workover rig components pdf in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

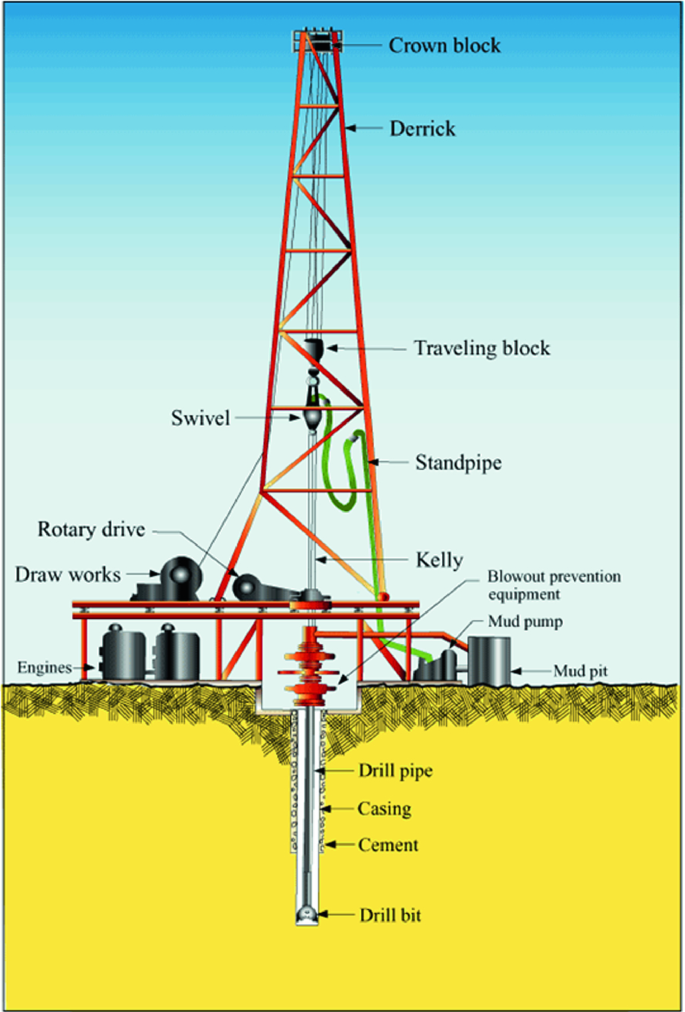

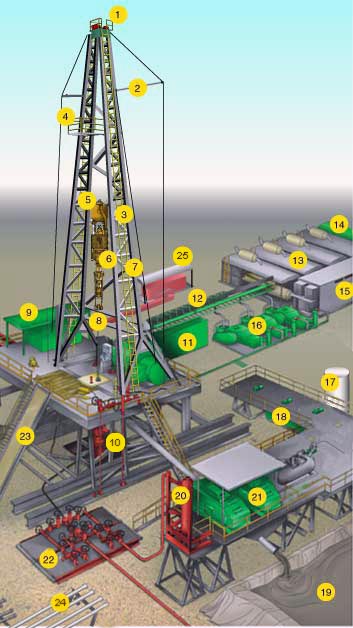

POLYTECH CENTRALE AU: 2014/2015 POLYTECH Kelly CENTRALE AU: 2014/2015The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.Rotary table POLYTECH CENTRALE AU: 2014/20156-Top Drive-The top drive rotates the drill string end bitwithout the use of a kelly and rotary table.The top drive is operated from a controlconsole on the rig floor. POLYTECH 7-Mast / Derrick CENTRALE AU: 2014/2015 - A portable derrick capable of being erected as a unit, as distinguished from astandard derrick, which cannot be raised to a working position as a unit. POLYTECH 8-Drill Pipe CENTRALE AU: 2014/2015 - The heavy seamless tubing used to rotate the bit and circulate the drilling fluid.Joints of pipe 30 feet long are coupled together with tool jointsas a result of the weight the, lower part of drill stringwill be damaged.

The BHA is made up of: a drill bit, which isused to break up the rock formations; drillcollars, which are heavy, thick-walled tubesused to apply weight to the drill bit;and drilling stabilizers, which keep theassembly centered in the hole. The BHA mayalso contain other components such asa downhole motor and rotary steerablesystem, measurement while drilling (MWD),and logging while drilling (LWD) tools. Thecomponents are joined together using ruggedthreaded connections. Short "subs" are usedto connect items with dissimilar threads.

POLYTECH CENTRALE AU: 2014/20159-Doghouse - A small enclosure on the rig floor used as an office for the driller or as a storehousefor small objects. Also, any small building used as an office or for storage.

BlowOut Preventer command panel11- Water Tank POLYTECH CENTRALE AU: 2014/2015-Is used to store water that is used for mud mixing, cementing, and rig cleaning.12- Electric Cable Tray- Supports the heavy electrical cables that feed the power from the controlpanel to the rig motors.

POLYTECH CENTRALE AU: 2014/201513- Engine Generator Sets- A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with amechanical transmission and generator for producing power for the drilling rig. Newerrigs use electric generators to power electric motors on the other parts of the rig.

POLYTECH CENTRALE AU: 2014/201514-Fuel Tanks POLYTECH CENTRALE- Fuel storage tanks for the power generating system. AU: 2014/2015 15-Electric Control House - On diesel electric rigs, powerful diesel engines drive large electric generators.The generators produce electricity that flows through cables to electric switchesand control equipment enclosed in a control cabinet or panel. Electricity is fed toelectric motors via the panel.

POLYTECH CENTRALE AU: 2014/2015Circulation POLYTECH CENTRALE AU: 2014/2015 16- Mud Pump- A large reciprocating pump used to circulate the mud (drilling fluid) on a drilling rig.

Casing/CIMENTATIONCASING/CIMENTATION POLYTECH CENTRALE AU: 2014/2015Casing POLYTECH CENTRALE AU: 2014/2015CASING- CENTRAGE POLYTECH CENTRALE AU: 2014/2015 Centreur rigide

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.†

The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus raises or lowers the drill stem and bit.†

On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Schlumberger offers surface equipment, such as state-of-the-art drilling rigs, managed pressure drilling (MPD) systems and services, and wellhead systems.

Our equipment and experts provide reservoir-to-flare services, from planning the well to handling mud and gas as they flow to surface. OEM equipment is also available for rental or sale, and we can supply everything for your rig—from driller"s cabin needs to MPD equipment.

Depending on your requirements, we can prepare rigs to accept the appropriate MPD equipment, install and commission the equipment, or both—for a specific well or to increase the capabilities of your rig. We can analyze, plan, and execute MPD programs while working with and training your personnel, both offshore and on land. In addition, specialized services are available for deepwater and high-efficiency land operations.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291