workover rig vs drilling rig quotation

Drilling calls for complex, carefully engineered equipment — and inevitably this equipment can wear down over time and require replacement. That’s where a workover rig comes in. Workovers are among the most expensive and complicated tasks in the drilling industry, so here are a few things you should understand about them.

A workover is a complex maintenance task that involves pulling completion hardware out of a well in order to extend the life of the well. A workover rig is a specially designed rig that makes it easier to take out or insert tubing into a well.

To complete a well servicing, the well is first killed. This halts the flow of fluids in the reservoir. The wellhead and flow line will then be removed and the completion hardware will begin to be pulled out of the well using the workover rig. Replacement parts will then be lowered into the hole accordingly.

Because workovers are involved in time-consuming processes, through-tubing workovers might be initiated, which can occur without forcing teams to kill a well and do a full well servicing. This might be considered first before deciding on a full well servicing.

A workover rig is needed when a well is no longer suitable for the drilling job it was originally built for. Maybe the production tubing has incurred damage over time or downhole tubing has stopped functioning correctly. Or perhaps the contents of the reservoir that the tubing is drawing from has changed and requires adjusted tubular components. In any case, the well is unable to perform efficiently and could even compromise the safety of those working on the well. At that point, its components must be replaced and a workover rig must be constructed.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

Many people are surprised to learn that the large oil and gas companies that they see in the news or purchase their gasoline from do not drill their own wells. The actual drilling of wells is typically performed by a Drilling Company or Drilling Contractor that specializes in drilling operations. These drilling companies have the expensive equipment (drilling rigs), personnel, and expertise for performing the complex activities associated with oil or gas well drilling. In almost all cases, a Field Operator or Field Operating Company (the oil or gas company operating the field and requiring the services of a drilling company) will develop a contract with a drilling contractor to drill wells in the field. To minimize rig transport time (and cost) and to develop reasonable terms for a good long-term contract, field operators will normally develop a one- to two-year queue of desired work to guarantee to the drilling company. Therefore, the contracting process is performed after the field operator has a mature, robust plan for the field or lease development and a viable rig schedule.

In a day-rate contract, the drilling engineers for the operating company design the well, and the operating company leases the drilling rig, its personnel, and routine supplies at a fixed daily rate (Day Rate) from the drilling contractor. This day rate may or may not include fuel (depending on the terms of the contract) and does not include the costs of Capital Goods or special services (such as well logging, cementing, or stimulation). Capital Goods or Tangible Drilling Supplies are tangible items required for the well, such as Casing, Tubing, Completion Equipment, Down-Hole Pumps, etc. (the term “tangible items” refers to items that can literally be touched). Typically, the day rate accounts for approximately one half of the costs required to drill the well. The Total Daily Cost required to drill a well is referred to as the Spread Rate.

To summarize, in a day-rate contract, drilling engineers working for the operating company design the well and plan all of the equipment specifications. In addition, the operating company leases the rig and its rig crew at a specified daily rate (day rate) which accounts for approximately one half of the daily expenditures. The actual daily rate to drill the well is the spread rate.

In a turnkey contract the operating company pays the drilling contractor to design and drill the well for a fixed cost. Thus, the operating company provides the objectives of the well, the desired data acquisition program for the well, the surface location of the well, the bottom-hole location of the well, and the target depth(s) of the well. Drilling engineers working for the drilling company then design and execute the well and coordinate all service work with the Service Companies.

The design of drilling rigs for the petroleum industry has remained basically unchanged for the last four decades. Today"s offshore rigs have evolved from the basic land rig concept towed offshore in the 1950"s. Factors such as deeper waters and harsher environments have increased demands for additional auxiliary equipment such as active crown mounted motion compensator, topdrive and comprehensive mechanised pipehandling equipment. Implementation additional equipment and new systems have followed an "add-on" philosophy which has resulted in concepts of monstrosity. Further development to meet today"s and future demands of versatility, such as integration of capabilities for snubbing and coiled tubing operations, will probably evolve to a stage where the "multi-functional" course could turn to the "multi-useless" curse.

A thorough review of the status, combined with the desire to be able to contribute with more optimal solutions, have lead Maritime Hydraulics to the development of the RamRig concept.

Main Objectives. Maritime Hydraulics launched the idea in 1987, whereafter a joint venture engineering study with British Petroleum Development Norway Ltd. was carried out in 1988 and 1989. The study evaluated all known rig concepts with emphasise on the aspects of hoisting and tubular handling efficiency. The main objectives of the development work were:Improve safety by reduced manning and improving working environments,

The study concluded the RamRig concept to be the most optimal of the alternatives considered. However, as it was found to be too bold and radical for its time, it was decided that the project was to be shelved. This was mainly due to the lack of field experience of important components like the control system and the large hydrostatic transmission required.

After about 5 years Saga Petroleum"s efficient exploration, "EfEx", study, re-vitalised the concept in 1994. The detailed design of a complete drilling rig for an application for deepwater exploration operations was completed by June 1995. In this study the RamRig was found to be an important enabler for developing more efficient total concepts.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

Enjoy the best returns on your investment with these supreme workover rig price ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

workover rig price options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Are you looking for a wholesale workover rig price? Look no more as Alibaba.com has all sorts of pile drivers that will ease your next pile driving process. A pile-driving machine is critical equipment in constructing structures and buildings as it helps in driving piles into the soil. These piles help in providing foundation support for a structure or building under construction. In that way, you can comfortably move a load of the structure to a difficult depth without a machine. Regarding your liking workovers rig price, visit Alibcom.com as they have unlimited pile available at wholesale prices. Inther you are looking for pneumatic tools or hydraulic pipes, you will find them type at affordable prices. If you need a drill, it can advisable to have a workover r price.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Workovers rank among the most complex, difficult and expensive types of wellwork. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

Before any workover, the well must first be killed. Since workovers are long planned in advance, there would be much time to plan the well kill and so the reverse circulation would be common. The intense nature of this operation often requires no less than the capabilities of a drilling rig.

The workover begins by killing the well then removing the wellhead and possibly the flow line, then installing a B.O.P commonly known as a blowout preventer, then lifting the tubing hanger from the casing head, thus beginning to pull the completion out of the well. The string will almost always be fixed in place by at least one production packer. If the packer is retrievable it can be released easily enough and pulled out with the completion string. If it is permanent, then it is common to cut the tubing just above it and pull out the upper portion of the string. If necessary, the packer and the tubing left in hole can be milled out, though more commonly, the new completion will make use of it by setting a new packer just above it and running new tubing down to the top of the old.

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

The American Petroleum Institute has released the fourth edition of Recommended Practice 54 (RP 54), Occupational Safety and Health for Oil and Gas Well Drilling and Servicing Operations, which provides procedures for promoting and maintaining safe and healthy working conditions for personnel in drilling and well servicing operations.

The document applies to rotary drilling rigs, well servicing rigs, and special services as they relate to operations on location. First published in 1981, significant revisions in this edition of Recommended Practice 54 include a new section on flowback operations which is key for safe well testing, revised requirements for facility and site process hazard assessment and mitigation, and introduction of formal risk assessments as well as expanded provisions for offshore operations.

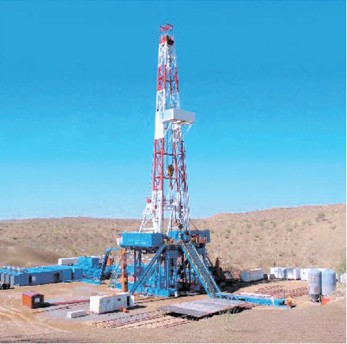

ZPEC 2000HP Workover Rig VFD possess excellent driving properties in desert, mountain and other impassable terrains. Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs. ZPEC 2000HP Workover Rig VFD is real workhorses, perfectly adapted to operate in even the roughest environments.

ZPEC 2000HP Workover Rig VFD is used in the heaviest application, such as complete well work-over operations, whereby a well is killed (production stopped) and tubing and completion equipment is removed. A Workover Rig is similar to a hoist or a telescoping tower secured with wires, that allows pipe and down-hole equipment to be run into and out of a well.

VFD rigs help advanced drilling technologies such as pad drilling, horizontal drilling and directional drilling. ZPEC VFD rigs come with high level of automation that involves automated drilling pipe handling, drill pipe connection and auto drilling.

Working on a drilling rig is risky business by anyone’s standards. Safety must a matter of paramount concern in order to prevent injuries and accidents.

Unfortunately, accidents that result from failure to pay attention to safety protocols and procedures happen all too often. A good motto to keep in mind is that no job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Workers on drilling and workover rigs may sometimes take matters into their own hands, resulting in safety violations or, worse, injury. And while it is the rig operator’s responsibility to see that they are sufficiently trained and that the workplace is free from hazards, it is vital that every person on a rig site develop a keen sense of safety.

Grainger says that routine safety audits at rig sites are essential. Both the Occupational Safety and Health Administration (OSHA) and OGP provide fact sheets and a variety of tools for performing on-site safety audits.

Implement the use of wearable ID tags and routine shift check-in/check-out procedures. This let supervisors and emergency responders know the location of every worker on the rig at all times.

Oil and gas rig workers may require ready access to tool boxes equipped with equipment needed to take care of repairs and to perform routine maintenance. Depending on the worksite, these may include electrical parts, material handling aids, plumbing components, hand tools, power tools, and welding gear.

Emergency Preparedness OSHA requires emergency response plans for every drilling site, which can vary depending on the rig’s location and layout. Grainger says that an effective plan should always include the ready availability of appropriate emergency and rescue equipment, as well as a program for training and drilling of all supervisors and workers on emergency escape and rescue procedures.

Oilfield safety is no different than safety anywhere else. Common sense, good judgment, and the right equipment for the job help to ensure workers are protected from injury. But remember the motto: No job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Energy Drilling Company is a privately owned land drilling contractor with headquarters in Natchez, Mississippi. Energy Drilling’s fleet is made up of nine drilling rigs operating in Louisiana, East Texas, Mississippi, Arkansas, and Alabama.

Nomac provides drilling services for oil and natural gas operators in Kansas, Louisiana, New Mexico, Ohio, Oklahoma, Pennsylvania, Texas, West Virginia and Wyoming. Nomac Drilling was founded in 2001 and is based in El Reno, Oklahoma. Nomac Drilling, L.L.C. is a subsidiary of Chesapeake Oilfield Operating, L.L.C.

Established in 1987, Ensign is a land based drilling and well servicing contractor whose services include drilling, directional drilling, well servicing, well testing, and pressure drilling. Ensign serves crude oil, natural gas, and geothermal energy operators. Ensign operates rigs worldwide, with locations in the United States, Canada, Australia, Libya, Oman, Argentina, and Venezuela.

The Nabors rig fleet represents one of the world’s youngest and most advanced fleets in the gas drilling and land drilling industries. From standard rigs to more unique constructions, Nabors’ rigs provide solutions for any scale or environment. Even harsh environments that require marsh buggies.

As of June 9th, 2016, there are 27 active drilling rigs operating in North Dakota. A partial list of current rig operators includes SM Energy Company, Newfield Production Company, Burlington Resources Oil Gas Company, and Continental Resources.

Independence Contract Drilling is a land drilling services provider headquartered in Houston, Texas. The company was established in 2011, and it currently operates pad optimal rigs throughout the Permian Basin in Texas.

True Drilling uses rotary rigs to drill for oil and natural gas from depths of 4,000 to 25,000 feet. True Drilling operates primarily in the Rocky Mountain area, with some service in North Dakota. The company’s main office is located in Casper, Wyoming.

For most operators, improving profitability on their wells is an ongoing battle between getting the right equipment, making the job easier, and keeping a strict eye on the bottom line.

A perfect example of this is that many operators go with a full-size drilling rig for surface interval drilling because it is more convenient. Often, they are already engaged with the service provider and the equipment is already on site — so it seems like this is the most cost-effective decision. In the end, though, operators end up paying more in fuel and personnel costs, and increasing their HSE risks, with this option.

Full-size rigs are made for constructing wells with total depths over 20,000 feet. These are enormous machines for enormous jobs. As a result, they have an enormous footprint in terms of costs and risks. When drilling surface intervals and running surface casing, a full-size rig is not the right equipment for the job. While it may seem more effective at the time, a surface drilling rig or spudder rig is the better choice.

Less fuel consumption and lower fuel costs: Surface drilling rigs are highly engineered for surface drilling and running surface casing. They are smaller in size as compared to full-size rigs, which means they use a lot less fuel. To be exact, spudder rigs actually burn up to 50% less diesel compared to full-size rigs, which means they also cost about 50% less to operate.

Equipment optimization:When operators use full-size rigs for surface drilling and running surface casing, they aren’t able to reserve the machines for their intended use. If operators have a separate spudder rig, then the full-size rigs can be used for applications better suited for them, reducing overall operating costs.

Lower personnel costs: Typically, a full-size rig requires a crew of 16 people to operate, while a top hole rig only has a crew of nine. With a lower personnel count, there are lower payroll costs. Not only that, the costs for personnel transportation are lower as well, in addition to the HSE risks.

Safer work environment: With a full-size rig, operators must switch between mud systems, which means that the crew has to mix different muds on location. Handling more fluids increases the chances of spills, which is detrimental to the environment and to the crew. A top hole drilling rig uses a closed-loop mud system, so there is no need to switch between different mud systems or handle different types of mud on location.

A smaller, fit-for-purpose preset surface drilling rig is a more economical choice than a full-size rig when it comes to drilling surface intervals and running preset surface casing.

A differentiating factor between EnerCorp’s surface drilling rigs and our competitors is the customized casing running tools (CRT) that enable us to be faster and more cost effective than other service providers.

Fit-for-purpose equipment: Our CRT’s are specifically designed for our RD20 XC rigs. This allows for the casing to be torqued up to proper torque specs per the casing manufacturer’s specifications.

Better processes:Competitors use alternative methods to run casing: Wishbone style casing elevators. In this process, a tool is used to run casing on our competitors rigs that does not keep the casing full and requires a swedge to be rigged up to fill it. There is far greater exposure and risk to the man in the basket on a board suspended from the derrick. Plus, dry casing run with this method is far less efficient because each joint needs to be filled via the swedge on top of the casing, taking more time. The Wishbone is a far more dangerous method as sometimes it does not latch correctly and can cause the casing to be unsettled during the run.

When working with EnerCorp, operators not only get the benefits of using a surface drilling rig, but also the additional advantages of using fit-for-purpose equipment that is highly optimized as compared to competitor options.

Adding rigs and other large equipment to a fleet is a major decision. Contractors need to consider how much they can afford to pay, how to best structure the terms to leave some cash flow intact, whether to lease or buy, and a host of other questions. Often, these decisions have a major impact on a business’ near and long-term financial health and revenue potential.

A. I’ve been in the industry for over 35 years. When I graduated from college, I went right to work in the financing and leasing business. My first job was with the Hertz Corporation, which everyone knows, and it wasn’t car leasing at the time. It was the Hertz Equipment Rental Group, and I was in their collections field. … Along the route, I switched from collections to credit and credit to sales and then sales to management, and then to where I am today running the captive financing arm in the United States for Epiroc AB, which is the holding company over in Stockholm, Sweden. We are a spin-off of the Atlas Copco Group, formerly known as the Atlas Copco Mining and Rock Excavation business.

A. All of our sales are done either through an authorized distributor, which also could be known as a dealer. We just like to use the name distributor in our modeling, or it could be done through a direct sale by one of our own sales people. I guess it all depends on what section or region of the country that particular end user or quarry or whoever is purchasing or acquiring our equipment [is in]. So, based on those facts, at the captive financing arm of Epiroc, which was formerly known as Atlas Copco Customer Finance, the procedure is this: The customer decides, “Hey, I want to purchase this … and I wish to know if there are financing or leasing options available through the manufacturer.” The answer is, of course, “Yes.” That’s why we have Epiroc Financial Solutions. At that point, either the distributor salesman or our own direct sales person would be in contact with me. I am kind of the first step. So they would come to me and they would say, “Hey, ABC Quarry is interested in acquiring a piece of Epiroc equipment in the drilling side of our business, and they would like to speak with you to know what options they might have.” And that’s how the process starts.

A. If you’re not aware … there are many changes coming in the laws of lease accounting as a principle in the United States, right? I’m sure you’ve either written articles or have had, you know, other articles written or talked about by businesses. And I guess that this is a sweeping change that is occurring from an accounting basis — it might be on a global basis, to be very honest with you. But the accounting bases are changing. … How you qualify it, how you account for it, and what sort of depreciation or tax benefits you can take are all changing at the end of this year and the beginning of next year sometime. It’s still to be determined as far as official dates, but the the government and the accounting boards have been telling customers to look into — especially, you know like CFOs and accountants and stuff like that, tax advisors — to look into what that’s going to look like.

So, believe it or not, you would think that the market would be retreating as far as their needs or interest in leasing. I’m seeing quite the opposite right now. I’m seeing a lot more customers asking for leasing options. … When you define a lease, what are we speaking about? Are we speaking about an operating lease, which a lot of companies call a true lease? Or are you talking about a stated purchase option, guaranteed purchase option, which could also be classified in a lot of ways as a capital lease, right? So with a capital lease, you either have a stated purchased option amount, whatever that might be, or it reverts to maybe $1.

A. You are correct. There’s a reason for that. The reason is that when you do a lease, the lease is actually owned by the financial institution. … We operate just like a bank or lending institution, and all of the requirements and all the banking regs — everything that goes into transactions — are still applicable. But when you’re talking about leasing, there really is at least two types of leases. To simplify it: It’s either a fair market value purchaser, bargain purchase option, at the end of the lease, which qualifies it by accounting standards and by IRS standards as an operating lease. Which goes back to your question. Yes, it’s an off-balance sheet expense because what happens is Epiroc Financial Solutions buys or purchases the equipment from the distributor or from its own entity, Epiroc USA LLC. It buys the equipment from them and leases it back to the end user customer. Therefore, the end user customer — the quarry, let’s say — has no rights. [It’s] almost like renting the equipment from us. They have no ownership. Therefore, they cannot depreciate it, in fact, because they don’t own it.

A. I call it a capital lease. It has a stated purchase option in the agreement. So in the operating lease, it says there, “Mr. Customer, you have a few options at the end of the term.” And the term could be anything, right? … We go everywhere from you know, 12 months to 60 months on average, but I have done 72 months and I have done 84 month deals, depending on the situation at hand and the requirements of the customer. Based on those parameters ... it’s a stated purchase option in the agreement that says, at the end of the term … you may purchase this equipment for $1. At the end of the 60-month term, you may purchase this equipment for $500, or so on.

With an operating lease, there’s nothing in writing on the contract that talks about a dollar amount. It talks about, at the end of the term, you may purchase the equipment for its then fair market value. Or, you may agree to extend or renew this lease for an agreed-upon term. So they can say, “Listen. I want to keep it for another 12 months, and I’ll continue making the same payments and can you give me credit toward reducing the principal amount, the reduction of the final amount?” We usually do that. Or, [they could say,] “I don’t wish to pay for this any longer, and I’m going to turn it back in to you and walk away from it with no penalties. I will give the drill rig back.” That’s an operating lease.

What’s interesting about this here, Jeremy, is that … I’m starting to see more and more quotes for leasing options than ever before, which I thought it would go the opposite, right? If we’re having all these tax law changes and everything saying, “Hey, I’m not sure what you’re going to be able to write off or not.” Why are people coming now and asking for more? I mean, I think that I’ve had more lease quotes done in 2018, than I think I’ve had combined over the previous two years, 2016 and 2017.

A. That’s a great point, and I think you’re onto something here. It’s not for me to question a customer when they call. I’m in a service business, right? To say, “Oh, wait a second, why do you want to do that?” Or, “You know the laws are changing there, right?” Now, we do sometimes have that conversation where somebody says, “What do you think about these tax law changes or changes in the accounting method?” I say, “Listen, everybody — every single customer, every single business — is starting to face that so, obviously, my advice to you will always be, please check with your accountant or your tax advisor for what is the best scenario for your particular business needs.”

Now, to answer your question honestly, yeah, we’re getting a lot of people asking about leasing versus financing. I think your point is valid, Jeremy. I think that … the customer is starting to look at the rising costs of machines in general, equipment in general. I think that they are concerned about maybe looking at a drill rig that once cost X, but now really costs Z. I mean, forget Y. It’s jumped right from X to Z. It’s just the way it is today, right?

I think that it’s a two-fold answer here: Pricing is going up, and I think customers are really concentrating their efforts on cash flow today. … I can tell you I’ve looked at a lot of different transactions with a lot of different variations, but I think what it comes down to, at the end of the day, is can you afford the monthly payment of that drill rig and when you go to put that to use, can you make money utilizing that drill rig and be able to pay for the monthly payment and then, above that, have your profitability taken care of? That’s really, I think, the bottom line question.

A. The standards have never changed. It’s the normal blocking and tackling, as I call it. … The standard is to ask for a signed credit application. If you have one on file within, let’s say, the past five years, I get an updated credit app on file signed by the customer. Then, the normal requirement on transactions greater than $250,000 in costs — which, let’s face it, most drill rigs are greater than $250,000 — is that we ask for the last two years audited or reviewed financial statements, or U.S. tax returns, obviously, and most recent interim financial statements, like a balance sheet and income statement for some period of time here in 2018 — January to June, January to July, something like that since we’re now here at September.

One of the most key pieces of oil drilling rig systems is the rig substructure. The first step in setting up a drill rig, setting up the rig substructure involves unloading equipment and moving it to the location where it will remain during drilling. From there, personnel must assemble, weld and level the various pieces of equipment. During this process, personnel can become injured due to a number of hazards that exist.

Are your personnel being as safe as they should be while setting up the drill rig substructure? To improve the safety of your oil drilling equipment, be sure to follow these three impossible-to-ignore tips:

First and foremost, all personnel must be properly trained in safety procedures and job hazards for setting up the rig substructure. Whether the training takes place during pre-job safety meetings or during JSA briefings, no one should be working on your drilling rig systems without undergoing safety training first.

When setting up the rig substructure, personnel should be wearing protective equipment like eye and face protection for welding, long-sleeved clothing and more. Welding, in particular, can be very dangerous work. Ensure that your workers never look directly into a welding flame.

8613371530291

8613371530291