workover rig components pdf free sample

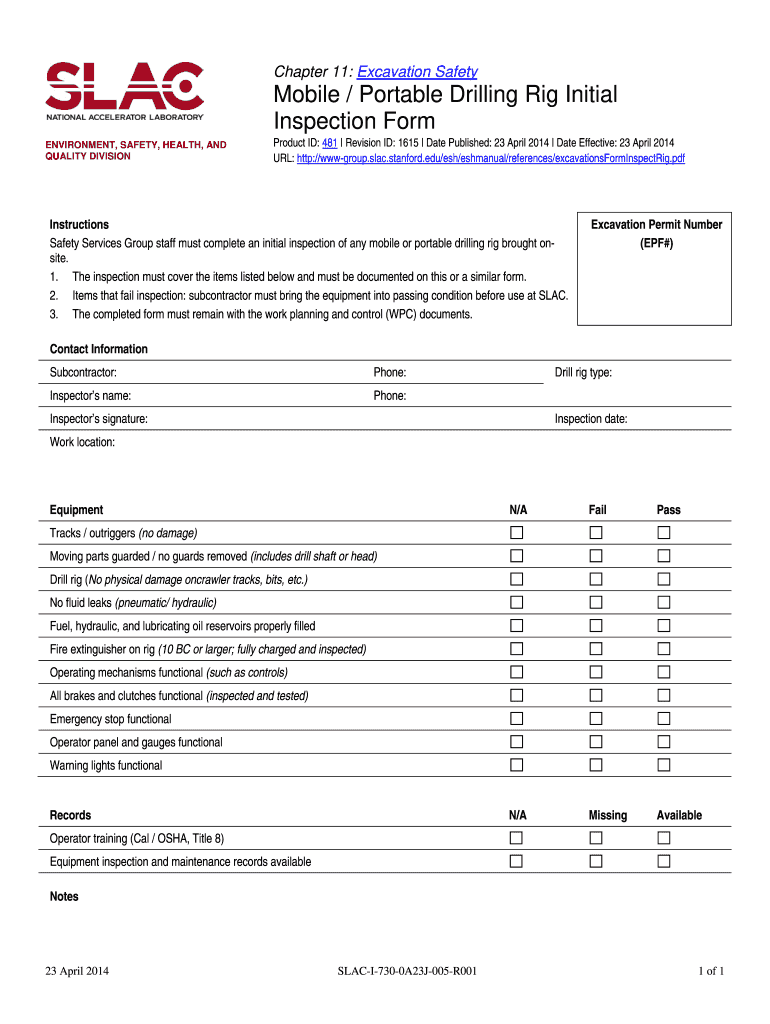

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Considering the number of Workover Rigs off contract and stacked it is now highly important that contractors have their equipment in ready to go on contract condition. Major oil companies and operating companies will require a history of good Rig Maintenance.

This Workover Rig Maintenance program consist of a complete maintenance schedule for all the equipment listed below. Any item listed on any of the check list worksheets can be changed and edited to suite any Workover Rig and any piece of equipment. It also covers Diesel Haulers and Water Haulers if you own your own trucks. Any item can be removed or changed to suite your Workover Rig and equipment.

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.†

The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus raises or lowers the drill stem and bit.†

On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Summary :Drill Rig Operator with extensive knowledge of working on a drill crew Profound knowledge of supervising a drill crew In-depth knowledge of geothermal procedures and top head drive rig Proficient with a drill rig, crane, Bauer, it and soil mix Excellent verbal and written communication skills.

Summary :Multiple years experience as Drill Rig Operator in the chemical industry Six years experience in drill rig operation in the field. Applied work experience in warehousing and inventory control and management. Training/certification in health & safety, materials handling, transportation, and cleanroom procedures.

Objective :Drill Rig Operator professional with strong leadership and relationship-building skills. Highlights Excavation and loading Rigging up/rigging down Vertical shaft installation Equipment maintenance/scheduling Belt maintenance Equipment operation Pipefitting Crew supervision Troubleshooting Minor computer/office equipment skills Hardworking Strong verbal communication Quick learner Extremely organized Team leadership File/records maintenance Reports generation and analysis Financial records and processing.

Summary :To obtain a Drill Rig Operator position that will utilize my knowledge of machine tools and machining procedures. I"m a highly skilled machinist with over 9 years of experience and an exceptional ability to quickly produce high-quality, close tolerance parts. As a dedicated machinist, I hope to further my career by becoming a dedicated programmer.

Summary :As a Drill Rig Operator experienced in operating Diedrich D-50 and D-70 drills used in the GeoTech construction field. Applicant must have documented experience operating drills similar to D-50, D-70, and CEM 55 type drill rigs along with OSHA 10hr or greater and Frist Aid and Safety training.

Objective :To establish a long-term career in a company where I may utilize my Drill Rig Operator professional skills and knowledge to be an effective Associate Program Manager and inspiration to those around me.

Description :Performed repairs and preventative maintenance of the drilling equipment and other components of the rig while adhering to Precision maintenance standards.

Objective :As a Drill Rig Operator, responsible for Inspecting truck equipment and supplies such as tires, lights, brakes, gas, oil, and water and requests as needed, Performing emergency roadside repairs such as changing tires, installing light bulbs and tire chains.

Objective :Drill Rig Operator with 3+ years of experience in Operating drill rig and drilling equipment with varying ground conditions, and also Assuring safety training is being logged in a timely manner.

Description :Ran floors, picking up the pipe, picking up rods, pump change-outs, trip pipe, run tubing board, assist driller, hammer, setup pump, rigging up, rigging down.

Objective :Experienced Floor Hand with over one plus years of oil field experience. Very familiar with several different types of drilling rigs and workover rigs. Also skilled at welding and other trades. Seeking a career where my diverse experience and training in management, leadership, and teamwork can help support the company"s vision.

8613371530291

8613371530291