workover rig inspection checklist pricelist

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Drilling in oil and gas is the process of creating holes in the earth"s surface in preparation for the exploration of oil and gas. Drilling rigs come in a variety of sizes, from a one-person operation to those capable of drilling thousands of meters below the surface. As well as drilling, the rigs can test sub-surface material, to understand the physical properties of a drill site.

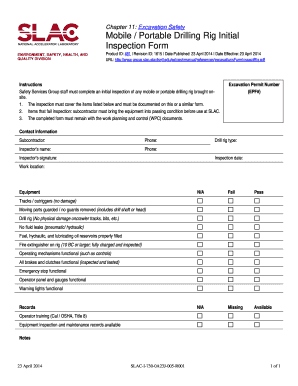

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

We offer inspection for used civil-engineering equipment ans special heavy machinery such as pile drivers, drill rigs, desanding machines, vibrators, vibration hammers and leaders, diesel impact hammers, telescopic leaders, RTG equipment, grab systems, duty-cycle cranes and diaphragm wall grabs.

We offer inspection for used civil-engineering equipment ans special heavy machinery such as pile drivers, drill rigs, desanding machines, vibrators, vibration hammers and leaders, diesel impact hammers, telescopic leaders, RTG equipment, grab systems, duty-cycle cranes and diaphragm wall grabs.

We are one of the leading service provider for Coring, Air Drilling, Workover and Drilling Rig Services to various Oil and Gas Companies in India. Our strength is in providing complete Rig Package with all associated equipment and services to onshore Oil and Gas Industry. We currently hold wide range of Onshore Workover Rigsread more...

workover rigs without guyline are designed for small-scale and fast workover operations. Since it is not necessary to install external windload guylines, operating efficiency is greatly enhanced. They can work at 60 kn of wind in adjustment mode, and 35 kn of wind in operating mode, and are suitable for shallow wells in variousread more...

We have 6 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

- "Service Work" consists of using a rig to pull down hole pumps, rods, and tubing from the wellbore. Other service including cleaning and swabbing a method used to remove fluid from the well bore. Well depths range from several hundred feet to 10, 000 feet belowread more...

We are one of the leading service provider for Coring, Air Drilling, Workover and Drilling Rig Services to various Oil and Gas Companies in India. Our strength is in providing complete Rig Package with all associated equipment and services to onshore Oil and Gas Industry. We currently hold wide range of Onshore Workover Rigsread more...

We have 6 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

The SKA is manned by a set of highly experienced global crew (India, Australia, United Kingdom, Brazil, Azerbaijan, South Africa etc) who bring significant knowledge, expertise and diversity to the rig. We continually maintain and develop an extensive network of people associated with this industry. Our long-term associationread more...

With an internationally experienced crew of drillers and technicians credited with completing complicated drilling programs in difficult and diverse terrain, Punj Lloyd Upstream has a fleet of brand new AC VFD 1500HP and 2000HP onshore rigs with a drilling capacity of 6, 000 m.

We have 5 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

With an internationally experienced crew of drillers and technicians credited with completing complicated drilling programs in difficult and diverse terrain, Punj Lloyd Upstream has a fleet of brand new AC VFD 1500HP and 2000HP onshore rigs with a drilling capacity of 6, 000 m.

Here"s when workover operations come into play. Every time a well has production problems it needs to be repaired. In this article you"re going to be reading about one particular problem in a well and what we did to solve it. If you"re a young professional in the oil industry and never had the chance to be present in a workover operation, I invite you to go through these lines, hoping they help you knowing a little more about this amazing and unpredictable world.

A few years ago, my rig team received information about the next oil well that we would be repairing. Just by reading the well"s name we immediately inferred that we were going to deal with a really old well. The job program indicated us that this well had a high water cut, this means that most of the production of the well was formation water. We needed to isolate the water producing sandstone in order to leave an upper sandstone open to production.

The well was originally drilled in the 70´s by a split drilling rig, this type of rig was used in the past for operations on shallow waters and it was not like a typical cantilever drilling barge. In this rig, the derrick was separated from the barge and it had to be armed above the foundation of the well. This type of foundation is known as Light Rig Mover foundation and it is formed by four heads with two piles each and a square metal frame 24’ x 24’ approximately. With this particular well, we recall that old saying that states: "Don’t judge a book just by its cover". Let’s move on to the seven steps

The first thing we do before working on any well is an inspection of the location before the rig move, this is very important to determine wheatear the barge can fit in the well location or not. During this well’s inspection we could see that both the well foundation and the wellhead were not in the best condition, but this was fixable and the job could be done, though it would be a real challenge. Finally, the rig was moved and positioned on the well location.

Before removing the christmas tree in order to install the BOPs, we had to secure the tubing by settling a safety valve in the upper landing nipple. In most cases we secure the well by installing a check valve in the tubing hanger, but this well did not have an extended neck hanger, instead it had a wrap around tubing hanger which made the use of slickline tools necessary. We always make a calibration trip before running anything else into a well. In this particular case the tubing string originally installed in the well was 2-7/8”, 6.5 lb/ft from surface to 11413’, and 2-3/8”, 4.7 lb/ft from 11413’ to the entry guide at 11706’. With a Baker Hughes FH Hydraulic packer at 11415’ and an Evolution R3 retrievable packer at 11697’, five gas lift mandrels, a 1.875” landing nipple at 11704’, a 2.313” landing nipple at 214’ and no sliding sleeves. We first ran a 1-27/32” gauge cutter to the bottom of the hole at 12211’ and then a 2-9/32” gauge cutter to 11413’ locating the crossover 2-7/8” x 2-3/8”. Then, before running the valve we ran a slickline tubing scratcher in order to guarantee a good setting of it. So, after a few trips, we installed the valve at 214’ and let the well secured to install de BOP and continue the operations with proper safety.

This saved us from all the fishing jobs, which in this type of wells is at least two fishing trips (without any complications) and perhaps a few milling trips if the tubing is somehow damaged by the wireline cutters, and this represent lots of saved rig time for the well. In general, the fishing operations take from 40% to 50% of the time needed to finish a workover job. The only thing we had to do was a quick calibration trip to 11945’ with a 4-5/8” tapered mill to guarantee a good operation in our next step.

Once we retrieve an old completion string from a well, we usually run a mechanical packer to make a casing integrity test, in this case we ran an Evolution R3 packer for 5-1/2”, 17-20 lbs/ft casing (not the same one that was retrieve from the original completion, obviously), down to 11645’, 20’ above the first perforated intervals. After successfully testing the casing, the following step was a wireline job.

The last step of this workover job, after solving the bottom hole problem and replacing the wellhead, was to run the well completion. The equipment was ran down to 11402’ and it was composed by 368 joints of 2-7/8” 6.5 lbs/ft tubing, five gas lift mandrels, two 2.313” landing nipples, and a Weatherford Stratobar hydraulic packer, the completion was hanged in the new tubing head installed and then we performed the final slickline jobs to test the tubing string and set the hydraulic packer without any major complications.

This sums up our entire work on this well, leaving it ready for production. Yes, after more than 40 years of being originally drilled, this well is still capable of producing a very significant amount of crude oil. That’s how important workover operations are, if a well has the proper maintenance, its commercial life is longer and more productive. Besides, a workover operation is not as expensive as the drilling of a new well.

I think is only fair to say that each one of the steps I described include several activities that might need a little more detailed explanation to be completely understood, but it would be extending my writing too much. I also think it’s important to let readers know the reason why I decided to write about this particular well; if you look back in step 3, I said that the fishing activities take 40-50 % of the rig time needed to finish a workover job, the special thing about this well is that we didn’t required fishing activities since the original well completion was entirely retrieved just by pulling it out of the well. So, this is one of those cases when you get very, very lucky, and after a not quite good first impression we ended up successfully completing a job estimated to be done in 20 days in only 12.5 days, congrats for us!

This outline is provided as an informal guide to members of the public seeking information or legal services the Railroad Commission of Texas cannot provide. Since the Texas Legislature has given the Railroad Commission of Texas limited authority to regulate the oil and gas industry in Texas, our staff cannot advise you in all oil and gas matters. Areas over which the Railroad Commission of Texas has no authority include lease and royalty matters (including leasing, payment of royalties and the right to receive royalties), the financing of or investment in oil and gas activities, property rights matters and bankruptcy.

A key decision when executing an inspection survey for the selection or acceptance of a drilling rig is what to inspect. In an effort to be efficient, the typical approach is to focus on the critical equipment. Determining the list of critical equipment is fairly straightforward – it’s the equipment the failure of which would prevent the successful completion of your drilling campaign.

In another example, the rig exhibited an excellent overall physical condition and appeared ready to operate. However, upon arrival at the location and drilling had started it was discovered that a necessary certification was missing, resulting not only in a suspension of drilling but also the imposition of hefty fines for violating regulatory requirements.

Crew competency –The ability of the crew to understand and execute the process is evaluated. The normalization of deviance is considered here – are the procedures being modified in any way from original requirements to cut corners.

Athens Group principal technical staff have been designing, building and verifying integrated controls-based equipment systems longer than many of these types systems have been in use in the Oil and Gas industry. We implement a domain-specific engineering discipline to design and execute a survey, inspection, and test activities, rooted in the principles of evaluating the people, plant, and process integrated systems. Only a comprehensive consideration of all three elements will yield a proper evaluation of what is actually critical to the success of your drilling campaign.

The Workover Rigs market will remain attractive over the forecast period owing to rising consumption of petroleum products. As a result, the Exploration and Production (E&P) located globally will increase their investment due to increasing demand and positive outlook of the oil and gas market.

The ongoing rise in oil prices can be regarded as new phase for the companies operating in the sector. Adding to this, the participants are looking to attain growth through domestic and international expansion as well as adding new production related services. As Workover Rigs providers play important role in the production operation making them key segment in the reviving upstream sector and hold massive share in the overall spending of the companies.

Moreover, the investment from government as well as private sector in the drilling activities is also expected to rise and surge in shale gas production is expected to fuel the growth of the Workover Rigs market in the coming years. The oversupply of Workover Rigs in the cyclical oil & gas market is one of the major restraint to the market.

However, the industry has recovered successfully from the recent oil price crisis and industry outlook will remain positive in the coming years. One of the major trend in the market will use of environment friendly Workover Rigs. The government authorities are directing energy companies to decrease carbon footprint that will shift the focus of the companies towards use of components that run renewable energy in the coming years.

8613371530291

8613371530291