workover rig specifications brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

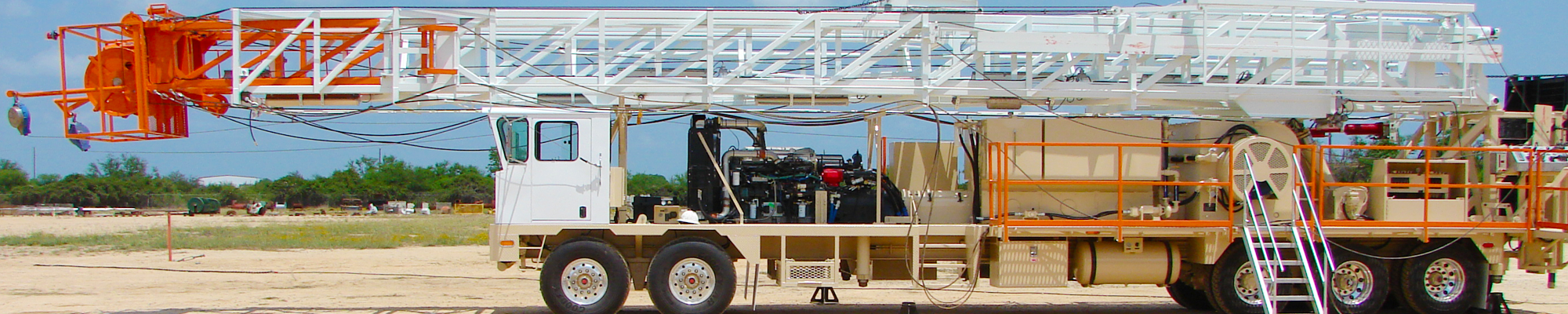

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Jereh truck/trailer mounted workover rig is mechanically and hydraulically driven. The power system, drawworks, mast, travelling system and transmission mechanism of the workover rig are mounted on the self-propelled chassis, which improves the moving efficiency greatly. Now, Jereh truck mounted workover rig series cover the workover depth from 2500m to 7000m and drawworks power from 250HP to 1000HP, featuring high operation load, reliable performance, excellent off-road performance, convenient movement and low operation/moving cost. Besides, workover rigs for arctic, desert and highland applications are available.

If within 7 days you would like to return a photograph for any reason just place the photograph in the original shipping carton and return undamaged to us.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

Founded in 1969, RG Petro-Machinery Group Co., Ltd. is the manufacturing base of Chinese major technical equipment and fast move petroleum drilling rigs. At present, it has 12 subsidiaries with 9 production and supporting branches. Its main products include 12 series of more than 200 varieties, such as truck-mounted drilling rigs, skid-mounted drilling rigs, trailer-mounted drilling rigs, workover rigs, oilwell logging equipment, and integrated automatic well service equipment.RG Group has established a complete scientific and technical research and development system. It has academician workstation, post-doctoral scientific research workstation, and the National Petroleum Truck-mounted Equipment Standardization Work Department. It is responsible for hosting in drafting the national petroleum and petrochemical industry truck-mounted equipment standards. It has a nationally recognized enterprise technology center and metrology inspection laboratory, and has strong machinery fabrication and system integration capabilities. The company has passed ISO9001 and API Q1 international quality system and been authorized to use API 4F, 7K, and 8C monograms since 1990s.RG provides the oil and gas drilling equipment and all-round services according to the demands of the customers globally, including drilling services, equipment maintenance services, engineering services, inspection services, and equipment leasing etc. RG Petro-Machinery Group Co., Ltd. makes the great efforts to provide the first class equipment and services for the oil and gas industry of China and the world.

Well Service | Workover Rigs - 844/80 Double drum draw works. looks to be recently rebuilt. Has new Lebus Grooving on Tubing Drum. Comes w/ 250 HP 2 speed jackshaft/RA BOX. More Info

Well Service | Workover Rigs - CARDWELL KB200B Freestanding Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Cardwell KB200B Freestanding Service Rig, 5 Axle Carrier, Detroit 8V71... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - COOPER 350 Well Service Unit p/b DETROIT 8V-92 Diesel Eng, ALLISON 750 Trans, 42X12-38x8 DRAWWORKS w/dual disc assist, 97â 200,000# Telescoping M... More Info

Well Service | Workover Rigs - CROWN 350 SERIES -- SERVICE KING 104" 205,000# DERRICK, CAT3406, ALLISON 5860,38X10 DOUBLE DRUM DRAWWORKS, CROWN SHEAVES REBUILT 2013 MAIN26âX4,SANDLINE 22â, NE... More Info

Well Service | Workover Rigs - 2008 Crown/Cabot 1058 Service unit mounted on 4 axle carrier w/Detroit 60 Power. New 5860 Drop Transmission. 72" Double rod/single tubing Derrickmast 125000# Rig is in Ex... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - FRANKS 1287-160-DTD-HT D/D Well Service Unit p/b DETROIT 8V-71N Diesel Eng, ALLISON CBT-4460-1 Trans. SERVICE KING 96" 180,000# Hydraulically Raised & ... More Info

Well Service | Workover Rigs - FRANKS 300 D/D 1287 w/hydromatic brake, Well Service Unit p/b DETROIT 8V-71 Diesel Eng, ALLISON 750 Trans, (Reman Dec 2011) FRANKS 96âH 150,000# Tri-Scope Telescopin... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b CAT 3406 Diesel Eng, ALLISON HT-750 Trans, FRANKS 96âH 180,000# 4-Leg Telescoping Mast, Hydraulically Raised & Scoped w/4-Sheave... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b Series 60 Detroit Diesel Eng, ALLISON 5860 Trans, 102âH 225,000# (on 4 line) Telescoping Mast, Hydraulically Raised & Scoped, Db... More Info

Well Service | Workover Rigs - IDECO H35 96̢۪ 210,000 MAST, DETROIT 60 SERIES ENGINE, ALLISON 5860 TRANSMISSION, REFURB 2005, IDECO DERRICK REPLACED WITH NATIONAL DERRICK, TUBING DRUM CON... More Info

Well Service | Workover Rigs - IDECO RAMBLER H-35 Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Ideco Rambler H-35 workover rig / service rig / pulling unit, 4 axle carrier, De... More Info

Well Service | Workover Rigs - 2015 INTERNATIONAL PAYSTAR 5900 Flushby Unit. C/w 2003, Refurbished in 2015, Western Fab Ltd. flushby unit, s/n 03-09-1008, 50 Ft. Mast height, 50,000 lb. pull rating, fr... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800 Flusby Unit. C/w Lash Ent. flushby unit, 47 ft mast, slant compatible, 3x5 Gardner Denver triplex pump, 5000 psi, 2005 Advance 8m3 tank, TC 406 code, P... More Info

Well Service | Workover Rigs - 2003 KENWORTH T800 Flushby Unit. c/w Online flushby unit, 47 ft. mast, slant compatible, Pullmaster HL25 wotking winch, Pullmaster PL5 catline winch, 2002 wabash two comp... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800B Flushby Unit. c/w Online flushby unit model 50-50, s/n 24641, 40 ft. mast,Salnt compatable, Pull master HL25 and PL5 winch, Gardner Denver 3x5 triplex... More Info

Independent producers and operators ramping up shale exploration and development programs are pushing the limits of conventional drilling equipment. Whether they are drilling multiple long-lateral horizontal wells from single pads, testing new bits and mud motors to boost penetration rates, or deploying next-generation rig floor and automation systems to slash “spud to sales” times, independents and their service company partners continue to find ways to improve resource play economics and crack the unconventional drilling frontier wide open.

Goodrich Petroleum is a case in point. Over the past two years, the company has transitioned from vertical Cotton Valley wells to horizontal wells in the Cotton Valley and the underlying Haynesville Shale. To unlock the shale’s vast potential, the company worked with its partners and service providers to discover the right casing points and to choose bottom hole assemblies that could build at sufficient rates to maximize lateral lengths, reports Clarke Denney, the company’s vice president of drilling. He notes that in the Haynesville Shale, Goodrich is utilizing robust directional equipment and mud cooling units to drill laterals at vertical depths of 15,000 feet, where circulating temperatures can reach upward of 340 degrees Fahrenheit.

Drilling wells in either play requires rigs with the right equipment, says Denney. He says top drives are important because they allow pumping and rotating the drill string while coming out of the hole, which is necessary at times for hole cleaning. This reduces drag and the chance of getting stuck. Top drives also maximize directional drilling performance.

Drawworks that can deliver at least 1,500 horsepower are also key, Denney adds. “We believe in high horsepower,” he stresses. “A 1,500-horsepower rig carries a premium over a 1,000-horsepower rig, but it speeds trips and puts less strain on the equipment. We get our money’s worth.”

Just as important as the drawworks and top drive is having powerful mud pumps on the rig, Denney says. “In the Eagle Ford, we would prefer to have at least 1,600-horsepower pumps, especially when drilling long laterals,” he relates. “That horsepower is needed for mud hydraulics to keep the hole clean, and to drive the downhole motor and other equipment. We have achieved up to 6,000-foot laterals to date, and we are targeting 9,000-foot long laterals in the near future.”

In many cases, it makes sense for the rig to have the ability to skid, Denney says. He explains that drilling multiple horizontal well bores on one pad reduces construction costs and rig transit times. “In the Eagle Ford, if we can skid, our drilling costs can be reduced as much as $500,000 a well,” he says.

Goodrich Petroleum is far from the only company that needs “high-spec” rigs with powerful top drives, hoisting systems and pumps. According to industry sources, rigs with larger (+1,000) horsepower ratings account for an estimated 60 percent of the active rig fleet. Moreover, rigs with at least 1,000 horsepower account for nine of every 10 rigs that are under construction or planned for the near future.

With its operational focus transitioning from the Cotton Valley trend to the Haynesville Shale, and more recently to the Eagle Ford Shale, Goodrich Petroleum is achieving consistent production and reserve growth through horizontal drilling with high-spec land rigs and advanced downhole tools. Even during the economic recession of 2009, the company increased average net daily production 24 percent and proved reserves 5 percent. Over the past four years, it has more than doubled its daily production while expanding its reserves 30 percent.

Trent Latshaw, the founder and head of Latshaw Drilling in Tulsa, can verify that the demand for 1,000-2,000 horsepower rigs is high. He says the company’s fleet, which includes 15 rigs within that range, has 100 percent utilization. In fact, Latshaw reports that the only unused rig his company has on the books is a new, 1,700-horsepower diesel electric that is still under construction.

Many of today’s high-spec rigs have closed-loop mud systems, Latshaw notes. “Closed-loop mud systems do away with the need for a reserve pit,” he says. “The systems also processes drilling fluid more efficiently. They are able to take more solids from the drilling fluid, which enables more fluid to be reused and makes the solids dryer and easier to dispose of. That becomes very important when dealing with oil-based mud, which often is used in horizontal wells.”

Latshaw encourages operators to consider using high-horsepower rigs when the class they want is difficult to obtain. “We consider our 2,000-horsepower rig to be identical to our 1,500-horsepower rigs, except for the drawworks size and the mast/substructure capacity,” he says. “The 2,000-horsepower rigs have the same footprint and move as fast as the 1,500-horsepower units, and for all practical purposes, the day rates are the same.”

He also says diesel-electric SCR rigs are comparable to AC rigs. “They have the same top drives, the same mud pumps, the same mud systems, the same engines, and the same blowout preventers,” he reports. “From the customers’ perspective, they drill wells as fast as AC rigs.”

In reference to safety, Latshaw says people matter more than technology. “You can try to design a piece of equipment that is accident proof, but safety comes down to the people on the rig floor and what their mindsets are,” he insists. “We are putting more money into training, beefing up our safety department, and having more safety coaches go around the rigs to work with the hands.”

He points out that many rigs, including several of Latshaw Drilling’s units, use automated iron roughnecks to improve safety. “Those are expensive, high-maintenance pieces of equipment,” he says. “We decided to take some of them off our rigs, then track closely to see if we had more finger and hand accidents on the rigs using manual tongs and a drill pipe spinner versus the rigs that had iron roughnecks. We have not seen a difference.”

For Joe Hudson, the president of Nabors Drilling USA, the future looks bright. “We have at least 103 AC rigs deployed at this point,” he reports. “We are in the process of building 25 more, and we always are looking for opportunities to expand further, be it in the Bakken, the Mid-Continent, West Texas, the Eagle Ford, or the Marcellus.”

Hudson says the new rigs include larger pumps, AC top drives, and tubular handling tools such as automatic catwalks and floor wrenches. “With the automatic catwalk, there is no need for a rig hand to pick pipe off the catwalks, pull it up with a hoist, and drag it to the rig floor,” he says. “Instead, the catwalk picks up pipe and elevates it to the rig floor. No one is touching the pipe or rolling pipe onto the catwalk, which keeps people away from tubulars, reducing the risk of pinch-point injuries.”

The rigs also employ advanced software. “With conventional rigs, the driller would drill ahead with a hand on the brake handle. He had only basic drilling information available to him, and his skill and his experience with the area dictated his ability to drill the well,” Hudson recalls. “Today, the software associated with smart drilling systems allows him to drill the well with a better understanding of the factors that influence drilling performance, such as delta P, hydraulic horsepower, weight on bit and rate of penetration. That translates to a faster rate of penetration.”

To ensure that its employees work as safely and efficiently as possible, Nabors has fully functional training rigs in Williston, N.D., Casper, Wy., and Tyler, Tx., where it trains personnel with no previous experience, Hudson reports. He adds that the company carefully defines the training and competency individuals need to be promoted.

The newest generation of high-spec land rigs purpose-built for horizontal drilling in unconventional resource plays features integrated subsystems to automate key processes such as pipe handling. Automated catwalks and floor wrenches not only increase operating efficiency, but also improve rig floor safety and extend pipe longevity by reducing handling damage.

When downturns do occur, Nabors tries to keep competent people and trainers on staff, Hudson says. By doing so during the last economic downturn, he says the company managed to go from 92 rigs in fall 2009 to 190 rigs today without compromising its personnel or safety standards.

Regardless of the market condition, Hudson says it is vital to design rigs for specific areas. “Every area is unique,” he says. “Carrying the top drive in the mast is a great way to reduce the number of loads needed, but in areas where road weights are critical, other approaches have to be adopted.”

To illustrate regional developments, Hudson points to Nabors’ B-series rigs, which were designed to accommodate pad drilling in the Bakken Shale. “We built a box-on-box substructure because we can close in that substructure, which makes it easier to winterize,” Hudson says. “Also, the way we can rotate the substructure lets the company conduct completion and production-related operations on one well while we are drilling another on the same location.”

Dealing with cold weather is also important, he observes. “We protect the rig floor from wind by putting the dog house and wind walls around it, then put heaters on the floor,” he says.

Like other contractors, Cyclone is expanding its fleet. “We built five rigs in 2010 and we are scheduled to build four more in 2011,” Hladky details. “They all have 1,600-horsepower pumps, with 270- and 500-ton AC top drives.”

Hladky says Cyclone tries to keep the rigs’ designs simple. “We engineer all the rigs similarly,” he adds. “Even if they are different sizes or different applications, the basics are all the same. That lets employees move from rig to rig efficiently and safely.”

Like the other drilling contractors, Hladky stresses the importance of good people. “A high-spec rig is nothing without good people,” he declares. “We are drilling with mechanical rigs built in the 1980s and 1990s with good people right next to and as efficiently as high-spec rigs.

Cyclone skids its rigs with hydraulic feet rather than rails because rigs can get slightly off target each time they move from one well to the next. “If you are on a rail system, the error is difficult to deal with. A walking rig can move in any direction needed to position exactly over the well bore,” he says.

“We started looking at these pads primarily from a surface usage viewpoint,” Cox says. “Since the terrain in North Dakota can be difficult, we wanted to reduce the number of pads, handling facilities, power lines, and pipelines we had to build. As we dug into the process, we began to ask if we would save any money beyond the cost of building the location and moving the rigs. The batch process provided the cost savings that gave us the impetus to keep working on the project.”

To explain the process’s economic and environmental benefits to investors, Continental dubbed it ECO-Pad® and produced a video, which is now available on its website. “It’s been amazing how many people have watched the video and asked to show it to others,” says Brian Engel, Continental’s vice president of public affairs. “The walking rig is something almost no one has seen before, especially in the investor community.”

The ideal operating range varies with motor sizes and configurations, Stuart says. “Experience goes a long way in determining the right range, and it comes not only from the drilling motor provider, but also from the service companies and operators. Collaboration among the three is important for efficient drilling operations,” he advises.

Drilling contractors are expanding their fleets to accommodate growing demand for high-horsepower land rigs equipped with powerful mud pumps, heavy-duty drawworks, closed-loop mud systems, automated rig floor equipment and ‘smart’ data management systems. As with this 1,500-horsepower electric rig, these new high-spec units often are fitted with top drives to rotate the drill string to optimize drilling efficiency and reduce the chance of pipe sticking while coming out of long horizontal laterals.

“Getting hydration right can be tricky,” Anderson says. “The coagulants and flocculants typically used to dewater drilling fluid have long, fragile chains, so they are sensitive to high mechanical shear forces and temperatures. Low pressure is also a concern; it increases residence times.”

Latshaw Drilling’s Trent Latshaw says improvements in rig designs, downhole motors, and fluids handling equipment are only a small part of a larger effort to improve drilling efficiency. “Polychrystalline diamond compact bits, measurement-while-drilling tools and rotary steerables will continue to be major drivers,” he predicts.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

Registration. Buyers must register as Bidders prior to bidding at any auction sale. All Bidders must provide their name, company (if applicable), mailing address and phone number prior to the auction. Bidders are required to deposit with NMC a valid Visa or MasterCard to secure its obligations hereunder. Electronic Bidders are required to provide a valid email address and Visa or MasterCard number, together with security code. In its sole discretion, NMC may charge Bidders a registration fee or deposit for electronic or onsite bidding and also maintains the right to deny approval of registration of any bidder for any reason it sees fit. Registration fees or required deposits will be clearly displayed during the registration process or communicated directly to Bidders prior to registration approval. For any and all winning bids, the registered party or parties and company’s liability to perform in accordance with the purchase and terms of sale is joint and several.

Deposits. For onsite bidding, NMC requires a non-refundable deposit of not less than twenty five percent (25%) of the Buyer’s TOTAL PURCHASE PRICE by the end of sale day – with the balance due by the end of the next business day. The non-refundable deposit can be in the form of cash, a cashier’s check, or business check with a bank letter of guarantee or, at NMC’s option, by way of a charge to the credit card referred to in Paragraph 2, above. For Electronic Bidders, at its discretion, NMC may contact Bidders via email or telephone before or during the sale to require a bank letter of guarantee or wire transfer as a deposit. If NMC does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, NMC reserves the right refuse Buyer’s additional bids with Buyer responsible for all lots or Goods purchased to that point or to cancel Buyer’s bids and re-sell Goods. Online Buyers shall effect payment in full no later than twenty-four (24) hours after receiving an invoice from NMC.

Payments. NMC must receive the balance of the total purchase price no later than the close of business on the day following the auction for onsite sales or 48 hours after the last lot of the sale closes for online sales (the “Final Payment Date”). For online winning bidders, NMC sends winning invoices to bidders to the email provided at registration. No other communication from any party including any online bidding platform will be deemed an award of winning bid or invoice. All payments must be in the form of cash deposit, cashier’s or certified check or federal wire transfer of immediately available funds. All of the foregoing must be in form, scope and substance acceptable to NMC in its sole discretion. Credit cards, which are accepted for electronic bidding registration and for payment of deposit will not be accepted for payment of the balance of the total purchase price, however, if Buyer or Bidder is in default of payment, NMC reserves the right to charge the credit card on file for up to the full winning bid, inclusive of buyers premium and sales tax. No title shall pass to Buyer until the total purchase price and all Taxes (defined in Section 6 below) have been paid to NMC in collected funds.

Taxes. Buyer must also pay to NMC on or before the Final Payment Date, all sales, export, use, delinquent taxes due and penalties thereon, and all other applicable taxes due to any federal, state or local taxing authority (the “Taxes”) as a result of Buyer’s purchase, including without limitation, any taxes arising from any Buyer’s Premium (as defined in Section 7 below). To receive the benefit of any sales tax exemption, Buyer must supply NMC with a state sales tax exemption certificate acceptable in form, scope and substance to NMC in NMC’S sole discretion. If Buyer does not submit evidence of their exemption prior to the close of the auction, Buyer will be charged sales tax, which may be refunded upon Buyer providing documents necessary to prove their qualified exemption within 15 business days from the date of purchase. After 15 business days, Buyer will be required to submit any refund request directly to the state for which the original sales tax was collected and remitted by NMC.

Buyer shall be responsible for the safe and proper removal of any Goods purchased by Buyer and to secure any permitting either individually or through a third party machinery mover, rigger or contractor required to remove Goods if such is required by federal, state or local government agency or entity. Title and risk of loss passes to Buyer upon full payment of invoice. NMC may remove any party or individual from the auction site for theft, attempted theft, unsafe behavior and harassment or unsafe work practices with no guarantee for re-entry to the auction site. NMC does not pack, ship, store, crate or rig items or Goods. In some instances, NMC may collect fees on behalf of a third party service provider. Any cost for rigging, machinery moving, or third party service providers invoiced by or collected by NMC for services, removal or rigging on behalf of any third party, rigger, machinery mover or contractor is done strictly as a convenience to Buyers and is remitted 100% to the party rendering the services. NMC’s invoicing and collection of such fees as a convenience or listing of third party service provider or riggers approved to work at the auction site in no way whatsoever represents any warranty, guarantee or implied liability of NMC related to any third party service provider, rigger, removal party, removal of Goods or endorsement of the listed third party service provider, riggers or exclusive rigger. NMC shall not be liable or responsible for any action or actions of any machinery mover, machinery rigger, contractor, third party transportation company, or for proper or timely delivery of Goods to Buyer. Buyers may either pick up Goods at the designated auction site personally or can contract with a third party agent to manage the removal process for them. Before Goods can be removed by an Agent, Agent must provide NMC with (1) proof of payment in full (Paid In Full Invoice) and (2) an “Agent Release Authorization” form which allows NMC to release items to a third party contractor for shipping, crating or packing purposes. If an exclusive rigger(s) is appointed to the auction, Buyer is urged to contact any third party service provider, the listed riggers or exclusive rigger(s) prior to bidding to determine in Buyer’s sole opinion and discretion that such party is fit to perform the services or removal and loading of Buyer’s Goods and to understand the fees and services to be rendered. When an exclusive rigger is assigned, buyer will abide to the posted fees. No exceptions. Should NMC collects rigging fees on behalf of an exclusive rigger or in the case of seller loading, Buyer accepts that any and all disputes and claims related to rigging and removal of Goods is between Buyer and the exclusive rigger or seller in the case of seller loading.

Goods that cannot be removed by hand carry from the auction site, or premises, or that require any utility disconnection, or tools to remove Goods, must be removed by a qualified, insured rigger, approved by NMC, including exclusive riggers. Before any removal, Buyer must provide NMC with a certificate of insurance from the rigger, which certificate must be in form, scope and content acceptable to NMC in NMC’S sole discretion. Without limiting NMC’s discretion, such certificate must show that the rigger carries comprehensive liability insurance written by an insurance carrier of national standing, in an amount of not less than two-million dollars ($2,000,000.00) and naming NMC, any landlord, and building owner as an additional insured party. NMC will provide parties required to be listed as additional insured upon inquiry by the rigger or removal company to gain access to auction site for removal. Without limiting the generality of the foregoing, Buyer shall be responsible to restore and repair all real and personal property and fixtures that are altered or damaged as a result of Buyer’s removal of the Goods to a condition substantially similar to the pre-removal condition. NMC shall review the repair and make a determination in its sole discretion, whether the repair is acceptable to NMC. NMC shall have no responsibility to disconnect utilities to the Goods, including but not limited to electric, gas, waste and water lines. Under any circumstance, utility disconnection shall take place at the first junction from the machinery, capped and left in safe condition. Electrical will be locked out, tagged out at the box with all conduit, wire and piping remaining in tact between the first disconnect and the lockout. Utility lines, air lines, etc. shall not be altered other than to be capped and left safe. In any removal of goods, the responsibility and liability of Buyer and Buyer’s rigger, representatives and contractors for any damage or loss due to removal of goods shall be joint and several. Buyer is solely responsible for the proper removal and storage in appropriate containers of all fluids, oils, hazardous chemicals, etc., from machinery purchased. Buyer does hereby indemnify NMC, the owner of the Goods and the owner of the premises in which the Goods are located, from any and all claims, damages, and losses arising from Buyer’s actions or actions with respect to the Goods and Buyer’s presence on the premises in which the Goods are located, including without limitation, injuries to persons or property and environmental violations or contamination. Risk of loss on any Goods shall pass to the Buyer upon payment in full to NMC of all sums due from Buyer in respect to the Goods.

NMC shall not be responsible for any damages, loss or theft of Goods or delays contemplated in Section 8 of these Terms and Conditions. Without limiting the foregoing, NMC shall not be responsible for damages or losses caused by strikes, civil disorders, acts of nature, government delay or imposed sanctions, machinery movers, riggers or acts of God.

Minimum or Reserve Prices. NMC, in its sole discretion, reserves the right to establish a reserve or minimum price on any Goods at any time without having to announce, post or publish notice to attendees, bidders and buyers at any auction, whether online or onsite. NMC reserves the right to confirm or reject the final bid. Further, NMC, and/or its employees, officers, owners, affiliates or subsidiaries, may bid at the auction on any Goods at any time either for its own account, benefit or on behalf of a third party or proxy bid.

NMC, in its sole discretion, reserves the right to refuse the bid or cancel the lot sale of any person without providing any notice or reason therefore.

NMC reserves the right, in its sole discretion, to sell items advertised as a public auction sale, on a piece-by-piece basis or as a complete lot. Without limiting the generality of the foregoing, NMC may accept a complete lot bid and then conduct an item by item auction which auction shall be effective only if the total proceeds therefrom exceed the amount of the complete bid.

Buyer hereby agrees to comply with all US export and import control and related laws, and acknowledge that NMC is not the exporter or importer of any purchased item. New Mill Capital does not provide customs information, such as HTS codes or certificates of origin, for purchased Goods. It is the sole responsibility of Buyer to provide such information or obtain the information from the original equipment manufacturer (OEM). Certain items offered for sale at the auction may constitute “Restricted Technology.” Under federal law, such items may not be shipped outside the United States. NMC makes no representation or warranty concerning, and has conducted no investigation to ascertain which items, if any, constitute Restricted Technology, or whether any item may have been imported in violation of any U.S. laws or international treaties.

If the Buyer fails to comply with any of the Terms and Conditions herein, in addition to the remedies provided for Default, NMC shall have all rights and remedies available to it at law and in equity. Without limiting the generality of the foregoing, NMC may retain all deposits and partial payments received from Buyer and may resell any Goods that Buyer fails to purchase. Buyer shall be responsible for all costs, losses, and damages suffered by NMC (i) as a result of Buyer’s breach of any of the Terms, including without limitation, lost profits and consequential damages, and (ii) incurred in connection with the enforcement of NMC’S rights, including, without limitation, legal fees and costs and expenses related to the resale of Goods, including storage and rigging fees.

workover rigs without guyline are designed for small-scale and fast workover operations. Since it is not necessary to install external windload guylines, operating efficiency is greatly enhanced. They can work at 60 kn of wind in adjustment mode, and 35 kn of wind in operating mode, and are suitable for shallow wells in variousread more...

- "Service Work" consists of using a rig to pull down hole pumps, rods, and tubing from the wellbore. Other service including cleaning and swabbing a method used to remove fluid from the well bore. Well depths range from several hundred feet to 10, 000 feet belowread more...

We are one of the leading service provider for Coring, Air Drilling, Workover and Drilling Rig Services to various Oil and Gas Companies in India. Our strength is in providing complete Rig Package with all associated equipment and services to onshore Oil and Gas Industry. We currently hold wide range of Onshore Workover Rigsread more...

We have 6 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

We have 6 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

With an internationally experienced crew of drillers and technicians credited with completing complicated drilling programs in difficult and diverse terrain, Punj Lloyd Upstream has a fleet of brand new AC VFD 1500HP and 2000HP onshore rigs with a drilling capacity of 6, 000 m.

The SKA is manned by a set of highly experienced global crew (India, Australia, United Kingdom, Brazil, Azerbaijan, South Africa etc) who bring significant knowledge, expertise and diversity to the rig. We continually maintain and develop an extensive network of people associated with this industry. Our long-term associationread more...

We have 5 Nos. of Mobile Work over Rigs with a capacity of 30 Tons. The following Job can be done: Setting of packer, Releasing of packer, Testing of casing, Bysetting of R3 packer, Testing of Tubing, Abandon of well by putting Cementing plug, Testing of plug, Installation of SRP, Testing of SRP, Clearing of well bore with withread more...

We have successfully executed numerous contracts for operation and maintenance of client owned Work Over Rigs. Amongst other esteemed contractors, we have emerged as winners in the field of Safety, Best Performance, etc. Our trained technical manpower is vigilant and extremely careful with handling the equipment. For over 15read more...

8613371530291

8613371530291