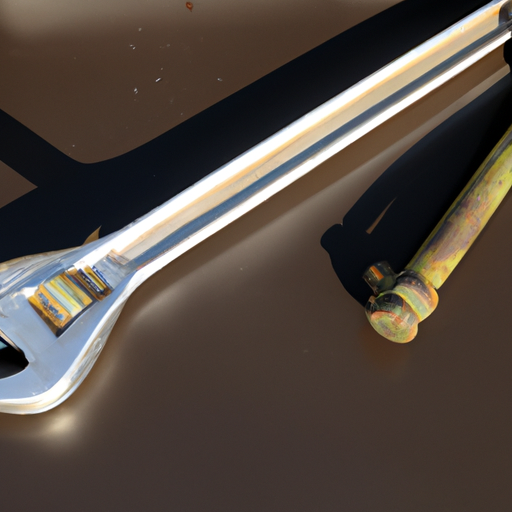

Sucker Rod Wrench: An Essential Tool for Oilfield Operations

Introduction (100 words):

In the dynamic world of oilfield operations, efficiency and safety are paramount. One vital tool that plays a crucial role in the smooth functioning of oil wells is the sucker rod wrench. This article delves into the significance of sucker rod wrenches, their various types, how they are used, and the key benefits they offer in maintaining and optimizing oilfield operations. Whether you are an industry professional or an enthusiast seeking to understand the intricacies of oilfield equipment, this comprehensive guide will provide you with valuable insights into the world of sucker rod wrenches.

Section 1: Understanding Sucker Rods (200 words)

Before diving into the specifics of sucker rod wrenches, it is crucial to comprehend the role of sucker rods in oilfield operations. Sucker rods are long, threaded steel rods used to connect the surface pumping unit to the downhole pump. They play a pivotal role in the extraction of oil and gas by transmitting the reciprocating motion from the pumping unit to the downhole pump, thereby lifting the fluids to the surface.

Section 2: The Importance of Sucker Rod Wrenches (250 words)

As sucker rods are subjected to extreme pressure, temperature, and corrosive environments, routine maintenance and occasional replacement become essential. This is where the sucker rod wrench proves invaluable. A sucker rod wrench is a specialized tool designed to securely grip sucker rods during installation, removal, or adjustment processes. It ensures that operations are carried out safely, efficiently, and in compliance with industry standards.

Section 3: Types of Sucker Rod Wrenches (250 words)

Sucker rod wrenches come in various designs and sizes to cater to different rod dimensions and operational requirements. The most common types include:

1. Manual Sucker Rod Wrench: This type is manually operated and requires physical effort to adjust or tighten sucker rods. It is suitable for low-intensity operations or situations where power sources are limited.

2. Hydraulic Sucker Rod Wrench: Hydraulic wrenches utilize hydraulic power to adjust or tighten sucker rods. They offer greater convenience, speed, and control, making them ideal for high-intensity operations or situations requiring rapid rod adjustments.

3. Pneumatic Sucker Rod Wrench: Pneumatic wrenches use compressed air to operate, providing a reliable and efficient option for rod maintenance. They are often preferred in situations where electricity or hydraulic power sources are limited.

Section 4: Benefits of Using Sucker Rod Wrenches (250 words)

The utilization of sucker rod wrenches provides numerous advantages for oilfield operations. These benefits include:

1. Enhanced Safety: Sucker rod wrenches facilitate secure gripping and manipulation of rods, reducing the risk of accidents, injuries, or damage to equipment during operations.

2. Increased Efficiency: By providing a firm grip on rods, these wrenches enable quicker and more precise adjustments, leading to improved operational efficiency.

3. Extended Equipment Lifespan: Proper maintenance and regular adjustments using sucker rod wrenches contribute to the longevity of sucker rods and associated equipment, minimizing the need for replacements and reducing downtime.

4. Time and Cost Savings: The efficiency and precision offered by sucker rod wrenches allow for faster rod adjustments, reducing labor time and associated costs.

Section 5: Best Practices for Using Sucker Rod Wrenches (150 words)

To ensure optimal performance and longevity of sucker rod wrenches, certain best practices should be followed:

1. Regular Inspections: Inspect the wrench for any damage, wear, or malfunctions before each use. Replace or repair any faulty components promptly.

2. Proper Lubrication: Apply a suitable lubricant to the wrench's moving parts to minimize friction and ensure smooth operation.

3. Adequate Training: Provide proper training to personnel using the wrenches to ensure correct and safe usage.

4. Appropriate Storage: Store the wrenches in a clean, dry, and secure area to prevent any damage or corrosion.

Conclusion (100 words):

Sucker rod wrenches are an indispensable tool for the oilfield industry, aiding in the safe and efficient operation, maintenance, and adjustment of sucker rods. By ensuring a secure grip and precise control, these specialized wrenches enhance safety, increase operational efficiency, extend equipment lifespan, and ultimately contribute to significant time and cost savings. Whether you are an oilfield professional or an enthusiast, understanding the importance and benefits of sucker rod wrenches is essential to appreciate their critical role in the extraction of oil and gas.

8613371530291

8613371530291