workover rig components pdf made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

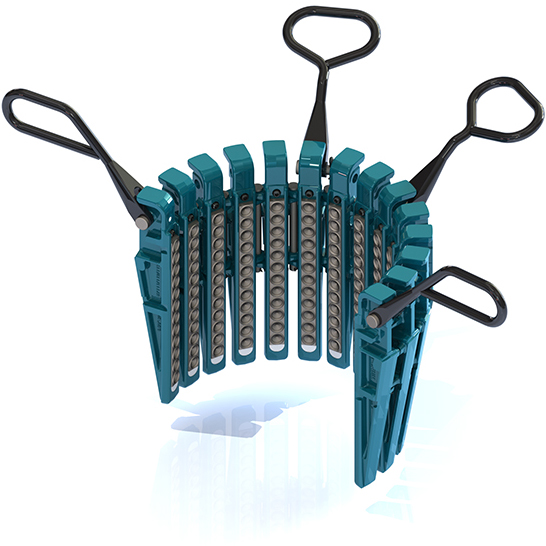

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

BEIJING, China, June 2021 – Sinopec SJ Petroleum Machinery Co. (SJP), a leading Chinese oil field equipment maker, has selected Allison Transmission’s 4500 Oil Field Series™ (OFS) for its new light workover rig.

During oil and gas recovery operations from underground reservoirs, chemical and mechanical processes can affect the wellbore, negatively affecting production and causing surface and downhole equipment to fail. Light workover rigs, which can reach remote oil fields swiftly and handle production emergencies efficiently, are always in high demand.

SJP’s latest light workover rig model (GVW at 46 ton) adopts a truck-mounted CNHTC chassis and is equipped with an MC11.40-60 diesel engine rated at 297 kW, coupled to a light and compact Allison Transmission 4500 OFS, which can deliver maximum torque of 1900Nm. The new light workover rig model also carries hydraulic lifting derricks, winches and drilling rigs.

“Our latest model, a light truck-mounted drilling and workover rig, has two main duty cycles: driving the rig to the work site (road mode) to running a second function (work mode), specifically in oil wells that require consistent, durable power and high reliability,” said Zhang Bin, Vice President of SJP Drilling & Repair R&D Center. “Allison has a wide range of oil field transmissions for different work conditions. The Allison 4500 OFS model can be matched with the biggest engines where it can deliver maximum output torque up to 2237 Nm, while being light and compact. It meets the needs of both duty cycles very well.”

This article is about the onshore oil rig. For offshore oil rig, see Oil platform. For drilling tunnels, see Tunnel boring machine. For handheld drilling tool, see Drill.

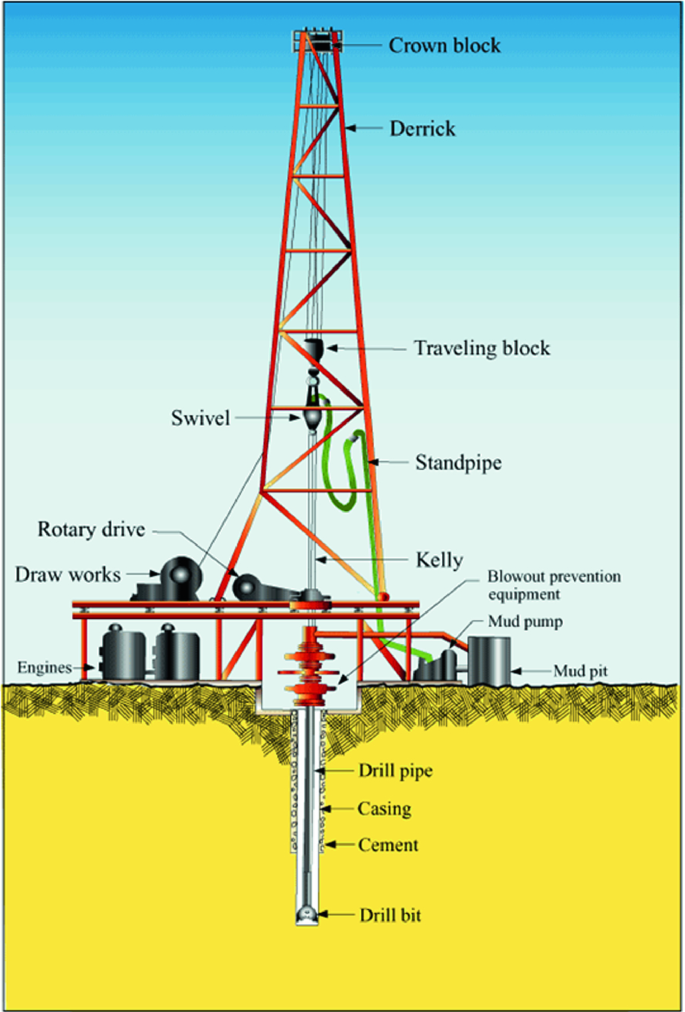

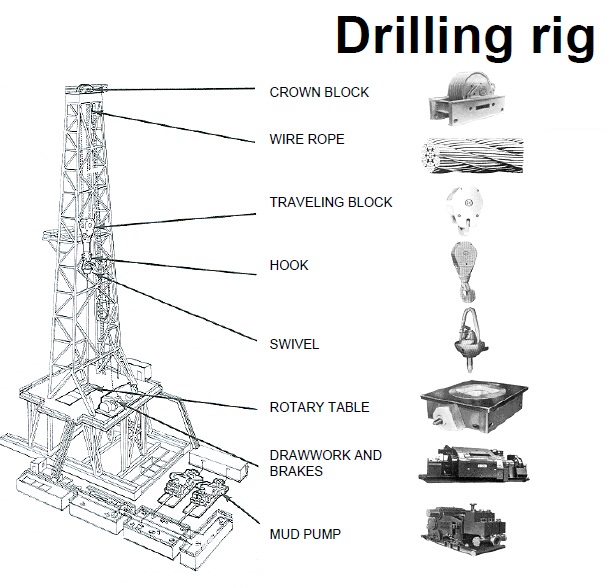

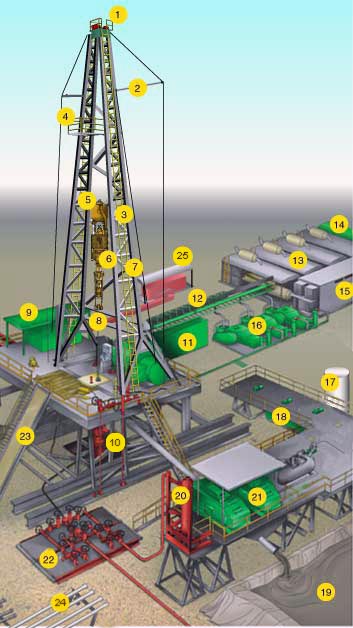

A drilling rig is an integrated system that drills wells, such as oil or water wells, in the earth"s subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called "offshore oil rigs" even if they don"t contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth"s crust.

Small to medium-sized drilling rigs are mobile, such as those used in mineral exploration drilling, blast-hole, water wells and environmental investigations. Larger rigs are capable of drilling through thousands of metres of the Earth"s crust, using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled. Hoists in the rig can lift hundreds of tons of pipe. Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas; and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred). Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

Antique drilling rig now on display at Western History Museum in Lingle, Wyoming. It was used to drill many water wells in that area—many of those wells are still in use.

Until internal combustion engines were developed in the late 19th century, the main method for drilling rock was muscle power of man or animal. The technique of oil drilling through percussion or rotary drilling has its origins dating back to the ancient Chinese Han Dynasty in 100 BC, where percussion drilling was used to extract natural gas in the Sichuan province.Edwin Drake to drill Pennsylvania"s first oil well in 1859 using small steam engines to power the drilling process rather than by human muscle.Cable tool drilling was developed in ancient China and was used for drilling brine wells. The salt domes also held natural gas, which some wells produced and which was used for evaporation of the brine.

Oil and natural gas drilling rigs are used not only to identify geologic reservoirs, but also used to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in onshore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose-built for completions will be moved on to the well to get the well on line.

Mining drilling rigs are used for two main purposes, exploration drilling which aims to identify the location and quality of a mineral, and production drilling, used in the production-cycle for mining. Drilling rigs used for rock blasting for surface mines vary in size dependent on the size of the hole desired, and is typically classified into smaller pre-split and larger production holes. Underground mining (hard rock) uses a variety of drill rigs dependent on the desired purpose, such as production, bolting, cabling, and tunnelling.

In early oil exploration, drilling rigs were semi-permanent in nature and the derricks were often built on site and left in place after the completion of the well. In more recent times drilling rigs are expensive custom-built machines that can be moved from well to well. Some light duty drilling rigs are like a mobile crane and are more usually used to drill water wells. Larger land rigs must be broken apart into sections and loads to move to a new place, a process which can often take weeks.

Small mobile drilling rigs are also used to drill or bore piles. Rigs can range from 100 short tons (91,000 kg) continuous flight auger (CFA) rigs to small air powered rigs used to drill holes in quarries, etc. These rigs use the same technology and equipment as the oil drilling rigs, just on a smaller scale.

An automated drill rig (ADR) is an automated full-sized walking land-based drill rig that drills long lateral sections in horizontal wells for the oil and gas industry.Athabasca oil sands. According to the "Oil Patch Daily News", "Each rig will generate 50,000 man-hours of work during the construction phase and upon completion, each operating rig will directly and indirectly employ more than 100 workers." Compared to conventional drilling rigs", Ensign, an international oilfield services contractor based in Calgary, Alberta, that makes ADRs claims that they are "safer to operate, have "enhanced controls intelligence," "reduced environmental footprint, quick mobility and advanced communications between field and office."steam assisted gravity drainage (SAGD) applications was mobilized by Deer Creek Energy Limited, a Calgary-based oilsands company.

Baars, D.L.; Watney, W.L.; Steeples, D.W.; Brostuen, E.A (1989). Petroleum; a primer for Kansas (Educational Series, no. 7 ed.). Kansas Geological Survey. p. 40. Archived from the original on 8 November 2020. Retrieved 18 April 2011. After the cementing of the casing has been completed, the drilling rig, equipment, and materials are removed from the drill site. A smaller rig, known as a workover rig or completion rig, is moved over the well bore. The smaller rig is used for the remaining completion operations.

"Ensign Launches Newest And Most Powerful Automated ADR 1500S Pad Drill Rigs In Montney Play", New Tech Magazine, Calgary, Alberta, 21 November 2014, archived from the original on 10 December 2014, retrieved 6 December 2014

A new type of the 8000m drilling rig ZJ80/5850 has been researched, manufactured and successfully applied for ultra-deep well drilling in the submountain region of China"s Tarim oilfield. The new kind of rig was developed to deal with the problems of load incapacity of drilling with the 7000m rig and high cost of drilling with the 9000m rig in ultra-deep well drilling.

Deep or ultra-deep well drilling operations in the piedmont area were predominated by the 7000m rigs. In order to tackle the situation of ultra-deep well drilling in the piedmont zone in Tarim oilfield, primary technical parameters of the rig had been enhanced with maximum hook load capacity 5,850kN, 52MPa high pressure rig pumps were equipped, compacted strands high tension wirelines were first used, derrick structure of the rig was optimized, and high strength material was selected for the main structure. Thereby a perfect general technical scenario of rig and associated techniques were formed.

The Tarim basin in northwestern China featured complex geological conditions and deep buried reservoirs. The potential risk of the 7000m rig safety as drilling around 8,000m ultra-deep wells emerged and the rig accident occurred as the big-size casing was deeply set due to the bare weight of the casing exceeding the load capacity of 4,500kN. Drilling efficiency has significantly been enhanced after 22 rigs of the type 8000m rig were applied for ultra-deep well drilling in the Tarim oilfield in less than three years. The 8000m rig has become prevailing equipment for drilling operations in the submountain region of Tarim. The procurement cost of roughly USD2.5bln was cut down per set of the 8000m rig as compared to that of the 9000m rig. The daily drilling rate per rig was saved by 20%-30%. Total amount of USD36.8bln for integral cost of drilling was saved per rig per year.

The optimization of the 8000m rig parameters and advanced associated technologies have filled in the gaps of China"s rig standards and perfected the standard series of China"s rigs. R&D of the new type 8000m rig was a result of market demand and satisfied by clients for the exploration and production of ultra-deep buried reservoirs.

Researchers plan to develop a drilling rig capable of boring a hole 15,000 meters deep, following up on the success of a domestically developed rig that reached 7,018 meters last month.

The development of the new rig will be based on knowledge gained from the Crust-1 10K ultradeep scientific rig, currently the best China has developed, said Sun Youhong, vice-president of Jilin University and the research and development director of the deep continental scientific drilling equipment program.

Last month"s successful Songke 2 project, which drilled to a depth of 7,018 meters, made China the third country to develop a rig capable of hitting 10,000-meters, after Germany and Russia.

In 2014 ConocoPhillips entered a new era of collaboration, as operational control of the Bohai Penglai Field was transferred to CNOOC Limited per the terms of Production Sharing Contract (PSC) 20 years after the original Bohai PSC was signed. Later that month, the newest phase of field development began when Chairman and CEO Ryan Lance approved the first new platform to be installed since the Bohai Phase 2 project was completed in 2010.

Bohai Phase 3, which began operations in third quarter 2018 is the largest new project initiated since the ConocoPhillips upstream-downstream split. The project includes three wellhead platforms, three drilling-completion-workover rigs, a central process platform, 186 new wells, 49 sidetracks and brownfield modifications.

On July 20, 2005, the Chinese Government and the Government of Turkmenistan signed a preferential loan framework agreement for the Gas Field Drilling Equipment Acquisition and Installation Project. Then, on May 18, 2006, China Eximbank and the State Bank for Foreign Economic Affairs of Turkmenistan signed an RMB 200 million government concessional loan (GCL) agreement for the Gas Field Drilling Equipment Acquisition and Installation Project. The borrowing terms of the GCL are unknown. However, it is known that the borrower was to use the proceeds of the GCL to finance an RMB 200 million commercial contract between China Petroleum Technology & Development Corporation (CPTDC), a wholly-owned subsidiary of China National Petroleum Corporation (CNPC), and a Turkmen state-owned enterprise called “Turkmengeologiya." The purpose of this project was to facilitate (a) the design and construction of a water cooling and softening unit and pumping stations at the headworks-2 of the Dovletabat gas field-3; (b) the supply of component equipment for a Chinese-made ZJ70D drilling rig; (c) the supply of drilling equipment for the reconstruction of three Russian RUZD86 drilling rigs and the supply of one Chinese-made ZJ70D drilling rig for Turkmengeologiya; and (d) the supply of seven Chinese-made XJ250 lift units and spare parts for a Turkmen state-owned oil company called Turkmeneft (or Türkmennebit or TurkmenOil). AidData has not identified any evidence of this project reaching implementation. However, in May 2016, Turkmengeologiya re-announced an international tender for the supply of off-site and drilling equipment (that would be financed with the proceeds of a concessional loan from the Chinese Government).

8613371530291

8613371530291