workover rig floorhand duties free sample

Description :Ran floors, picking up the pipe, picking up rods, pump change-outs, trip pipe, run tubing board, assist driller, hammer, setup pump, rigging up, rigging down.

Objective :Experienced Floor Hand with over one plus years of oil field experience. Very familiar with several different types of drilling rigs and workover rigs. Also skilled at welding and other trades. Seeking a career where my diverse experience and training in management, leadership, and teamwork can help support the company"s vision.

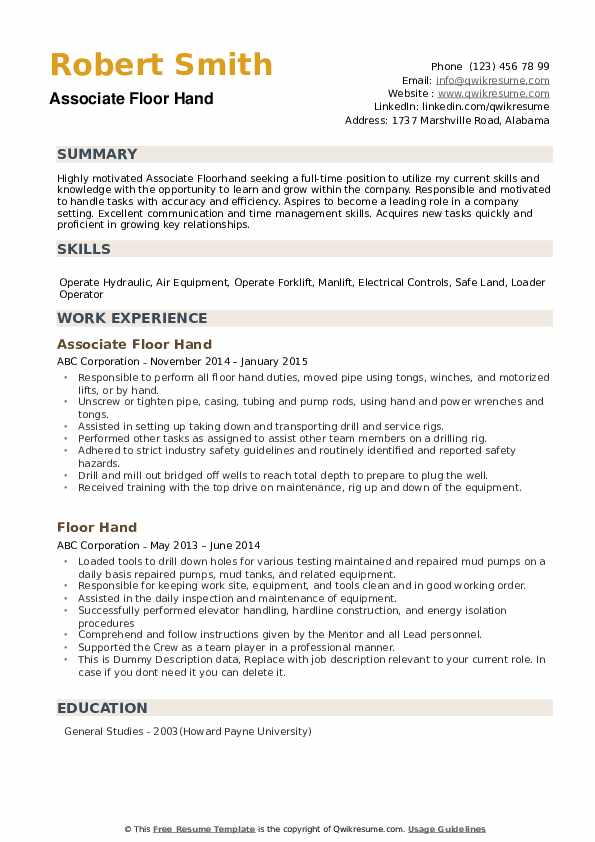

Objective :Highly motivated Associate Floorhand seeking a full-time position to utilize my current skills and knowledge with the opportunity to learn and grow within the company. Responsible and motivated to handle tasks with accuracy and efficiency. Aspires to become a leading role in a company setting. Excellent communication and time management skills. Acquires new tasks quickly and proficient in growing key relationships.

Maintains tubing, rod tongs and hand tools on the rig. A minimum of one (1) year rig floor operation experience. Keeps pipe deck and main deck areas orderly.

Maintains tubing, rod tongs and hand tools on the rig. A minimum of one (1) year rig floor operation experience. Keeps pipe deck and main deck areas orderly.

May be required to work floors or operate the rig when needed. Assists in picking up or laying down tubing, manually lifting the tubing from the rack onto the…

Performs housekeeping around rig, keeping rig floor clean and clear of tools after each trip. Assists in drilling rig erection (rig up) and dismantling (rig…

Available to work to tight deadlines. Works as crew member during the actual installation/work. Other duties as directed including but not limited to driving…

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Roughneck is a term for a person whose occupation is hard manual labor. The term applies across a number of industries, but is most commonly associated with the workers on a drilling rig. The ideal of the hard-working, tough roughneck has been adopted by several sports teams who use the phrase as part of their name or logo.

Originally the term was used in the traveling carnivals of 19th-century United States, almost interchangeably with roustabout. By the 1930s the terms had transferred to the oil drilling industry. In the United Kingdom"s oil industry starting in the 1970s, roughneck specifically meant those who worked on the drill floor of a drilling rig handling specialised drilling equipment for drilling and pressure controls. In practice, these workers ranged from unskilled to highly skilled, depending subjectively on the individual worker"s aptitude and experience. By contrast, a roustabout would perform general labor, such as loading and unloading cargo from crane baskets and assisting welders, mechanics, electricians and other skilled workers. The word roughneck was in use in the U.S. oil drilling industry even earlier and had a similar meaning.

In oil fields, a roughneck"s duties can include anything involved with connecting pipe down the well bore, as well as general work around a rig. The crew of a land-based oil rig can be further divided into several positions:

Derrickhand (derrick-man): Responsible for the drilling mud, the mud pits where drilling fluids are circulated around the system, and the mud pumps, as well as being the hand up in the derrick manipulating stands into and out of the fingers during tripping operations. Acting as a lead for the driller who is mostly restricted to the rig floor. In many cases the derrickman is exclusively responsible for work in the derrick during "tripping" pipe in and out of the hole.

Motorman (motorhand): Responsible for maintenance of various engines, water pumps, water lines, steam lines, boilers and various other machinery incorporated into the rig on a daily basis. Also responsible for movement of equipment on site. On a four-man drilling crew the motorman is also the chainhand.

Boilerman: Though this position is now obsolete, before the mid-20th century, when most rigs were steam-powered, the boilerman was responsible for the boilers. The boilerman also functioned as the laundryman, steam-cleaning the last crew"s greasy work clothes in the "blow barrel" and then hanging them up to dry in the warm air near the boilers.

Chainhand (Floorhand): This position is given to a floorhand that can also throw the chain that helps spin up the connections, but as of 2013automated on the drilling rigs is pretty much just another floorhand that watches out for the worm and does not get as filthy.

Leadhand/Floorhand ("worm"): Usually the lowest member of the drilling crew, those in this position are often nicknamed "worm", because this hand has the dirtiest and most physically demanding position. The floorhand works primarily on the rig floor where he is the one actually operating the tongs, iron roughneck, tugger, and catwalk, and doing pretty much any other job which is asked of him.

Roustabout (leasehand): On bigger rigs and offshore rigs, a roustabout does most of the painting and cleaning so roughnecks can take care of other work.

The Edmonton Oilers of the National Hockey League used to use an oil rigging roughneck with an ice hockey stick as one of their secondary logos. The roughneck, as a symbol of hard work and fortitude, was the inspiration for the Calgary Roughnecks lacrosse team, as well as the Tulsa Roughnecks of the North American Soccer League, the Tulsa Roughnecks of the United Soccer Leagues, and the Tulsa Roughnecks FC of the USL. The West Texas Roughnecks of the Indoor Football League also use this nickname. In the BAFA National Leagues, the Aberdeen Roughnecks have also adopted the nickname. In the AUDL (American Ultimate Disc League) the Dallas team is also the Roughnecks. One of the inaugural teams of the revamped XFL was the Houston Roughnecks

The Yard Hand is responsible for keeping the yard location and shop clean, picked up and clear of safety hazards. It is necessary that every hand be mentally alert and physically fit during the workday. The Yard Hand will assist in sorting and staking incoming and outgoing materials and inventory. Responsibilities include assisting welders, mechanics, and/or electricians. General assembly of drilling equipment is required along with minor sandblasting and painting. Driving a Fork Lift (after receiving Fork Lift Training Classes) will be included in the general duties. Activities will be as follows: The ability to push/pull items weighing 50lbs 20 to 50 times in a 12 hour period. The ability to lift items weighing 50lbs from the floor to the waist 8 to 10 times a day for a 12 hour period. The ability to carry items weighing 25lbs 8 to 10 times a day for a 12 hour period. The ability to stand up to 100% of the time. The ability to climb up to 35% of the time 20 to 50 steps. Primary Duties of this position require maximum level of physical activity. The employee must be able to tolerate 12 hours of standing, climbing, lifting, pulling, pushing, and carrying weights of up to 50 lbs. The work performed outside with prolonged exposure to the environment, both hot and cold. Operations could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet. Muscle groups include: Quadriceps, Low Back Extensors, Hip Extensors, Abdominal, Latissimus Dorsi, Deltoid, Pectorals, and Hand Grip.

There are two floor hand positions: Floor Hand and Lead Tong Hand. Each must daily inspect the tongs, breakout line, snub lines, and tong dies for damage, excessive wear, fraying oil soaks, etc. and keep them safe and in good repair. During normal drilling operations duties include washing, cleaning, mechanical repairs, digging ditches, drill pipe connections, drill pipe trips and other manual handling and/or maintenance activities as required by operational needs. While tripping (adding additional pipe to the stand), the Lead Tong Hand must pull and install the busing assembly. This activity will include lifting the tongs and lateral movement of the tongs to attach them to the drill pipe. The tongs are on counterweights and the exertion required to lift them would vary, but is estimated to be similar to lifting weights between 10-30 pounds. The lifting range up or down is 1-2 feet, in the area of the waist. This activity is repeated and could be performed as many as 175 times in a 12-hour Shift. Another activity conducted between tong usages is “pulling the slips.” This activity is performed by 2 or 3 men (depending on crew size) and could be conducted as many as 175 times per a 12-hour shift. The slips weigh between 100 and 175 pounds and the weight would be distributed between the 2 or 3 employees. The slips are located at floor level and would be lifted a distance of 18-24 inches. Racking pipe is another function performed by one of the Floor Hands during a drill pipe trip and involves manually pushing a suspended length of pipe to the area where it is racked. The reverse activity involves restraining the suspended pipe and guiding it across the rig floor. This activity is performed in the standing position and could be performed as many as 100 times per a 12-hour shift. Tripping the pipe string is an operation which involves removing all of the pipe from the well bore and racking it in the derrick. The pipe may be removed for various reasons, but usually is done to replace a drill bit on the end of the drill string. After the operation is complete, the pipe is “tripped” back into the well bore. The tripping operations vary depending on the depth of the well and other factors. Employees may be involved in the tripping operation for the full 12 hours of their work shift. The Floor Hand is responsible for catching and cleaning samples of formation cuttings while drilling. If drilling in gas, he must keep the flare bucket burning. At times it is necessary for the Floor Hand to climb up in the derrick and assist the derrick hand such as bridling up or bridling down. He must also be able to go up and grease the traveling blocks and bridle line sheaves. All hands working together must keep the rig clean, picked up and free of safety hazards. It is necessary that every hand be mentally alert and physically fit during his tour. Activities will be as follows: The ability to push/pull items weighing 50lbs 20 to 175 times in a 12 hour period. The ability to lift items weighing 100lbs from the floor to the waist 8 to 10 times a day for a 12 hour period. The ability to carry items weighing 100lbs 8 to 10 times a day for a 12 hour period. The ability to stand up to 100% of the time. The ability to climb up to 35% of the time 20 to 50 steps. (Up and Down @ 12 times per shift) Primary Duties of this position require maximum level of physical activity. The employee must be able to tolerate 12 hours of standing, climbing, lifting, pulling, pushing, and carrying weights of up to 100 lbs. The work is performed outside with prolonged exposure to the environment, both hot and cold. Operations could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet. Muscle groups include: Quadriceps, Low Back Extensors, Hip Extensors, Abdominal, Latissimus Dorsi, Deltoid, Pectoralis, and Hand Grip.

The motorman’s primary responsibility is to take care of all the motors on the rig. He must have a mechanical mind and the ability to trouble shoot and identify and repair minor problems that arise. He is responsible for checking the oil, oil pressure, temperature, fuel pressure and radiator water level and to record his findings in the daily engine report during his tour. He must be mentally alert and physically fit during his tour. Other responsibilities include racking pipe on the racking board when coming out of the hole and fill pipe when going in the hole. He is responsible for operation of the closing unit when shutting the well. Activities will be as follows: The ability to push/pull items weighing 50lbs 20 to 150 times in a 12 hour period. The ability to lift items weighing 100lbs from the floor to the waist 8 to 10 times a day for a 12 hour period. The ability to carry items weighing 100lbs 8 to 10 times a day for a 12 hour period. The ability to stand up to 80% of the time. The ability to kneel up to 15% of the time. The ability to climb up to 35% of the time 20 to 50 steps. (Up and Down @ 12 times per shift) Primary Duties of this position require maximum level of physical activity. The employee must be able to tolerate 12 hours of standing, climbing, lifting, pulling, pushing, and carrying weights of up to 100 lbs. The work is performed outside with prolonged exposure to the environment, both hot and cold. Operations could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet. Muscle groups include: Quadriceps, Low Back Extensors, Hip Extensors, Abdominal, Latissimus Dorsi, Deltoid, Pectorals, and Hand Grip.

The Derrick Hand is the crew member whose work station is in the derrick while drill pipe is being hoisted or lowered in the hole. He attaches the elevators to the stands of drill pipe while the pipe is being lowered into the hole and detaches the elevators and racks the pipe while the pipe is being hoisted out of the hole. Both operations involve the use of the arms and upper body to hold or pull the pipe. This operation could be repeated as many as 80 to 100 times during a 12-hour shift. He is responsible for greasing and inspecting the crown and all sheaves in the derrick. He must be mentally alert and physically fit while on duty. Other responsibilities of the Derrick Hand include mixing chemicals. The chemicals are packaged in paper bags and plastic buckets. The packages vary in weight from 20 to 80 pounds. Lifting and carrying is required to get the materials from the storage area to mixing areas. Manual handling of the packages or bags could require lifting from floor level to levels between 36 and 42 inches high. Unusual circumstances might require the lifting of numerous bags during a 12-hour shift. He is also responsible for watching the mud pits for an increase or decrease of mud volume, mud weight, and changes in funnel viscosity and gas cut mud. He must also watch and listen to the mud pumps to know when there is a problem. Activities will be as follows: The ability to push/pull items weighing 50lbs 20 to 175 times in a 12 hour period. The ability to lift items weighing 100lbs from the floor to 42" 10 to 20 times a day for a 12 hour period. The ability to carry items weighing 100lbs 10 to 20 times a day for a 12 hour period. The ability to stand up to 99% of the time. The ability to climb up to 35% of the time 20 to 50 steps. (Up and Down @ 12 times per shift) Primary Duties of this position require maximum level of physical activity. The employee must be able to tolerate 12 hours of standing, climbing, lifting, pulling, pushing, and carrying weights of up to 100 lbs. The work is performed outside with prolonged exposure to the environment, both hot and cold. Operations could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet. Muscle groups include: Quadriceps, Low Back Extensors, Hip Extensors, Abdominal, Latissimus Dorsi, Deltoid, Pectorals, and Hand Grip.

The Driller (crew foreman) is directly responsible for the rig crew during normal operations. He must be able to perform any job on the rig required of his hands, in order to instruct his crew on the “how to” procedure or to fill in as a Floor Hand as necessary. Refer to Job & Task Descriptions forms on Floor Hand, Motor Hand, and Derrick Hand for position requirements. He must know the safe operating limits of the rig and keep within those bounds. He is responsible for the operation of drilling and hoisting equipment. Actual rig operations involve the use of both hands and feet to operate controls. The Driller must be able to see gauges and dials at distances between 1 to 10 feet. He must be able to see the Derrick Hand at a distance of 60 to 90 feet away. He must be physically fit and mentally alert at all times to the operations taking place and crew participation. Activities will be as follows: The ability to lift items weighing 100lbs from the floor to the waist 8 to 10 times a day for a 12 hour period. The ability to carry items weighing 100lbs 8 to 10 times a day for a 12 hour period. The ability to stand up to 100% of the time. The ability to climb up to 35% of the time 20 to 50 steps. (Up and Down @ 12 times per shift) Primary Duties of this position require maximum level of physical activity. The employee must be able to tolerate 12 hours of standing, climbing, lifting, pulling, pushing, and carrying weights of up to 100 lbs. The work is performed outside with prolonged exposure to the environment, both hot and cold. Operations could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet. Muscle groups include: Quadriceps, Low Back Extensors, Hip Extensors, Abdominal, Latissimus Dorsi, Deltoid, Pectorals, and Hand Grip.

Mechanics and Techs are responsible for repairing and rebuilding equipment used on conventional and advanced drilling rigs. Employees will be trained on the job to service TOP DRIVES, MUD PUMPS, DRAWWORKS, IRON ROUGHNECKS, HYDRAULIC UNITS along with CONTROLS and INSTRUMENTATION for electronic drilling rigs. Mechanics and Techs must be mechanically inclined, work safely, able to work long hours, self-motivated, and proficient with various tools. It is necessary that every hand be mentally alert and physically fit during the workday. Also, employees must have a clean driving record and available to be “on-call”. Activities include: The ability to work and communicate with a team of people, the ability to push/pull/lift items weighing 80lbs repeatedly; the ability to climb up 20 to 50 steps, and the ability to exert a maximum level of physical activity. The majority of work will be performed outside with prolonged exposure to the environment, both hot and cold. Service calls could also involve prolonged exposure to wet or damp conditions, i.e. working in rain, snow, and sleet.

The educational and training requirements for oil field jobs vary by job type. For example, oil rig workers and other blue-collar oil field employees must have a high school diploma and be at least 18 years old. Most oil field employers prefer to hire candidates who have oil rig training and certification that covers OSHA regulations, safety practices, pipe laying and winching. There are several institutions around the U.S. that offer oil field training.

Do you have the skills and qualities oil field employers are looking for? Make sure they stand out on your resume. If you’re not sure where to begin, try using Monster’s resume samples and writing best practices to learn how to write and format your resume. Many oil field employers will want you to submit a cover letter with your resume. This gives potential employers the opportunity to screen applicants to ensure that they’re the right fit before reviewing their resumes. Learn how to maximize your chances of getting an interview by referring to our cover letter samples and writing tips.

The amount of money you can make in an oil field job depends on your experience level and the job type. For example, the median pay for oil field and rig workers in the U.S. is $19.63 per hour. Petroleum engineers earn a median yearly salary of $65,682. Find out how much you will likely earn at your job by using Monster’s Salary Tool. All you have to do is enter the job title and your location. You’ll also see a list of locations where your job is in the highest demand, potential next career steps, and top oil field job postings.

Ready to mine for the best oil field jobs? Check them out right here. Then create your free profile at Monster and start getting custom job notifications. We also offer valuable tips on how to excel in your career and the opportunity to connect with recruiters.

Are you trying to land a job on a drilling rig and start a career in the oil and gas industry? Like you - I started at the bottom and over a 15-year career progressed from an entry-level position to a project manager earning a six-figure income $$$,$$$. After this, I worked as a Recruiter and I am now an Executive CV / Resume Writer so have a very good understanding of the environment and what it takes to progress a career in the international oil and gas industry. This article will help you land an entry-level position like roustabout, operator, rigger or trainee graduate. It also contains a comprehensive guide of all the positions on a rig and descriptions of various types of rigs so that you can choose a career direction.

It is a realistic option for you to break into the industry, it just requires patience and for you to apply everywhere necessary but make sure your CV is looking its absolute best before you apply, if not, it’s a wasted exercise... You only have one chance at making the right first impression!

Jobs on the rigs will include cleaners, painters and roustabouts (both entry-level), riggers (slingers), floor hands, catering staff, crane operators, welders, electricians, mechanics, motormen, engineers, chief engineers, derrickman, assistant drillers, drillers, tool pushers, warehousemen, medics, (HSE) safety supervisors, ballast control men, dynamic position (DP) operators, barge operators, barge engineers, offshore installation managers (OIMs), rig managers and rig superintendents.

All these positions except entry-level will require some type of prior experience and specialist training unless you just get very, very lucky. Below is a guide for a more in-depth look at the permanent positions on a rig.

If you want to work overseas, understand that drilling contractors seldom if ever send lower echelon people overseas. An overseas crew usually have Expatriate Rig Managers, Tool pushers, Drillers, Assistant Drillers, Crane Operator, Barge Engineer, Electrician and Mechanic. Maybe even a few more, maybe a few less, it varies from company to company, rig to rig, job to job. All lower positions will be locally hired!

You are not going to see expatriate roustabouts, cleaners, painters, riggers or floor hands going overseas and working a 28/28 schedule because the country where the rig is working will use (nationals) for those jobs. Often local governments stipulate that a certain percentage of the crew needs to be national so expatriate positions are reduced.

Laid out below are the basic jobs on an offshore drilling rig starting with the lowest level of the worker through to the Offshore Installation Manager (OIM) also including the support staff after the OIM.

Roustabout - The job of roustabout is about the easiest entry level job to get. It involves a lot of hard manual labor and long work hours. Roustabouts typically are involved on the main deck with painting and sandblasting, unloading pipe and other kinds of physical work. During breaks they also fill in for the roughnecks on the rig floor.

Roughneck - Higher up are the roughnecks also known as floor hands who do the jobs on the rig floor. The job of the roughnecks is to make connections in the drill pipe using pipe tongs or an automatic device known as an “iron roughneck”. Roughnecks “trip pipe” joints of drill pipe into and out of the hole when drill bits, etc, need to be changed.

Derrickman - Aligns and manipulates the sections of pipe or drill stem from a platform on the rig derrick during the removal and replacement of strings of pipe, or drill stem and drill bit. Assist in setting up, taking down and transporting drilling and service rigs. Supervises the roughnecks. This job entails working at height in the derrick usually at 170ft.

Crane Operators - Responsible for all crane operations on the rig and to and from the supply boats. Cranes are used to load supplies, such as casing, pipes and rig equipment, onto the oil rig. Crane operators also assist in general labour around the rig. Crane operators supervise the roustabouts and the crane operator assistant. This is a senior deck crew position.

Assistant Driller (AD)- Runs the work crew and takes information from the driller and gives it to their crew. While the assistant driller acts in a predominately supervisory role, they may also work alongside the roughnecks to run machinery. ADs train roughnecks to recognize abnormal well conditions in order to prevent leaks and rig blowouts.

Driller - A driller is a person in charge of the rig floor and of overseeing the drilling of an oil well. They directly control the rate of drilling and it is a skilled position that requires extensive knowledge of rock types and drilling procedures. Drillers must be highly knowledgeable and make real-time decisions in a calm and controlled manner.

Tool Pusher - On a land drilling rig the tool pusher may be the rig manager and responsible for all operations, but on drillships and offshore drilling rigs, tool pushers are in charge of the drilling department and report to the Offshore Installation Manager (OIM).

OIM (Offshore Installation Manager) - is the most senior manager of an offshore installation. If an emergency were to arise they control the situation and manage the response. He is responsible for all personnel and operations and reports to the Rig Manager who is onshore.

Rig Electrician - They are responsible for ensuring that all electrical systems on the rig are functioning properly. Duties include repairing, maintaining, installing and operating all electrical equipment on the rig. They need to be competent in the use of electricity in hazardous areas and communicate with the rig crew.

Motorman / Rig Mechanic - The primary job function is oil rig equipment maintenance. The motorman checks the rig motors and other mechanical equipment on the rig for proper functioning and takes all necessary steps including lubrication and regular maintenance to render equipment in a working condition.

Barge Engineer - The Barge engineer is in charge of control room operations, including anchor handling, rig stability and supply vessel operations. A barge engineer should have a good knowledge of Coast Guard operations and water safety. Most barge engineers have experience as master merchant in the Navy.

Radio Operator - Efficiently communicating vital information between land bases, rigs, boats and helicopters. Sets up, operates and maintains sensitive equipment to establish verbal, data and encoded interactions regarding emergency situations, weather conditions and important job directives.

The most commonly used rigs in the industry are Jack-ups, used to drill in shallow water, Semi-submersibles used to drill in deep water and land rigs which are moved on trailers and spotted on concrete bases on land, I will also mention fixed platforms which can have drilling facilities on board. The most expensive to run is the semi followed by the jack-up and finally the land rig. This is all down to the size, equipment differences and also the difficulty with logistics to and from the rig. Each rig will have similar drilling equipment on board but some will vary due to the nature of the rig.

These types of rigs come in a variety of sizes depending on the type of well you will be drilling. The rig breaks down into many parts so that it can be transported with trucks and trailers. First, a concrete base will be laid at the location of the well and a pit will also be dug next to the location for the cuttings from the well to be temporarily dumped into. These rigs can be assembled very quickly usually within 3-7 days and can be transported in as little as 12 truckloads.

These rigs are towed into location and then jack their 3 legs down until the legs reach the sea bed. Some larger rigs can have up to 5 legs. The rig will then raise itself out of the water to the deserved height. Jack-ups are good in water depths of up to 400ft (120m) and can be found most commonly in the North Sea because of the seas shallow nature. Once settled the Jack-up rig has a static base in which to drill from. Occasionally rocks has to be placed around the legs to keep the platform from sinking or tilting into the seabed.

Sit on pontoons and float high above the water. The ballast tanks can be adjusted to raise or lower the rig and they can be moved under their own power or towed into place. Once in place the rig will deploy its six anchors and they will be tensioned accordingly to move the rig over the drilling location. Semi-Submersible rigs can be used in water depths from 200ft – 10,000ft (60m – 3000m). The main difference with drilling from a Semi is that the rig is not static and is constantly moving with the swell, therefore the drill pipe moves up and down with the swell. The rig is fitted with heave compensators which keep the drill pipe firmly at the bottom whilst drilling. When the rig moves upwards the heave compensators push down the drill pipe and vice versa.

A drillship is a mobile offshore drilling rig where a mono-hull ship, catamaran, triple-hull ship, or barge is adapted or built for use as a platform. After reaching the well position, the drillship first gets into position with the mooring system or dynamic positioning (DP) system and then begins to drill a well. From the action of wind and waves, the drillship will encounter a heaving motion and sway on all sides, hence, it needs measures such as a drilling string heave compensation device and swing angle reduction device as well as dynamic positioning (DP) to guarantee displacement of drillship within the allowable limits, so as to properly drill a well.

Fixed drilling platforms offer stability but not mobility. Today they’re usually used to tap shallow, long term oil deposits. These platforms are permanently anchored directly to the seabed with the use of a steel structure known as a “jacket”. This rises from the seabed to support a surface deck that is above the ocean. The jacket provides the rig’s sturdy base and holds everything else out of the water, while the drilling modules and crew quarters are located on the surface deck. They can drill to depths of about 1,500 feet below the surface but are expensive to build, so they usually require a large oil discovery to justify their construction.

ENSCO, Dallas, TX, USA One of the leading offshore oil and gas drilling contractors in the world with a fleet of 56 offshore drilling rigs and 27 oilfield support vessels. Work Area: Gulf of Mexico, Australia, Asia, Latin America, the North Sea, the Middle East and West Africa. http://www.enscous.com/\

FEMCO, Far East Marine Company, Sakhalin Region, Russia - A regular participant of all oil and gas development projects in offshore Sakhalin who plans to extend the sphere of theor traditional fleet activities as well as mastering new opportunities. 1 rig working in the Far East, 3 in the Persian Gulf. http://www.femco.ru/

Helmerich and Payne, Inc, Metairie, LA, USA Owns and operates12 platform rigs and manages 4 offshore management contracts in the Gulf of Mexico and the West Coast Santa Barbara Channel. H&P"s diverse offshore fleet consists of deepwater tension leg platform (TLP) rigs, self-moving rigs and traditional self-contained platform rigs. Work Area: Gulf of Mexico, West Coast California. http://www.hpinc.com/

Mannai Offshore, Doha, Qatar Operates a fleet of vessels, jack-up accommodation rigs and early production facilities that provide a wide range of specialized services to the offshore oil and gas industry. Work Area: Offshore Qatar and surrounding areas. http://www.mannai.com/

Nabors Industries, Houston, TX, USA The largest land drilling contractor in the world. One of the largest well-servicing and workover contractors in the United States. A leading provider of offshore platform workover and drilling rigs. A provider of ancillary well site services such as oilfield management, engineering, transportation, construction, maintenance and well logging. Work Area: Gulf of Mexico, Latin America and the Middle East. http://www.nabors.com/

Odfjell Drilling, Bergen, Norway Owns and operates semi-submersible drilling rigs in the North Sea and is also a leading platform drilling contractor with operations on fixed and floating production platforms. http://www.odfjelldrilling.com/

Parker Drilling Company, Houston, TX, USA A global drilling company providing drilling rigs, labor management and rental tools to the energy industry. Parker"s primary business segment is drilling rigs with 33 in the United States Gulf of Mexico and 46 internationally. The company’s international rig fleet consists of barge rigs in the Caspian Sea and Nigeria and land rigs in 12 countries. Work Area: Gulf of Mexico, Eastern Europe and West Africa. http://www.parkerdrilling.com/

Prosafe ASA, Tananger, Norway World"s leading owner and operator of semi-submersible service rigs, the largest platform drilling contractor in Norway and a major owner and operator of floating production- and storage vessels outside the North Sea. http://www.prosafe.no/

Paterson UTI, INC., Houston, TX, USA The second-largest provider of onshore contract drilling services to exploration and production companies in North America. The company owns 324 land-based drilling rigs and is also engaged in drilling and completion fluid services and pressure pumping services. Work Area: Texas, New Mexico, Oklahoma, Louisiana, Mississippi, Utah and western Canada. http://www.corporate- ir.net/ireye/ir_site.zhtml?ticker=PTEN&script=2100&layo/

Petrolia Drilling ASA, Oslo Owns and charters drilling vessels for offshore, deepwater oil and gas exploration and development drilling. It intends to continue to expand its current rig fleet through a strategy of acquiring, refurbishing and selectively deploying offshore drilling rigs and drillships on fixed-rate, long-term contracts. http://www.petrolia.no/

Precision Drilling, Alberta, Canada Maintains a fleet of 240 plus land rigs working in Canada and other countries, making the company one of the largest land drilling contractors in the world. Operations include drilling, catering, well servicing and oilfield rentals. Work Area: Canada, Mexico, Columbia, Venezuela, Brazil, Argentina, the United Kingdom, the Netherlands, Germany, Egypt, the Middle East, China, India, Indonesia and Kazakhstan. http://www.precisiondrilling.com/

Pride International, Houston, TX, USA One of the world"s largest drilling contractors providing offshore and onshore drilling, workover and related services in more than 30 countries. Fleet of 328 rigs includes 2 ultra deep water drillships, 12 semi submersibles, 35 jackups, 5 tender assisted rigs, 3 barge rigs, 21 offshore platform rigs and 250 land based drilling and workover rigs. Work Area: Gulf of Mexico, West Africa, the Mediterranean, Latin America, the Middle East, Australia and Asia. http://www.mardril.com/

Prosafe SE, Stavanger, Norway Prosafe is the world ́s leading owner and operator of semi- submersible service rigs and a major owner and operator of floating production and storage vessels. http://www.prosafe.com/

Rowan Companies, Houston, TX, USA A provider of international and domestic contract drilling and aviation services. Rowan has a marine division which has designed or built over one third of all mobile offshore jack up drilling rigs, including 22 operated by the company. Work Area: Gulf of Mexico, East Coast of Canada http://www.rowancompanies.com/

Floorhand is to safely and efficiently perform all manual labor tasks on the drilling floor and B.O.P. area under the direct supervision of the Driller or, in his/her absence, the Assistant Driller. This include the operating of the tongs, slips and spinner hawk to connect and disconnect drilling pipe, tubular and drilling bits or tools as well as performing all maintenance of the equipment and physical space of the drilling floor. It further includes right up and down procedures, nipple up and down and care of the B.O.P. system, the monitoring and operation of the shakers and when called up to do so, to assist the Derrickhand within the mud pit, mud pump and chemical sack rooms. The Floorhand is responsible for the housekeeping activities on the drill floor including washing, chipping and painting. When trained, the Floorhand will provide relief for the Derrickhand

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291