workover rig equipment list brands

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

A custom quote for drilling rigs will be according to your requirement. This will allow you to get the best rates for drilling rigs from drilling rig companies across the globe. We work on a zero commission and zero referral fee business model, eliminating any unnecessary expense. We maintain complete transparency, which means that the buyers and suppliers can directly communicate through our platform and negotiate the prices. All this comes at a reasonable annual fee from manufacturers and suppliers who subscribe to our plans.

Energy Dais is a transparent oil and gas directory where equal opportunities are provided to all manufacturers and service providers to showcase their products. It gives you a chance to be visible in the higher positions of the directory. We understand that every company has a specific budget for marketing itself in the market. Thus, we offer a pretty reasonable pricing chart for companies. We make sure that you get the best quotation for your products and services. Here, you will be at an advantage with respect to drilling rigs.

Yes. We help you find the best drilling rigs irrespective of your location. We simplify your search for the best drilling rigs by connecting you with the top drilling rig companies at zero cost and according to your budget and business requirement.

Various drilling rigs and drilling equipment are included in the Direct Push technology. Direct push rigs include both cone penetration testing (CPT) rigs and direct push sampling rigs such as a PowerProbe or Geoprobe. However, these rigs are generally limited to drilling in unconsolidated soil materials and rock soft in nature.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Drilling and exploration have never been more challenging. Drilling equipment must operate in harsher and more remote environments than ever before, and Grayford Industrial are on hand to assist with equipment purchases suitable for your environment.

Grayford Industrial provide various types of Drilling Equipment, including drawworks, travelling blocks, generators, coiled tubing units, completion tools, oil tools, wireline handling systems, oilfield clutches and many others. We offer mechanical components for land and offshore drilling rigs, complete land drilling and well servicing rigs, tubular inspection and internal tubular coatings, drill string equipment, extensive lifting and handling equipment, and a wide range of downhole drilling motors, bits and tools.

Drawworks are normally skid-mounted and designed for continuous drilling service. Providing the power to the rig, they are a vital element of the drilling system.

Many drilling rigs are in difficult and hard-to-reach locations, and generators are often required for power production, either using natural gas supply or liquid fuel.

As with coiled tubing, we can offer a wide range of wireline equipment for use in wells reliant on gravity. Our USA office works closely with us on our clients requirements for wireline equipment.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Under these rental contracts, a turnkey cost is paid by an E&P business to a middleman. This includes an insurance premium, which is returned if nothing goes wrong, but may be lost if there are difficulties. Higher specification equipment commands a larger premium.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

The International Association of Drilling Contractors (IADC) lists 547 members in the category of Land Drilling Contractors. According to Statista, the key US land drilling contractors are: Nabors Industries Ltd, Helmerich & Payne Inc, Patterson-UTI Energy Inc, Precision Drilling Corporation and Pioneer Energy Services Corp.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Drilling Rigs - Misc. - DRILLERâS CABIN with control panels - Aker MH Drillers Cabin removed from offshore drilling rig. In excellent condition with good space and large windows. Listing ID... More Info

Land Rigs - DRAWWORKS-DMS-800 HP DW, POWER-2CAT 3406 DIESELS, DERRICK-BUTLER&PARKS 107’ 300,000# HOOK LOAD CANTILEVER MAST. BUTLER & PARKS SUBSTRUCT-8’HX14’WX40’L & 3’ PONY... More Info

Well Service | Workover Rigs - 844/80 Double drum draw works. looks to be recently rebuilt. Has new Lebus Grooving on Tubing Drum. Comes w/ 250 HP 2 speed jackshaft/RA BOX. More Info

Land Rigs - Cardwell 250 Carrier Mounted Drilling Rig, 12"H Substructure, Hacker Rotary Table, Mud King MZ-9 Triplex Pump powered by Cat 3508, EWCO 15W600 duplex pump powered by 60 S... More Info

Well Service | Workover Rigs - CARDWELL KB200B Freestanding Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Cardwell KB200B Freestanding Service Rig, 5 Axle Carrier, Detroit 8V71... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - COOPER 350 Well Service Unit p/b DETROIT 8V-92 Diesel Eng, ALLISON 750 Trans, 42X12-38x8 DRAWWORKS w/dual disc assist, 97â 200,000# Telescoping M... More Info

SIMCO® Drilling Equipment, Inc. began designing and building all-hydraulic, long stroke, tophead drive drilling rigs in 1971 at our manufacturing facility located in Osceola, Iowa. Today, SIMCO drilling rigs, drilling rig equipment and water well equipment are working on every continent in the world. Backed by over 50 years of experience in the drilling industry, our drill rigs are used for water well and geothermal well drilling, geotechnical and environmental drilling, mineral exploration, geothermal wells, construction and utility work, and a wide range of other diverse applications.

Our featured water well drilling rig is the SIMCO 7000. The 7000 is truly the work horse of the SIMCO water well drilling rigs stable. With an auto indexing drill rod carousel (10 or 16 drill rod) and up to 1,100 foot air or wet rotary drilling depth, the SIMCO 7000 is the ideal geothermal drilling and water well drilling solution. This truly state of the art drill rig will make short work of any geothermal drilling and water well drilling jobs.

At SIMCO, our customers are family. And we support our family with whatever they may need, whenever they need it. Trying to determine which drilling rig best fits the job? Call us and we can guide you towards the best option. Our trained customer support team stands ready to assist you with whatever it is that you may need to keep your SIMCO drilling rig running like new. We have a fully stocked parts department to make that happen. Next day parts delivery will ensure that downtime is kept to a minimum and jobs get completed on time.

Electric generators powered by large diesel engines (the prime movers) generate electricity that move the heavy rig equipment such as the rotary table (or top drive), mud pumps and drawworks.

Electric Drilling Rig AdvantagesSafer: Stepless speed regulation allows for accurate control of the circulating, hoisting, and rotating equipment. Computerized driller’s cabin with touch screens for the display and control of drilling parameters.

Sovonex electric drilling rigs are available in two types that either use direct current (DC) or alternating current (AC) to power the rig components:

On a DC drilling rig, alternate current (AC) produced by one or more AC generator sets is converted into direct current (DC) by means of a silicon-controlled-rectifier (SCR) system.

On an AC powered rig, AC generator sets (diesel engine plus AC generator) produce alternating current that is operated at variable speed via a variable-frequency drive (VFD).

Apart from being more energy efficient, AC powered rigs allow the drilling operator to more accurately control the rig equipment, thus enhancing rig safety and reducing drilling time.

On mechanical drilling rigs, also called power rigs, the rotary energy of the diesel engines is transferred directly to the drawworks, mud pumps, and rotary table (or top drive) via a system of chains (chain drive) or belts (belt drive), torque converters and clutches.

In addition, a separate generator set produces electricity to power the lighting system of the rig as well as small AC motors used by equipment of the mud control system.

Most truck-mounted drilling rigs are mechanical drilling rigs where the diesel engine or engines that are mounted on the carrier drive both the drawworks and the rotary table. In addition, each mud pump has its own diesel engine driving the pump via belts or chains.

Although mechanical drilling rigs are less expensive than electric drilling rigs, they are less reliable due to the fact, that the failure of a single main engine can can bring drilling to a halt. The main drives of a mechanical drilling rig are also less precise to control.

The rotary table (or top drive), on the other hand, runs on electricity produced by one or more separate generator sets. The electric power for the lightning system and smaller equipment like the shale shaker and degasser, is also produced this way.

Due to size constraints on a mobile rig’s standard substructure, installing an electric rotary table would be difficult, the rotary table also is driven mechanically by the prime movers on the truck.

The most important drive on a rig, the rotary table or top drive, is powered electronically and can thus be precisely controlled thanks to stepless speed regulation.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Aztec Drilling inventories various sizes of drilling rigs from the best manufacturers in the oil drilling industry. We maintain rigs from manufacturers such as Load Craft, Wilson, Hyduke and Service King.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Casing head (#27) is a large metal flange welded or screwed onto the top of the conductor pipe (also known as drive-pipe) or the casing and is used to bolt the surface equipment such as the blowout preventers (for well drilling) or the Christmas tree (oil well) (for well production).

Derrick (#14) is the support structure for the equipment used to lower and raise the drill string into and out of the wellbore. This consists of the sub-structure (structure below the drill floor level) and the mast.

Drill floor (#21) is the area on the rig where the tools are located to make the connections of the drill pipe, bottom hole assembly, tools and bit. It is considered the main area where work is performed.

Drill pipe (#16) is a joint of hollow tubing used to connect the surface equipment to the bottom hole assembly (BHA) and acts as a conduit for the drilling fluid. In the diagram, these are stood in the derrick vertically, usually to save time while tripping pipe.

Setback (#17) is a part of the drill floor (#21) where the stands of drill pipe are stood upright. It is typically made of a metal frame structure with large wooden beams situated within it. The wood helps to protect the end of the drill pipe.

Stand (#16) is a section of 2 or 3 joints of drill pipe connected and stood upright in the derrick. When they are pulled out of the hole, instead of laying down each joint of drill pipe, 2 or 3 joints are left connected and stood in the derrick to save time.

According to the Global 500 list published by Fortune Magazine, Schlumberger bagged the 287th position in 2016 and has always been one of the top 300 corporations in the world with a large revenue turnover.

Fluor Corporation is the world’s third-biggest offshore drilling company and a major producer of anti-pollution products. It provides services through its subsidiary companies operating in the oil and gas sector, industries and manufacturing, engineering and construction. The Global 500 list ranked it as the 196th biggest corporation since it recorded annual revenue of around 15.66 billion dollars in 2021.

Baker Hughes provides a range of services pertaining to the oil and natural gas sector including Casing and Lining Drilling, cementing, drilling automation, providing rig equipment, coiled tubing services, drill bits, drilling fluids, optimization services and so on.

The company owns and operates a fleet of 49 offshore drilling units comprising ultra-deepwater oil rigs, out of which 15 are located in extremely harsh environments. Around 85 per cent of the company’s rigs were delivered in the last 8 years, hence it is known for the most diverse and flexible rigs in the industry. The upcoming rigs feature their patented hybrid technology for optimum reservoir productivity. It also constructed the ultra-deepwater drillship named Deepwater Titan.

A provider of offshore drilling services across the globe, Ensco Plc owns a diverse fleet consisting of 39 oil rigs, 13 ultra-deepwater drillships, semisubmersibles and modern jack-ups. Based in London, UK, the company earns annual revenues of over a billion US dollars and is run by a team of 5400 professionals. The company operates in strategic basins such as the US Gulf of Mexico, Brazil, Middle East, Asia, Africa, Pacific Rim.

The company is known for operating one of the youngest fleets in the industry consisting of more than 30 jack-up rigs and 4 drillships. It has drills in Louisiana, the Gulf of Mexico, Alaska, the Middle East, the North Sea and West Africa. The Gorilla class heavy duty offshore drilling rigs can reach a depth of 35,000 feet whereas the ultra-deepwater rigs can drill down to 40,000 feet.

Noble Corporation provides offshore-drilling services in the oil and gas sector with a fleet of around 20 mobile offshore drilling units comprising 12 floaters and 8 jack-up rigs focussing on deep-water and jack-up drilling operations in established as well as emerging markets across the world. Its clients include independent companies and also government-owned enterprises. The company has been in the offshore drilling sector since 1985 and is known for possessing one of the most versatile fleets in the energy industry.

The company owns and operates 35 drilling rigs and maintains a standardised fleet using its rig asset management platform offering real-time information regarding the asset’s functioning and performance analysis. It also owns 10 drillships and 4 semisubmersibles. The company earns revenues of over 1 billion US dollars every year.

Tasman recognizes the importance to the client of not just supplying equipment, but the necessity of offering a total package of assets, oil and gas services and engineering support. Tasman has the knowledge and expertise that comes with vast experience in the oilfield services industry. With Tasman you can trust you have chosen the right partner for your oil and gas project.

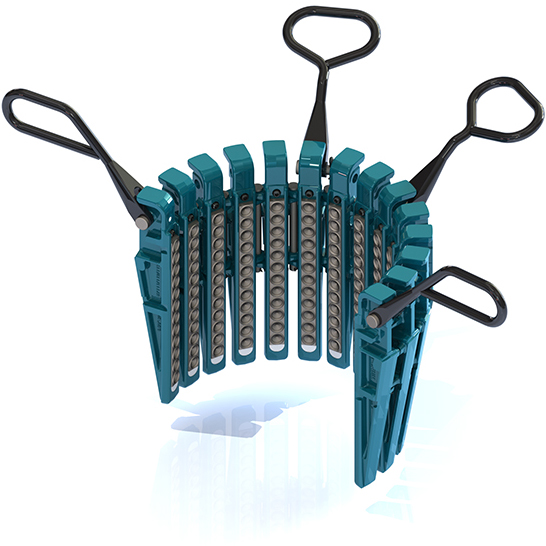

Stray and damaged tools can result in equipment lost downhole causing downtime to drilling and workover operations. Tasman has a large range of fishing and re-entry products engineered to maximize overall drilling operation efficiency and reduce Non Productive Time (NPT). Learn more

The importance of Pressure Control Equipment cannot be underestimated as a critical component in the industry. Tasman can supply Blow Out Preventers from 4.1/16in to 21.1/4in as well as a large selection of other associated pressure control equipment, including adapter spools, hydraulic hoses and more. Learn more.

Tasman offers a range of mud management equipment to assist with drilling waste removal. Tasman’s range of drilling waste and mud management equipment includes: ditch magnets, mud buckets, mud hoppers, wash down pump units and vacuum fluid retrieval units. Learn more.

Tasman offer the added value to our clients by the in-house repairing, maintaining, testing and third party NDT inspecting for either our own or client owned equipment. Learn more.

The American oil and gas industry plays a huge role in our everyday lives and the national economy — and oil drilling equipment is behind it all. This industry employs 9.8 million Americans — a number that continues to grow — and makes up approximately 8% of the U.S. economy. And with global proven oil reserves growing by an impressive 27% over the last decade, the market for oil and gas shows no sign of slowing; there are now adequate reserves to allow global oil production for another 53.3 years.

The driving force behind this thriving industry is the oil drilling equipment used to extract crude oil and petroleum from the earth. But do you know all there is to know about oil drill rigs and tools?

The drill rigs used throughout the oil and gas industry today are highly complex structures made of many components. To get a glimpse at some of the more crucial components in these systems, here is an introductory outline of the most important pieces of oil drilling equipment used in today"s oil drill rig systems — along with some information about the types of oil drilling processes that utilize them.

The rig required for a job depends on the type of drilling that needs to be done. There are three main drilling processes that are commonly used, but the method used in the oil and gas industry is known as “deep drilling.”

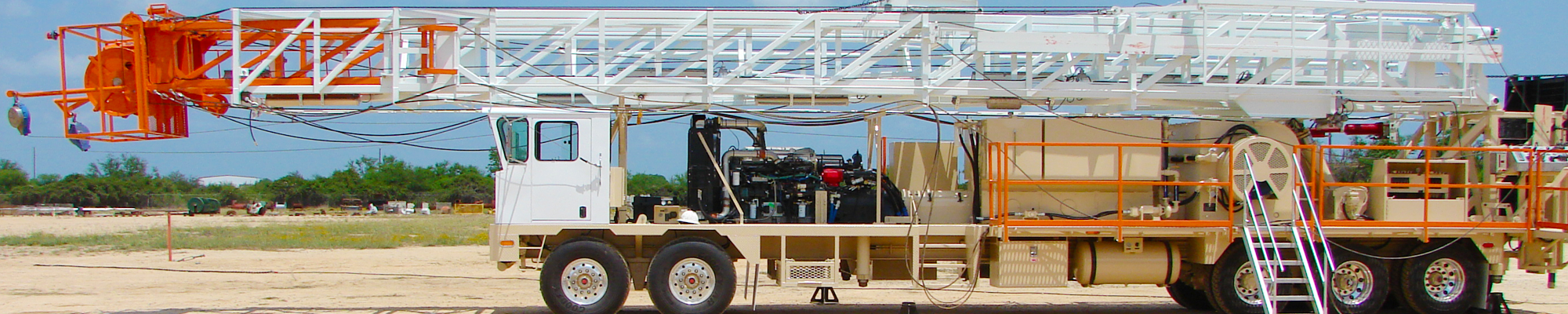

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

8613371530291

8613371530291