can power tools be stored in cold garage pricelist

If you own power tools, you know how expensive they are. Therefore, storing them properly (and safely) is of the utmost importance. If you don’t, they’re likely to rust and/or break, which can be quite costly to repair and/or replace.

If possible, store power tools in the original boxes or the cases in which they were purchased. If you choose to store your power tools in toolboxes, put silica gel packs inside to absorb excess moisture and prevent your tools from rusting.

If you prefer to keep your power tools in a tool chest or cabinet, place anti-rust liners inside the drawers for extra protection. Or, to keep your power tools safely off the ground, you can hang them on pegboards in the basement or garage.

I’ll discuss the proper places to store power tools and why safe storage is so important. I’ll explain how to correctly hang power tools in a garage and if it’s okay to keep them there in the winter or if the garage is cold.

The best way to store all your power tools is back inside the box or case that they were purchased in. Not only will this keep the dust-out but also prevent them from rusting.

Another good place for power tools storage is in a toolbox. Be sure to put some silica gel packs inside to keep moisture levels down. You can buy silica gel packs on Amazon at a good price.

A tool chest or cabinet is also a good idea for storing power tools. Once again, it’s important to lock out moisture that can cause tools to rust so line the drawers with anti-rust papers as an extra precaution. Check this TANKSTORM tool chest on Amazon.

Hanging tools is another way to store power tools and save space at the same time. Simply hang pegboards on the wall in your garage or basement to keep tools clean and organized.

The best places to store your power tools include a shed, garage, or basement. The most important thing to consider is humidity and how to manage and/or maintain it.

Power tools can also be stored in a shed, provided it’s well-insulated and properly ventilated. As sheds don’t typically come with insulation, you would likely have to design and build one yourself.

To maintain your power tools and keep them in good working condition, you must first prepare them for storage.The best way to do this is to clean them properly after each use. Simply wipe down the tools with a damp (not soaking-wet) cloth first and then towel-dry them afterwards.

However, freezing temperatures can make the metal and plastic parts on some power tools week or brittle. This can lead to damage or breakage, especially if you use them while still cold.

Hanging power tools in a basement, garage or shed is another way to store them. In a few hours or less, you can make and hang a pegboard to keep your tools safe and organized.

Hang your power tools safely and clean up the area.As a note of caution, be sure to use appropriate safety gear when working with wood, such as gloves and goggles. Put on a dust mask and use ear plugs, if possible. Avoid wearing long sleeves when operating a miter saw and have a shop vac handy to clean up the dust and debris afterwards.

Power tools can also be stored in toolboxes, provided you put some silica gel packs inside to absorb excess moisture and protect your tools from rusting.

Hi there! My name is Jack and I write for ToolsOwner. I have a passion for everything related to tools and DIY projects around the house. You often find me in my workshop working on new projects.

Storing your power tools properly for the winter months can extend the life of your tools by years. View our simple tips to help store your power equipment.

When the cold weather rolls around, we tend to put a lot of things in storage, only to break them When the cold weather rolls around, we tend to put a lot of things in storage, only to break them out at the first sign of a spring breeze. This is why having a storage shed can be a very useful addition to your home. But, some things may not be able to be kept in the cold shed during the winter months. This can be true for some power tools. “Knowing how to get your power tools ready and where to store them can lengthen the life of your tools”, says Dave Malcolm, expert, and shed builder at Mediage LLC.

The winter months have higher humidity than the summer months which means there’s more moisture in the air. Paired with less sunlight, this can be damaging to any tools that are made from metal and plastic. Condensation and moisture on your metal tools will lead to corrosion over time.

Make sure your tools are cleaned well before storing them. Wipe dirt, grease, leaves, grass, or other debris off them with a rag or towel. If anything other than this is needed, follow the recommendations of the manufacturer for cleaning. Make sure the tool is completely dry before it goes into storage. There are different things you have to do to get different types of tools ready.

Throw away broken or defective tools. If it’s something that cannot be repaired, it will only take up space and will likely just sit there for seasons to come if not dealt with.

For gas-powered tools: Empty any remaining gas from the tool into an approved gas can.Top up the oil levels. If needed, completely change the oil.Start it up to burn excess fuel out of the carburetorClean the air filter, replacing it as needed.Clean and dry the chassis.Sharpen blades, chains, or knives and coat with mineral oil.

For battery-powered tools: Take the battery out of the tool and put it on the charge.After it’s charged, put it into its storage bag and store it somewhere dry.When you clean these tools, avoid excess moisture around the battery port.Sharpen blades, chains, or knives and coat with mineral oil.

Once your tools are ready for storage, you should determine where the best place to store them is. Keep in mind cold weather and freezing temperatures can cause havoc on power equipment. So it’s best to store items like outdoor power equipment, lawn equipment, battery operated cordless tools , the leaf blower, and pressure washer indoors and out of the freezing temperature. Turning a regular outdoor shed into a power tool storage shed may be the best investment you can make to save on replacing expensive power tools. Simply take a little extra care to seal up any areas that would allow for water and wind to get in.

When possible you should store all your power tools back inside the box in which they were purchased. This will help keep dust out and help prevent rust from forming on them.

You can use a tool chest or cabinet to store power tools but, again, you would need to keep the moisture low because that can cause rust so you can use anti-rust papers as a precaution.

To save space you can hang tools on pegboards on your wall in the garage or shed and this will help you stay clean and organized. This will also keep them off the floor and away from ground moisture.

If you are storing your power tools in a shed make sure it is a well-insulated and properly ventilated shed. Sheds don’t typically come with insulation so you might have to insulate it yourself. You will also need the ability to have a heater or dehumidifier running to decrease moisture.

Most power tools have oils and grease that do not run when they are cold. Because of this, power tools should be brought into the house and given a chance to warm up before using them. You should give it at least two hours for this.

Use plastic bins for smaller tools. This is an extra layer of protection for them. They are also stackable and easy to carry, making them more convenient.

In conclusion, it is safe to store most electric tools in your shed as long as the temperature and humidity can be controlled. Freezing temperatures can cause the metal or plastic to become brittle on some tools, which can cause them to be damaged or broken, especially if they are used while still cold. Taking the necessary precautions should help you safely store your power tools and help them have a long life.

When winter rolls around in cold climates, we rarely give much thought to the tools we"ve stored in the garage, barn, shop, or shed. This can be an expensive mistake because many tools can suffer damage of some type if they are kept in the cold all winter long. That"s especially true of power tools that you may use in sub-freezing temperatures.

Generally, most hand tools won"t suffer damage from being stored in a cold garage or shed. Freezing temperatures, however, can make many metal or plastic parts brittle and particularly susceptible to breakage if you use them at very cold temperatures. To avoid this, get into the habit of taking hand tools out of cold storage before use; let them sit inside the house for an hour or more before use.

Also, keep in mind that metal tools can rust. Big swings in temperature and humidity can accelerate that process. If you are worried about rust, try to find a good spot inside the house for tool storage. If you do store them indoors, make sure to clean them carefully before storing them, and perhaps apply a fine oil or rust protector to all metal surfaces.

In regions with very cold winter temperatures, the air is typically fairly dry and not likely to rust tools over the course of the winter. But if you bring them into the house, especially to store them in a basement, rust can then be a problem. And if you live in a coastal area where winter air is damp rather than bitterly cold, rust is more likely. If you are storing your tools in damp conditions, consider using a dehumidifier in the space where you are storing your tools.

Rinse off and dry your garden tools, and if you see spots of rust, remove them with a wire brush or steel wool. Rub a light oil, such as WD-40 over the metal parts. Wooden handles can crack and splinter in the dry conditions of a cold winter; now is the time to check them for splinters, sand handles smooth, and coat the wood with linseed oil. Shovels and other digging tools should be hung up on the wall above the floor. Thoroughly wash out and rinse garden sprayers and hoses.

Lawn mowers should be cleaned of all grass residue clinging to the underside of the deck, and power tillers should have their blades cleaned of dirt and polished clean of rust and corrosion.

Any power machinery will face some stress if it is used in very cold conditions, and your power tools are no different. As the motors heat up, the stress of metal parts going from very cold temperatures to very warm may cause some tools to suffer an early death if this pattern happens frequently. For this reason, it is better to store power tools indoors if they will be used over the winter.

Most tools with electrical motors contain oils and grease which should be allowed to warm up a bit before using the tool. So if you have stored a saw or other piece of power equipment in a cold space, bring it indoors for two hours or so before using it. Lubricants will be more effective if they are allowed to warm up to room temperature before using the tools. This applies even if the tools will be used outdoors—bring them indoors first to warm up before taking them back outdoors to cut or drill.

Try to keep cordless power tools and their chargers inside during cold weather. Freezing temperatures seem to accelerate battery discharge, and many cordless tools come with a warning that the chargers won"t work when cold.

Lawnmowers, chainsaws, and other tools powered by gas engines have their own set of guidelines for storage in the winter. If not properly winterized, gasoline left in an engine can gum up the carburetor or other parts, unlubricated engine parts can corrode, and moisture may affect the ignition systems. A standard winterizing procedure:

If you regularly work in a garage or outdoor workshop, equipping the space with a heater is a good idea. You can either heat up the space to a comfortable temperature just before work sessions, or you can keep the heaters running all winter at a low setting to keep the temperature just above freezing. Tools need not be at full indoor room temperature to operate well—a temperature just above freezing is all you need.

When winter rolls around, we think about keeping ourselves warm, along with our houses, but we don’t give much (if any) thought to the tools stored in the garage, shop or shed. That can be an expensive mistake. Many tools can suffer damage of one kind or another by being kept in the cold all winter long. Here are some tool storage suggestions for protecting your investments.

Most hand tools will not suffer damage from being stored in a cold garage or shed. Freezing temperatures, however, can make many metal or plastic parts brittle and particularly susceptible to breakage. To avoid this, get into the habit of taking hand tools out of cold storage before use; let them sit inside the house for an hour or more before use.

Also keep in mind that metal tools can rust. Big swings in temperature and humidity can accelerate that process. If you are worried about rust, try to find a good spot inside the house for tool storage. Alternatively, apply some rust protector to all metal surfaces.

The biggest problem you can run into regarding power tool storage in winter stem from plugging in a cold tool and operating it before it has a chance to warm up. This causes a big, rapid temperature swing from very cold to very hot, which is a stress that will cause some tools to suffer an early death.

Tools containing grease or oil should be allowed to warm up before starting. The lubricants just aren’t as effective as they need to be when cold. Pneumatic tools often come with instructions on which oil to use in cold weather.

Try to keep cordless power tools and their chargers inside during cold weather. Freezing temperatures seem to accelerate battery discharge, and many cordless tools come with a warning that the chargers simply won’t work when cold.

If you have some source of heat in your garage, shed or shop, turn it on for awhile before turning on any power tools. You might also want to consider keeping the heater on throughout the winter; all it really needs to do is maintain a temperature above freezing.

After a long summer season, the last thing on most people"s mind is preparing their tools for winter storage. Whether you"re keeping them in a shed, the garage or somewhere in the home, properly preparing them before putting them away is important. Especially if your tools are power tools.

Leaving fuel in the tank, grass on the blades or debris on the chassis over winter can turn out to be a very expensive mistake. Fuel stagnation and corrosion are two of the main culprits from improper preparation and storage. When properly maintained, electric and petrol-powered garden tools will last you for many years to come.

If you"re one of those who are guilty of finishing up for the season and throwing your tools in a shed, you might just benefit from these simple tips for storing your tools during winter.

If you"ve ever owned a bicycle (or splashed out on one for the kids) you probably already know how corrosive winter weather can be. We"ve all gone outdoors to get the bike in spring, only to find the chain and spokes rusted up, the brakes seized in position and the frame looking less than ideal. The same is true for your garden tools.

Unlike the warm, low-humidity summer months, winter can wreak havoc on metal and plastic. Early morning mist, afternoon fog, excessive rainfall and less sun all work against garden tools. This can be exasperated when they"ve been left with organic matter on them that oxidises and breaks down the surface.

Even if you"ve covered your tools with plastic sheeting to protect them from rain, plastic is no barrier to moisture. In fact, plastic sheeting can trap moisture inside your tools, leading to stress-inducing mechanical and electrical malfunctions - the last thing you want when the grass is tickling knees.

As soon as you have got your lawn, tree"s, shrubs, hedges and ground in order, it"s time to prepare your garden tools for storage. Depending on the type of tools you have, you"ll need to do different things.

If you think the climate where you live might be too harsh for an EV, consider a plug-in hybrid. You’ll have the advantage of electric power around town and for short commutes but still have the safety net of an internal combustion engine for longer trips and extreme temperatures.

High summer temperatures can have direct and indirect effects on natural gas prices. Hot weather tends to increase demand for air conditioning in homes and buildings, which generally increases the power sector"s demand for natural gas. During high demand periods, natural gas prices on the spot market may increase sharply if natural gas supply sources are relatively low or constrained. In addition, increases in natural gas consumption by the electric power sector during the summer may lead to smaller-than-normal injections of natural gas into storage and to lower available storage volumes in the winter, which could affect prices.

Some large-volume fuel consumers such as power plants and iron, steel, and paper mills can switch between natural gas, coal, and petroleum, depending on the cost of each fuel. When the costs of the other fuels fall, demand for natural gas may decrease, which may reduce natural gas prices. When the prices of competing fuels rise relative to the price of natural gas, switching from those fuels to natural gas may increase natural gas demand and prices. However, the capability of the U.S. manufacturing sector to switch fuels has declined in recent decades. Favorable natural gas prices in recent years have contributed to increased natural gas use by the electric power sector.

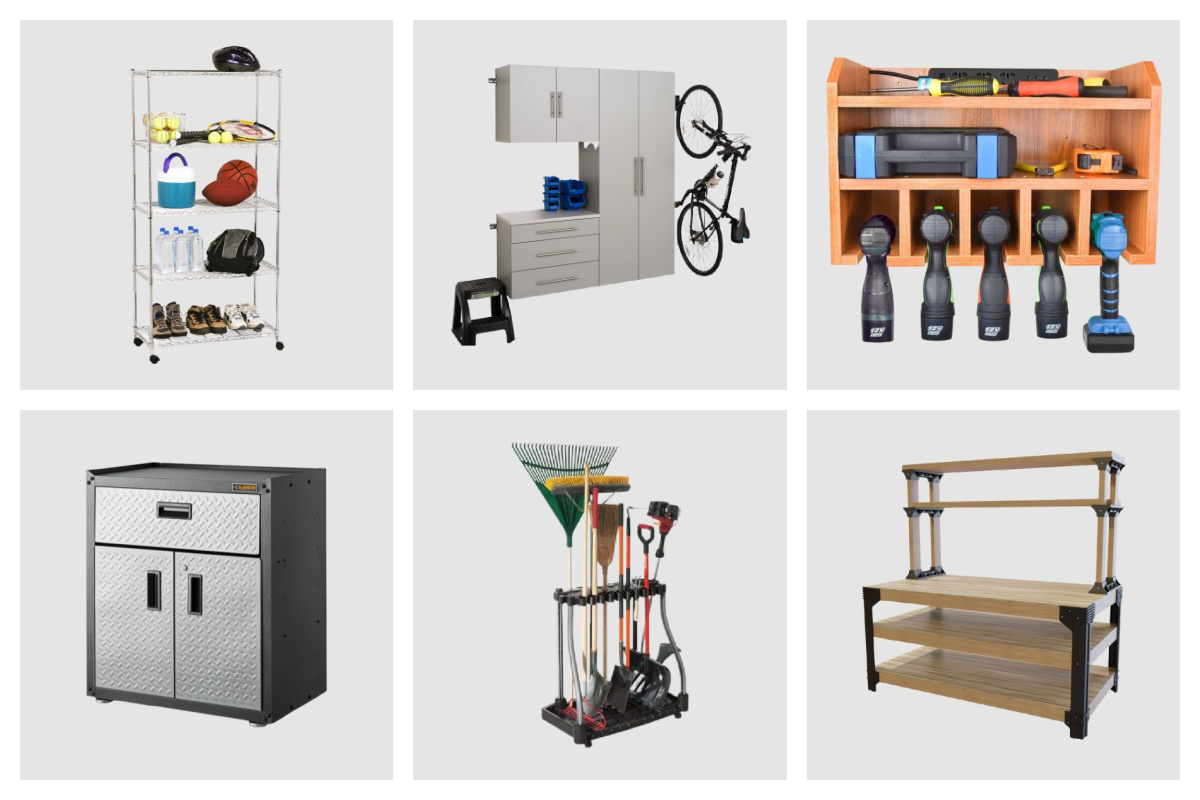

Since tools come in weird shapes and sizes and often have additional parts and attachments, they can be difficult to organize. Luckily, at Sam"s Club, we have everything you need for tool organization so all your tools will have their own little home instead of cluttering up your workbench.

Because you"ll be able to find everything, making your life easier and more efficient. Think about how nice it will be to tackle that DIY project without running around searching for the tools you need.

Toolboxes are essential when it comes to tool organization. These can be as simple as a portable option you can carry around the house for various DIY repairs to large chests with many drawers and caster wheels to move around a shop. We carry a range of toolboxes in various sizes and styles to organize all your tools.

Pegboards are a great space-saving storage solution, as they allow you to store your tools on the wall. Pegboards use specially designed tool holders for everything from small wrenches to larger power tools. You can even attach bins to hold parts or your tool belt. We have pegboards large and small in a variety of finishes. Some even come with organizational guides to make everything easier.

Shelving is great for storing larger tools that are difficult to hang or put in a box. We carry sturdy shelves you can mount on the wall that are perfect for storing larger items like sanders, drills, or even your toolbox itself. You can also use shelves with bins to hold smaller items like nails and screws.

Tools chests are a great solution if you want to put everything into one space and need some heavy duty security. Our tool chests have deep and shallow drawers to hold large and small items. Plus, they"re lockable so you can control access to your tools.

Selecting the right tool storage solution depends on what tools you"re storing. If you have a lot of tools and do a lot of handiwork, you may need a complete storage system with cabinets, toolboxes, pegboards, and more. If you just have basics, a simple toolbox should do the trick.

Always measure the dimensions when you"re selecting any kind of storage. You need to know how much space you have to work with and the size of what you"re storing, before making a purchase. If you need drawers or a toolbox, consider the depth. If you have large tools, they likely won"t fit in a shallow drawer.

Magnetic tool storage is a good option if you need to be able to quickly grab things as you go. It"s not ideal for heavier tools and items, but a magnetic board for nails and drill bits can be very useful.

Many of our storage solutions have drawers ranging in depth so you can properly store all your tools and accessories. If you need extra security, we have locking options.

Garage storage cabinets are a great solution for tools and anything else that needs a home in your garage. At Sam"s Club, we have a ton of storage cabinet options to choose from.

We carry a range of wall storage options, from pegboards to shelves to wall cabinets. These are great for keeping things off the ground and in plain sight. Our wall storage solutions can hold everything from storage bins to cordless tools and more.

When storing tools, you need sturdy materials. We carry toolboxes and other storage solutions made from steel, stainless steel, polypropylene, plastic, aluminum, and more, for durable, long-lasting organization. If you need heavy duty organization systems, we"ve got those too.

It"s best to keep your tools inside, like in your garage, shed, or workspace. Wherever you decide to store your tools, we carry many organization options that will keep your tools safe.

Having proper security for your tools is important, especially if you have kids. Plus, tools are expensive and can be dangerous, so you don"t want them ending up in the wrong hands. We sell a variety of tool organization options with locking features, from key locks to electronic locks.

There are many tools that are necessary for a home, but if you"re only in need of essentials, these basic hand tools will do: hammer, multi-bit screwdriver, drill, adjustable wrench, pliers, tape measure, level, and a flashlight.

It"s generally not a good idea to store tools outside, especially if you live in a harsh climate. Tools left outside can rust or break, and electronic tools should always be kept indoors.

Have your tools outgrown your good ole’ toolbox and you now want a bigger space for optimal organization and storage? If so, a tool shed might be just the right solution! While tool sheds are a bit more expensive than most toolboxes (obviously!), they are still quite affordable. Plus, you will not have to deal with missing or misplaced tools next time you are ready to conquer a building project or heroically fix the sink. In this article, we’ll cover the most common tool shed options, average tool shed prices, and the most asked questions surrounding outdoor tool sheds. Let’s get started!

A tool shed is smaller than most sheds, usually ranging in size from 3’x5’ to 10’x12’. Due to their smaller size, tool sheds are more affordable and offer greater flexibility in terms of placement on your property. Plus, tool shed interiors are often designed for easy organization and accessibility of your tools.

Some of the most popular tool shed sizes include:3×5 – Perfect for very basic tool storage like a few rakes, hand tools, and a bag or two of potting soil, etc. This size is common among plastic/resin tool sheds. (This size is not available from Sheds Unlimited.)

4×8 – This size holds enough room for basic tool storage, plus enough space to add a bike or a couple of larger-sized tools like a blower or chainsaw. (This size is not available from Sheds Unlimited.)

An 8×10 Standard Saltbox tool shed gets the job done for many homeowners’ basic tool storage needs, while adding a little extra flare to their properties! Your push mower and tools will stay safe and sound inside this cute little shed with its extra-wide overhang.Wood Siding = $3,032

10×12 is a popular tool shed size for storing larger outdoor equipment in addition to hand tools. Thanks to its gambrel (or barn-style) roof, the Standard MaxiBarn style offers the greatest storage flexibility out of all our tool shed models. We offer built-in lofts as an option; they’re a great way to take advantage of all the extra overhead space.Wood Siding = $4,209

The real answer is, “It depends.” If a tool shed is not properly built and ventilated, then your tools could begin to rust over time due to moisture buildup. If your shed is built on a concrete slab without a moisture barrier, condensation can form on the concrete floor and encourage rust on your tools.

Yes, power tools can be stored in a shed. Be sure your tool shed is built weathertight and is well ventilated. If you want to ensure the best quality of life for your power tools, consider insulating the walls of your tool shed to help keep temperatures more regulated. Plus, proactive care of your tools, such as keeping them off the ground and regularly applying a protective oil coating will certainly help to maintain their quality.

It depends.If you have all the necessary tools, lots of free time, and general construction knowledge, you may be able to save off the up-front cost of a pre-built tool shed. The average cost for building your own small tool shed ranges from $1,300 – $5,000 depending on the size, type of materials, accessories, and the shed’s level of complexity.

8613371530291

8613371530291