Drill Pipe Protectors: Ensuring Safety and Efficiency in Oil and Gas Operations

Introduction (Word count: 150)

In the oil and gas industry, drill pipe protectors play a critical role in safeguarding valuable equipment and ensuring the smooth operation of drilling processes. These protective devices shield drill pipes, one of the most significant components in drilling operations, from damage and wear. This article delves into the importance of drill pipe protectors, their types, benefits, and the role they play in enhancing safety and efficiency in oil and gas operations.

1. Understanding Drill Pipe Protectors (Word count: 200)

Drill pipe protectors are specialized coverings designed to safeguard drilling pipes during transportation, storage, and usage. They shield the threaded connections of drill pipes from external damage, including impact, abrasion, moisture, and corrosive substances. By preserving the integrity of drill pipes, these protectors minimize the risk of failures, such as thread galling, cross-threading, and corrosion, which can lead to costly downtime, equipment replacements, and compromised safety.

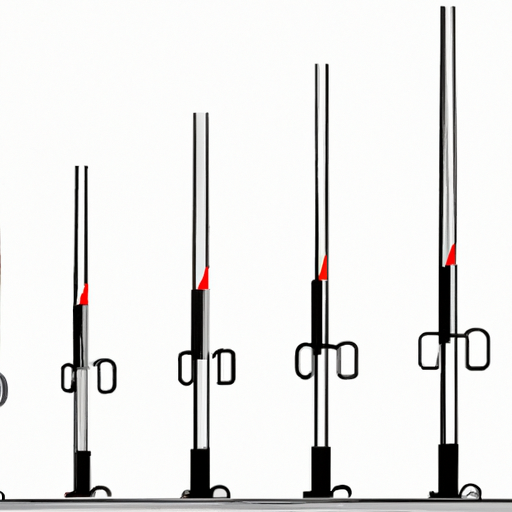

2. Types of Drill Pipe Protectors (Word count: 200)

There are several types of drill pipe protectors available in the market, each designed to cater to specific requirements. These include:

a) Plastic Protectors: Made from high-density polyethylene or other durable plastics, plastic protectors are lightweight, cost-effective, and easily installed. They offer excellent resistance to impact, corrosion, and UV radiation, making them suitable for both onshore and offshore drilling operations.

b) Steel Protectors: Constructed from robust steel alloys, steel protectors provide enhanced durability and protection against extreme conditions. They are commonly used for heavy-duty applications and can withstand high-pressure environments.

c) Composite Protectors: Combining the benefits of plastic and steel, composite protectors offer the strength of steel with the lightweight and corrosion-resistant properties of plastic. They are an optimal choice for drilling activities that require a balance between durability and weight reduction.

3. Benefits of Drill Pipe Protectors (Word count: 200)

The utilization of drill pipe protectors offers numerous benefits that contribute to the overall success of oil and gas operations. Some key advantages include:

a) Enhanced Equipment Lifespan: By safeguarding drill pipes from external factors, protectors extend their lifespan and reduce the need for frequent replacements. This not only saves costs but also minimizes downtime caused by equipment failures.

b) Improved Thread Integrity: Drill pipe protectors provide an extra layer of protection to threaded connections, preventing damage and maintaining their integrity. This reduces the risk of leaks, cross-threading, and other issues that could compromise drilling efficiency and safety.

c) Time and Cost Savings: By mitigating the risk of equipment failures and reducing downtime, drill pipe protectors help operators save both time and money. Additionally, the extended lifespan of drill pipes results in decreased replacement and maintenance costs.

d) Safety Enhancement: Protecting drill pipes helps prevent accidents caused by equipment failures, ensuring the safety of personnel involved in drilling operations. A secure and reliable drilling process promotes a safer working environment.

4. Proper Usage and Maintenance (Word count: 200)

To maximize the effectiveness of drill pipe protectors, proper usage and maintenance are essential. Some best practices include:

a) Regular inspections for damage or wear and immediate replacement of damaged protectors.

b) Correct installation of protectors, ensuring a tight fit and protection of the entire thread length.

c) Cleaning and drying the drill pipes before applying protectors to prevent moisture-related issues such as corrosion.

d) Proper storage of drill pipes with protectors in a dry and well-ventilated area, away from corrosive substances.

Conclusion (Word count: 150)

Drill pipe protectors are indispensable in the oil and gas industry, offering significant benefits in terms of safety, efficiency, and cost savings. By effectively safeguarding drill pipes from damage and wear, these protective devices contribute to the smooth operation of drilling processes and ensure the longevity of equipment. It is crucial for oil and gas operators to prioritize the usage and maintenance of drill pipe protectors to optimize their effectiveness and mitigate potential risks. Investing in high-quality protectors tailored to specific drilling requirements is a prudent choice that pays dividends in terms of improved safety, increased efficiency, and reduced operational costs.

8613371530291

8613371530291