Annular BOP 5000psi: Ensuring Safety in Oil and Gas Operations

Introduction (Word Count: 150)

In the oil and gas industry, safety is of paramount importance. With high-pressure environments and complex operations, it is crucial to have reliable equipment that can prevent potential hazards and protect both personnel and the environment. One such critical piece of equipment is the Annular Blowout Preventer (BOP), specifically designed to control wellbore pressure during drilling, completion, and intervention activities. This article delves into the significance of Annular BOPs, with a focus on the 5000psi variant, exploring its features, working mechanism, and the benefits it brings to the industry.

Understanding Annular BOPs (Word Count: 200)

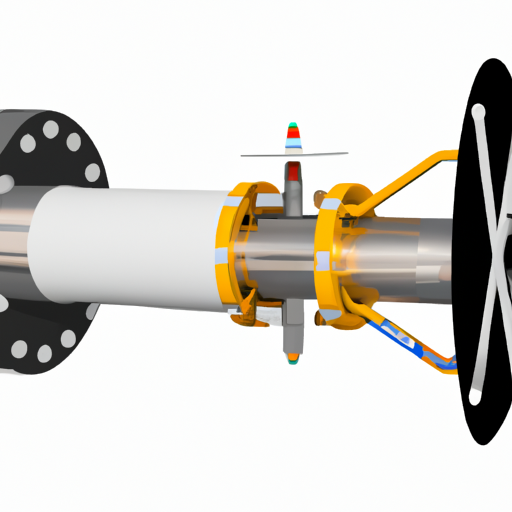

Annular BOPs, also known as spherical BOPs, are a type of BOP that provide a seal around the drill string, casing, or any other tubular component in oil and gas wells. They are designed to control wellbore pressure by preventing the uncontrolled flow of fluids from the well, thereby mitigating the risk of blowouts and other hazardous situations. The Annular BOP 5000psi, as the name suggests, is specifically engineered to handle pressure up to 5000 pounds per square inch (psi), making it suitable for a wide range of drilling operations.

Features of Annular BOP 5000psi (Word Count: 200)

The Annular BOP 5000psi is built with robust materials and advanced engineering to withstand high pressures and harsh operating conditions. Some key features of this equipment include:

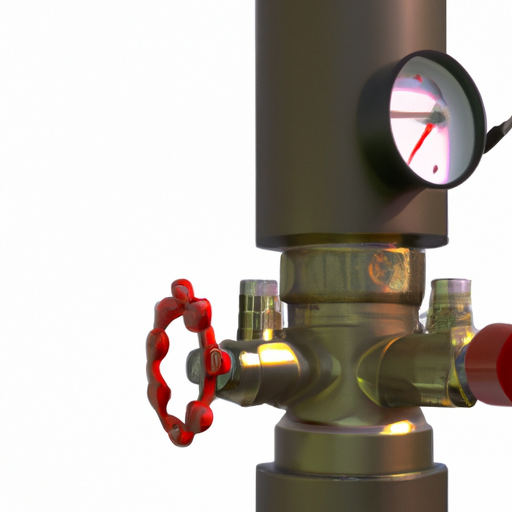

1. Pressure Rating: With a rating of 5000psi, this BOP variant can effectively handle high-pressure situations encountered during drilling, completion, and intervention activities.

2. Compact Design: The 5000psi Annular BOP is designed to be compact and lightweight, allowing for easy installation and removal from the wellhead. This feature enhances operational efficiency and reduces downtime.

3. Sealing Mechanism: The Annular BOP utilizes elastomeric seals to create a reliable pressure barrier. These seals are made from high-quality materials that offer excellent resistance to wear, tear, and chemical degradation.

4. Remote Activation: Many Annular BOPs, including the 5000psi variant, offer remote activation capabilities. This allows operators to control the BOP from a safe distance, minimizing exposure to potential risks.

Working Mechanism of Annular BOP 5000psi (Word Count: 200)

The Annular BOP 5000psi operates on a hydraulic system. When activated, hydraulic pressure is applied to the piston, causing it to move downward. This downward movement compresses the elastomeric seals, creating a tight seal around the tubular component. The hydraulic system maintains constant pressure to keep the seal intact and prevent any fluid influx from the wellbore. In case of an emergency, the BOP can be closed remotely within seconds, effectively shutting off the well and preventing a blowout.

Benefits of Annular BOP 5000psi (Word Count: 250)

1. Enhanced Safety: The primary benefit of the Annular BOP 5000psi is the improved safety it offers to personnel and the environment. By preventing uncontrolled fluid flow, it minimizes the risk of blowouts, well kickbacks, and other potentially catastrophic events.

2. Versatility: The 5000psi variant is highly versatile and can be used in various drilling operations, including onshore and offshore activities. Its compact design and ease of installation make it suitable for both temporary and permanent applications.

3. Cost-Effective: Investing in a quality Annular BOP 5000psi can lead to long-term cost savings. Its robust construction and reliable sealing mechanism minimize the need for frequent maintenance and replacement, reducing downtime and associated costs.

4. Regulatory Compliance: The oil and gas industry is subject to stringent safety regulations. By utilizing a certified Annular BOP 5000psi, operators can ensure compliance with industry standards and regulations, avoiding potential penalties and reputation damage.

Conclusion (Word Count: 100)

The Annular BOP 5000psi is an essential piece of equipment that plays a crucial role in maintaining safety and preventing well control incidents in the oil and gas industry. Its high-pressure rating, compact design, and reliable sealing mechanism make it an ideal choice for drilling operations. By investing in this advanced technology, operators can enhance safety, improve operational efficiency, and comply with industry regulations, ultimately contributing to a safer and more sustainable energy sector.

8613371530291

8613371530291