workover rig tripping pipe quotation

Tripping refers to the process of removing and/or replacing pipes from the well when it is necessary to change the bit or other piece of the drill string, or when preparing to run certain tests in the well bore.

Most oil well interventions or Workover are done because the well is not performing up to expectations. Other reasons could be regulatory requirements, data gathering, supplemental recovery project requirements, etc. Wellbore workover might involve casing or equipment repair, maintenance and installation of new equipment. And some of the techniques are known as wireline, coiled tubing and snubbing.

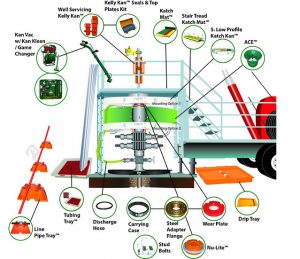

The Mini Kelly Kan controls and redirects fluids being released from wet tubing or pipe. The fluids are captured in the 2nd Stage Low Profile Load Rated Katch Kan, and then can be drained through a two-inch discharge line to the containment area

When tripping out of the hole to service tools such as packers, swabbing effect may cause fluids to run over top of B.O.P. This problem is solved as these fluids are captured and redirected by the 2nd Stage Low Profile Load Rated Katch Kan

The Mini Kelly Kan / Katch Kan system will reduce the need for waiting on wire line trucks to perforate tubing thus reducing rig time by simply pulling wet

The Mini Kelly Kan/ Katch Kan system is designed for the dirtiest and messiest jobs in the oilfield. As well as keeping the worker safe and clean, use of the system lowers clean-up costs, minimizes vacuum truck work and reduces tripping time

The 2nd Stage Low Profile Load Rated Katch Kan will clamp on to most well heads, capturing leaking fluids from saver heads, when stripping the sand line while swabbing, also when changing the swab cups

Pipe handling devices minimize human interaction to handle and move pipe. They lower the overall cost of well site interventions by increasing pipe-handling efficiency through

Tongs are used for breaking and making-up tubing connections. Tubing/rod tongs are hydraulic wrenches used to turn and torque pipe and rods, open-face and close-face

Blowout Preventers (BOPs) are a critical piece of safety equipment, as they protect rig crews, the rig, and the wellbore. Key maintains an inventory of

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The Attorneys at Spurgeon Law Firm know what it’s like to spend countless hours tripping pipe on a drilling rig. Stephen and Sam both have experience working on drilling rigs where they have roughnecked on Kelly and rotary drilling rigs.

Running in the hole or pulling out of the hole (aka tripping pipe) is one of the most labor intensive job tasks a worker will engage in while on a drilling rig. Long hours of throwing the slips in, breaking or making connections, and racking back stands of pipe in the derrick is mentally and physically exhausting whereby your brain will start to populate abnormal thoughts. Your mind will start to drift due to fatigue and exhaustion and thus cause you to lose focus on the job at hand. Because of this, people are more susceptible of making mistakes, which in turn will cause injury to themselves or someone else. This is why it is imperative that companies have adequate personnel on the job and to allow that personnel to take breaks as needed. Your safety should be priority and always put your health first and the company’s profit second.

All oilfield workers have the right to work in a safe environment. The oilfield is governed by rules, laws, and guidelines to keep workers safe. However, these rules and laws are not always followed and often lead to serious injury. If you have sustained injuries in the oilfield contact our experienced oilfield lawyers at 318-224-2222. Attorneys, Stephen and Sam, have both worked in the oilfield and know the ins and outs. Prior to becoming an attorney, Stephen worked offshore as a Petroleum Engineer gaining valuable experience which he uses to get his clients maximum compensation. Their experience can make the difference when it comes to getting the payment you deserve. Contact Spurgeon Law Firm today for a free consultation.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

In addition to its main function of suspending the pipe string, it also has the functions of automatic tubing mouth match, make-up and break-out, and is also equipped with a guide device bearing reverse torque, which can realize the functions of automatic well washing, sand flushing, drilling, grinding and milling.

Main function: connect to the wellhead flange and clamp the pipe string. Slip teeth are common with other manufacturers for easy replacement. The hydraulic cylinder is clamped and the pipe string is forced to be centered. The clamping is reliable and convenient for automatic operation. Open and close state detection, and realize safety interlock with other equipment.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

The hydraulic system includes hydraulic source, wellhead automatic operation device control valve group, hydraulic elevator, hydraulic slip valve group, conveyor control valve group and pipeline, etc.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Canadian drilling rigs meet some of the highest regulatory and safety standards in the world. It"s a dynamic and exciting community to build a career in.

Canada’s drilling fleet is always changing to incorporate new technology and meet market demand. Most noticeably, the Canadian drilling fleet is growing in numbers. The fleet has 40% more rigs than it did 15 years ago. Today, the rig fleet offers just over 600 rigs.

For the most part, a rig is a rig is a rig. For example, all rigs have a derrick (the mast-like structure that holds the pipe to be lowered into the well bore) a catwalk that holds the drill pipe, a rig floor where floorhands handle the drill pipe, a drawworks which is the machinery that hoists and lowers pipe and a blowout preventor that enables a driller to control well pressure.

But different size rigs are used depending on the drilling target formation. Oil formations tend to be deeper than gas formations. When investors are most interested in producing oil, large rigs are in high demand. When the market prefers gas production, small rigs are in demand. Western Canada has plenty of both gas and oil, and activity cycles back and forth between preferences of one over the other.

Drilling rigs come in three sizes: singles, doubles and triples. These categories refer to how many lengths of pipe can stand in the rig’s derrick. On a single, the derrick holds one length of pipe. A double holds two, and a triple holds three.

A tall derrick isn’t necessary to drill deeper. If more pipe is needed to drill deeper, a single section of pipe is hoisted to the rig floor and added to the drill string. But sometimes the entire drill string needs to be pulled out of the hole (to change the drill bit, for instance). A derrick that holds multiple lengths of pipe comes in handy and helps the crew to complete this evolution quickly.

A crew working on a triple is able to pull three lengths of pipe out of the hole before unscrewing the pipe. The Derrickman, working from the monkeyboard, sets the ‘stand’ of pipe in the derrick. Then the crew pulls up the next three joints of pipe. This evolution is called ‘tripping’.

The larger derrick is efficient to drill deep wells but isn’t necessary for shallow wells. Single rigs drill wells that are around 1 to 2 kilometres deep. These wells usually access gas basins. Single rigs and their crews change drilling locations often, sometimes every day or every other day.

Doubles and triples are larger rigs with bigger substructures and taller derricks. These rigs drill between 3 and 6 kilometres into the earth and might be at the same location for several months to complete deep drilling operations.

Singles, doubles and triples refer to conventional rig categories. Additional new categories of rigs have introduced different ways of handling pipe. For instance, some companies run coil-tubing rigs that stream tubing from a large reel instead of using drill pipe, or automated drilling rigs that are outfitted with a pipe-handling arm that raises the pipe into the derrick, eliminating the need for a derrickhand to work from the monkeyboard.

Through the 1990s, rig activity focused evenly on the two commodities. Then in 1998, there was a shift: gas wells began to make up the bulk of drilling activity. Through the early 2000s, rig activity increased year over year, but gas wells—which are shallower and can be drilled faster—far outstripped the increase in oil wells. Between 2001 and 2006, oil wells made up about 25% of rig activity, and gas wells 75%.

The drilling industry reacted to this demand by expanding the fleet. In 2007, the rig fleet grew faster than it ever it had before: 49 rigs were added. Most of these new rigs were the smaller ones best suited for gas drilling. Then in 2008, natural gas was on the market in abundance, and the stock market price of natural gas started to fall. Investors pulled back on gas drilling. In 2010, industry was back to an even split between gas wells and oil wells.

And then the turn-around happened: oil drilling overtook gas drilling in western Canada. In 2011, 61% of the wells drilled were seeking an oil formation, versus the 39% seeking gas. Today’s market continues to favour large rigs that can reach deep oil formations. There also is increased interest in accessing these formations at an angle: rig crews drill a well bore that curves toward a drilling target. Drilling rig contractors have been adding equipment in 2013. Unlike 2007"s fleet expansion, these rigs will be the larger, heavier rigs, primed for oil drilling.

The rig site, like any industrial environment, contains several areas and processes that can prove dangerous without the proper amount of caution and the right equipment. Anyone that has spent any amount of time on oil rigs knows that a majority of the hazards can be described as “slips, trips, and falls” and “pinch points.”

Oil rigs are designed to be space and layout efficient, making the rig floor feel congested with personnel, equipment, supplies, and drill pipe stands. It’s a fact of the job that at times the floor will be slippery, hoses will be spread out, and downhole tools will be staged on the rig floor. All of which lead to the possibility of someone tripping or falling over something. On land rigs the drilling platform can be as much as 30 feet from the ground, increasing the danger for personnel that may be operating near the edge of the platform.

A number of pinch points exist on oil rigs, including anything from rolling pipe on the ground stands to stabbing pipe for connections, and even throwing slips on the rig floor. Pinch points exist anywhere that two objects can come together with no guard and catch an operator’s fingers, hands, or legs. Major pinch points are created when connections are being made between the box and pin end of tubular products (casing or drill pipe) on the rig floor. As the pin end is dropped down to be placed into the box of the stump, or “stabbed”, any appendage caught between the two pieces of pipe will likely be lost.

Combatting accidents on the rig site is first and foremost done through safety monitoring and awareness of personnel operating on the floor. Optimizing personnel safety in all operations is key to ongoing site safety. Job Safety Analyses and pre-job safety meetings help increase the overall awareness of safety hazards on the rig site. However, in the 24/7 production environment that exists on oil rigs, additional precautions in the way of safety equipment and guards can further decrease the number of injuries and help safeguard inexperienced employees from danger.

Keystone Energy Tools offers a wide variety of safety tools to make your oil rig a safer environment. We offer high quality safety tools and add-ons to ensure that all of your personnel go home in one piece at the end of the day.Since much of the imminent danger on a rig site is involved with the moving parts during connection makeup, most safety equipment is targeted during this time of heightened personnel movement and equipment use.

Throwing slips is a time honored tradition in the oilfield; however, this practice can lead to back injuries and increased fatigue during connections. It can also lead to lost time if an inexperienced employee throws the slips in too soon or too late, changing the height of the stump in the rig floor. Hydraulic or pneumaticslip lifting devices combat these issues by allowing the driller to control the entire operation from the control panel.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Backreaming is the practice of pumping and rotating the drillstring while simultaneously pulling out of the hole. When reliable topdrive drilling systems (TDSs) on conventional drilling rigs were introduced more than 25 years ago, the practice of backreaming became a popular technique in the driller"s toolbox for tripping out of hole initially in deviated wells.

In general, backreaming operations have become a popular solution to poor hole conditions while pulling out of hole, but they are also notorious for causing the very same problems they are supposed to prevent, such as stuck pipe. If backreaming is not performed properly, it may complicate the operations, cause wellbore-stability issues, cause higher equivalent circulating densities (ECDs), and cause stuck-pipe incidents caused by packoffs.

As part of the company"s stuck-pipe prevention initiative, it became clear that when backreaming is carried out in a wellbore that has a large amount of cuttings and/or cavings, it can cause problems rather than solve them if it is not done with sufficient care. Also, backreaming and tripping operations were usually occasions when the rig-based team went to a "low-vigilance" level. On the basis of historical cases, it was concluded that in the majority of instances, there were no clear guidelines on when to start, how to do it, when to slow down, and when to stop backreaming operations. A review of industry literature also indicated a lack of procedures generally for backreaming.

As a result of the analysis of the real-time data from several case histories, a plan was put in place to improve backreaming operations, define the situations that require backreaming, and focus on tripping practices to prevent stuck-pipe incidents and tool failures.

This paper focuses on one of the industry"s most controversial subjects, reviews the implications of backreaming by using real-time data and case histories, and suggests proven procedures to trouble-free backreaming. It recommends the conditions that require backreaming and also suggests wellbore conditions that are not recommended for backreaming. More importantly, it proposes key drilling parameters that need to be monitored when backreaming. These include pump pressure, torque, hookload, cuttings rate, and downhole measurements (if available) to detect and prevent backreaming-induced operational problems. In addition, this paper provides guidelines for successful backreaming operations and defines conditions that may be resolved without needing to backream. Backreaming guidelines have been developed on the basis of the company"s worldwide operations, supported by real-time case histories and an extensive stuck-pipe prevention program.

Industry retooling is no longer confined to new high-spec drilling rigs. The well service/workover market has embarked on a newbuild cycle with 2014 manufacturing capacity essentially sold out.

A Hart Energy survey of equipment manufacturers in the well service/workover segment found respondents reporting strong demand for newbuild workover rigs. The newfound interest points to change underway in the completions side of the business. As operators push lateral lengths beyond a mile, coil tubing has become less effective, and oil and gas operators are expressing renewed interest in the tried and true workover rig with or without a snubbing unit.

That trend is pushing demand for beefier workover rigs at the high-spec end of the market as the industry transitions into the resource harvest phase of the tight formation hydrocarbon development cycle.

Manufacturers participating in the Hart Energy survey identified recent technological improvements in rig braking systems and demand for specialized workover rigs suited to pad drilling and batch completions as the main drivers in the newbuild cycle. Multiple innovations are under development that will allow workover rigs to adapt to multiwell pads, including removing the need to reset guy wires around the location when transitioning from well to well on pads. In a few cases, rigs are sporting outriggers in a fit-for-purpose design custom configured for multiwell pads.

Manufacturers cited rising delivery times for newbuild workover units, and a few larger manufacturers are expanding production capacity to meet rising demand. Both trends illustrate a healthy market in the well services/workover segment.

In all, manufacturers contacted in the Hart Energy survey reported 316 well service/workover rigs on order in 2014, with 285 destined for the domestic market. Most manufacturers noted their 2014 order books are filled—or close to it—and a few commented that they were taking orders for 2015 delivery.

The demands of pad drilling and batch completions are prompting contractors to expand the utility of the formerly humble workover unit. Some larger series rigs have adjustable-height rig floors—up to 34 feet—and can trip pipe as a doubles unit. In other cases manufacturers report that customers are adding rotary tables so the rig can double as a top hole drilling unit.

New rig demand is broad across the spectrum. Manufacturers point to growing international interest in newbuild workover rigs, although the current crop of equipment undergoing manufacture in the U.S. is weighted to domestic deliveries. For international orders, manufacturers are building masts and components in the U.S. and shipping them overseas, where customers assemble them into units that will meet destination-specific transportation standards.

8613371530291

8613371530291