar generates $7 to $10 in revenue. Since labor costs are typically lower internationally, the cost of your rig won’t be as high.

Always expect and prepare for the unexpected by setting aside a portion of the budget for allowances. Once you start drilling, you can’t be sure what you’re going to find, and variances in the geological structure could require different equipment and delay the process. Both of these instances will increase the cost of the rig being used.

Preparing an area for drilling can mean building roads to the site. These roads need to support heavy machinery and can take 15 to 20 days to build. Preparation also varies based on the environment.

Marshes, land, and offshore drilling all have their own preparation needs. It can take several weeks before drilling can begin, and each day spent getting the site ready comes with a hefty cost.

The drilling depth and well complexity are primary cost influencers. Once the drill rig is moved into position, it can take a team of 30 to 40 companies to complete the process. Costs can easily top $4 million during the drilling phase and take about three weeks to finish.

Positioning drilling rigs isn’t an easy task. It takes 3 to 5 days to move in and assemble a rig for well digging. Once the job is complete, the rig has to be disassembled and moved again. Rates hover between $100,000 and $350,000 depending on how far the rig is being transported.

The oil industry is very lucrative, and the machines used to drill for the resource are not cheap. Oil rigs are heavy-duty machines needed to reach extreme depths.

The harsh environments they’re in demand that they are built with the best materials available. If you need a drill rig, it’s important to keep in mind all the factors that contribute to the cost of the equipment so you can budget correctly.

Drilling a well is one the most exciting and challenging experiences for anyone involved in the oil industry. But, what happens after you drill and complete a well? You don"t just drill and leave the well alone producing oil until it dries out. Think of it like assembling a car, once someone buys the car they don"t just drive it until it"s broken, instead, every time the owner feels something is wrong with the car he takes it to the dealer to check it out. Thereby, just like a car, an oil well needs Maintenance.

Here"s when workover operations come into play. Every time a well has production problems it needs to be repaired. In this article you"re going to be reading about one particular problem in a well and what we did to solve it. If you"re a young professional in the oil industry and never had the chance to be present in a workover operation, I invite you to go through these lines, hoping they help you knowing a little more about this amazing and unpredictable world.

A few years ago, my rig team received information about the next oil well that we would be repairing. Just by reading the well"s name we immediately inferred that we were going to deal with a really old well. The job program indicated us that this well had a high water cut, this means that most of the production of the well was formation water. We needed to isolate the water producing sandstone in order to leave an upper sandstone open to production.

The well was originally drilled in the 70´s by a split drilling rig, this type of rig was used in the past for operations on shallow waters and it was not like a typical cantilever drilling barge. In this rig, the derrick was separated from the barge and it had to be armed above the foundation of the well. This type of foundation is known as Light Rig Mover foundation and it is formed by four heads with two piles each and a square metal frame 24’ x 24’ approximately. With this particular well, we recall that old saying that states: "Don’t judge a book just by its cover". Let’s move on to the seven steps

The first thing we do before working on any well is an inspection of the location before the rig move, this is very important to determine wheatear the barge can fit in the well location or not. During this well’s inspection we could see that both the well foundation and the wellhead were not in the best condition, but this was fixable and the job could be done, though it would be a real challenge. Finally, the rig was moved and positioned on the well location.

Before removing the christmas tree in order to install the BOPs, we had to secure the tubing by settling a safety valve in the upper landing nipple. In most cases we secure the well by installing a check valve in the tubing hanger, but this well did not have an extended neck hanger, instead it had a wrap around tubing hanger which made the use of slickline tools necessary. We always make a calibration trip before running anything else into a well. In this particular case the tubing string originally installed in the well was 2-7/8”, 6.5 lb/ft from surface to 11413’, and 2-3/8”, 4.7 lb/ft from 11413’ to the entry guide at 11706’. With a Baker Hughes FH Hydraulic packer at 11415’ and an Evolution R3 retrievable packer at 11697’, five gas lift mandrels, a 1.875” landing nipple at 11704’, a 2.313” landing nipple at 214’ and no sliding sleeves. We first ran a 1-27/32” gauge cutter to the bottom of the hole at 12211’ and then a 2-9/32” gauge cutter to 11413’ locating the crossover 2-7/8” x 2-3/8”. Then, before running the valve we ran a slickline tubing scratcher in order to guarantee a good setting of it. So, after a few trips, we installed the valve at 214’ and let the well secured to install de BOP and continue the operations with proper safety.

And then, the surprise began. Usually in a single packer completion we have to pull the string for several hours in order to release it, or in some cases, we must make an internal cut in the tubing with wireline tools, especially in old wells. But every time I have been involved so far in these cases with two packers, it was always necessary to make as many wireline internal cuts, as there are packers in the well completion: One cut above the upper packer and one between packers. Lucky for us, not this time; after only 25 klb of overpull both packers were released and we were able to retrieve the entire well completion joint by joint in a single tubing trip.

This saved us from all the fishing jobs, which in this type of wells is at least two fishing trips (without any complications) and perhaps a few milling trips if the tubing is somehow damaged by the wireline cutters, and this represent lots of saved rig time for the well. In general, the fishing operations take from 40% to 50% of the time needed to finish a workover job. The only thing we had to do was a quick calibration trip to 11945’ with a 4-5/8” tapered mill to guarantee a good operation in our next step.

Once we retrieve an old completion string from a well, we usually run a mechanical packer to make a casing integrity test, in this case we ran an Evolution R3 packer for 5-1/2”, 17-20 lbs/ft casing (not the same one that was retrieve from the original completion, obviously), down to 11645’, 20’ above the first perforated intervals. After successfully testing the casing, the following step was a wireline job.

The plan for this particular well was to isolate a sand formation with a high water cut, in order to start draining another sands from the same formation. This had to be accomplished by setting a bridge plug at 11930’ and also, placing 12’ of cement slurry above the plug with a dump bailer. As in the slickline jobs, we run a calibration trip before doing any wireline job, even though we had run a tapered mill before. After running a 4-9/32” gauge ring and a 3-1/8” junk basket, we ran the bridge plug with the wireline and activated the setting tool, letting the plug installed at 11930’. A final wireline trip was made in order to place the cement slurry above the plug with a Dump Bailer, this is a tool consisting of one or several cylindrical metal containers that are run in a wellbore to place small volumes of cement slurry or similar material. At the top of tool there is a hole through which the containers are filled with the material, the bottom of the tool is covered with a cap that will be removed with a small explosive charge once the tool is in position. In this well we coupled four containers into the well, placing the charge at the bottom and leaving the upper hole just above the rotary table. Then, we proceed to mix the cement slurry and filled the dump bailer, running it into the wellbore and detonating the charge at 11915’ leaving a volume of slurry enough to cover 12’ of a 5-1/2”, 20 lbs/ft casing.

As I stated before, this was a really old well, and the wellhead was pretty damaged and rusty. Hence, the next step for us was to replace the tubing head. This step required to remove the BOP, so it was necessary to run a mechanical packer along with an inside blowout preventer, setting the packer at 90’ to prevent the well from flowing uncontrollably while we worked on the wellhead. The tubing head size was 11” (bottom) x 7-1/16” (top), 5000 psi, and it was replaced with a new one with the same size and working pressure. However, this was not just removing one piece of wellhead and installing the new one, because once we started disassembling the bottom flange (11”, 5000 psi) we found that many of the bolts and nuts were highly corroded and it was impossible to remove them with the wrenches. Only 6 out of 12 bolts were removed with the wrenches, for the rest of them, we had to use a blowtorch equipment to cut and retrieve them. Finally, the new tubing head was in place, the BOP were reinstalled and we were ready for the final step of the job.

The last step of this workover job, after solving the bottom hole problem and replacing the wellhead, was to run the well completion. The equipment was ran down to 11402’ and it was composed by 368 joints of 2-7/8” 6.5 lbs/ft tubing, five gas lift mandrels, two 2.313” landing nipples, and a Weatherford Stratobar hydraulic packer, the completion was hanged in the new tubing head installed and then we performed the final slickline jobs to test the tubing string and set the hydraulic packer without any major complications.

This sums up our entire work on this well, leaving it ready for production. Yes, after more than 40 years of being originally drilled, this well is still capable of producing a very significant amount of crude oil. That’s how important workover operations are, if a well has the proper maintenance, its commercial life is longer and more productive. Besides, a workover operation is not as expensive as the drilling of a new well.

I think is only fair to say that each one of the steps I described include several activities that might need a little more detailed explanation to be completely understood, but it would be extending my writing too much. I also think it’s important to let readers know the reason why I decided to write about this particular well; if you look back in step 3, I said that the fishing activities take 40-50 % of the rig time needed to finish a workover job, the special thing about this well is that we didn’t required fishing activities since the original well completion was entirely retrieved just by pulling it out of the well. So, this is one of those cases when you get very, very lucky, and after a not quite good first impression we ended up successfully completing a job estimated to be done in 20 days in only 12.5 days, congrats for us!

Day rate refers to all in daily costs of renting a drilling rig. The operator of a drilling project pays a day rate to the drilling contractor who provides the rig, the drilling personnel and other incidentals. The oil companies and the drilling contractors usually agree on a flat fee per contract, so the day rate is determined by dividing the total value of the contract by the number of days in the contract.

Day rate (oil drilling) is a metric that investors in the oil and gas industry watch to evaluate the overall health of the industry. The day rate makes up roughly half the cost of an oil well. Of course, the price of oil is the most important metric by far in the oil and gas industry.

That said, investors can gain insights into the oil supply and demand picture by watching metrics like day rate and rig utilization in addition to global inventories. Day rate fluctuations, which can be wide, are used by investors as an indicator of the health of the drilling market. For example, if day rates fall, investors may take it as a sign to exit oil and gas positions.

Day rates can be used to assess the current demand for oil, ultimately gleaming insight into where oil prices are headed. An increase in the price of oil increases the number of projects that can recover their extraction costs, making difficult formations and unconventional oil reserves feasible to extract. The more projects greenlit on an economic basis, the more competition there is for the finite number of oil rigs available for rent – so the day rate rises. When oil prices waver and fall, the day rate that rigs can command drops.

As an example of actual day rates – Transocean signed a contract in December 2018 with Chevron to provide drilling services. The contract is for one rig, will span five years and is worth $830 million. The effective day rate for the rig is $455,000:

Like the day rate, the rig utilization rate is a key metric for determining the overall health of the oil and gas sector. The day rate lays out a large part of the costs of drilling a well, while the utilization rate is how many wells are being used.

Investors use both of these metrics and a fall in each could signal a slowdown in oil demand. High utilization rates mean a company is using a large part of its fleet, suggesting oil demand, and ultimately, oil prices are on the rise. There is a positive correlation between oil prices and both day rates and rig utilization.

The strength of the correlation between oil prices and day rates is not consistent. The correlation is strong when oil prices and rig utilization are both high. In this situation, day rates increase almost in lockstep with prices. In an environment of rising oil prices and high utilization, the day rates in a long-term contract will shoot up even faster than short term contracts as rig operators demand a premium for being locked in on a project.

In a low price environment with falling utilization, however, the day rate may plunge much faster than the oil prices as rigs enter low bids on long contracts just to keep busy in a potential slowdown. Due to the volatility and the varying strength of the correlation, investors and traders can flip between seeing day rates as a leading or a lagging indicator for oil prices and the health of the oil and gas industry as a whole.

By using this site, you are agreeing to security monitoring and auditing. For security purposes, and to ensure that the public service remains available to users, this government computer system employs programs to monitor network traffic to identify unauthorized attempts to upload or change information or to otherwise cause damage, including attempts to deny service to users.

Unauthorized attempts to upload information and/or change information on any portion of this site are strictly prohibited and are subject to prosecution under the Computer Fraud and Abuse Act of 1986 and the National Information Infrastructure Protection Act of 1996 (see Title 18 U.S.C. §§ 1001 and 1030).

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

If a user or application submits more than 10 requests per second, further requests from the IP address(es) may be limited for a brief period. Once the rate of requests has dropped below the threshold for 10 minutes, the user may resume accessing content on SEC.gov. This SEC practice is designed to limit excessive automated searches on SEC.gov and is not intended or expected to impact individuals browsing the SEC.gov website.

There are a number of problems that can develop in a producing well that can negatively affect operations, production and ultimately revenue generated, such as failure of mechanical equipment, changes in production characteristics, plugging and increases in injection pressure. After a well goes into production, these events may occur, requiring modification of the well in order to achieve optimal production; this is called well intervention.

Many times, at the slightest hint that there may be a problem with a producing well, well intervention solutions are sought. Should these problems be overlooked, the well may reach zero production over time. The problem within the well and the economics of the proposed solution are weighed in deciding how to solve the production problem.

Many times, remedial work constitutes employing a workover rig to repair the well. Similar to a drilling rig, a workover rig is smaller and requires no mud pumping or pressure-control systems. A workover rig is used to retrieve the sucker rod string, pump or production tubing from the well or run wireline cleaning and repair equipment into the well. It is important to note that with workover activities, production must be stopped and the pressure in the reservoir contained, a process known as �killing� the well.

A cost- and time-effective solution for well intervention operations employs coiled tubing. Instead of removing the tubing from the well, which is how workover rigs fix the problem, coiled tubing is inserted into the tubing against the pressure of the well and during production.

The coiled tubing is a continuous length of steel or composite tubing that is flexible enough to be wound on a large reel for transportation. The coiled tubing unit is composed of a reel with the coiled tubing, an injector, control console, power supply and well-control stack. The coiled tubing is injected into the existing production string, unwound from the reel and inserted into the well.

Coiled tubing is chosen over conventional straight tubing because conventional tubing has to be screwed together. Additionally, coiled tubing does not require a workover rig. Because coiled tubing is inserted into the well while production is ongoing, it is also a cost-effective choice and can be used on high-pressure wells.

All performed on a live well, there are a number of well intervention operations that can be achieved via coiled tubing. These include cleanout and perforating the wellbore, as well as retrieving and replacing damaged equipment.

Additionally, some advances in coiled tubing allow for real-time downhole measurements that can be used in logging operations and wellbore treatments. Enhanced Oil Recovery (EOR) processes, such as hydraulic and acid fracturing, can also be performed using coiled tubing. Furthermore, sand control and cementing operations can be performed via coiled tubing.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time d94a2288d76f819e65e1cc71545d07c7 63.210.148.230 10/25/2022 10:41 AM UTC

Drilling calls for complex, carefully engineered equipment — and inevitably this equipment can wear down over time and require replacement. That’s where a workover rig comes in. Workovers are among the most expensive and complicated tasks in the drilling industry, so here are a few things you should understand about them.

A workover is a complex maintenance task that involves pulling completion hardware out of a well in order to extend the life of the well. A workover rig is a specially designed rig that makes it easier to take out or insert tubing into a well.

To complete a well servicing, the well is first killed. This halts the flow of fluids in the reservoir. The wellhead and flow line will then be removed and the completion hardware will begin to be pulled out of the well using the workover rig. Replacement parts will then be lowered into the hole accordingly.

Because workovers are involved in time-consuming processes, through-tubing workovers might be initiated, which can occur without forcing teams to kill a well and do a full well servicing. This might be considered first before deciding on a full well servicing.

A workover rig is needed when a well is no longer suitable for the drilling job it was originally built for. Maybe the production tubing has incurred damage over time or downhole tubing has stopped functioning correctly. Or perhaps the contents of the reservoir that the tubing is drawing from has changed and requires adjusted tubular components. In any case, the well is unable to perform efficiently and could even compromise the safety of those working on the well. At that point, its components must be replaced and a workover rig must be constructed.

You always want your well to perform to expectations. Katch Kan can help thanks to our zero-spill installation system, which ensures your well servicing operations will proceed safely and efficiently. We offer a wide array of well servicing solutions, which are designed to prevent fluid spills, keep workers safe, lower clean-up costs and reduce operation time.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291