API 7K Drilling Hose Ensuring Safety and Efficiency in Oil and Gas Operations

Introduction

In the oil and gas industry, safety and efficiency are paramount. To achieve these goals, the use of reliable equipment and tools is crucial. One such tool that plays a vital role in drilling operations is the API 7K drilling hose. Specifically designed to withstand high-pressure drilling applications, the API 7K drilling hose with a diameter of 4 inches ensures the smooth and secure transfer of drilling fluids, cement slurries, and other substances within the drilling process.

Understanding the API 7K Drilling Hose

The API 7K drilling hose is an industry-standard, high-pressure hose developed and regulated by the American Petroleum Institute (API). This hose is designed for use in rotary drilling and exploration work, including well testing, well stimulation, and cementing. The 4-inch diameter variant of the API 7K drilling hose is widely used due to its versatility and ability to handle demanding drilling conditions.

Features and Specifications

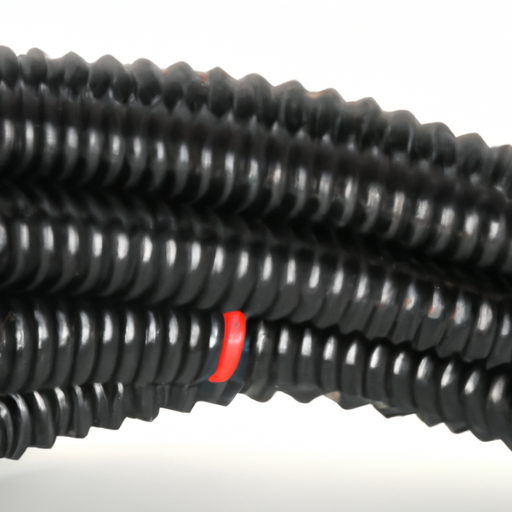

1. Construction: The API 7K drilling hose 4'' is typically composed of multiple layers to ensure strength, flexibility, and resistance to abrasion, corrosion, and extreme temperatures. These layers include an inner tube, reinforcement layers, and an outer protective cover.

2. Inner Tube: The inner tube of the drilling hose is made of synthetic rubber, specifically formulated to withstand the harsh conditions encountered during drilling operations. It resists chemical reactions with drilling fluids and maintains flexibility at high temperatures.

3. Reinforcement Layers: The reinforcement layers are crucial in providing strength and stability to the hose. These layers are typically made of high-strength steel wires or textile materials, depending on the specific requirements of the drilling application.

4. Outer Protective Cover: The outer cover of the API 7K drilling hose is designed to resist abrasion, weathering, and other external factors that could potentially damage the hose. It is typically made of a synthetic rubber compound with added protection against ozone and ultraviolet (UV) radiation.

Benefits of API 7K Drilling Hose 4''

1. High Pressure Resistance: The API 7K drilling hose is designed to withstand extreme pressure conditions, making it ideal for use in high-pressure drilling operations. It ensures the safe and efficient transfer of drilling fluids and other substances within the drilling process.

2. Flexibility: Despite its robust construction, the API 7K drilling hose maintains flexibility, allowing it to be easily maneuvered and connected to various drilling equipment. This flexibility ensures smooth operations and reduces the risk of hose failure or leaks.

3. Compatibility: The API 7K drilling hose is compatible with a wide range of drilling fluids, including water-based and oil-based fluids. This versatility enables its use in different drilling applications, providing a reliable solution for various drilling projects.

4. Resistance to Harsh Environments: The API 7K drilling hose is designed to withstand extreme temperatures, from arctic conditions to high-temperature drilling environments. It also offers resistance against chemicals, oils, and other substances commonly encountered during drilling operations.

5. Safety: The API 7K drilling hose undergoes rigorous testing and certification processes to ensure compliance with industry safety standards. This includes testing for burst pressure, flame resistance, and electrical continuity, among other critical parameters. Using a certified API 7K drilling hose reduces the risk of accidents and ensures the safety of personnel and equipment.

Application Areas

The API 7K drilling hose 4'' finds its applications in various drilling operations, including:

1. Exploration and Production: The drilling hose is used during the exploration and production stages of oil and gas operations. It facilitates the transfer of drilling fluids, mud, and cement slurries between the drilling rig and the wellbore, ensuring a continuous drilling process.

2. Well Stimulation: During well stimulation operations, such as hydraulic fracturing (fracking) or acidizing, the API 7K drilling hose is used to pump high-pressure fluids into the wellbore. Its robust construction and high-pressure resistance make it an ideal choice for these operations.

3. Well Testing: Well testing involves measuring the flow rates and pressure of fluids produced from the well. The API 7K drilling hose allows for the safe and accurate transfer of fluids from the wellhead to the testing equipment, providing crucial data for evaluating well productivity.

4. Cementing: Cementing is a critical step in well construction, ensuring the integrity of the wellbore by preventing fluid migration between different geological formations. The API 7K drilling hose is employed to pump cement slurries into the annular space between the casing and the wellbore, forming a secure seal.

Conclusion

The API 7K drilling hose 4'' is an essential component in the oil and gas industry, providing a reliable and safe method for transferring drilling fluids, cement slurries, and other substances during drilling operations. Its high-pressure resistance, flexibility, and compatibility with various drilling fluids make it a versatile tool suitable for a wide range of drilling applications. By adhering to industry standards and undergoing rigorous testing, the API 7K drilling hose ensures the safety of personnel and equipment while maintaining efficiency and productivity in oil and gas operations.

8613371530291

8613371530291