workover rig components pdf manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Stewart & StevensonDrilling, Workover & Well Servicing Equipment for the OilfieldStewart & Stevenson’s Crown model drilling, workover and wellservicing equipment serves the global oilfield service industry.Quality engineered with the latest advances in oilfield technology,our innovative rigs are at the forefront of making the recoveryprocess safer and more efficient. Manufactured completely inNorth America since 1987, Stewart & Stevenson rigs meet therigorous industry standards established by the AmericanPetroleum Institute (API) and the International StandardsOrganization (ISO).With in-house design, engineering, manufacturing, testingand after-sales capabilities, Stewart & Stevenson servesclients from concept to completion and beyond.Our pioneering technological advancements in rigmanufacturing, such as drawworks componentsand AC/DC control systems, serve oilfield servicecompanies locally and internationally.Major operators around the globe rely on thesuperior quality of Stewart & Stevenson rigs.We offer:• Drilling rigs• Workover and well servicing rigs• Flushby rapid service rigs• Masts• Substructures• Drawworks• Controls• Power generation• Support units• Aftermarket parts and service• Complete turnkey packageswww.stewartandstevenson.comTable of ContentsDrilling, Workover & Well Servicing Rigs............. 4Flushby Rapid Service Rig....................... 7Rig Specifications ............................. 8Mast Specifications ......................... 10-11Drawworks Specifications .................... 13-15Power Generation ............................ 16Engineering & Project Management . ............. 17Manufacturing & Certifications................... 19Support Units, Commissioning & Field Service....... 20Aftermarket ................................. 232

Stewart & StevensonDrillingStewart & Stevenson’s drilling rigs are rugged, modular unitsdesigned to maximize efficiency and performance on the jobsite. Engineered to perform in the most extreme climates,these units are durable, mobile and fuel-efficient. Our innovativedesigns feature fewer moving parts, which translates tobetter performance with minimal downtime.• Available as trailer-mounted, self-propelled or skid-mountedconfigurations with electrical or mechanical drawworks• Freestanding or externally-guyed masts are available onall API monogrammed rigs. ATEX certification available• Complete turnkey packages to suit any working conditionor natural environment, whether high ambient or arctic• Option of Silicon Controlled Rectifier (SCR) for DC Rigs;Variable Frequency Drive (VFD) for AC Rigs; and Mechanicalor Hydraulic Drive (MECH) for Mechanical Rigs• Engineered with consideration to environmental impactand noise control• Substructures, rotary drives, top drives, pipe handlingequipment and skidding systems are also available tosuit any of your drilling or workover needs• Rig models can be custom-built up to 1000 hp to meeteven the most challenging operational requirementsWorkover & Well ServicingOur workover and well servicing rig models are lightweight,durable and versatile. Known for fast and easy rig up anduser friendly operation and maintenance, these self-containedunits have very few removable parts and require little or noassembly at the job site, thus benefiting customers withreduced down time and saved man-hours.• Available in carrier (drive-in or back-in), trailer or skidmountedconfigurations to accommodate any of ourclients’ oilfield service requirements• Rigs feature state-of-the-art drawworks; self-supporting,modular units designed for flexibility, ease of maintenance,performance and durability• Designed to accommodate varying climates from desertto arctic• All equipment is designed to be safe for personnel andenvironmentally responsible• Masts, available in freestanding or externally guyedconfigurations, are all API monogrammed and certified• Design configurations can accommodate specialized transportationrequirements, for example, via train or helicopter4

Drilling, Workover & Well Servicing RigsBoth lightweight and durable,Stewart & Stevenson rigs offerfast and easy rig up along withuser-friendly operation andmaintenance.5

Drilling, Workover & Well Servicing RigsFlushby Rapid Service RigAlso known as a Rod Rig, the Flushby rig is built on a carrier.With aluminum tanks, these units are lighter weight, smallerand more mobile than a service rig. They are designed andconfigured for ease of operation and economy.The Flushby is used in the following applications:• Polished rod changes• Trip and hang double rods• Pump changes• Well flushing• Pumping—triplex high pressure• Well abandonmentsMastFree-standing API 4F hydraulically raised and telescoping mast:Masts Height Rating LinesSingle 59" 50 K 2100 K 4Double 76" 65 K 2100K 4• Outriggers• Hollow structural steel construction• Nylatron or steel crown sheaves• Equipped with ladder, 110 volt lighting package, fall arrestassembly, block cradle and load linesPumps• 4˝ x 5˝ 165 hp triplex pump complete with hydraulic driveand electronic controls. Maximum pressure 10,000 psi(68.9 mPa), maximum flow 245 gpm (5.8 bbl/min)• 3˝ fluid transfer/charge pump with hydraulic drive• 4˝ suction manifold• 2˝ high pressure discharge manifoldDrawworks• Failsafe spring-applied emergency/park brake• Lebus grooving on main drum• 200 Model■ Single line pull: 28,000 lb (12,701 daN)■ Line speed: 480 ft/min (146 m/min)• 500 Model■ Single line pull: 32,500 lb (13,345 daN)■ Line speed: 700 ft/min (213 m/min)Fluid Tank• One 50 bbl (8 m 3 or 9 m 3 ) aluminum flushbytank to meet hazardous transport codes7

Stewart & StevensonRig SpecificationsFlushby, Workover, Well Servicing & Drilling RigsDrawworks Hookload Power Mast Depth Ratings Configurationlb metric ton hp kW ModelWell Serviceft (m)Workoverft (m)Drillingft (m)Mobile SkidMechVFD/SCR200Flushby65,000 29 200 74 72"-65K10,000(3,048) 500Flushby65,000 29 500 22372"-65K76"-65K10,000(3,048) 200100,000 45 200 199150,00063 200 14965"-100K 6,000(1,829)72"-150K 8,000(2,438) 250 150,000 63 250 186 72"-150K9,000(2,738)7,500(2,286) 150,000 63 350 26072"-150K79"-150K10,000(3,048)8,000(2,438) 350180,000 81 350 260 96"-180K12,000(3,657)9,000(2,743) 205,000 92 350 260 104"-205K13,000(3,962)10,000(3,048)6,500(1,286) 550225,000 103 550 410250,000 113 550 41096"-225K 14,000(4,267)104"-250K107"-250K110"-250K16,000(4,877)11,000(3,353)12,000(3,657)7,500(2,286)8,000(2,438) 600 300,000 136 600 447 110"-300K19,000(5,791)13,000(3,962)8,500(2,591) 650 300,000 136 650 484 108"-300K118"-300K20,000(6,096)15,000(4,572)9,000(2,743) 750350,000 158 750 559 118"-350K375,000 170 750 559 118"-375K22,000(6,706)16,000(4,877)16,500(5,029)10,000(3,084)10,500(3,200) 900 400,000 181 900 671 118"-400K124"-400K17,000(5,182)11,000(3,353) 1000440,000 199 1000 745 118"-440K500,000 227 1000 745 124"-500K18,000(5,486)12,000(3,657)14,000(4,267) 8

Stewart & StevensonMast SpecificationsStewart & Stevenson manufactures a complete line of telescopicand cantilever masts for the oilfield industry. Structuredout of alloy steel, we offer a full selection of working heightsand hookloads to meet any service or drilling requirement.Our rugged configurations stand up to the most arduousworking conditions and climates. Designed for ease ofassembly and mobility, our masts ensure quick rig up andrig down times making the process more efficient.Single Mast SpecificationsType Clear Height (ft) Clear Height (m) Number of Lines Hook Load (lb) Hook Load (metric ton)Single Swabbing 50 15.2 1 80,000 36Single TelescopingPole MastSingle Stiff Leg65 (extended)55 (retracted)596519.816.817.919.8332455,00062,00065,000100,000Single Telescoping 72 21.9 2 65,000 29Single Stiff Legor Telescoping727921.924.146100.000160,000Single Stiff Leg 73 22.3 8 300,000 136Single Stiff Leg 76 23.2 4696,500140,000Single Stiff Leg 86 26.2 6 240,000 109All single masts are offered in freestanding, externally guyed or slanted patterns.252829454568446410

Drilling, Workover & Well Servicing RigsDouble Mast SpecificationsType Clear Height (ft) Clear Height (m) Number of Lines Hook Load (lb) Hook Load (metric ton)Double Telescoping 96 29.346160,000180,0007382Double Telescoping 96 29.3468200,000225,000240,00091101109Double Telescoping 104 31.746160,000180,0007382Double Telescoping 104 31.746140,000205,0006493Double Telescoping 104 31.7468210,000250,000265,00095113120Double Telescoping 107 32.6468210,000250,000265,00095102109Double Telescoping 108 32.968286,000300,000130136Double Telescoping 110 33.5468210,000250,000265,00095113120Double Telescoping 110 33.568290,000300,000122136Double Telescoping 112 34.168270,000300,000122136Double Telescoping 118 36.068270,000300,000122136Double Telescoping 118 36.068275,000350,000124159Double Telescoping 118 36.0468200,000300,000375,00091136170Double Telescoping 118 36.06810300,000375,000400,000136170181Double Telescoping 118 36.06810300,000375,000440,000136170200Double Telescoping 124 37.86810275,000350,000400,000124159181Double Telescoping 124 37.86810300,000400,000500,000136181226All double masts are offered in freestanding or externally guyed patterns.11

Stewart & StevensonStewart & Stevenson’s innovativeproduct engineering and qualitymanufacturing processes resultin reliable, high performance,durable rig packages for localand international customers.12

Drilling, Workover & Well Servicing RigsDrawworks SpecificationsStewart & Stevenson designs and manufactures a full line ofAC, DC and mechanical drawworks for the drilling industry.Our drawworks are designed for optimal performance, superiorcontrol and optimal safety. Both light-weight and compact,our drawworks operate under the most extreme climateconditions. The modular design allows for easy maintenanceand repair. Drawworks packages can be customized to meeteven the most challenging operational requirements.AC & DC Gear Driven DrawworksModel CE550E CE750E CE1100EHorsepower (hp) 550 750 1100Drilling Depth (ft) 3,000–7,500 6,000–10,000 8,000–13,000Wireline Size (in) 1 1-1⁄8 1-1⁄4Drum Size (in) 18 × 37 22 × 49 25 × 62Single Line Pull (lb) 40,000 45,000 55,000Gear Box Single Speed Single Speed Single Speed or DoubleMain Brake AC or DC Motor AC or DC Motor AC or DC MotorParking/Emergency DiscBrakeDisc Brake238 DBBS338 DBBSor 336 WCSBDrilling Motors 1 1 1Options: Auto-driller motor and Eddy Current Brake.Actual hook load depends on the number and capacity of motors used. Drawworks can be furnished with an emergency/auto-driller system.13

Stewart & StevensonDrawworks SpecificationsMobile Rig DrawworksModel Single Line Pull (lb) Maindrum OptionsMaindrum ClutchOptionsMaindrum BrakeOptionsCE20030,00034,00015-7⁄8" × 36-3⁄4"13-7⁄8" × 36-3⁄4"PO-3188" × 38"40" Disc × 2CE250 50,000 13-7⁄8" × 36-3⁄4" PO-224 8" × 38"CE35052,00046,00013-7⁄8" × 36-3⁄4"15-7⁄8" × 36-3⁄4"PO-22410" × 38"48" Disc × 2CE550 46,000 15-7⁄8" × 36-3⁄4" PO-22412" × 42"52" Disc × 2CE600 46,000 15-7⁄8" × 36-3⁄4" PO-324 12" × 42"CE650 50,000 17-7⁄8" × 35-1⁄2" PO-324 12" × 42"CE750 50,000 19-7⁄8" × 35-1⁄2" 37VC650CE1000 60,000 21-7⁄8" × 37-1⁄4" 32VC100011" × 44"236 WCSB11" × 44"336 WCSBAll mobile rig drawworks can be furnished with an emergency/auto-driller system.14

Drilling, Workover & Well Servicing RigsEngineering & Product DevelopmentAt Stewart & Stevenson’s manufacturing facility in Calgary,Alberta, innovative product engineering and quality manufacturingprocesses result in reliable, high performance, durablerig packages for our local and international customers.Our dedicated engineering team, composed of structural,mechanical and electrical engineers, CAD designers anddraftsmen, apply their extensive experience to the developmentof rig equipment. For every rig or support unit we build,we provide comprehensive engineering that includes:• Full 3-D engineering documentation package• In-house certified structural engineering• System schematics for all electrical and mechanicaloperating systems• General arrangement and interface control diagrams toassist with locating critical installation detail• Technical manuals to assist with equipment operation• In-house finite element analysis to ensure design integrity• Virtual prototyping allows for flexible andfast configuration changesProject ManagementProject management is an important part of the rig manufacturingprocess at Stewart & Stevenson. Our structured approachgives a competitive advantage as projects move quickly andefficiently during all phases. We coordinate with in-house teamsat every stage of the project and we work closely with third partysuppliers and experts to ensure the highest level of quality andservice. Our proven process goes beyond the design andproduction stages to include complete aftermarket care.17

Drilling, Workover & Well Servicing RigsManufacturingFrom Stewart & Stevenson’s rig manufacturing facilities inCalgary, Alberta; Edmond, Oklahoma; Houston, Odessaand Victoria, Texas, we deliver ready-to-operate oilfielddrilling, workover and well servicing rigs. Through concept,design and manufacturing, our focus is on meeting thecustomer’s requirements.• Our field-experienced personnel work with customers todevelop the best concept for their application.• Our in-house engineers and drafting team use the latestsoftware to design each rig• All rigs are manufactured in state-of-the-art facilities• Our fabrication and assembly capabilities include an inhousemachine shop, electrical research and development,advanced welding and inspection technologies, andon-site sandblasting and paintingQuality control is involved in every step of the process.Work-in-progress inspections are conducted in compliancewith API and ISO quality control standards. After delivery,our commissioning team employs extensive testing standardsand inspection procedures on each unit, and our 8,000-foottest well is available for extensive operational testing.QMS CertificationsAll Stewart & Stevenson rigs meet the rigorous industrystandards established by the American Petroleum Institute(API) and the International Standards Organization (ISO).Our Quality Management System is certified and compliantwith API Q1, ISO9001-2008, and ISO/ TS29001.Product Certifications/Design Practices• CE/ATEX for Rigs: Europe and International• GOST R and GOST Ex for Rigs: Russia• API 4F 3rd Edition: Drilling and Well ServicingStructures (PSL1 and PSL2)• API 8C: Production Hoisting Equipment (PSL1 and PSL2)• API RP 500 and 505: Practice for Classification ofLocations for Electrical Installations• IEC 60079-144F – 0075 8C – 0082 4F – 0092 4F – 022119

Stewart & StevensonSupport UnitsFor clients who require more comprehensive rig packages,Stewart & Stevenson designs and manufactures a completeline of support equipment for the oil and gas industry. Each unitor combination of units is designed to meet the specific needsof our clients. Whether you require mobile or skidded equipmentto support your well servicing and drilling needs, wehave the solution.Equipment includes:• Pumping equipment (mobile or skidded)• Transporters• Doghouse/Crew Quarters (mobile or skidded)• Mud tanks• Substructures• Catwalk/pipe rack packages• Pipe handling packagesCommissioning & Field ServiceStewart & Stevenson maintains a staff of licensed heavyduty mechanics, millwrights and electronics technicians whoget your equipment up and running as quickly as possible.Our technicians are available 24 hours a day, 7 days a week.Services available:• All warranty repair work on Stewart & Stevensonbuilt equipment• Field commissioning on all new units• Field service support on initial jobs is available• Field service representatives are availablefor international work• Training on electrical and/or hydraulic systems, N2maintenance and other service or maintenance-relatedtopics can be arranged for groups of three or more• Accident repair• General maintenance and repair work20

Drilling, Workover & Well Servicing RigsRig commissioning and fieldservice are provided by licensedStewart & Stevenson technicianswho quickly get your equipmentup and running.21

Drilling, Workover & Well Servicing RigsAftermarketRefurbishingWhether you have one rig or a fleet, Stewart & Stevenson canrefurbish or retrofit your equipment with limited down time,giving you and your customers the confidence that the equipmentwill perform safely. From simple cleaning, repair and newpaint to a complete rebuild, Stewart & Stevenson will haveyour equipment back in the field in no time. We offer standard,all-inclusive and AESC Category IV / CAODC Level IV inspectionand repair on your mobile rig using standard and premiumparts with a stamped and certified letter from licensed engineers.Service can be done in-house or in the field.BeforeServices available:• Mast repairs, recertification or total mast replacement• Engine/transmission re-power packages• Total drawworks refurbishment or replacement• Facilities include modern sandblasting and paint boothsand licensed vehicle inspection stationsPartsDistributors for some of the best brands in the industry,Stewart & Stevenson has the OEM replacement componentsand operational accessories you need and can deliver themto you quickly. Parts and service are available for mostmajor brands.AfterParts and components:• McKissick Blocks• Elevator links• Handling tools• Crown model B&Cand CHD spiders• Crown model tongs• Crown drawworks• Right angle gear boxesDistributors for:• MTU• Detroit Diesel• Deutz• Allison Transmission• McKissick• Silverline• Mud pumps• Drop boxes• Open face / closed facetubing / rod• Sheaves• Rod elevators• Brake blocks• BMW Handling• CTW Brake Rims• Hawk Industries• Guiberson Well Service• O’BannonBefore23After

Rig Manufacturing, Sales and Service LocationsCANADACalgary, Alberta3111 Shepard Place SECalgary, Alberta T2C 4P1+1 403-215-5300UNITED STATESOdessa, Texas4501 S. County Road, 1310Odessa, Texas 79765+1 432-561-9400INTERNATIONAL SALESHouston, Texas10750 Telge RoadHouston, Texas 77095+1 281-345-5200TEXASVictoria, Texas7303 Houston HighwayVictoria, Texas 77901+1 361-570-3004U.S. RIG BRANCH LOCATIONSOKLAHOMAEdmond, Oklahoma6024 NW 178th StreetEdmond, Oklahoma 73003+1 405-348-9954WYOMINGCasper, Wyoming240 Chamberlin RoadCasper, Wyoming 82644+1 307-577-5600www.stewartandstevenson.comCompany Headquarters1000 Louisiana, Suite 5900Houston, Texas 77002+1 713-751-2700Headquarters@ssss.comCopyright © 2012 Stewart & Stevenson 12-01-17

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Considering the number of Workover Rigs off contract and stacked it is now highly important that contractors have their equipment in ready to go on contract condition. Major oil companies and operating companies will require a history of good Rig Maintenance.

This Workover Rig Maintenance program consist of a complete maintenance schedule for all the equipment listed below. Any item listed on any of the check list worksheets can be changed and edited to suite any Workover Rig and any piece of equipment. It also covers Diesel Haulers and Water Haulers if you own your own trucks. Any item can be removed or changed to suite your Workover Rig and equipment.

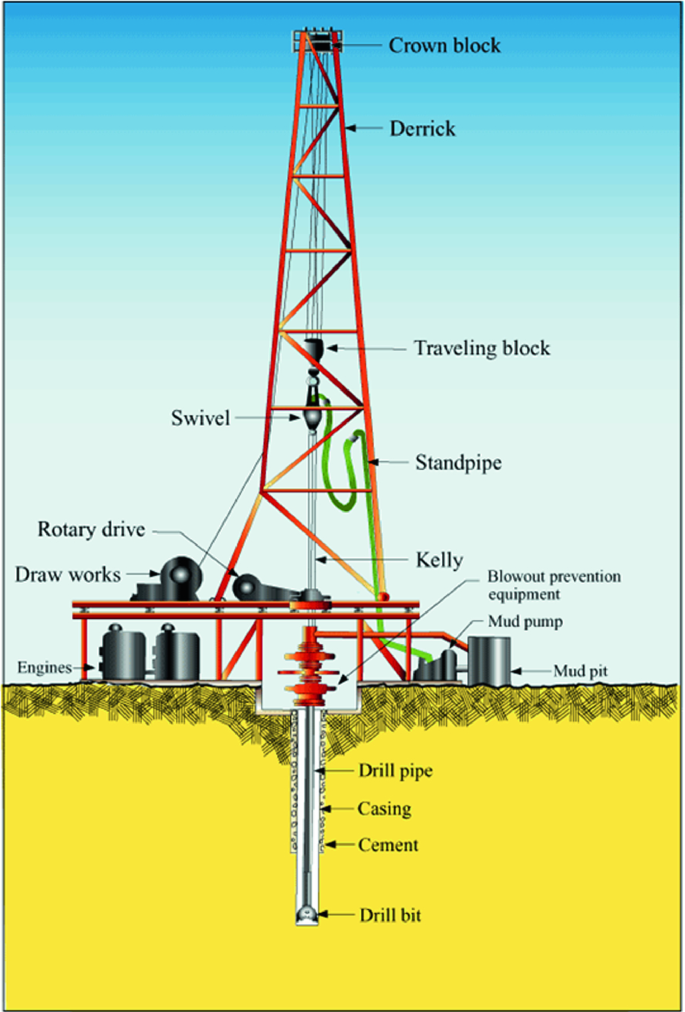

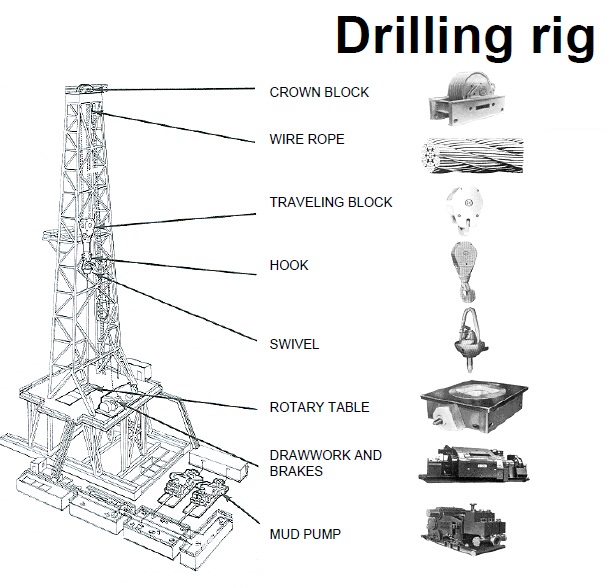

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Workover rigs are specialized rigs designed for carrying out certain operations in a well. Drillmec is a leader in the production of specialized service rigs, we have rigs that cover a variety of workover operations in the oil and gas industry. Our service rigs have a wide range of applications and provide the best performance in different situations. Drillmec’s mobile drilling rigs are self-propelled, and trailer mounted for easy transportation for a variety of workover well services.

We manufacture a full range of workover rigs with capacities between 60 to 250 metric tons for a variety of well service applications. Our rigs are designed to be electrically or mechanically driven and are built to withstand varying extreme climatic conditions and a variety of terrains. Whether scorching heat of the desert or the bitter cold in the polar region or even the extreme elevation changes of Utica shale, our rigs are ready to deliver optimal performance always.

Machinery and equipment from BAUER has been a byword for top performance and quality as well as for continuous innovation. BAUER Maschinen GmbH designs and manufactures rotary drilling rigs, foundation cranes, diaphragm wall equipment and all related tools.

8613371530291

8613371530291