what does a workover rig do quotation

Drilling calls for complex, carefully engineered equipment — and inevitably this equipment can wear down over time and require replacement. That’s where a workover rig comes in. Workovers are among the most expensive and complicated tasks in the drilling industry, so here are a few things you should understand about them.

A workover is a complex maintenance task that involves pulling completion hardware out of a well in order to extend the life of the well. A workover rig is a specially designed rig that makes it easier to take out or insert tubing into a well.

To complete a well servicing, the well is first killed. This halts the flow of fluids in the reservoir. The wellhead and flow line will then be removed and the completion hardware will begin to be pulled out of the well using the workover rig. Replacement parts will then be lowered into the hole accordingly.

Because workovers are involved in time-consuming processes, through-tubing workovers might be initiated, which can occur without forcing teams to kill a well and do a full well servicing. This might be considered first before deciding on a full well servicing.

A workover rig is needed when a well is no longer suitable for the drilling job it was originally built for. Maybe the production tubing has incurred damage over time or downhole tubing has stopped functioning correctly. Or perhaps the contents of the reservoir that the tubing is drawing from has changed and requires adjusted tubular components. In any case, the well is unable to perform efficiently and could even compromise the safety of those working on the well. At that point, its components must be replaced and a workover rig must be constructed.

You always want your well to perform to expectations. Katch Kan can help thanks to our zero-spill installation system, which ensures your well servicing operations will proceed safely and efficiently. We offer a wide array of well servicing solutions, which are designed to prevent fluid spills, keep workers safe, lower clean-up costs and reduce operation time.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Workovers rank among the most complex, difficult and expensive types of wellwork. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

Before any workover, the well must first be killed. Since workovers are long planned in advance, there would be much time to plan the well kill and so the reverse circulation would be common. The intense nature of this operation often requires no less than the capabilities of a drilling rig.

The workover begins by killing the well then removing the wellhead and possibly the flow line, then installing a B.O.P commonly known as a blowout preventer, then lifting the tubing hanger from the casing head, thus beginning to pull the completion out of the well. The string will almost always be fixed in place by at least one production packer. If the packer is retrievable it can be released easily enough and pulled out with the completion string. If it is permanent, then it is common to cut the tubing just above it and pull out the upper portion of the string. If necessary, the packer and the tubing left in hole can be milled out, though more commonly, the new completion will make use of it by setting a new packer just above it and running new tubing down to the top of the old.

Although less exposed to wellbore fluids, casing strings too have been known to lose integrity. On occasion, it may be deemed economical to pull and replace it. Because casing strings are cemented in place, this is significantly more difficult and expensive than replacing the completion string. If in some instances the casing cannot be removed from the well, it may be necessary to sidetrack the offending area and recomplete, also an expensive process. For all but the most productive well, replacing casing would never be economical.

Workover rigs without guyline are designed for small-scale and fast workover operations. Since it is not necessary to install external windload guylines, operating efficiency is greatly enhanced. They can work at 60 kn of wind in adjustment mode, and 35 kn of wind in operating mode, and are suitable for shallow wells in various oilfields.

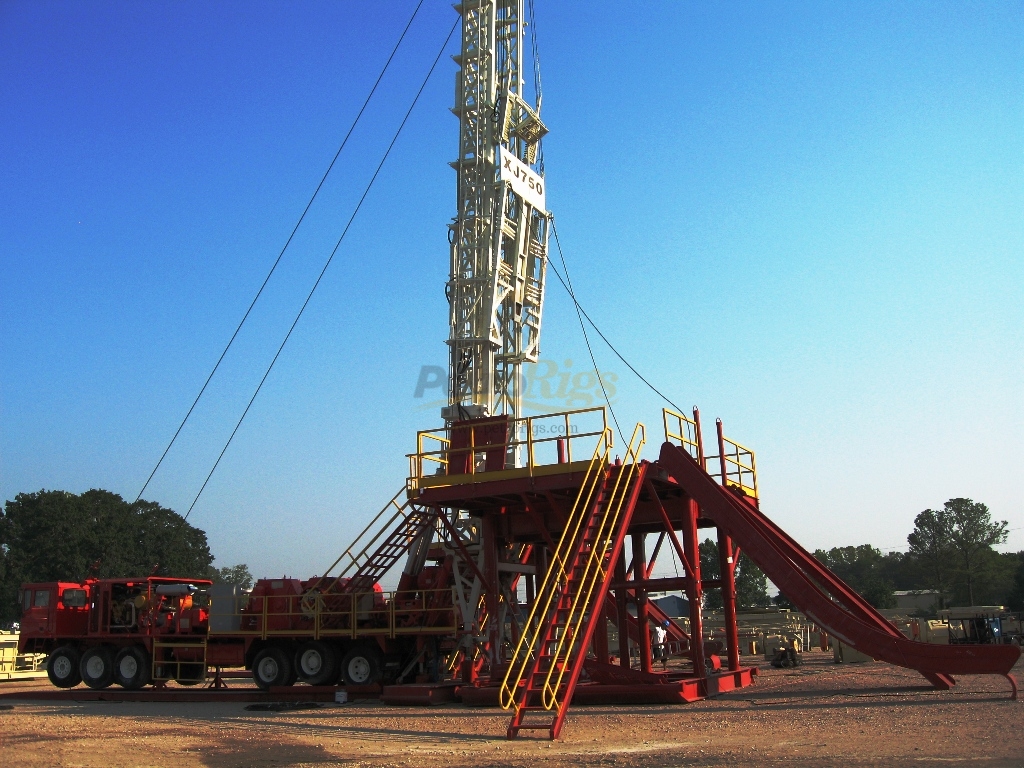

Main Parts and Quotation for XJ550 Workover RigItem Descriptions Model Technical Specification Qty/UnitWorkover Rig XJ550RemarkI Main part The main unit is self-propelled structure,including: self-propelled carrier, powersystem, double engines, transmissionsystem consists of two hydraulic torqueconverters, angle gear, transfer case, doubledrum drawworks, three sets of clutches,rotary table, auxiliary brake, chain drivingdevice, mast and crown block assembly,double telescoping cylinders, hydraulic cat,double raising cylinders, double hydraulicwinches, hydraulic system, pneumaticsystem, operation system, crown saverdevice, electrical system, substructure andMud boat etc.Max. hook load: 1350kNTraveling system: 5x4Hook up speed: 0.2-1.3m/swireline diameter: Φ26mmmast height:33msubstructure height: 3.7mmove way: self-propelledmax. road speed: 45km/hoverall dimension: 19000x2910x3100mm1 Carrier Drive way 10 x 8Max. road speed 45km/hSlope gradient 30%Approach angle/departure angle: 33 o /18 oMax. ground clearance 311mmTurning radius 16.5mMax. width 3mIncluding: cab, axles, suspension, frame, subframe, four hydraulic jacks and steeringmechanism, steering hydraulic system,double fuel tanks, air bag, transmissionsystem, took kit, mud fender and safetyguardrail, electrical system and lightingsystem, back alarm device1 set1 set1.1 Frame CJ-01B Including crossbeam assembly, frontboarding, mud-guard, raising cylinderbracket and beam of hydraulic jack

Oilfield Favorites-Long before there was "Dancing with The Stars" there was Dancing For Oil! These are some of the moves and talent it takes to get the oil to the surface. Good job hands!

The design of drilling rigs for the petroleum industry has remained basically unchanged for the last four decades. Today"s offshore rigs have evolved from the basic land rig concept towed offshore in the 1950"s. Factors such as deeper waters and harsher environments have increased demands for additional auxiliary equipment such as active crown mounted motion compensator, topdrive and comprehensive mechanised pipehandling equipment. Implementation additional equipment and new systems have followed an "add-on" philosophy which has resulted in concepts of monstrosity. Further development to meet today"s and future demands of versatility, such as integration of capabilities for snubbing and coiled tubing operations, will probably evolve to a stage where the "multi-functional" course could turn to the "multi-useless" curse.

A thorough review of the status, combined with the desire to be able to contribute with more optimal solutions, have lead Maritime Hydraulics to the development of the RamRig concept.

Main Objectives. Maritime Hydraulics launched the idea in 1987, whereafter a joint venture engineering study with British Petroleum Development Norway Ltd. was carried out in 1988 and 1989. The study evaluated all known rig concepts with emphasise on the aspects of hoisting and tubular handling efficiency. The main objectives of the development work were:Improve safety by reduced manning and improving working environments,

The study concluded the RamRig concept to be the most optimal of the alternatives considered. However, as it was found to be too bold and radical for its time, it was decided that the project was to be shelved. This was mainly due to the lack of field experience of important components like the control system and the large hydrostatic transmission required.

After about 5 years Saga Petroleum"s efficient exploration, "EfEx", study, re-vitalised the concept in 1994. The detailed design of a complete drilling rig for an application for deepwater exploration operations was completed by June 1995. In this study the RamRig was found to be an important enabler for developing more efficient total concepts.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/MJCU3NS2MBNBFATPGEU7BOLGMQ.jpg)

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This material does not amend, or otherwise affect, the provisions or coverages of any insurance policy or bond issued by Travelers. It is not a representation that coverage does or does not exist for any particular claim or loss under any such policy or bond. Coverage depends on the facts and circumstances involved in the claim or loss, all applicable policy or bond provisions, and any applicable law. Availability of coverage referenced in this document can depend on underwriting qualifications and state regulations.

All rights reserved. Travelers and the Travelers Umbrella logo are registered trademarks of The Travelers Indemnity Company in the U.S. and other countries.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

Each part of the device has different structural forms and can be selected arbitrarily for personalized configuration according to the needs of users.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

In addition to its main function of suspending the pipe string, it also has the functions of automatic tubing mouth match, make-up and break-out, and is also equipped with a guide device bearing reverse torque, which can realize the functions of automatic well washing, sand flushing, drilling, grinding and milling.

Main function: connect to the wellhead flange and clamp the pipe string. Slip teeth are common with other manufacturers for easy replacement. The hydraulic cylinder is clamped and the pipe string is forced to be centered. The clamping is reliable and convenient for automatic operation. Open and close state detection, and realize safety interlock with other equipment.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

The hydraulic system includes hydraulic source, wellhead automatic operation device control valve group, hydraulic elevator, hydraulic slip valve group, conveyor control valve group and pipeline, etc.

Workover rigs perform numerous functions including handling rod and tubing work and other associated activities to improve well output and perform plug and abandonment services. The increasing demand for oil and gas has will drive the expansion of workover rigs market. The increase in crude demand will make the companies enhance production. Consequently, significant growth in the share of this equipment is predicted.

We help you find the best workover rig companies irrespective of your location. We simplify your search for the best workover rig companies by connecting you with top centralizer companies in your location, at zero cost and according to your budget and business requirement. We majorly target regions including India, Middle East, USA & Canada.

You can list your products at Energy Dais once you get your company registered with us by creating an account. To join now, click here: https://www.energydais.com/account-selector/.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Used for production, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a range of

Johnston Fishing Jars (hydraulic jars) deliver impact at any hydrostatic pressure and they hit quick, hard and long – even at bottom-hole temperatures up to

Pipe handling devices minimize human interaction to handle and move pipe. They lower the overall cost of well site interventions by increasing pipe-handling efficiency through

Whether re-entering an existing wellbore or sidetracking around a stuck bottom hole assembly, our equipment and services have proven to reduce trips, milling time and

Fishing Services are used to remove wellbore obstructions. Key is highly capable of providing Fishing services for cased and open-hole applications. Our tool fleet ranges

The SmartTong® system takes the guesswork out of rod connections. As the world’s first computer-controlled connection service, algorithms ensure correct circumferential displacement on every connection

Tongs are used for breaking and making-up tubing connections. Tubing/rod tongs are hydraulic wrenches used to turn and torque pipe and rods, open-face and close-face

Blowout Preventers (BOPs) are a critical piece of safety equipment, as they protect rig crews, the rig, and the wellbore. Key maintains an inventory of

Key has the largest fleet of high quality ‘tubulars’, manufactured to industry-leading specifications. Tubulars are crucial components for drilling, completion and production programs, and we

Saltwater disposal wells allow us to handle produced fluids responsibly and efficiently. Key operates more than 50 disposal injection wells, where produced water is run

For tow and recovery requirements, these trucks are an everyday essential. Their flexibility and usefulness makes them an indispensable asset for our fleet.

Our pump/kill trucks are used for well pressure control. Uses include testing casing, pressure testing tubing and flow lines, to support well stimulation, and in

Sand-X® Sand Management System is a custom-engineered frac tank retrofitted with a special auger to separate sand from the fluid return automatically, in a safe,

Key’s vacuum trucks transport non-hazardous fluid or waste to or from your well operation. The materials commonly carried include fresh water, field salt water, 10

Used for completions, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a

Used for completions, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a

Used for production, completions, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for

Used for production, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a

Used for production, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a

Used for production, clean out jobs and ‘plugging and abandonment’, our spread equipment delivers quality and reliability every time. Ideally suited for a range of

Our trailer-mounted Nitrogen Production Unit (NPU) can deliver this essential resource to your drilling operation wherever you are based. Using a Lufkin or Great Dane

Working on a drilling rig is risky business by anyone’s standards. Safety must a matter of paramount concern in order to prevent injuries and accidents.

“At sea, risks include storms and inclement weather, humidity, strong winds, tides and sun exposure, as well as relative isolation for extended periods of time. On land, workers may experience excessive heat and humidity or, at the opposite extreme, cold temperatures and strong winds.

“In both locations, long shifts, arduous labor, wet, slippery work surfaces, and uneven terrain may create potentially hazardous conditions under foot that may result in falls and injuries. In addition, constant exposure to excessive noise is fatiguing and working with heavy equipment daily may lead to safety lapses that result in both minor and major threats to life safety and health.”

Other industry standards (like ABS, and DNV) provide a series of comprehensive documents that ensure the safety, health and environmental performance of equipment and offshore structures.

Unfortunately, accidents that result from failure to pay attention to safety protocols and procedures happen all too often. A good motto to keep in mind is that no job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Workers on drilling and workover rigs may sometimes take matters into their own hands, resulting in safety violations or, worse, injury. And while it is the rig operator’s responsibility to see that they are sufficiently trained and that the workplace is free from hazards, it is vital that every person on a rig site develop a keen sense of safety.

In an effort to help those in the industry adopt a safety first mindset, Grainger, a supplier of MRO products to the oil and gas industry, offers the following guidelines:

Build a safer and more secure worksite by eliminating hazards wherever possible. This sets the stage for preventing mistakes and accidents before they occur.

Grainger says that routine safety audits at rig sites are essential. Both the Occupational Safety and Health Administration (OSHA) and OGP provide fact sheets and a variety of tools for performing on-site safety audits.

Proper training, electrical surge protection, regular equipment checks and maintenance, along with appropriate lockout/tagout tools and procedures will reduce accidents and injuries that result from improper handling and maintenance of energized or mechanical equipment.

Falls can result when working in wet, slippery conditions or when performing tasks in elevated areas or uneven terrain. Examining work surfaces and utilizing material and products can reduce the likelihood that such falls will take place.

Implement the use of wearable ID tags and routine shift check-in/check-out procedures. This let supervisors and emergency responders know the location of every worker on the rig at all times.

Oil and gas rig workers may require ready access to tool boxes equipped with equipment needed to take care of repairs and to perform routine maintenance. Depending on the worksite, these may include electrical parts, material handling aids, plumbing components, hand tools, power tools, and welding gear.

Emergency Preparedness OSHA requires emergency response plans for every drilling site, which can vary depending on the rig’s location and layout. Grainger says that an effective plan should always include the ready availability of appropriate emergency and rescue equipment, as well as a program for training and drilling of all supervisors and workers on emergency escape and rescue procedures.

Oilfield safety is no different than safety anywhere else. Common sense, good judgment, and the right equipment for the job help to ensure workers are protected from injury. But remember the motto: No job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Keystone Energy Tools offers a wide variety of safety products to help ensure a safer work environment. Contact us to learn more about these and the other oil and gas industry products we offer.

8613371530291

8613371530291